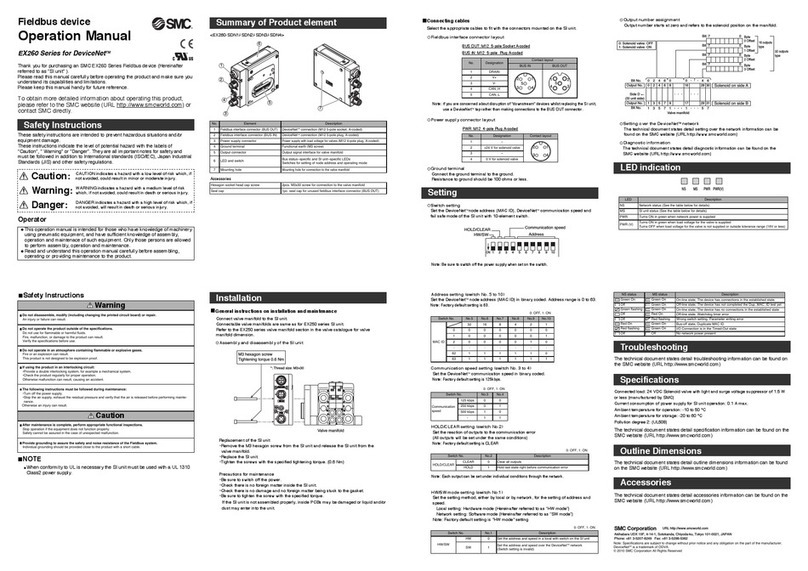

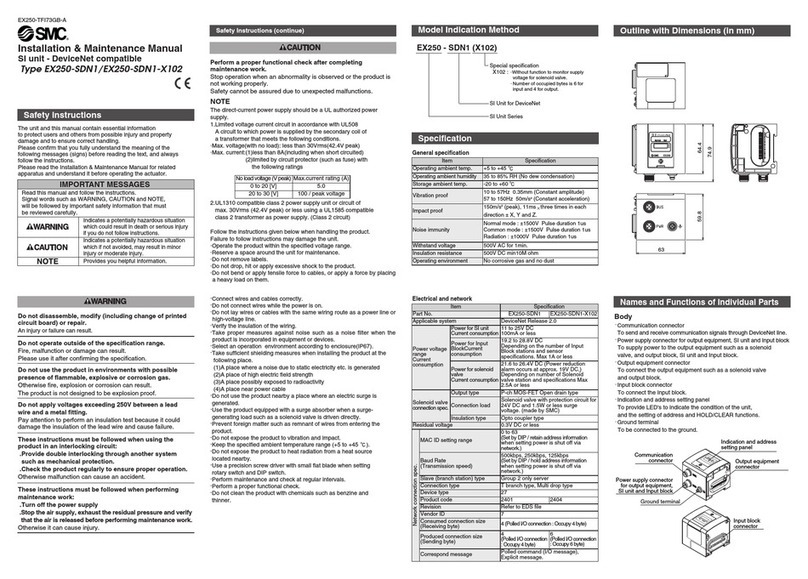

Green LED is flashing

LED Description

I/O connection established (on-line status)

OFF

I/O connection stand-by (on-line status)

PWR(V) Green LED is O when power for solenoid valve is supplied.

MOD/ ET

Power supply is off, on-line status or checking for MAC ID duplication.

Troubleshooti g

Technical documentation giving detailed troubleshooting information can be found

on the SMC website (URL http://www.smcworld.com).

Specificatio s

Power for SI unit: 11 to 25 VDC, 0.1 A or less

Power for input block: 24 VDC ±20%, 1 A or less (Depending on number of connecting

sensors and specifications)

Power for solenoid valve: 24 VDC +10%/-5%, 2 A or less

(Depending on number of solenoid valve station and

specifications)

Connection load: Solenoid valve with protection circuit for 24 VDC and 1.5 W or less surge

voltage. (made by SMC)

Operating ambient temp: -10 to 50 oC Storage ambient temp: -20 to 60 oC

Pollution degree: Pollution degree 3 (UL508)

Technical documentation giving detailed specification information can be found on

the SMC website (URL http://www.smcworld.com).

Outli e Dime sio s

Technical documentation giving detailed outline dimensions information can be

found on the SMC website (URL http://www.smcworld.com).

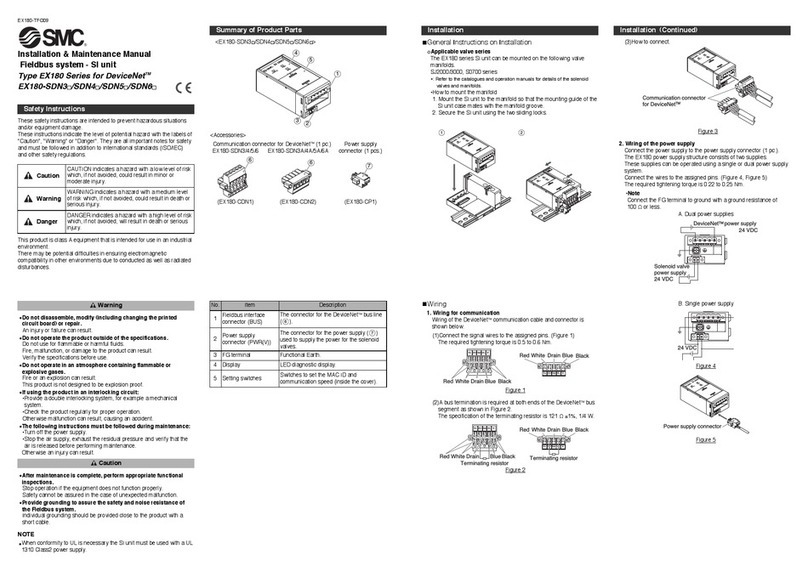

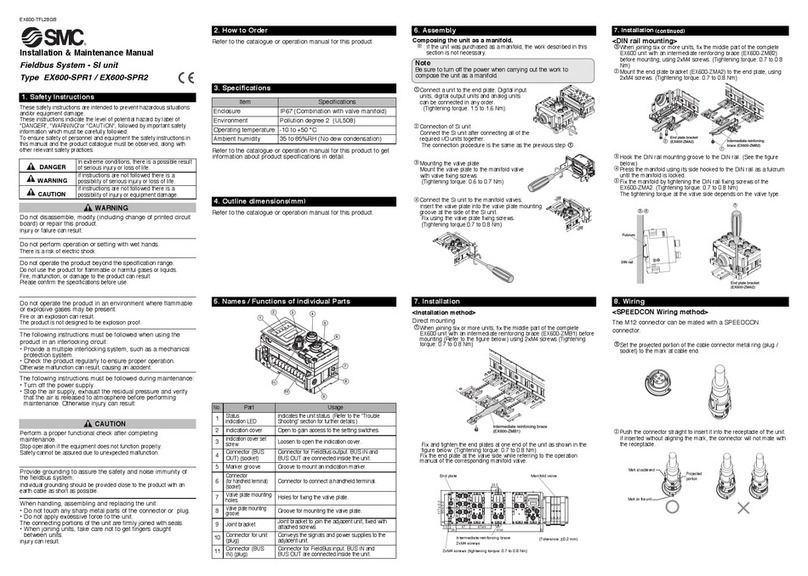

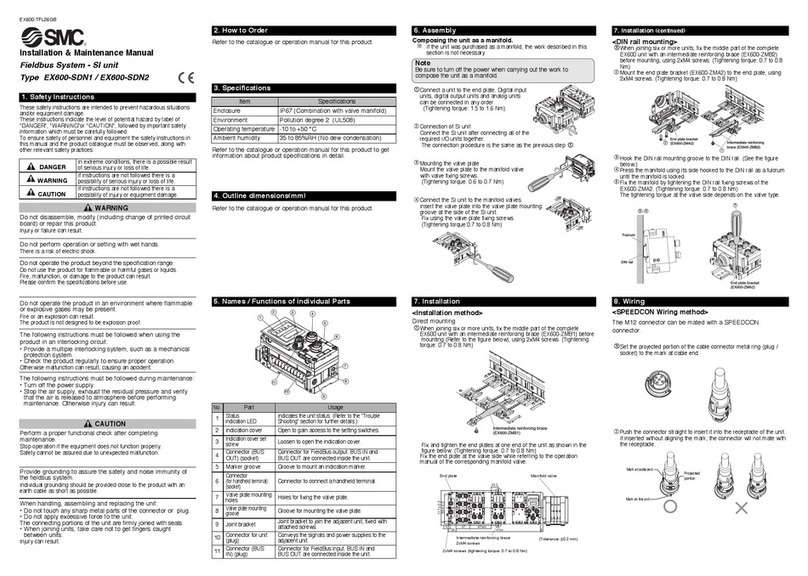

Assembly a d disassembly of the SI u it

NOTE

When conformity to UL is necessary the SI unit must be used with a UL1310

Class2 power supply.

Safety I structio s

Do ot operate the product outside of the specificatio s.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do ot disassemble, modify (i cludi g cha gi g the pri ted circuit board) or repair.

An injury or failure can result.

Do ot operate i a atmosphere co tai i g flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If usi g the product i a i terlocki g circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The followi g i structio s must be followed duri g mai te a ce:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance.

Otherwise an injury can result.

Provide grou di g to assure the safety a d oise resista ce of the Fieldbus system.

Individual grounding should be provided close to the product with a short cable.

Thank you for purchasing an SMC EX250 Series Fieldbus device (Hereinafter

referred to as "SI unit" ).

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations.

Please keep this manual handy for future reference.

To obtain more detailed information about operating this product,

please refer to the SMC website (URL http://www.smcworld.com) or

contact SMC directly.

Safety I structio s

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", " Warning" or "Danger". They are all important notes for safety and

must be followed in addition to International standards (ISO/IEC) and other safety

regulations.

War i g

Cautio

After mai te a ce is complete, perform appropriate fu ctio al i spectio s.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

CAUTIO indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Cautio :

War i g:

Da ger:

WAR I G indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

DA GER indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Operator

This operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenace of such equipment. Only those persons are allowed

to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

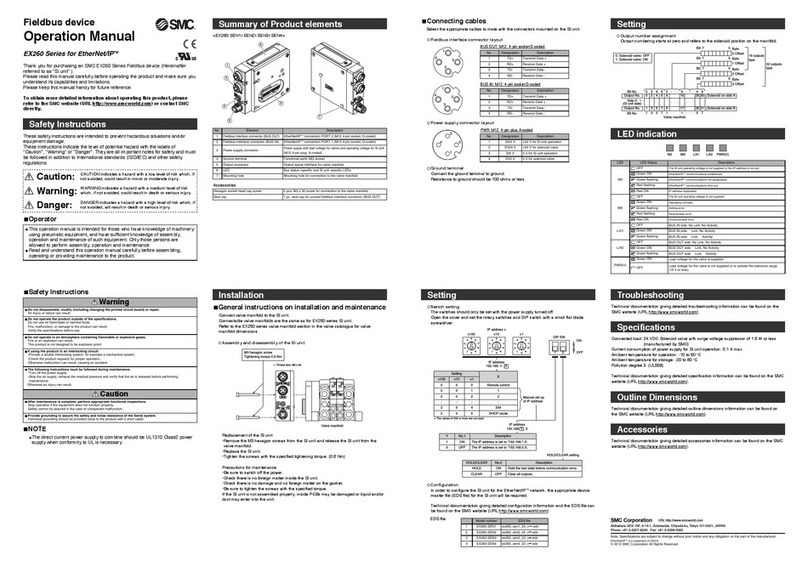

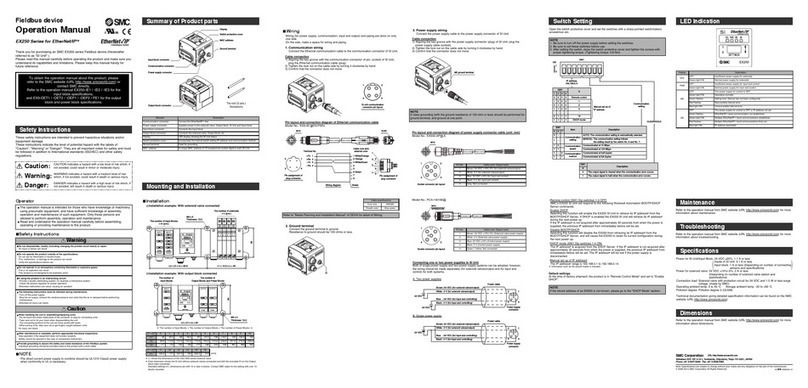

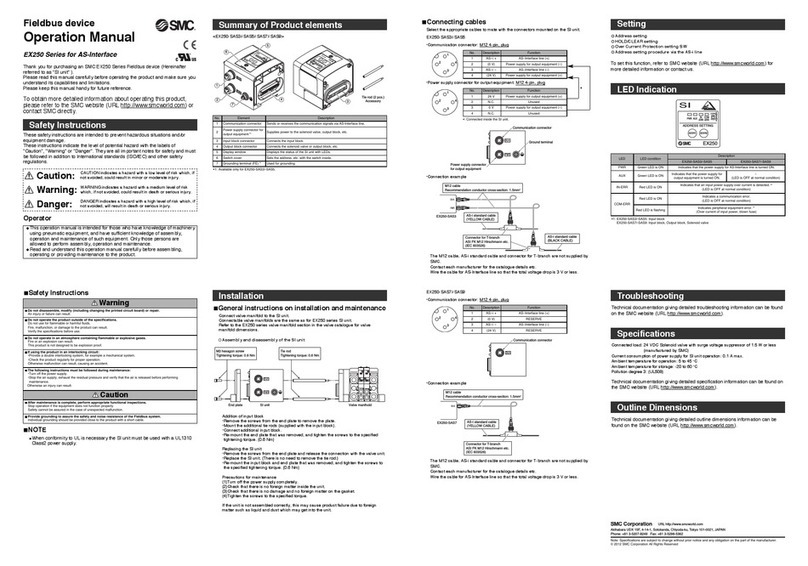

Wiri g

Commu icatio wiri g

M12 5-pin plug A-code

DRAI

Signal name Configuration

V+

V-

CA _L

1

Pin o.

2

3

5

CA _H4

SV24 V

Description Function

+24 V for solenoid valve.

SV0 V 0 V for solenoid valve

SW24 V +24 V for input block

FE Ground

1

o.

2

3

5

SW0 V 0 V for input block4

Power supply wiri g

Refer to "Safety Instructions" on this manual when selecting the power supply.

M12 5-pin B-code (reverse)

SW power is supplied to the sensor connected to the input block. There is a voltage drop up

to maximum 1 V inside the SI unit when SW power is supplied. Select a sensor taking this

voltage drop into consideration. If 24 V must be supplied to the sensor, it is necessary to

increase the SW power supply voltage so that the input voltage of the sensor will be 24 V with

the actual load. (Allowable SW power supply range: 19.2 V to 28.8 V)

FE co ectio

Connect the ground terminal to the ground. Resistance to the ground should be 100 Ω

or less.

PWR Green LED is O when power for Device etTM communication is supplied.

Green LED is O

Red LED is flashing

Red LED is O MAC ID duplication error or BUS OFF error (serious communication error)

I/O connection time-out (minor communication error)

Note

1. The power supply should be off while setting the switches.

2. Be sure to set the switches before use.

3. After setting the switches, close the switch cover and tighten the screw to the

specified torque. (Tightening torque: 0.6 m)

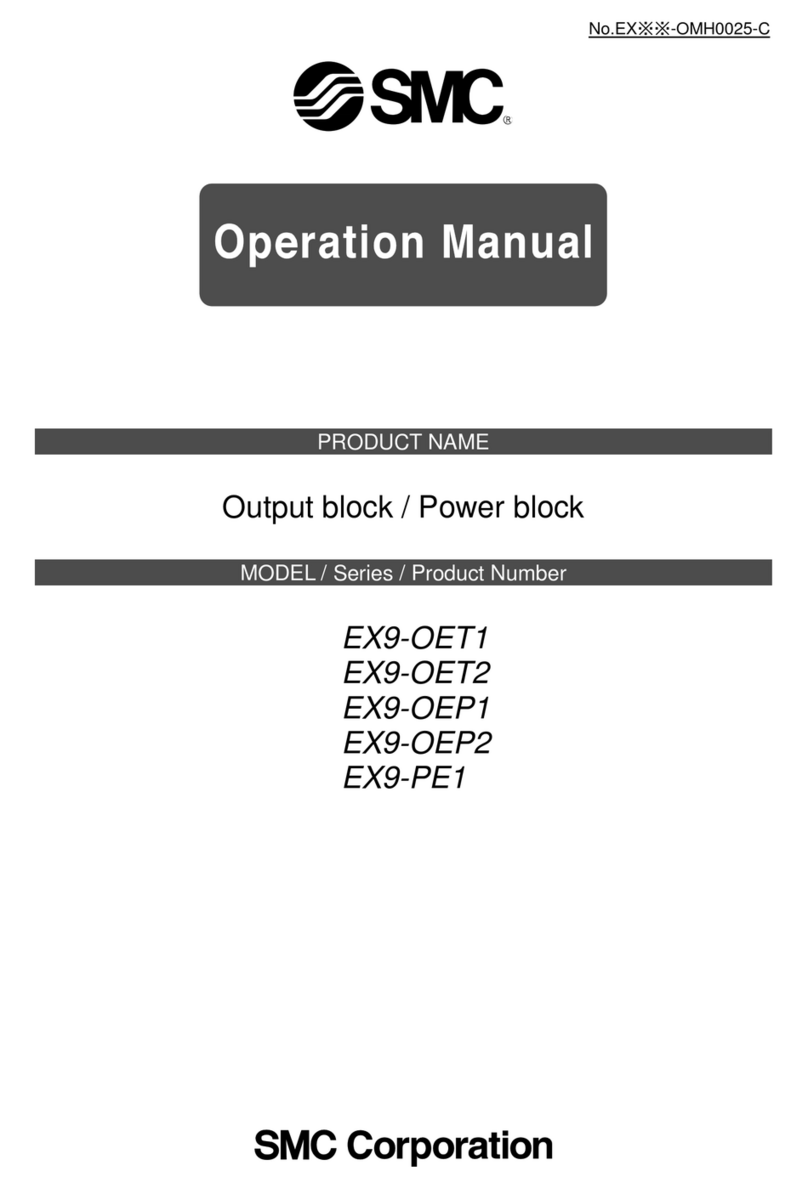

∗: Output o. starts from 0, and will be assigned to the valves in order from the SI unit mounted side

∗: Manifold wiring is double wired as standard ("double wiring specification"), and the output

numbers are assigned in order from A side to B side. If the mounted valves are single solenoid

valves, the output on B side will be empty. (See Figure a)

∗: Special wiring specification with a mixed wiring of single solenoid and double solenoid can be

specified with a wiring specification sheet. This makes it possible to specify the output numbers

without empty outputs. (See Figure b)

∗: Each bit status, 0 or 1, of the data shows the O or OFF solenoid valve status (0: OFF, 1: O ),

and the output number starting from 0 will be assigned to from the lowest bit of the memory data.

∗: EX250-SD 1 disconnects the I/O connection when the solenoid valve power supply decreases or

when the input block fuse is detected to be broken (EX250-SD 1-X102 does not disconnect the I/O

connection).

Address setting

I put No. assig me t

The inputs of the Input block are assigned from the SI unit side Input block in the order

0,1,2…maximum of 31.