VBA-OM-L007-E

If the product is used in a condition in which large amounts of drainage

remain in the filter, mist separator, and tank, drainage may flow out the

booster cause malfunction. Exhaust drainage from filters once a day to

prevent such failure. For the auto-drain type, also check the operation

once a day.

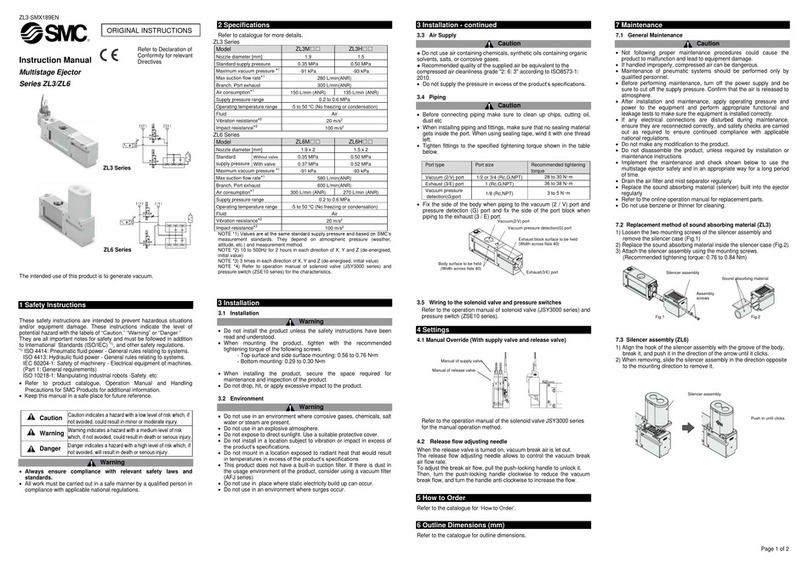

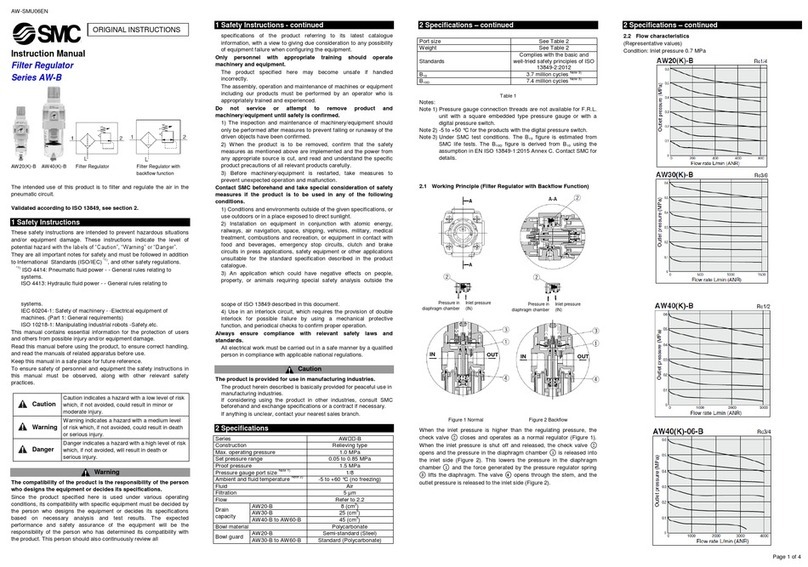

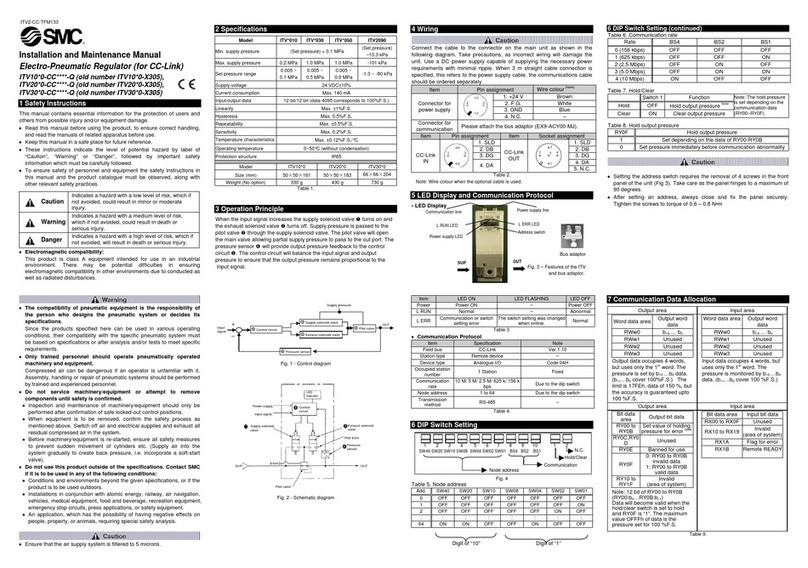

Pneumatic Circuit

WARNING

(1)Against abnormal outlet pressure

When it is foreseen that an unexpected failure of the booster

regulator world cause a significant damage to your system, please

take appropriate safety measure in your system design.

If the inlet pressure fluctuation is large, the outlet pressure maybe

over the setting range of governor, and that will result in an

unexpected accident. Take appropriate safety measures.

(2)Dealing With Residual Pressure

To quickly exhaust residual pressure downstream of the booster

regulator for maintenance, connect a 3-way valve to the OUT port of the

booster regulator (see drawing below). Please note that the booster

regulator downstream pressure cannot be exhausted through the

booster even if the 3-way valve is installed in the IN port of the booster

regulator.

After exhausting the downstream piping, exhaust supply pressure at

the booster regulator inlet side using the residual pressure relief valve

upstream the booster regulator .This will stop unnecessary operation

and prevent malfunction.

Pressure Control

(1)Handle operation type

To increase the set the pressure by unlocking the handle slightly pulling

it up, and, rotating it in the (+) direction of the arrow. To decrease the set

pressure after the pressure has been set, unlock the handle, and then

rotate the handle in the (-) direction of the arrow.

The handle is locked when it is pushed

down(PUSH), and released when it is pulled

up (PULL).

The residual air will be released from the

area of the handle, due to the relief

construction of the handle.

(2)Air operated type

Connect a regulator to the pilot port as

shown below.

AR20 and AW2000 are recommended for

the pilot regulator.

As shown in the drawing on the right, the

outlet pressure is twice of pilot pressure at

zero flow rate consumption.

When booster supply pressure is 0.4MPa

and pilot pressure is 0.2MPa to 0.4MPa the

outlet pressure is 0.4MPa to 0.8MPa at zero

flow rate.

WARNING

Operate the booster regulator within its

maximum operating pressure and set

pressure range.

Do not rotate the handle to a pressure

exceeding the max. set pressure.

Do not supply 0.5MPa or more of pilot pressure for VBA22A and

VBA42A.When the inlet pressure becomes 0.5MPa or more, the outlet

pressure will increase and finally exceed the operating pressure range.

The lower limit of the set pressure should be the inlet pressure plus

0.1MPa or more. When the booster regulator is operated with the

minimum operating pressure (0.1MPa) or less, the directional control

valve may stop at the intermediate position.

CAUTION

The pressure of the handle is set to 0 before shipment. When the air is

supplied, the pressure is relieved.

It is not possible to reduce the pressure to the inlet pressure or less.

This product does not have a pressure regulator function.

There are upper and lower limits to the handle operation. If the handle

is rotated too far, it will break.

Selection

This product consumes air because it uses compressed air to boost the

pressure. The air consumption is approx. 1.2 times (ratio of intensified

pressure 2) and approx. 2.7 times (ratio of intensified pressure 4) as

much as air consumed on the outlet side. Therefore, inlet air supply

should be approx. 2.2 times (ratio of intensified pressure 2) as more

than the air consumed on the outlet side. Inlet air supply should be

approx. 3.7 times (ratio of intensified pressure 4).

When running continuously for extended periods of time, confirm the

life expectancy. The life expectancy of a booster regulator depends on

the operational cycle. Thus the more frequently the actuator operates in

the outlet side or the higher the pressure, the shorter the life expectancy

will be.

3-way valve

residual

pressure

relief valve

Directional

control valve

3-way valve

residual pressure

relief valve

Directional

control valve

Pilot pressure(MPa)

(Outlet flow rate:0L/min)

Outlet Pressure (MPa)

0.1 0.2 0.3 0.4 0.5

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

●Check the following points in the event of product failure before returning to SMC to perform service investigation

Troubleshooting by end user

Leakagefromthe

handle

(Reliefairdoesnot

stop.)

Inletpressureis higherthanthesetpressure.

Setthepressuretotheinletpressureormorewiththehandle.

Iftheinletpressurefluctuation islarge,stabilizeitwitha regulator.

Sealingfailureofthegovernorduetoforeignmatter.

Disassemble the governor and remove the foreign matter (Refer to the

maintenanceprocedure).

Outletpressuredoes

notincrease.

INandOUTpipingconnectedthewrongwayround.

Reconnectthepipingproperly.

InsufficientsupplyofInletpressureandflowrate.

Outletflowrate(amountused)istoomuch.

(1)Decreasetheoperatingpressureandflowrate.

(2)Changethesizeoftheboostervalve(fromVBA2toVBA4).

(3)Increasethenumberoftheboostervalve(use in parallel or in series).

Thehandleisturningidly(handlebreakage).

Removethehandleandrotatethesquarenutwithaspannerwrench.

The booster valve stopped because the pressure was lower

thantheminimum operating pressure.

(Intermediatestopofthedirectionalcontrolvalve)

Relievethesupplypressureaftertheoperationisstopped.

Iftheinletpressurefluctuation islarge,stabilizeitwitha regulator.

Operationisstoppedduetointrusionofforeignmatter.

(Intermediate stop of the directional control valve due to

increaseininternalresistance.)

Initialphase

Middlephase

later

(1) Supply air and increase the exhaust pressure while holding the exhaust port

withyourfinger.Thenreleaseyourfingerquickly.

(2) Relieve the air from IN and OUT ports. After that, supply the air again and

increasethepressurerapidly.

Operationdoesnot

stop.Whenthereisno

airconsumptionfrom

theoutletport.

Airisleakingfromtheequipmentor pipingonthedownstream

sideoftheoutlet.

Checkwheretheairisleakingfromandfixit.

Sealingiswornoutor brokendue tointrusionofforeign matter

orlubricationrunningout.

Changetheseals (Refertothemaintenance procedure).

(1) The life of the boosterregulatordepends on the air qualityand operating conditions.The following are signs that it is reaching the end of its life.

Even when the outletflow rate is 0, the booster regulatordoesn'tstop. (When the interval of the exhaustnoise is lessthan 30seconds, the sealsarebeing worn out

ordamaged.)

Sliding noise(abnormal noise). (This indicates thatlubricationisrunning out).

The silencermountedon theexhaustturnsblack duetodirt.(Seals aregettingwornout,soparticlesgetstuck in thesilencer.)

(2) Maintenance

Only personnel who are fully trained and experienced in pneumatically operated machinery and equipment should perform the maintenance in accordance with the

maintenance manual.

Refer tothemaintenancemanualfor thereplacementparts.

(3) When making a request for maintenanceto SMC

Remove accessories such as fittings mounted on the booster

parts beforereturning toSMC.

Non-consumablesparts(example:body,tube,covers)whichare

worn outordamage cannotbereplace aspartof the

maintenance request.

URL http://www.smcworld.com

Akihabara UDX 15F

Phone: +81 3 5207 8249 Fax: +81 3 5298 5362

Specifications are subject to change without prior notice and any obligation the part of the manufacturer.

2012 SMC Corporation All Rights Reserved