Installation & Maintenan e Manual

SI unit - Devi eNet ompatible

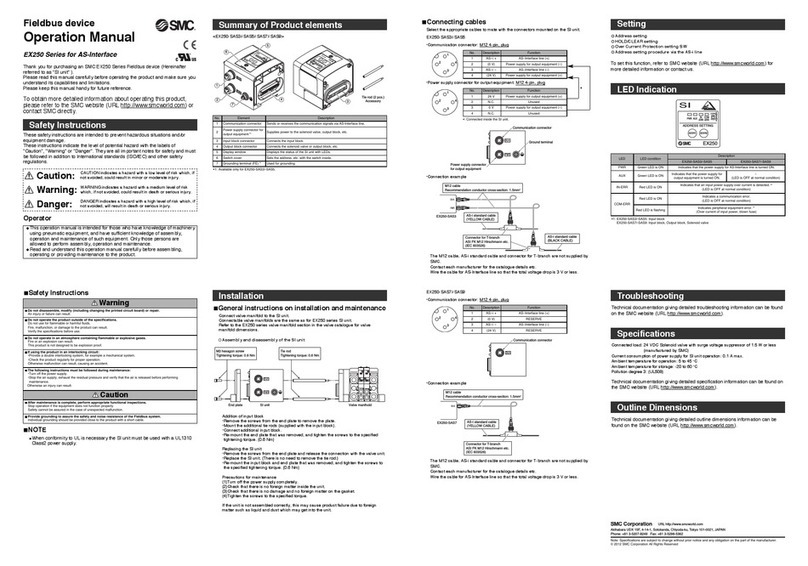

Type EX250-SDN1/EX250-SDN1-X102

The unit and this manual contain essential information

to protect users and others from possible injury and property

damage and to ensure correct handling.

Please confirm that you fully understand the meaning of the

following messages (signs) before reading the text, and always

follow the instructions.

Please read the Installation & Maintenance Manual for related

apparatus and understand it before operating the actuator.

Read this manual and follow the instructions.

Signal words such as WARNING, CAUTION and NOTE,

will be followed by important safety information that must

be reviewed carefully.

IMPORTANT MESSAGES

Indicates a potentially hazardous situation

which could result in death or serious injury

if you do not follow instructions.

Provides you helpful information.

Do not disassemble, modify (in luding hange of printed

ir uit board) or repair.

An injury or failure can result.

Do not operate outside of the spe ifi ation range.

Fire, malfunction or damage can result.

Please use it after confirming the specification.

Do not use the produ t in environments with possible

presen e of flammable, explosive or orrosion gas.

Otherwise fire, explosion or corrosion can result.

The product is not designed to be explosion proof.

.Connect wires and cables correctly.

.Do not connect wires while the power is on.

.Do not lay wires or cables with the same wiring route as a power line or

high-voltage line.

.Verify the insulation of the wiring.

.Take proper measures against noise such as a noise filter when the

product is incorporated in equipment or devices.

.Select an operation environment according to enclosure(IP67).

.Take sufficient shielding measures when installing the product at the

following place.

(1)A place where a noise due to static electricity etc. is generated

(2)A place of high electric field strength

(3)A place possibly exposed to radioactivity

(4)A place near power cable

.Do not use the product nearby a place where an electric surge is

generated.

.Use the product equipped with a surge absorber when a surge-

generating load such as a solenoid valve is driven directly.

.Prevent foreign matter such as remnant of wires from entering the

product.

.Do not expose the product to vibration and impact.

.Keep the specified ambient temperature range (+5 to +45 ).

.Do not expose the product to heat radiation from a heat source

located nearby.

.Use a precision screw driver with small flat blade when setting

rotary switch and DIP switch.

.Perform maintenance and check at regular intervals.

.Perform a proper functional check.

.Do not clean the product with chemicals such as benzine and

thinner.

Spe ifi ation

Safety Instru tions

Indicates a potentially hazardous situation

which if not avoided, may result in minor

injury or moderate injury.

Do not apply voltages ex eeding 250V between a lead

wire and a metal fitting.

Pay attention to perform an insulation test because it could

damage the insulation of the lead wire and cause failure.

These instru tions must be followed when using the

produ t in an interlo king ir uit:

.Provide double interlo king through another system

su h as me hani al prote tion.

.Che k the produ t regularly to ensure proper operation.

Otherwise malfunction can cause an accident.

These instru tions must be followed when performing

maintenan e work:

.Turn off the power supply

.Stop the air supply, exhaust the residual pressure and verify

that the air is released before performing maintenan e work.

Otherwise it can cause injury.

Perform a proper fun tional he k after ompleting

maintenan e work.

Stop operation when an abnormality is observed or the product is

not working properly.

Safety cannot be assured due to unexpected malfunctions.

NOTE

The direct-current power supply should be a UL authorized power

supply.

1.Limited voltage current circuit in accordance with UL508

A circuit to which power is supplied by the secondary coil of

a transformer that meets the following conditions.

.Max. voltage(with no load): less than 30Vrms(42.4V peak)

.Max. current:(1)less than 8A(including when short circuited)

(2)limited by circuit protector (such as fuse) with

the following ratings

2.UL1310 compatible class 2 power supply unit or circuit of

max. 30Vrms (42.4V peak) or less using a UL1585 compatible

class 2 transformer as power supply. (Class 2 circuit)

Follow the instructions given below when handling the product.

Failure to follow instructions may damage the unit.

.Operate the product within the specified voltage range.

.Reserve a space around the unit for maintenance.

.Do not remove labels.

.Do not drop, hit or apply excessive shock to the product.

.Do not bend or apply tensile force to cables, or apply a force by placing

a heavy load on them.

No load voltage (V peak)

0 to 20 [V]

20 to 30 [V]

Max.current rating (A)

5.0

100 / peak voltage

Item Specification

Operating ambient temp. +5 to +45

Operating ambient humidity 35 to 85% R (No dew condensation)

Storage ambient temp. -20 to +60

Vibration proof 10 to 57 z 0.35mm (Constant amplitude)

57 to 150 z 50m/s2(Constant acceleration)

Impact proof 150m/s2(peak), 11ms three times in each

direction

±

X, Y and Z.

Noise immunity

Normal mode :

±

1500V Pulse duration 1us

Common mode :

±

1500V Pulse duration 1us

Radiation :

±

1000V Pulse duration 1us

Withstand voltage 500V AC for 1min.

Insulation resistance 500V DC min10M ohm

Operating environment No corrosive gas and no dust

General spe ifi ation

Item Specification

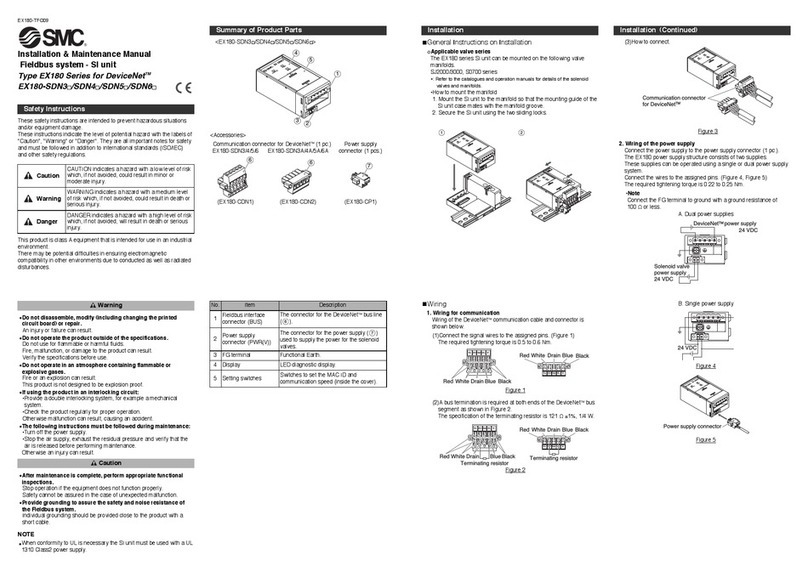

Applicable system DeviceNet Release 2.0

Power voltage

range

Current

consumption

Power for SI unit

Current consumption

11 to 25V DC

100mA or less

Power for Input

BlockCurrent

consumption

19.2 to 28.8V DC

Depending on the number of Input

Block stations and sensor

specifications. Max 1A or less

Power for solenoid

valve

Current consumption

21.6 to 26.4V DC (Power reduction

alarm occurs at approx. 19V DC.)

Depending on number of Solenoid

valve station and specifications Max

2.5A or less

Solenoid valve

connection spec.

Output type P-ch MOS-FET Open drain type

Connection load

Solenoid valve with protection circuit for

24V DC and 1.5W or less surge

voltage. (made by SMC)

Insulation type Opto coupler type

Residual voltage 0.3V DC or less

Network connection spec.

MAC ID setting range

0 to 63

(Set by DIP / retain address information

when setting power is shut off via

network.)

Baud Rate

(Transmission speed)

500kbps, 250kbps, 125kbps

(Set by DIP / hold address information

when setting power is shut off via

network.)

Slave (branch station) type Group 2 only server

Connection type T branch type, Multi drop type

Device type 27

Product code 2401

Revision Refer to EDS file

Vendor ID 7

Consumed connection size

(Receiving byte) 4 (Polled I/O connection : Occupy 4 byte)

Produced connection size

(Sending byte)

4

(Polled I/O connection

: Occupy 4 byte)

Correspond message Polled command (I/O message),

Explicit message.

Ele tri al and network

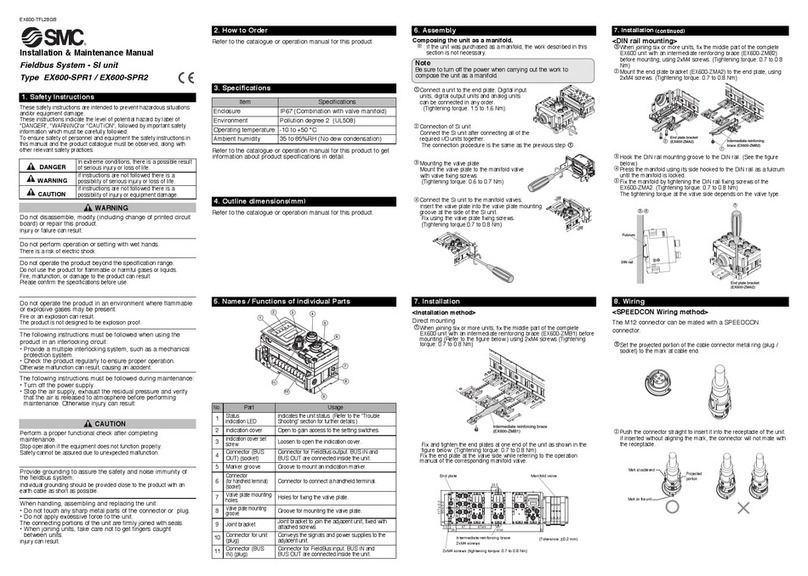

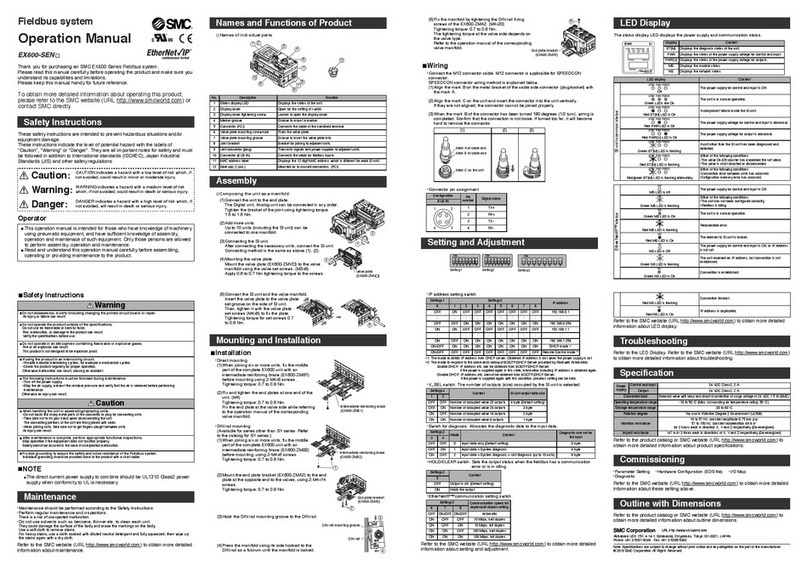

Names and Fun tions of Individual Parts