4 Operation etails

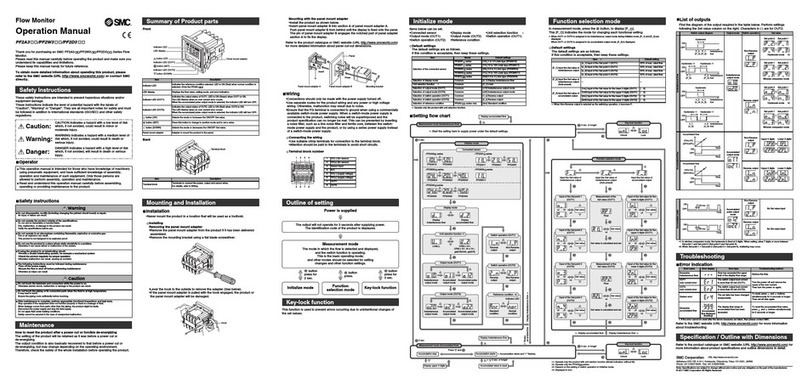

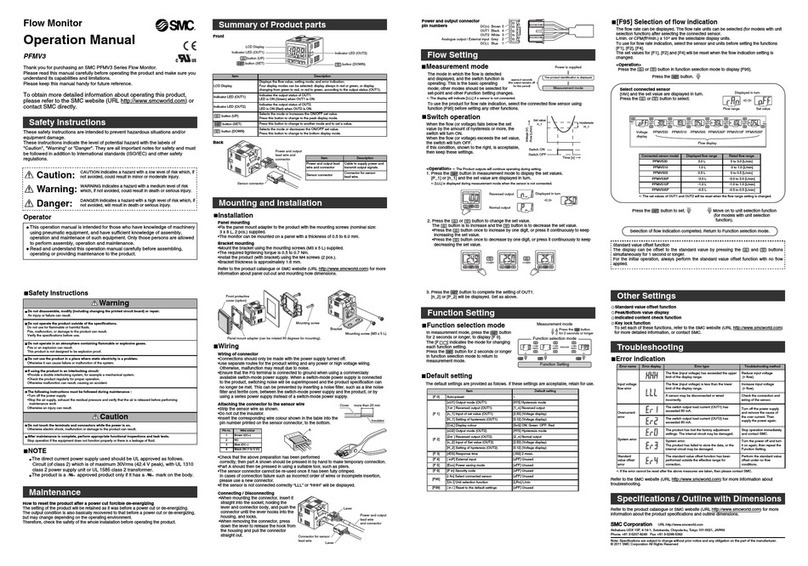

3 Wiring

Installation & Maintenance Manual

Simple spee meter (Request for Special)

For pneumatic cylin er with built-in magnet (roun groove)

IN574-95

I 574-TFT04

1 Safety Instructions

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

•Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

•Keep this manual in a safe place for future reference.

•These instructions indicate the level of potential hazard by label of

"Caution", "Warning" or "Danger", followed by important safety

information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

CAUTIO indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

WAR I G indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DA GER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

■Han ling Precautions

○Follow the instructions given below for selection and handling.

Product Handling

•This product is a tool to simply measure the speed of a pneumatic

cylinder, the cycle time and number of operations per minute. The

accuracy of the measurement is not guaranteed.

•It is the responsibility of the user to verify the product alone and as

part of a system and to determine the applicability of the product.

•Handle with care.

Warning

•This product uses AA batteries (1.5 V) only. Do not use any other

voltage as this may cause failure.

•Before mounting the sensor to the cylinder, stop the operation of the

device to avoid injury.

•Do not use the product if there is smoke or a strange smell.

•Do not handle with wet hands. Avoid getting the product wet.

•In case of a malfunction, stop using immediately.

•This product is a piece of precision equipment. Do not disassemble

or modify the product.

Precautions

•Do not insert wires or metal objects into any holes or gaps. This

may cause electric shock, failure or fire due to short-circuit.

•SMC will not be held responsible for any equipment problem or

failure due to the measurement results of this product.

•Avoid repeatedly bending or stretching the lead wire. This may

break the wire.

1 Safety Instructions (Continue )

2 Specifications

Sensor: 25 g, Unit: 65 g (Batteries excluded)Weight

Operation: 0 to 40 oC, Storage: -10 to 60 oC ( o condensation)

Ambient

temperature

range

1 mm/sec.

Min. display

unit

CE RoHSStandards

15 hours or longer continuous operation ∗4

Battery life

IP40

Enclosure

rating

-1999 to 1999 mm/sec.Display range

±20% or less

Measurement

accuracy

1.5 VDC AA alkaline battery x 2 ∗1

Power supply

voltage

Auto switch

(Specially machined) ∗2

Sensor

Speed measurement

mode

1 time

0 to 999 times

-

Count measurement

mode

0.01 sec.

(0.00 to 99.99 sec.,

0.00 to -99.99 sec.)

0.1 sec.

(100.0 to 999.9 sec.,

-100.0 to -999.9 sec.)

-999.9 to 999.9 sec.

±0.2 sec. or less

Applicable SMC 3-wire P Auto switch × 2 ∗3

Power supply voltage: 14 V or less

Output type: P open collector

O voltage: 2 V or less

OFF current: 100 μA or less

Cycle time

measurement mode

Item

■Installation

The Measurement value is indicated with a minus (-) to distinguish

between the extension and retraction of the cylinder.

Mounting as the figure below: ∗

Extension (Stroke direction): Positive direction

Retraction (Reverse stroke direction): Reverse direction is signified with

a (-) value

If the sensor are installed

incorrectly the speed will not

be measured (as above).

5 Spee measurement

Stroke direction to be measured

Red Green

Green Red

Head endHead end

Rod endRod end

GreenRed

Speed measurement

•This product uses the magnetic field of the pneumatic cylinder piston

(with built-in magnet) to measure the time taken for the piston to pass

two magnetic sensors, and converts the time into the speed of the

cylinder.

•The speed that is displayed is the speed close to the sensor. This is

the average speed between two sensors (approx. 3.7 mm). The speed

during acceleration is the average speed.

Cycle time and count measurement

•For measurement of cycle time or count, the supplied sensor cannot be

used. An auto switch must be purchased separately.

•A 3-wire P type auto switch is suitable for the measurement of cycle

time or count.

The speed results may vary depending on the conditions below.

•Individual variation between cylinders with built-in magnet.

•Magnetic characteristics due to cylinder bore size.

•Variation due to the magnetic field around the cylinder.

•Individual variation between sensors.

•Variation due to temperature change.

∗1: AA alkaline battery is not included. Prepared by the user.

∗2: For speed measurement mode, use the sensors supplied.

(Do not use any other sensor.)

∗3: For cycle time measurement mode, supplied sensor cannot be used (auto switch is

not included and must be purchased).

Auto switch (SMC 3-wire P auto switch) and connectors are purchased

separately.

∗4: Battery life depends on the operating environment.

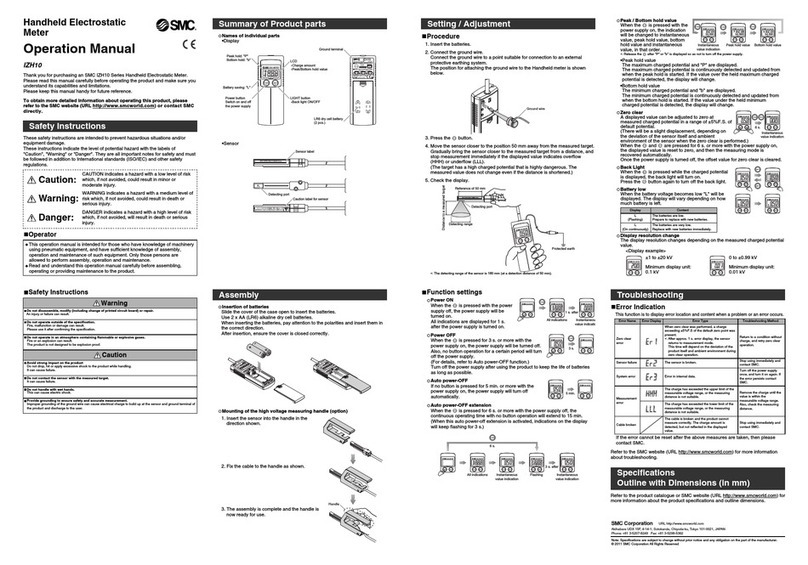

■Installing the batteries

(1) Slide the lid at the rear of the unit. Insert the batteries.

Applicable battery is "AA battery (1.5 V)"

Batteries are not included. Prepared by the user.

Make sure the polarity is correct when inserting the batteries.

(2) Close the lid after inserting the batteries.

(3) When the product is used and the battery has expired,

the low residual battery error will be displayed.

Replace the batteries.

■Wiring

•Connection of M8/M12 connector

(1) Tighten by rotating the knurled part of the connector body. Connection

is complete when the knurled part is fully tightened.

(2) Check that the connection is not loose.

•Assembilng the Auto switch and connector

Refer to "Assembly Procedure" attached to the connector for wiring of

PCA-1557730 (connector for M8) or PCA-1557743 (connector for M12).

Connect the lead wire colours as specified by the connector.

To obtain the operation manual for this product, please contact SMC.

To obtain the operation manual for this product, please contact SMC .

■Power ON

The power turns O when the button is pressed.

All segments will light up for 1 second when the power supply turns O .

The device will then be in its previous mode of operation.

∗: Default mode at the time of shipment from the factory is "Speed measurement

mode".

All segments

ON

Changes to the previous

measurement mode.

■Power OFF (Auto Power Off function)

The power turns OFF when the button is held for 3 seconds or longer.

If no buttons are pressed for 15 minutes, the power will turn OFF

automatically. (Auto Power Off function)

∗: Auto Power Off is disabled during measurement.

■Toggling the back light

When the power is O and the back light is OFF, the back light is turned

O by pressing the button for 5 seconds or longer.

When the power is O and the back light is O , the back light is turned

OFF by pressing the button for 5 seconds or longer.

∗: Although it is possible to measure when the sensor is mounted in reversed

direction, the displayed direction will be reversed.

○Switch setting

(1) Fully extend the rod, and slide the sensor towards the rod end.

(2) Stop the sensor when the green LED

turns O , and fix the sensor with the

mounting screw.

Tightening torque is 0.1 to 0.2 m.

∗: When the sensor is installed, the

speed from Rod to Head may not be

displayed depending on the type of

cylinder.

All segments

ON

Pressing the

button

for 3 sec.

or longer

Power OFF