-2-

NDEX

1.

GENERAL INFORMATIONS ....................................................................................................................................3

1.1.

MANUFACTURER / ASSISTANCE ............................................................................................. 3

1.2.

CERTIFICATION ................................................................................................................ 3

1.3.

PURPOSE OF THE MANUAL AND ITS CONTENTS ........................................................................... 3

1.4

CARE AND STORAGE OF THE MANUAL ...................................................................................... 3

1.5.

IMPORTANT SYMBOLS TO REMEMBER ....................................................................................... 3

2.

CHARACTERISTICS OF THE DEVICE....................................................................................................................4

2.1.

RECOMMENDED USE ........................................................................................................... 4

2.2.

SCHEMATIC REPRESENTATION ............................................................................................... 4

2.3

COMPONENTS .................................................................................................................. 5

2.4

DESCRIPTION .................................................................................................................. 5

2.5

TECHNICAL SPECIFICATIONS ................................................................................................. 6

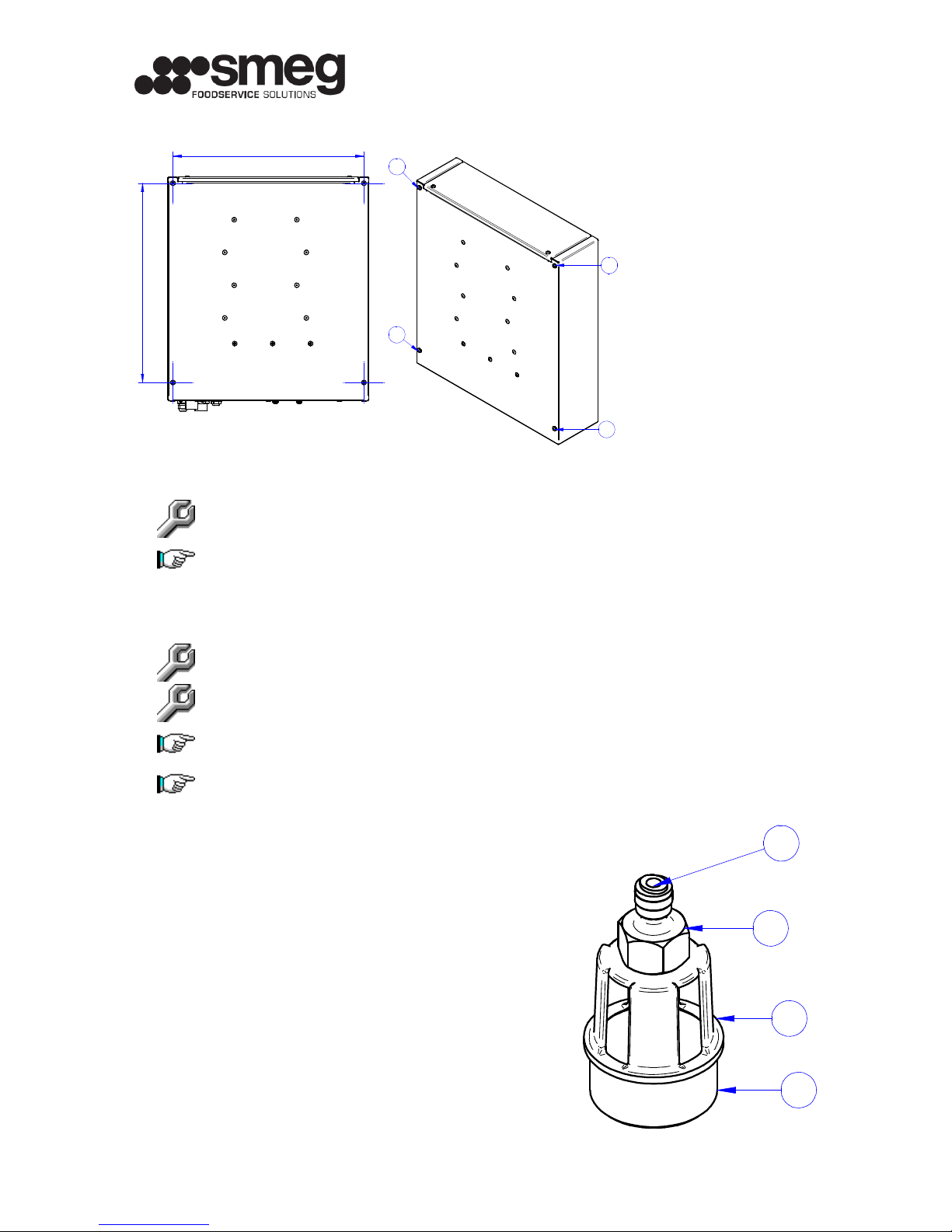

2.5

GENERAL DIMENSIONS ........................................................................................................ 7

2.6

INTERNAL LAYOUT ............................................................................................................ 7

3.

INSTALLATION ........................................................................................................................................................8

3.1

DISHWASHER REAR SIDE INSTALLATION ....................................................................................

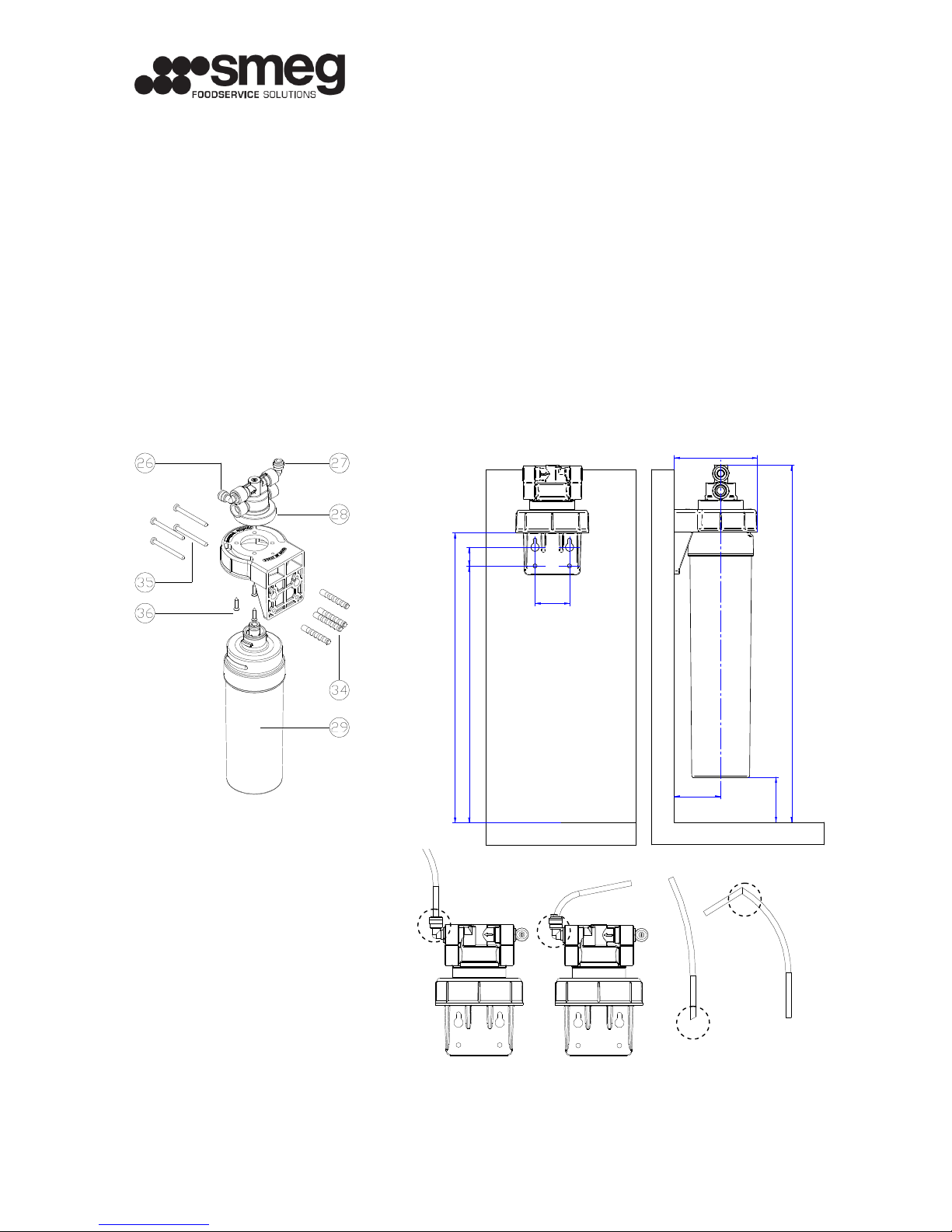

3.2

DRAIN FITTING EN1717 .......................................................................................................

3.3

EXTERNAL PREFILTER INSTALLATION ...................................................................................... 10

3.4

DRAIN CAPILLARY REPLACEMENT .......................................................................................... 11

4.

FUNCTIONING........................................................................................................................................................12

4.1

FIRST START-UP .............................................................................................................. 12

4.2

NORMAL USE .................................................................................................................. 12

4.3

LOW PRESSURE ALARM ...................................................................................................... 12

4.4

LEACKAGE ALARM ............................................................................................................ 12

4.5

INACTIVITY .................................................................................................................... 12

5.

ENDUSER ORDINARY MAINTENANCE................................................................................................................13

5.1

FILTER REPLACEMENT ....................................................................................................... 13

6.

PROFESSIONAL EXTRAORDINARY MAINTENANCE.........................................................................................14

6.1.

REQUIRED TRAINING FOR MAINTENANCE PERSONNEL ................................................................... 14

6.2.

RESPONSIBILITIES OF MAINTENANCE PERSONNEL ........................................................................ 14

6.3

POWER CORD / POWER PLUG REPLACEMENT ............................................................................ 14

6.4

CHECK/REPLACEMENT OF OSMOTIC MEMBRANES ........................................................................ 15

6.5

PUMP REPLACEMENT ........................................................................................................ 16

6.6

CLEANING SOLENOID VALVE FILTER / SOLENOID VALVE REPLACEMENT .............................................. 17

6.7

MACHINE SANITATION ....................................................................................................... 18

6.8

FUSE REPLACEMENT / ELECTRONIC BOARD REPLACEMENT ............................................................. 1

6.

VERIFICATION OF THE PRESSURE SETTINGS .............................................................................. 20

7

TROUBLESHOOTING ............................................................................................................................................21

ATTACHMENT I – CE LABEL .........................................................................................................................................24

ATTACHMENT II – MAINTENANCE LOG.......................................................................................................................24