Out

In

11

10

6

7

25

4

3

8

1

9

267

PURITY C Steam

Verschnitt- und Kapazitätstabellen / By-pass and capacity tables /

Tableau de réglage by-pass et de détermination de la capacité /

Bypass- en capaciteitstabellen / Tabelle del by-pass e della capacità /

Tablas de mezcla y capacidad / Tabela de bypass e capacidade /

Blandings- og kapacitetstabeller / By-pass och kapacitetstabell /

Tabeleobejśćiwydajności/Таблицыресурсовфильтрови

настроекbypass

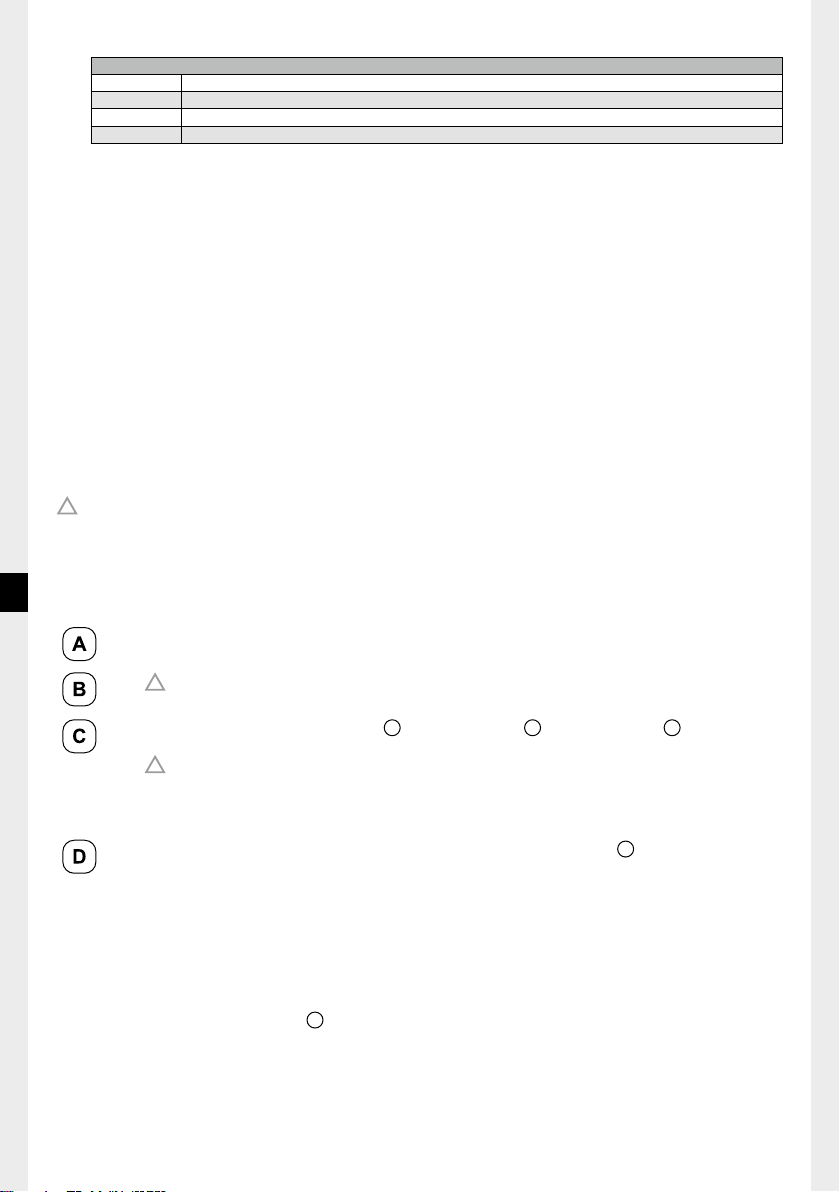

The bypass position can be adjusted to the local water quality or the machine type. The

following recommendations for bypass settings apply by default:

Position 0: All devices in areas with an extremely high water hardness level (CH ≥ 22 °dH)

Position 1: Combi ovens and conventional ovens with direct injection system

Position 2: Combi ovens and conventional ovens with boiler system

Position 3: All devices in soft water areas (CH ≤ 7 °dH)

You can obtain individual recommendations from your BRITA contact.

OperationoflteronlywithPURITYCSteamlterhead.

PURITY C Steam - Filter capacity in litre

°dH

(Carbonate

hardness)

PURITY C500 Steam PURITY C1100 Steam

By-pass setting By-pass setting

01/2 3 0 1/2 3

47083 7792 8677 11980 13178 14676

57083 7792 8677 11980 13178 14676

67083 7792 8677 11980 13178 14496

76071 6679 7438 10269 11295 12425

85313 5844 6508 8985 9884 10872

94722 5194 5785 7987 8785 9664

10 4250 4675 5206 7188 7907 8697

11 3864 4250 4733 6535 7188 7907

12 3542 3896 4339 5990 6589 7248

13 3269 3596 4005 5529 6082 6690

14 3036 3339 3719 5134 5648 6212

15 2833 3117 3471 4792 5271 5798

16 2656 2922 3254 4493 4942 5436

17 2500 2750 3063 4228 4651 5116

18 2361 2597 2892 3993 4393 4832

19 2237 2461 2740 3783 4161 4578

20 2125 2338 2603 3594 3953 4349

21 2024 2226 2479 3423 3765 4142

22 1932 2125 2366 3267 3594 3953

23 1848 2033 2264 3125 3438 3782

24 1771 1948 2169 2995 3295 3624

25 1700 1870 2083 2875 3163 3479

26 1635 1798 2002 2765 3041 3345

27 1574 1731 1928 2662 2928 3221

28 1518 1670 1859 2567 2824 3106

29 1466 1612 1795 2479 2726 2999

30 1417 1558 1735 2396 2636 2899

31 1371 1508 1679 2319 2551 2806

32 1328 1461 1627 2246 2471 2718

33 1288 1417 1578 2178 2396 2636

34 1250 1375 1531 2114 2326 2558

35 1214 1336 1488 2054 2259 2485

Note: All stated capacities were tested and calculated based on standard application and machine conditions. This

informationmayvaryaccordingtoexternalinuencingfactors(forexample,uctuatingwaterqualityand/ormachinetype).

9 Технические параметры

Фильтр-системы серии PURITY C

Рабочеедавление 2бардоmax.8,6бар

Рабочаятемператураводы 4°Cдо30°C

Температура

окружающей

средывовремя

работы 4°Cдо40°C

хранения/транспортировки –20°Cдо50°C

Размерсоединенийвход(IN)=выход

(OUT)наголовнойчастифильтра G3/8"

Фильтр-системы C500 Steam C1100 Steam

Скоростьпотокаприпадениидавленияна1бар 300л/час 300л/час

Номинальнаяскоростьпотока 100л/час

Потерядавленияприноминальнойскоростипотока 0,1 бар 0,2 бар

Объемпустогокартриджа 5,4л 8,7л

Вес

картриджа

безводы 4,6 кг 7,7 кг

сводой 6,9 кг 12,5 кг

Размеры

(ширина,

глубина,

высота)

Фильтр-система

144 мм,

144 мм,

557 мм

184 мм,

184 мм,

557 мм

Сменныйкартридж

144 мм,

144 мм,

548 мм

184 мм,

184 мм,

548 мм

Рабочееположениефильтр-системы горизонтальноеиливертикальное

RU