SAFEPRACTICES

1. It is your responsibility to read this manual and all publications associated with this machine (engine,

accessories and attachments).

2. Never allow anyone to operate or service the machine or its attachments without proper training and

instructions. Never allow minors to operate any equipment.

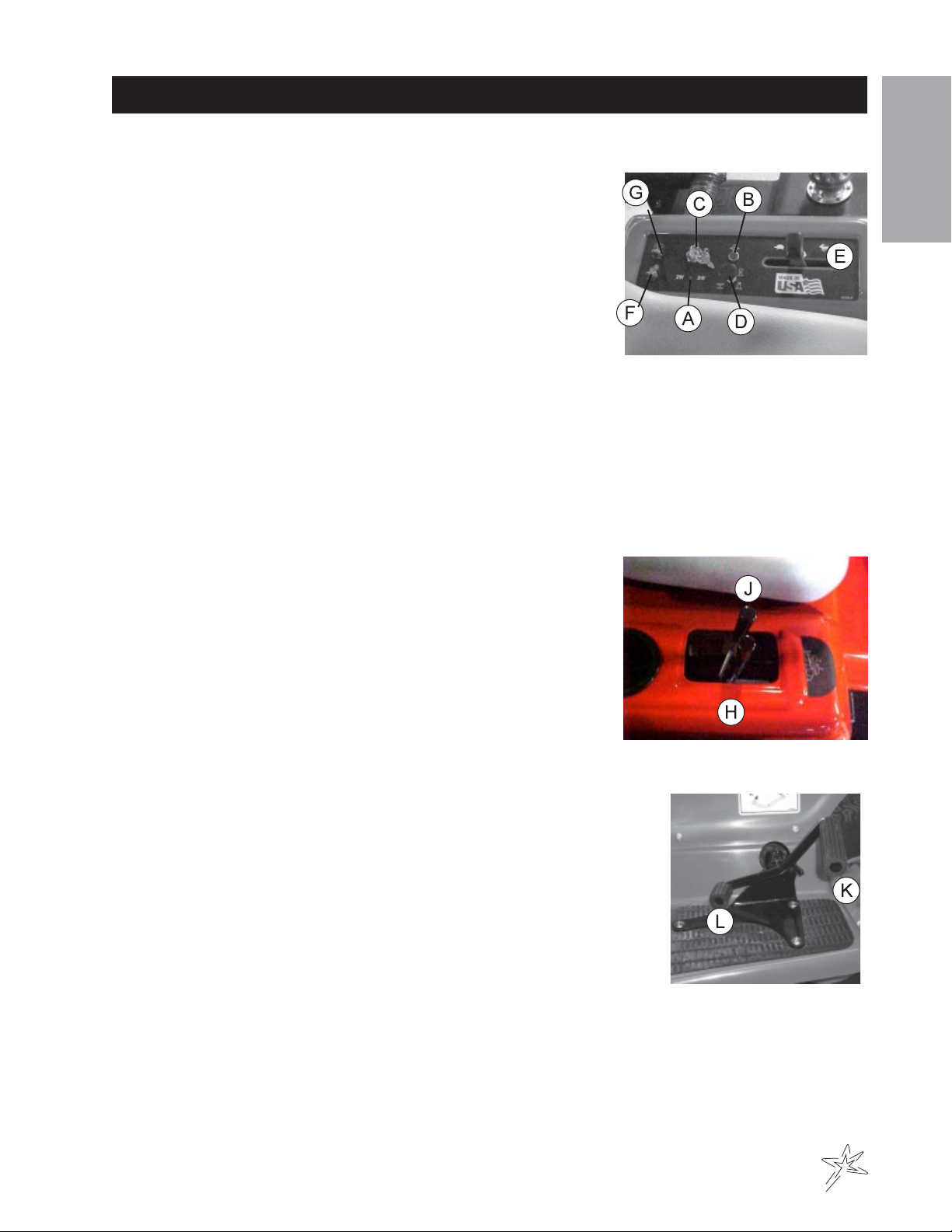

3. Learn the proper use of the machine, the location and purpose of all the controls and gauges before you

operate the equipment. Working with unfamiliar equipment can lead to accidents.

4. Wear all Personal Protective Equipment (PPE) on your head, eyes, ears, hands and feet. Operate the

machine only in daylight or in good artificial light.

5. Inspect the area where the equipment will be used. Pick up all debris you can find before operating.

Beware of overhead obstructions and underground obstacles. Stay alert for hidden hazards.

6. Never operate equipment that is not in perfect working order or without decals, guards, shields, or other

protective devices in place.

7. Never disconnect or bypass any switch.

8. Carbon monoxide in the exhaust fumes can be fatal when inhaled, never operate a machine without

properventilation.

9. Fuel is highly flammable, handle with care.

10. Keep engine clean.Allow the engine to cool before storing and always remove the ignition key.

11. After engine has started machine must not move. If movement is evident, the neutral mechanism is not

adjusted correctly. Shut engine off and readjust so the machine does not move when in neutral position.

13. Never use your hands to search for oil leaks. Hydraulic fluid under pressure can penetrate the skin and

cause serious injury.

14. This machine demands your attention. To prevent loss of control or tipping of the vehicle:

A. Use extra caution in backing up the vehicle. Ensure area is clear.

B. Do not stop or start suddenly on any slope.

C. Reduce speed on slopes and in sharp turns. Use caution when changing directions on slopes.

D. Stay alert for holes in the terrain and other hidden hazards.

15. Before leaving operator’s position for any reason:

A. Disengage all drives.

B. Lower all attachments to the ground.

C. Set park brake.

D. Shut engine off and remove the ignition key.

16. Keep hands, feet and clothing away from moving parts. Wait for all movement to stop before you clean,

adjust or service the machine.

17. Keep the area of operation clear of all bystanders.

18. Never carry passengers.

19. Stop engine before making repairs/adjustments or checking/adding oil to the crankcase.

20. Use parts and materials supplied by SmithcoSmithco

SmithcoSmithco

Smithco only. Do not modify any function or part.

hese machines are intended for professional maintenance on golf courses, sports turf, and any other

area maintained turf and related trails, paths and lots. No guaranty as to the suitability for any task is

expressed or implied.