LEF-TFN01

Installation and Maintenance Manual

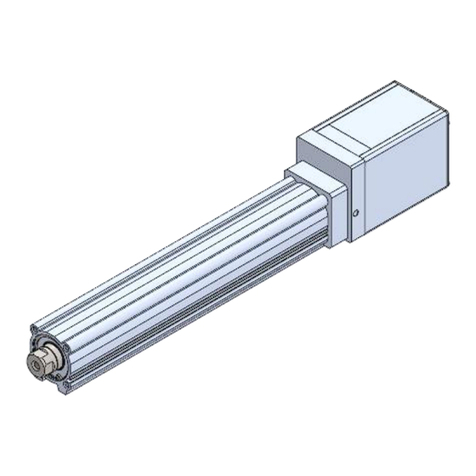

Electric Actuator / Slider Type

Series LEF

Applicable model number:

LEFS*A-*

LEFS*B-*

LEFB*T-*

1 Sa ety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage

• Read this manual before using the product to ensure correct handling

and also read the manuals of related apparatus before use

• Keep this manual in a safe place for future reference

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices

Caution

Indicates a hazard with a low level of risk

Which if not avoided, could result in minor or

moderate injury

Warning

Indicates a hazard with a medium level of risk

Which if not avoided, could result in death or

serious injury

Danger

Indicates a hazard with a high level of risk

Which if not avoided, will result in death or

serious injury

• Electromagnetic compatibility: This product is class A equipment that is

intended for use in an industrial environment There may be potential

difficulties in ensuring electromagnetic compatibility in other

environments due to conducted as well as radiated disturbances

Warning

• Do not disassemble, modi y (including change o printed circuit

board) or repair the product.

An injury or product failure may result

• Do not operate the product beyond the speci ication range.

Fire, malfunction or equipment damage may result

Use the product only after confirming the specifications

• Do not use the product in the presence o lammable, explosive or

corrosive gas.

Fire, explosion or corrosion may result

This product does not have an explosion proof construction

• When using the product as part o an interlocking system:

Provide a double interlocking system, for example a mechanical system

Check the product regularly to ensure correct operation

• Be ore per orming maintenance, be sure o the ollowing:

Turn off the power supply

Caution

• Always per orm a system check a ter maintenance.

Do not use the product if any error occurs

Safety cannot be assured if caused by un-intentional malfunction

• Provide grounding to ensure correct operation and to improve

noise resistance o the product.

This product should be individually grounded using a short cable

• Follow the instructions given below when handling the product.

Failing to do so may result in product damage

• Maintenance space should always be provided around the product.

• Do not remove labels rom the product.

• Do not drop, hit or apply excessive shock to the product.

• Unless stated otherwise, ollow all speci ied tightening torques.

• Do not bend, apply tensile orce, or apply orce by placing heavy

loads on the cables.

1 Sa ety Instructions (continued)

• Connect wires and cables correctly and do not connect while the

power is turned on.

• Do not route input/output wires and cables together with power or

high-voltage cables.

• Check the insulation o wires and cables.

• Take appropriate measures against noise, such as noise ilters,

when the product is incorporated into other equipment or devices.

• Take su icient shielding measures when the product is to be used

in the ollowing conditions:

• Where noise due to static electricity is generated

• Where electro-magnetic field strength is high

• Where radioactivity is present

• Where power lines are located

• Do not use the product in a place where electrical surges are

generated.

• Use suitable surge protection when a surge generating load such

as a solenoid valve is to be directly driven.

• Prevent any oreign matter rom entering this product.

• Do not expose the product to vibration or impact.

• Use the product within the speci ied ambient temperature range.

• Do not expose the product to any heat radiation.

• Use a precision screwdriver with lat blade to adjust the DIP switch.

• Close the cover over the switches be ore power is turned on.

• Do not clean the product with chemicals such as benzene or

thinners.

2 General Instructions

2.1 Wiring

Warning

• Adjusting, mounting or wiring change should not be done be ore

disconnecting the power supply to the product.

Electrical shock, malfunction and damage can result

• Do not disassemble the cables.

• Use only speci ied cables.

• Do not connect or disconnect the wires, cables and connectors

when the power is turned on.

Caution

• Wire the connector correctly and securely.

Check the connector for polarity and do not apply any voltage to the

terminals other than those specified in the Operation Manual

• Take appropriate measures against noise.

Noise in a signal line may cause malfunction As a countermeasure

separate the high voltage and low voltage cables, and shorten the wiring

lengths, etc

• Do not route input/output wires and cables together with power or

high voltage cables.

The product can malfunction due to interference of noise and surge

voltage from power and high voltage cables to the signal line Route the

wires of the product separately from power or high voltage cables

• Take care that actuator movement does not catch cables.

• Operate with all wires and cables secured.

• Avoid bending cables at sharp angles where they enter the product.

• Avoid twisting, olding, rotating or applying an external orce to the

cable.

Risk of electric shock, wire breakage, contact failure and loss of control

of the product can happen

• Fix the motor cables protruding rom the actuator in place be ore

use.

The motor and lock cables are not robotic type cables and can be

damaged when moved

• The actuator cables connecting the actuator and the controller are

robotic type cables. But should not be placed in a lexible moving

tube with a radius smaller than the speci ied value. (Min. 50 mm)

2 General Instructions (continued)

• Con irm correct insulation o the product.

Poor insulation of wires, cables, connectors, terminals etc can cause

interference with other circuits Also there is the possibility that excessive

voltage or current may be applied to the product causing damage

2.2 Transportation

Caution

• Do not carry or swing the product by the cables.

2.3 Mounting

Warning

• Observe the tightening torque or screws.

Unless stated otherwise, tighten the screws to the recommended torque

for mounting the product

• Do not make any alterations to this product.

Alterations made to this product may lead to a loss of durability and

damage to the product, which can lead to human injury and damage to

other equipment and machinery

• When an external guide is used, connect the moving parts o the

product and the load in such a way that there is no inter erence at

any point within the stroke.

Do not scratch or dent the sliding parts of the table or mounting face etc ,

by striking or holding them with other objects The components are

manufactured to precise tolerances, so that even a slight deformation

may cause faulty operation or seizure

• Do not use the product until you veri y that the equipment can be

operated correctly.

After mounting or repair, connect the power supply to the product and

perform appropriate functional inspections to check it is mounted

correctly

• When attaching to the work piece, do not apply strong impact or

large moment.

If an external force over the allowable moment is applied, it may cause

looseness in the guide unit, an increase in sliding resistance or other

problems

• Maintenance space

Allow sufficient space for maintenance and inspection

2.4 Handling

Warning

• Do not touch the motor while in operation.

The surface temperature of the motor can increase to approx 90°C to

100°C due to operating conditions

Energizing alone may also cause this temperature increase

As it may cause burns, do not touch the motor when in operation

• I abnormal heating, smoking or ire, etc. occurs in the product,

immediately turn o the power supply.

• Immediately stop operation i abnormal operation noise or vibration

occurs.

If abnormal operation noise or vibration occurs, the product may have

been mounted incorrectly Unless operation of the product is stopped for

inspection, the product can be seriously damaged

• Never touch the rotating part o the motor or the moving part o the

actuator while in operation.

There is a serious risk of injury

• When installing, adjusting, inspecting or per orming maintenance

on the product, controller and related equipment, be sure to turn o

the power supply to each o them. Then, lock it so that no one other

than the person working can turn the power on, or implement

measures such as a sa ety plug.

• In the case o the actuator that has a servo motor (24 VDC), the

“motor phase detection step" is done by inputting the servo on

signal just a ter the controller power is turned on.

The “motor phase detection step” operates the table/rod to the

maximum distance o the lead screw. (The motor rotates in the

reverse direction i the table hits an obstacle such as the end stop

damper.) Take the “motor phase detection step” into consideration

or the installation and operation o this actuator

2 General Instructions (continued)

Caution

• Keep the controller and product combined as delivered or use.

The product is set in parameters for shipment

If it is combined with a different product parameter, failure can result

• Check the product or the ollowing points be ore operation.

• Damage to electric driving line and signal lines

• Looseness of the connector to each power line and signal line

• Looseness of the actuator/cylinder and controller/driver mounting

• Abnormal operation

• Stop function

• When more than one person is per orming work, decide on the

procedures, signals, measures and resolution or abnormal

conditions be ore beginning the work.

• Also designate a person to supervise the work, other than those

per orming the work.

• An operation test should be per ormed at low speed, start the test

at a prede ined speed, a ter con irming there are no problems.

• Actual speed o the product will be changed by the workload.

Before selecting a product, check the catalogue for the instructions

regarding selection and specifications

• Do not apply a load, impact or resistance in addition to a

trans erred load during return to origin.

In the case of the return to origin by pushing force, additional force will

cause displacement of the origin position since it is based on detected

motor torque

• Do not remove the nameplate.

2.5 Actuator with lock

Warning

• Do not use the lock as a sa ety lock or a control that requires a

locking orce.

The lock used for the product with a lock is designed to prevent dropping

of work piece

• For vertical mounting, use the product with a lock.

If the product is not equipped with a lock, the product will move and drop

the work piece when the power is removed

• "Measures against drops” means preventing a work piece rom

dropping due to its weight when the product operation is stopped

and the power supply is turned o .

• Do not apply an impact load or strong vibration while the lock is

activated.

If an external impact load or strong vibration is applied to the product, the

lock will lose its holding force and damage to the sliding part of the lock

or reduced lifetime can result The same situation will happen when the

lock slips due to a force higher than its holding force, as this will

accelerate the wear to the lock

• Do not apply liquid, oil or grease to the lock or its surroundings.

When liquid, oil or grease is applied to the sliding part of the lock, its

holding force will be reduced significantly

• Take “measures against drops” and check that sa ety is assured

be ore mounting, adjustment and inspection o the product.

If the lock is released with the product mounted vertically, a work piece

can drop due to its weight

2.6 Please re er to the auto switch re erences in “Best Pneumatics “

when an auto switch is to be used.

2.7 Unpacking

Caution

• Check the received product is as ordered.

If a different product is installed from the one ordered, injury or damage

could result