7596040 –MANUALE WO-20 EN 21052018 REV.1

- 3 -

INDICE

1GENERAL INFORMATIONS.......................................................................................................................................- 5 -

1.1 MANUFACTURER / ASSISTANCE.......................................................................................... - 5 -

1.2CERTIFICATION ............................................................................................................ - 5 -

1.3 PURPOSE OF THE MANUAL AND ITS CONTENTS........................................................................ - 5 -

1.4 CARE AND STORAGE OF THE MANUAL .................................................................................. - 5 -

1.5 IMPORTANT SYMBOLS TO REMEMBER ................................................................................... - 5 -

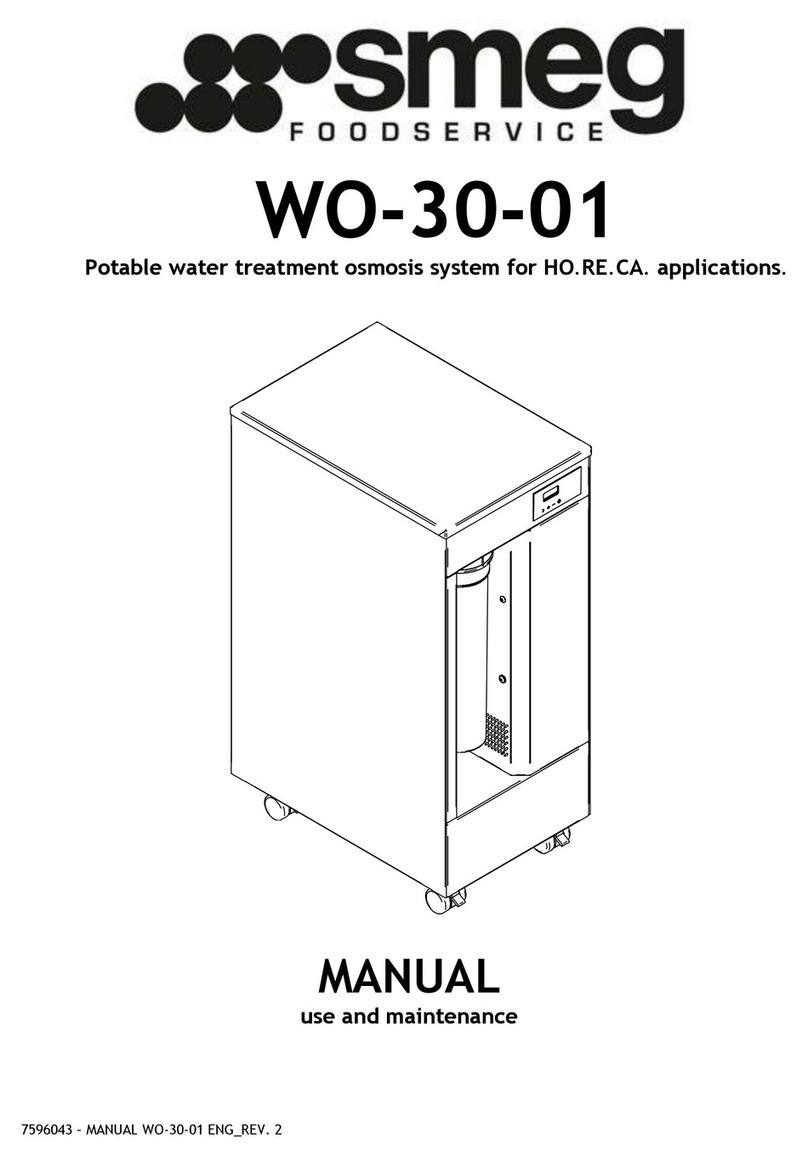

2CHARACTERISTICS OF THE DEVICE......................................................................................................................- 6 -

2.1RECOMMENDED USE ....................................................................................................... - 6 -

2.2 FORBIDDEN USE............................................................................................................ - 6 -

2.3 DESCRIPTION............................................................................................................... - 7 -

2.4 EXTERNAL DIMENSIONS ................................................................................................... - 7 -

2.5 TECHNICAL SPECIFICATIONS ............................................................................................. - 8 -

3INSTALLATION ..........................................................................................................................................................- 9 -

3.1 EN1717 DRAIN ADAPTER INSTALLATION ................................................................................ - 9 -

3.2 EXCHANGE OF DRAIN CAPILLARY....................................................................................... - 10 -

4FUNCTIONING..........................................................................................................................................................- 11 -

4.1 FIRST START-UP .......................................................................................................... - 11 -

4.2 NORMAL USE .............................................................................................................. - 11 -

4.3 MIX - BY-PASS............................................................................................................. - 11 -

4.5 LOW PRESSURE ALARM .................................................................................................. - 11 -

4.6 LEACKAGE ALARM ........................................................................................................ - 11 -

4.7 INACTIVITY ................................................................................................................ - 11 -

4.8 ELECTRONIC BOARD FUNCTIONING .................................................................................... - 12 -

4.9 CONFIGURATION MENU .................................................................................................. - 13 -

5ORDINARY MAINTENANCE TO BE DONE BY USER............................................................................................- 14 -

5.1 TASKS OF MAINTENANCE PERSONNEL.................................................................................. - 14 -

6EXTRAORDINARY MAINTENANCE TO BE DONE QUALIFIED PERSONNEL .....................................................- 15 -

6.1 TASKS OF MAINTENANCE PERSONNEL.................................................................................. - 15 -

6.2 PRE-FILTER REPLACEMENT .............................................................................................. - 16 -

6.3 PRECHARGE OF EXPANSION TANK...................................................................................... - 17 -

6.4 MACHINE SANITATION ................................................................................................... - 18 -

7TROUBLESHOOTING ..................................................................................................................................................19

8DISPOSAL ....................................................................................................................................................................21

ANNEX I –EU LABEL............................................................................................................................................................21

ANNEX II - CONNECTIONS OF THE ELECTRONIC BOARD...............................................................................................22

ANNEX III –MAINTENANCE LOG.........................................................................................................................................23