!Depending on the parameter's setting, the actuator will move

erratically when an input current of 4mA DC is applied.

!There is a capacitor for noise prevention between FG terminal (case)

and each input / output terminal of the positioner respectively.

Therefore, avoid conducting withstand voltage testing or insulation

resistance testing between the terminal and case.

!Please refer to the Operation manual for further details.

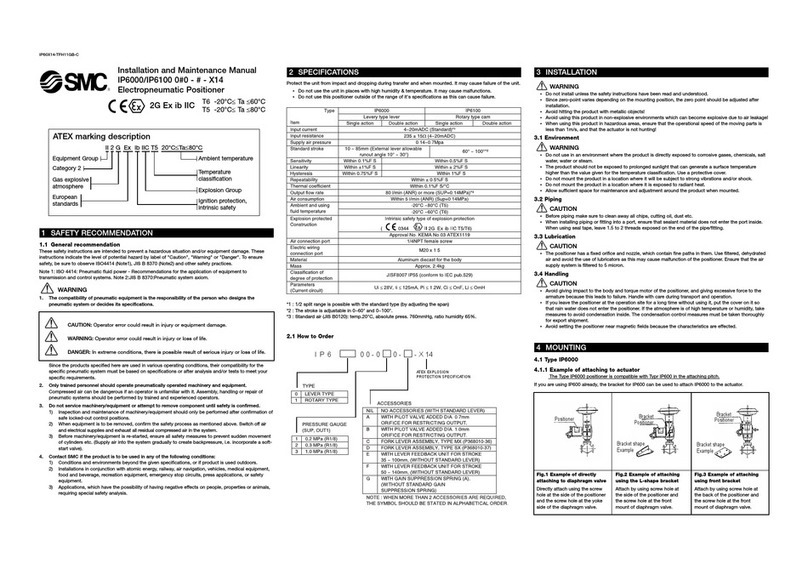

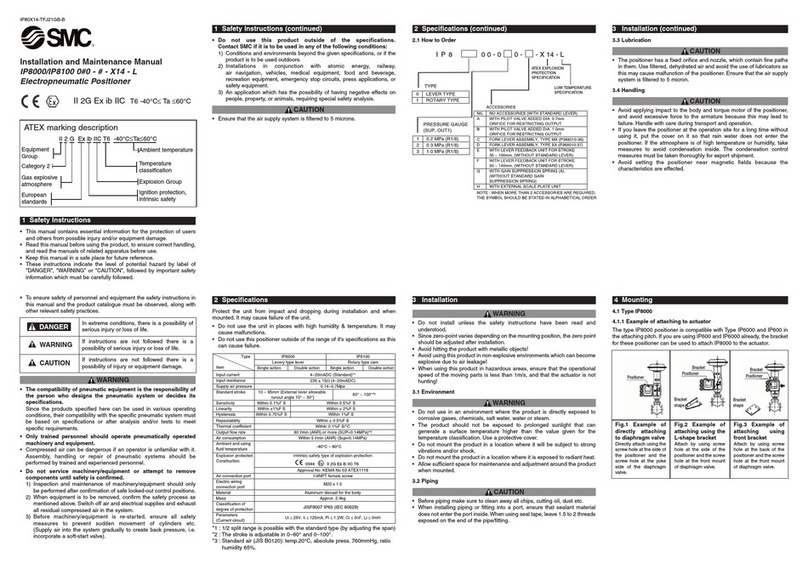

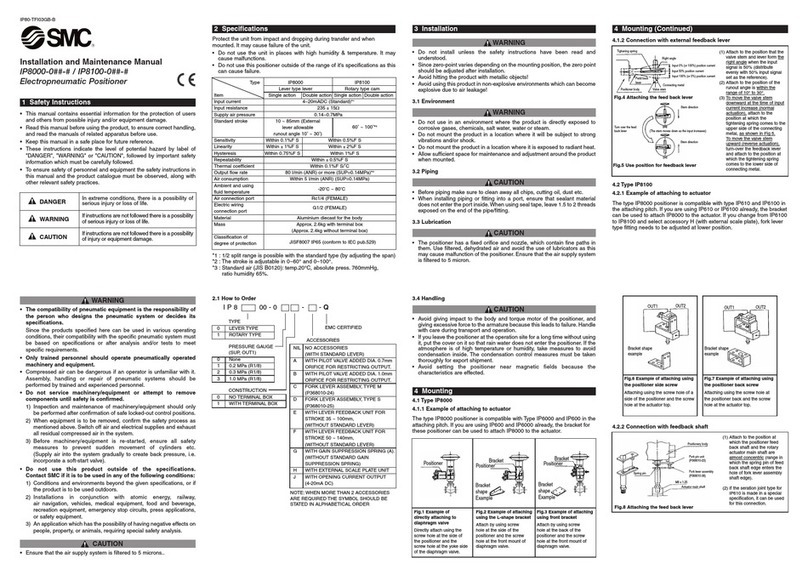

2 INTENDED CONDITIONS OF USE

2.1 Specifications

Protect the unit from impact and dropping during installation and when

mounted. This may cause failure of the unit.

!Do not use the unit in places with high humidity & temperature.

This may cause malfunctions.

!Do not use this positioner outside of the range of it's specifications as

this can cause failure.

Table1 Specifications

*1: 1/2 split range is available using the split range setting (parameter

code: 300).

*2: <Ex.> When applying an input current of 80mA DC, an input power

supply voltage of 12.5V DC or less will prevent damage to the

positioner.

Max. supply power = 80mA DC×12.5V = 1W

*3: If the feedback lever assembled to the positioner rotating angle is 30°

or less, its stroke can be adjusted optionally in a range from 0 to 10°

and from 0 to 30°. Please set the operation angle of the feedback

lever to 10°when accuracy is required.

*4: Linearity is a characteristic checked without loads using a factory

inspection machine. The positioner can not work independently and is

used as a part of loop including actuating equipment such as a valve,

actuator and DCS. Therefore, it should be noted that the described

characteristic values may vary depending on the loop conditions.

*5: (ANR) indicates standard air in accordance with JIS B0120.

Table2 Specifications of options

*6: When no input current has been applied, an alarm is output. Fig. 1

shows an internal alarm circuit.

Read this manual before using this product

!The information within this document is to be used by pneumatically

trained personnel only.

!For future reference, please keep manual in a safe place.

!This manual should be read in conjunction with the current catalogue.

1 SAFETY RECOMMENDATION

1.1 General recommendation

These safety instructions are intended to prevent a hazardous situation

and/or equipment damage. These instructions indicate the level of

potential hazard by label of "Caution", "Warning" or "Danger".

To ensure safety of personnel and equipment the safety instructions in this

manual and the product catalogue must be observed, along with other

relevant safety practices.

WARNING:

•The compatibility of pneumatic equipment is the responsibility of a person

who designs the pneumatic system or decides its specification.

!Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet your

specific requirements.

•Only trained personnel should operate pneumatically operated machinery

and equipment.

!Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be

performed by trained and experienced operators.

•Do not service machinery/equipment or attempt to remove components until

safety is confirmed.

!Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe of dangerous fluid.

!When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

!Before machinery/ equipment is re-started, ensure all safety measures

to prevent sudden movement of cylinders etc. (Bleed air into the

system gradually to create backpressure, i.e. incorporate a soft-start

valve).

•Contact SMC if the product is to be used in any of the following conditions:

!Conditions and environments beyond the given specifications, or if

product is used outdoors.

!Installation on equipment in conjunction with atomic energy, railway,

air navigation, vehicles, medical equipment, food and beverages,

recreation equipment, emergency stop circuits, press applications, or

safety equipment.

!An application, which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

CAUTION:

!Ensure that the air supply system is filtered to 0.3 micron.

1.2 Specific recommendations

!If the input current is disconnected during use, the output of OUT1 will

become 0MPa and the output of OUT2 will reach its maximum,

regardless of the operating direction of the parameter mode

(parameter code: 200), whether direct or in reverse.

!If reverse operation is selected in parameter mode (parameter code:

200), when the power supply is turned off, OUT1 output will become

0MPa and the positioner will start moving toward input current

20mADC direction.

Model

Item IP8001-0**-*-*-Q

Input current 4㨪20mADC 㧖1㧔2 wire system,

Separate power source unnecessary㧕eromroCDAm58.3tnerrucmuminiM

Voltage between

terminals

12VDC

㧔Input resistance equivalent to 600Ω, at 20mADC㧕Max supply power 1W 㧖2㧔100mADC, 28VDC㧕Supply air pressure 0.14㨪0.7MPa

Standard stroke 10o㨪30o㧖3

Sensitivity ±0.2%F.S. or less 㧖4

Linearity ±1%F.S. or less 㧖4

sselro.S.F%5.0siseretsyH

sselro.S.F%5.0±ytilibataepeR

/.S.F%50.0tneiciffeocerutarepmeT oC or less

Max output flow rate 80 l/min(ANR) or more (SUP=0.14MPa)㧖5

2 l/min(ANR) or less (SUP=0.14MPa) 㧖5

Air consumption 4 l/min(ANR) or less (SUP=0.4MPa) 㧖5

Ambient and operating

fluid temperature -20oC to 80oC

Classification of degree

of Protection JIS F8007 IP65 (IEC 60529)

Communication

Protocol HART communication

Air connection ports Rc1/4 female thread (or G1/4 or 1/4NPT)

Electrical connections G1/2 female thread (or 1/2NPT or M20x1.5)

Body/Cover : Die cast aluminium

㧔Coating : Epoxy resin baked㧕Material

Shaft / Screw : Stainless

gk6.2xorppAthgieW

Model

Item IP8001-0*2-*-Q

Alarm output1, 2 㧖6

metsyseriw2dohtemgniriW

Power supply voltage 10㨪28VDC

Load current 10㨪40mADC 㧖7

Internal resistance 350Ω±10㧑sselroCDAm5.0egakaeltnerruC

sselrocesm05emitesnopseR

Analogue output 㧖8

metsyseriw2dohtemgniriW

Supply source voltage 10㨪28V DC

Output current 4㨪20mADC

Load resistance 0㨪750Ω

sselro.S.F%5.0±ycaruccA 㧖9

1 SAFETY RECOMMENDATION (CONTINUED) 㧙㧙㧖㨧㨩㧙㧙