Operation Manual

19

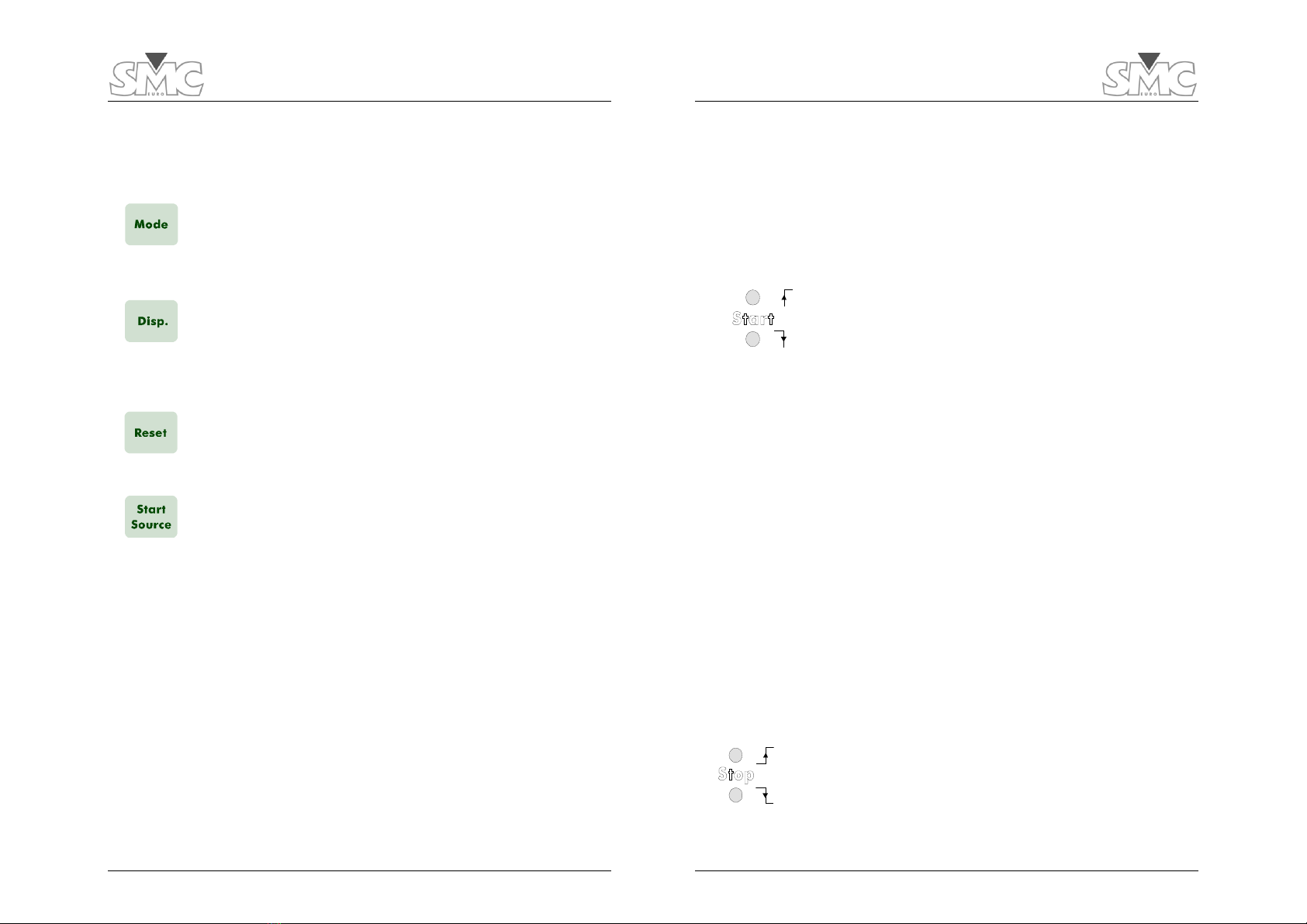

3.2.1. CONTROL KEYS AND KNOBS: Selecting the function mode

This section describes how to select the timer mode for the starting/stopping of

the timer, the timer reading, and how to reset it. The keyboard for the timer is as

follows:

This key works in a sequential way, that is to say by pressing

this key; the LED’s will indicate the different selection

combinations. There are 6 different possibilities to choose

from, see 3.2.2.

This key works in a sequential way, each time this key is

pressed, the reading in Display 1 located on the left-hand side

will change. This will display seconds or the number of

frequency cycles in alternating current.

Each time this key is pressed the timer will reset to 0, allowing

the operator to perform the next test. If the timer is not reset,

all the outputs and displays will remain on hold and blocked.

This key allows the selection of the Timer whether it is internal

or external. Each time this key is pressed the selection will

change from one to another. There are 2 VISUAL LED’s

associated with this key.

PTE-50-CE Pro

20

3.2.2. VISUAL INDICATORS AND DISPLAYS

oFunction mode indication

There are 6 green LED’s of 3 mm. When these are lit they indicate

mode function the equipment has. These LEDs are associated with the

Mode key:

a) START Mode indicators:

These 2 LEDs indicate the start mode of the Timer in

relation to the output control ON/OFF and to the 2nd Value

Step press key. These 2 LEDs are 3 mm and green. Only

one can be used at the same time:

When the upper LED is lit, it indicates that the Timer will start when:

oThe output control is activated (ON)

oWhen there is a Step to 2nd Value.

oWhen a contact is closed at the input of the external timer.

oWhen this LED is flashing it indicates that the Timer is in BUS mode,

meaning that it will start when there is a positive event in the BUS.

When the lower LED is lit, it indicates that the Timer will start when:

oThe output control is deactivated (OFF)

oWhen a Step to 2nd Value is deactivated.

oWhen a contact is open at the input of the external timer.

When this LED is flashing it indicates that the Timer is in BUS mode, meaning

that it will start when there is a negative event in the BUS.

b) Stop Mode Indicators

These 2 LEDs indicate the stop mode of the Timer in relation

to the Monitor state. These 2 LEDs are 3 mm and green.

Only one can be active at the same time .