ø2 ø3.2 ø4 ø6 ø8 ø10 ø12 ø16

ø2 ø3.2 ø4 ø6 ø8 ø10 ø12 ø16

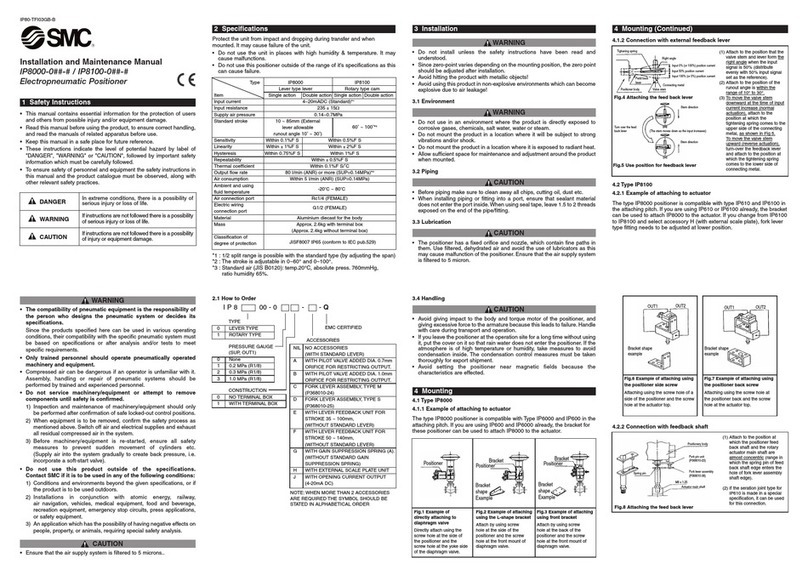

Sealant/Gasket Seal

One-touch Fittings KQ2

Series

Applicable tubing

Gasket Seal (Uni Thread)

Connection thread

Rc G NPT NPTF

Applicable tubing

Metric

Inch

Face Seal

Applicable tubing

Metric

Metric

Inch

Inch

Connection thread

M R Rc UNF NPT

Connection thread

G R Rc NPT R

P.5

P.29

P.49

P.57

P.65

P.73

P.81

P.87

P.95

Metric

Inch

Inch

Oval Type Release Button

How to Order

····························

P.6

Variations

································

P.7

Dimensions

······························

P.9

Made to Order/Clean Series/

Spare Parts

······························

P.27

How to Order

····························

P.30

Variations

································

P.31

Dimensions

······························

P.33

Made to Order/Clean Series/

Spare Parts

······························

P.48

How to Order

····························

P.50

Variations

································

P.51

Dimensions

······························

P.52

Made to Order/Clean Series/

Spare Parts

······························

P.55

How to Order

····························

P.88

Variations

································

P.89

Dimensions

······························

P.90

Made to Order/Clean Series/

Spare Parts

······························

P.93

How to Order

····························

P.96

Variations

································

P.97

Dimensions

······························

P.98

Made to Order/Clean Series/

Spare Parts

······························

P.100

How to Order

····························

P.58

Variations

································

P.59

Dimensions

······························

P.60

Spare Parts

······························

P.63

How to Order

····························

P.66

Variations

································

P.67

Dimensions

······························

P.68

How to Order

····························

P.74

Variations

································

P.75

Dimensions

······························

P.76

How to Order

····························

P.82

Variations

································

P.83

Dimensions

······························

P.84

ø1/8" ø5/32" ø3/16" ø1/4" ø5/16" ø3/8" ø1/2"

ø1/8" ø5/32" ø3/16" ø1/4" ø5/16" ø3/8" ø1/2"

ø1/8" ø5/32" ø3/16" ø1/4" ø5/16" ø3/8" ø1/2"

ø1/8" ø5/32" ø3/16" ø1/4" ø5/16" ø3/8" ø1/2"

ø1/8" ø5/32" ø3/16" ø1/4" ø5/16" ø3/8" ø1/2"

ø2 ø3.2 ø4 ø6 ø8 ø10 ø12 ø16

ø2 ø3.2 ø4 ø6 ø8 ø10 ø12 ø16

3