VM1000-TF222-003EN

Page 1 of 2

Instruction Manual

Micro Mechanical Valve

Series VM1000

The intended use of this product is to be used in pneumatic control

circuits to transmit signals at the short parts of long piping for machining

tools or general industrial machinery.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

2 Specifications

2.1 Standard specifications

Ambient and fluid temperature [ C]

Minimum operating frequency

Maximum operating frequency

Not required (If lubricated, use

turbine oil Class 1 ISO VG32)

Impact resistance [m/s2] Note 1)

Vibration resistance [m/s2] Note 2)

Table 1.

Note 1) Two axes (horizontal and vertical) and two directions were tested 3 times

and no malfunction of the valve occurred (pulse shape: sine shape).

2 Specification - continued

Note 2) No malfunction occurred in a sweep cycle test between 10 to 150 Hz at

vibration sweep 0.35mm. The test was performed in the two axes and two

directions, 7 min per cycle (20 cycles).

2.2 Semi-standard specification

Total travel (T. T.) [mm]

Table 2.

Note) Only available for ‘Basic’ actuator type.

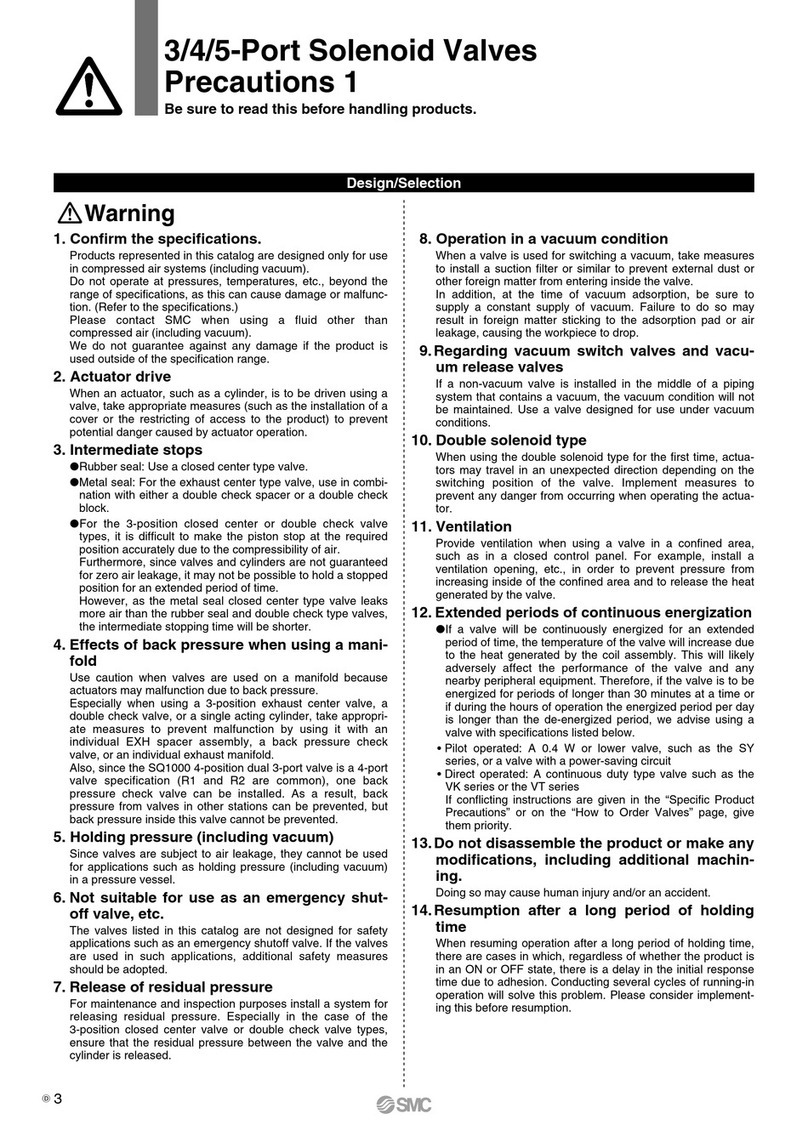

2.3 Definition of symbol

Figure 1.

Note) Figure shows VM100 series.

•F.O.F (Full operating force): Required force to total travel position.

•P.T. (Pre-travel): From free position to initial valve operating position.

•O.T. (Over travel): From initial valve operating position to total travel

position.

•T.T. (Total travel): From free position to total travel position.

Caution

Refer to catalogue for F.O.F., P.T., O.T. and T.T. values.

2.4 ON/OFF position of the “toggle lever” option

Figure 2.

Note) Refer to catalogue for applicable tubing.

2.5 Pneumatic symbol

Refer to catalogue for pneumatic symbol.

2.6 Special products Warning

Special products (-X) might have specifications different from those

shown in this section. Contact SMC for specific drawings.

3 Installation

3.1 Installation Warning

•Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

3 Installation - continued

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Do not use in high humidity environment where condensation can

occur.

3.3 Piping Caution

•Before connecting piping make sure to clean up chips, cutting oil, dust

etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1.5 to 2 threads

exposed on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

3.4 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is used in the system, refer to catalogue for details.

3.5 Air supply Warning

•Use clean air. If the compressed air supply includes chemicals,

synthetic materials (including organic solvents), salinity, corrosive gas

etc., it can lead to damage or malfunction.

Caution

•Install an air filter upstream of the valve. Select an air filter with a

filtration size of 5 μm or smaller.

3.6 Mounting Warning

•Do not perform mechanical operation exceeding the operation limit

position. The mechanical valve itself may be damaged leading to

equipment malfunction.

•Never perform additional machining such as enlarging the body

mounting holes as it could lead to unexpected abnormal conditions

such as air leakage.

3.6.1 Stroke range Warning

Operate the mechanism within the stroke range given below:

Table 3.

3.6.2 Cam and dog angle and maximum speed

Angle limit of cam and

dog

Max. speed limit of

cam and dog [m/s]

Roller lever,

One way roller lever

Table 4.

3.7 Operation Warning

•Operate the manual operation type mechanical valves (such as push

button, and toggle lever types) with your finger.

•The use of equipment such as a cylinder, cam or hammer, can result

in the actuator and the valve being damaged.

•Do not operate over the operation limit. If excessive operation force is

applied over total travel position, actuator part can get deformed and

lead to equipment malfunction.

•When operating the mechanical operation type mechanical valves,

select the angle and the maximum speed limit of cam and dog so that

valves do not operate over the following maximum values.

3 Installation - continued

Figure 3.

Note) Figure shows VM100 series.

3.7.1 Cam and dog material

Surface finish of cam

and dog

Table 5.

Caution

If the operating condition is maintained for long periods of time, it may

take some time for the valve to restart due to the adherence of the seals

and there might be a delay for recovery.

4 How to Order

Refer to catalogue for ‘How to Order’.

5 Outline Dimensions

Refer to catalogue for outline dimensions.

Caution

Dimensions of the roller lever type may exceed the values specified in

the catalogue if the roller lever is positioned in any direction other than

upwards, due to the design of the lever.

6 Maintenance

6.1 General maintenance Warning

•To prevent unexpected movements of the pneumatic actuator,the user

shall consider the state of the valve before conducting maintenance.

Additional consideration shall be given when the valve is held in the

ON position by an external mechanism such as cam, lever, etc., or in

the case that locking type valve actuators are used.

Caution

•Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•If handled improperly, compressed air can be dangerous.

•Maintenance of pneumatic systems should be performed only by

qualified personnel.

•Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•If any electricalconnections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

Over travel.

Excessive force

is applied due to

the maximum

travel position

being exceeded.

Sufficient travel.

The actuator can

reach the total

travel position

without

excessive force

being applied.