1. The compact manometer can be used for

measurement of air and non-corrosive gases.

Please note that the accuracy of measurement for other fluids

cannot be guaranteed. Furthermore, the construction is not

explosion proof, and therefore, flammable gases should not

be used.

2. Be certain to stay within the rated pressure range.

Operation outside the pressure range will cause failure.

3. Do not intentionally swing around by the hand

strap.

If the strap breaks or comes loose, there is a danger of injury

or damage, etc.

4. When installing or removing One-touch fittings on

tubing, first confirm that the fluid to be measured is

at atmospheric pressure.

If tubing is disconnected while the fluid to be measured is in a

pressurized state, the tubing may jump causing a danger of

injury or damage. Also when connecting tubing, confirm that it

is securely attached.

5. Instruction manual

Read it carefully and understand the contents before using a

product. Also, keep the manual in a location where it can be

referred to at any time.

Handling

Warning

1. Keep condensate and foreign matter from getting

into the fluid to be measured.

If condensate or foreign matter is mixed in the fluid to be

measured, this may cause failure or air leakage.

If there is a possibility of these being contained in the fluid,

use the meter via a filter or mist separator.

2. Do not drop or strike the unit, etc.

Do not drop, strike or apply a large impact shock (980 m/s2),

as this may result in a failure.

3. Be certain to perform the zero clear function with

pressure released to the atmosphere.

When perfoming the zero clear function, this should be done

with piping ports in an atmospheric release condition. If

adjustment is performed at a pressure other than atmospheric

pressure, the correct value will not be displayed.

4. Tighten One-touch fittings in accordance with the

following.

One-touch fittings should first be tightened by hand, and then

further tightened approximately 1/6 of a turn using a tightening

tool. If screwed in too far, this may cause air leakage due to

breaking of threads or distortion of the gasket, etc. If not

screwed in far enough, this may cause a loose fitting or air

leakage, etc.

Caution

1. Absolutely never use in an atmosphere where

explosive gases are used.

The compact manometer does not have explosion proof

construction. If used in an atmosphere of explosive gases,

there is a possibility of causing an explosion, and therefore,

should absolutely not be used under these conditions.

Operating Environment

Warning

1. Do not use where there is splashing of water or oil,

etc.

The compact manometer is not a dusttight and dripproof type,

and should not be used where there is splashing water or oil,

etc., as this may result in a malfunction.

Caution

1. Perform maintenance and inspection on a regular

basis.

If there is an unintended misaction, misoperation, etc., or

calibration has not been performed, there is a possibility of an

incorrect value being displayed, making it impossible to

ensure safety.

2. Do not disassemble or modify the unit.

Maintenance and Other

Warning

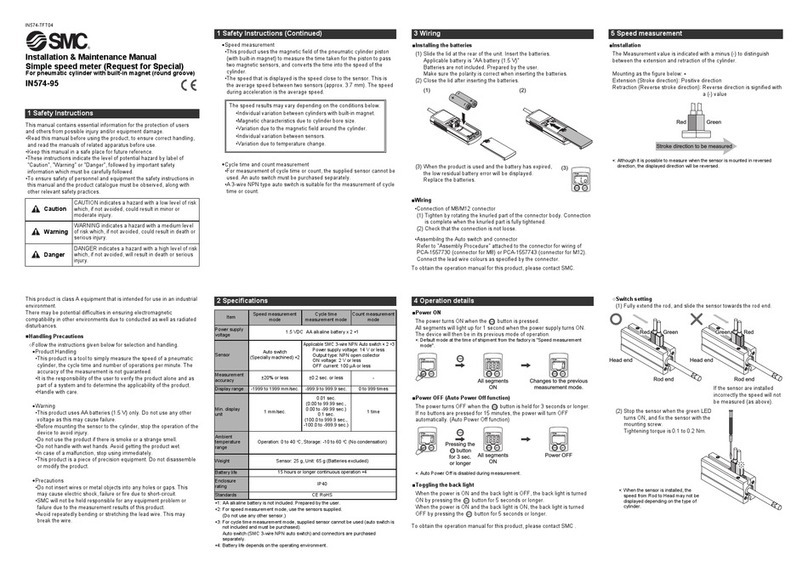

1. Use manganese type AA dry batteries (R6) or

alkaline type AA dry batteries (LR6).

Do not use batteries other than the above, as this may cause

failiure.

2. Insert the plus (+) and minus (–) terminals of the

batteries in the proper direction as indicated inside

the unit.

If the batteties are inserted incorrectly, this may cause them to

leak or explode and result in damage to the unit.

3. Do not use old and new batteries or mix different

types of batteries together.

This may cause batteries to leak and result in damage to the

unit.

4. Remove the batteries when the unit will not be

used for a long period.

5. Do not use batteries if their voltage has dropped.

Continuing to use them may lead to the display of incorrect

values.

6. Do not touch the span calibration trimmer except

when performing span calibration.

Touching the trimmer may cause generation of an error in the

measured pressure. Also do not turn it too hard (0.3 N·m or

less) or press it too hard (5 N or less).

7. Use a soft cloth to wipe the blot off of the body.

In case of heavy soiling, wipe it off with a cloth soaked in a

neutral detergent diluted with water after wringing it out

thoroughly, and finish up by wiping with a dry cloth.

Caution

Precautions

Be sure to read before handling. Refer to pages 14-21-3 to 14-21-4 for Safety Instructions and Common

Precautions.