SMW Autoblok ZHVD-SZ User manual

Type ZHVD-SZ

DOUBLE PISTON CYLINDER

HYDRAULIC

DEUTSCH

INSTRUCTION MANUAL

Date:

Version:

Language:

COPY OF THE

ORIGINAL

2015-04

4

English

SMW-AUTOBLOK 3

4

5

6

8

9

10

11

12

14

16

21

Übersicht

INSTRUCTION MANUAL

Hydraulic

Double Piston Cylinder

Type ZHVD-SZ

Declaration of incorporation

General safety instructions

Technical data

Description of function

Installation

Operation

Maintenance

Spare parts

Warranty 12 and 24 months

Documentation of maintenance

Confirmation of receipt of the manual

&

Content

Please read the instruction manual carefully

before installation and use and always follow the

regulations.

Please note especially the sections which are

marked with the following signs:

•Danger of injury or danger to life if instructions

are not followed.

•Danger of damage to the work holding, the

machine or the components.

Overview

Thank you for purchasing an Original-SMW-AUTOBLOK

cylinder type ZHVD-SZ

.

This instruction manual contains the installation, the use and the

maintenance instructions of the work holding „

ZHVD-SZ

“.

SMW-AUTOBLOK reserves the right to make changes without

notice.

This instruction manual is a part of the work holding and

must be passed to the new owner in case of sale.

This instruction manual may not be -in whole or in part- copied

without our written agreement.

4 SMW-AUTOBLOK

Einbauerklärung

ZHVD-SZ

29.12.2009

Eckhard Maurer

• DIN ISO 12100 (2011)

• DIN ISO 13857 (2008)

Responsible for documentation:

SMW-AUTOBLOK Spannsysteme GmbH

Wiesentalstrasse 28

88074 Meckenbeuren

Deutschland / Germany

Schilling Rainer

Chief designer

Product description:

Application range:

Declaration of incorporation

for an incomplete machine

Machinery Directive 2006/42/EC, Annex II, B

Date:

is intended to be installed into a completed machine. It must not be put into service until the final machine into which

the partly completed machinery it is to be incorporated has been declared in conformity with the provisions of the EU

machine directive (2006/42/EC) Annex II, B.

Applied harmonized norms:

Installation in machine tool

The manufacturer:

herby declares, that the following product:

The following basic requirements of

Annex I, 2006/42/EC are complied with:

• No. 1, 1.1, 1.1.1, 1.1.2, 1.1.3

• No. 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.3.8

• No. 1.5, 1.6.1

• No. 1.7.1, 1.7.3, 1.7.4

The special technical documents have been created in accordance with Annex VII, Part B. These documents will be

made available electronically on a reasoned request by the national authorities.

Place: Meckenbeuren (Germany)

Declaration of incorporation

President

Type:

Hydraulic double piston cylinder

SMW-AUTOBLOK 5

Allgemeine Sicherheitshinweise

Englisch

In case of doubts or questions please ask

SMW-AUTOBLOK or one of our authorized offices.

8. Maintenance

SMW-Autoblok cylinders in general are maintenance free.

The maintenance is limited to cleaning, inspection and

changing the oil and the filters on the hydraulic power unit.

Use original SMW-Autoblok spare parts and accessories

only. Insufficient and incorrect maintenance make any

warranty from SMW-Autoblok void.

7. Residual risks

The system machine tool/ chuck/ cylinder is affected by

the characteristic of the work piece (shape, unbalance,

material and so on) as well as by the cutting details which

can cause a residual risk.

This residual risk must be taken into consideration by the

operator and has to be eliminated by suitable actions.

6. Max. speed

Never exceed the max allowed speed (see technical data).

5.

Safety requirements for the machine

• Operate only with safety guards installed. Without safety

guards no persons must stay in the endangered area.

• SMW-Autoblok double piston cylinders are double-

acting cylinders on which cylinder 1 is equipped with

a safety non-return valve. At sudden loss of pressure

during operation, the pressure in the cylinder will remain

until the spindle has stopped. Never use cylinder without

non-return valve. Cylinder 2 is not equipped with a

safety non-return valve.

• The operation / monitoring of the cylinder by machine

CNC must be according to the relevant safety regulations.

• All maintenance and operation must be carried out at

safe stand still of the machine spindle only.

• In case of a sudden drop of pressure during machining

the pressure in the cylinder is maintained, until the

machine spindle has come to a standstill. Never operate

the cylinder without safety valves.

2. Demands on operators

SMW-AUTOBLOK cylinders must be installed, operated

and maintained by qualified and trained personal only.

1. Correct use

SMW-AUTOBLOK cylinders are designed to actuate chucks

on lathes or grinding machines. Any other use is dangerous

and is prohibited by the manufacturer, no other use of this

product is intended nor should any other use be attempted.

SMW-AUTOBLOK refuses any responsibility caused by

misuse of the cylinder.

4. Transport

Please use suitable lifting gear for product heavier than 16

kg!

3. Visual inspection

Please check the product for visible damage prior to use!

!

!9. Environment protection

Danger for environment when handling incorrect!

Incorrect handling of environment hazardous materials,

especially the disposal, may result in environmental

damage.

• Always follow below instructions.

• In case environmentally hazardous material polluted the

environment always take suitable actions immediately. If

in doubt, inform the local authority about the pollution.

The following hazardous materials are used: Lubricants

such as oil and grease can contain poisonous agents. They

must not pollute the environment. The disposal must be

carried out by a suitable waste management company.

For a proper function of the work holding, use original

SMW-AUTOBLOK lubricant only.

!

!

!

!

!

!

!

!

General safety instructions

6 SMW-AUTOBLOK

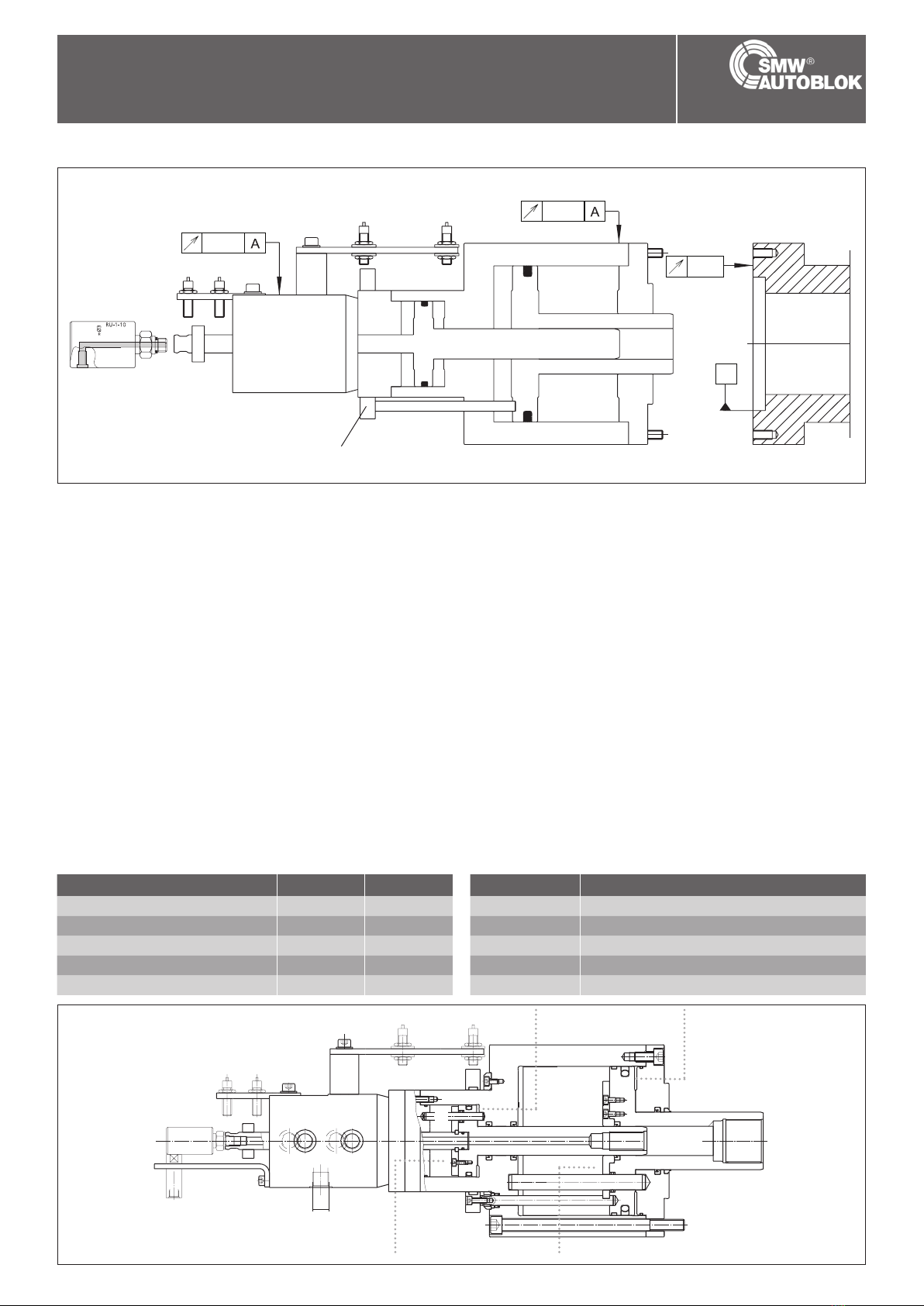

ZHVD-SZ 068-17 ZHVD-SZ 110-25 ZHVD-SZ 240-40

044429 044577 045220

70/15 90/15 105/20

68/54 110/88 241/144

60/48 92/73 222/133

16/12 25/20 40/24

14/11 21/16 36/21.6

5000 4000 4000

26 37 68

0.065 0.125 0.42

80 80 60

8-10 8-10 8-10

333

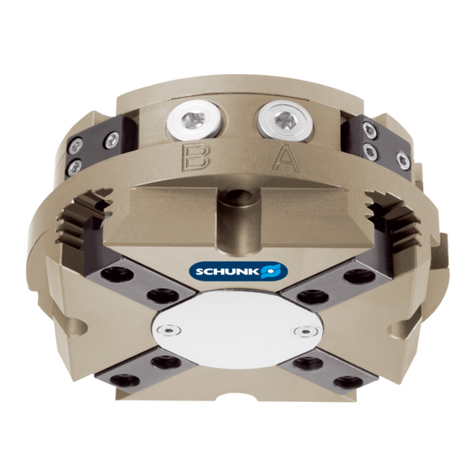

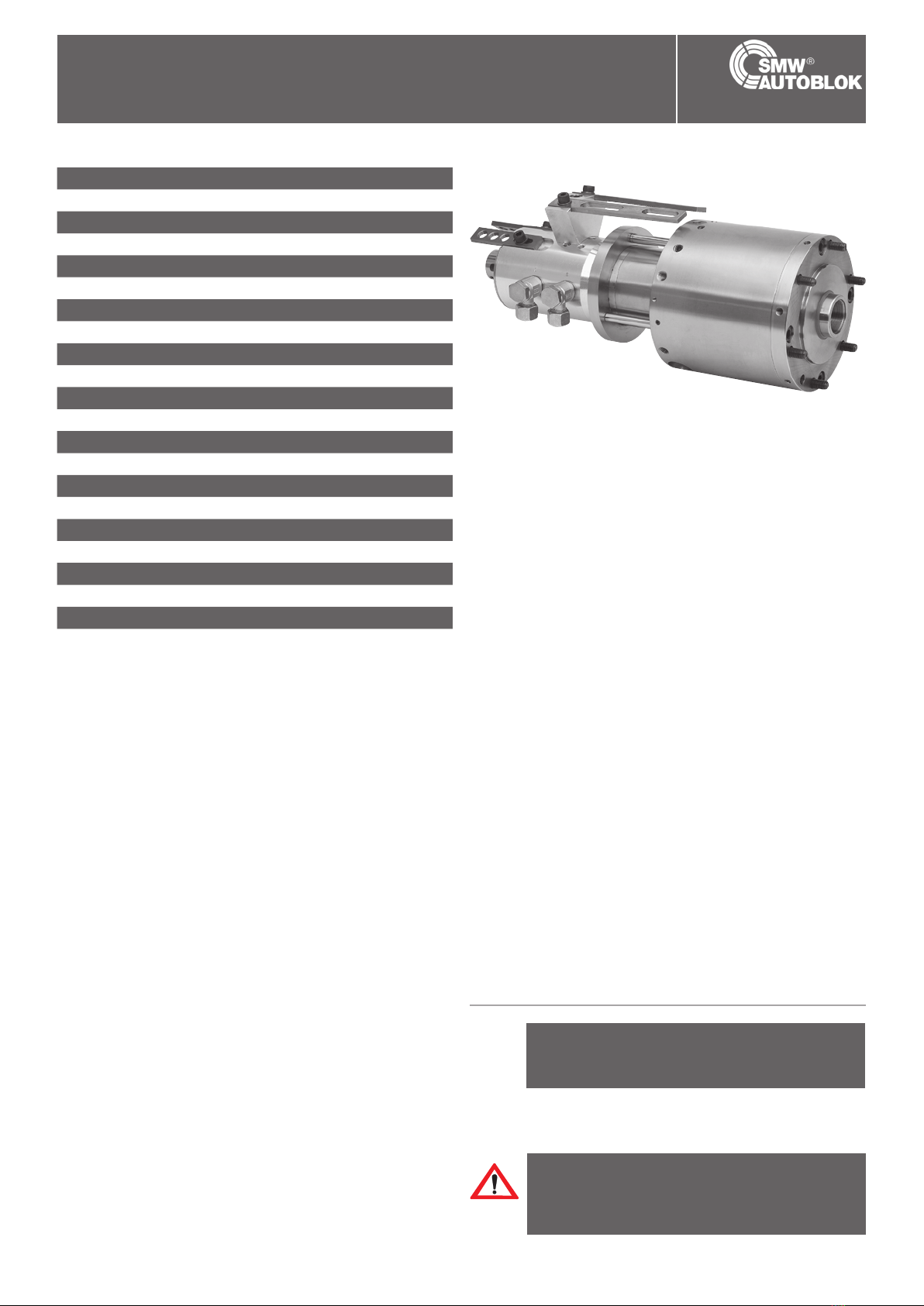

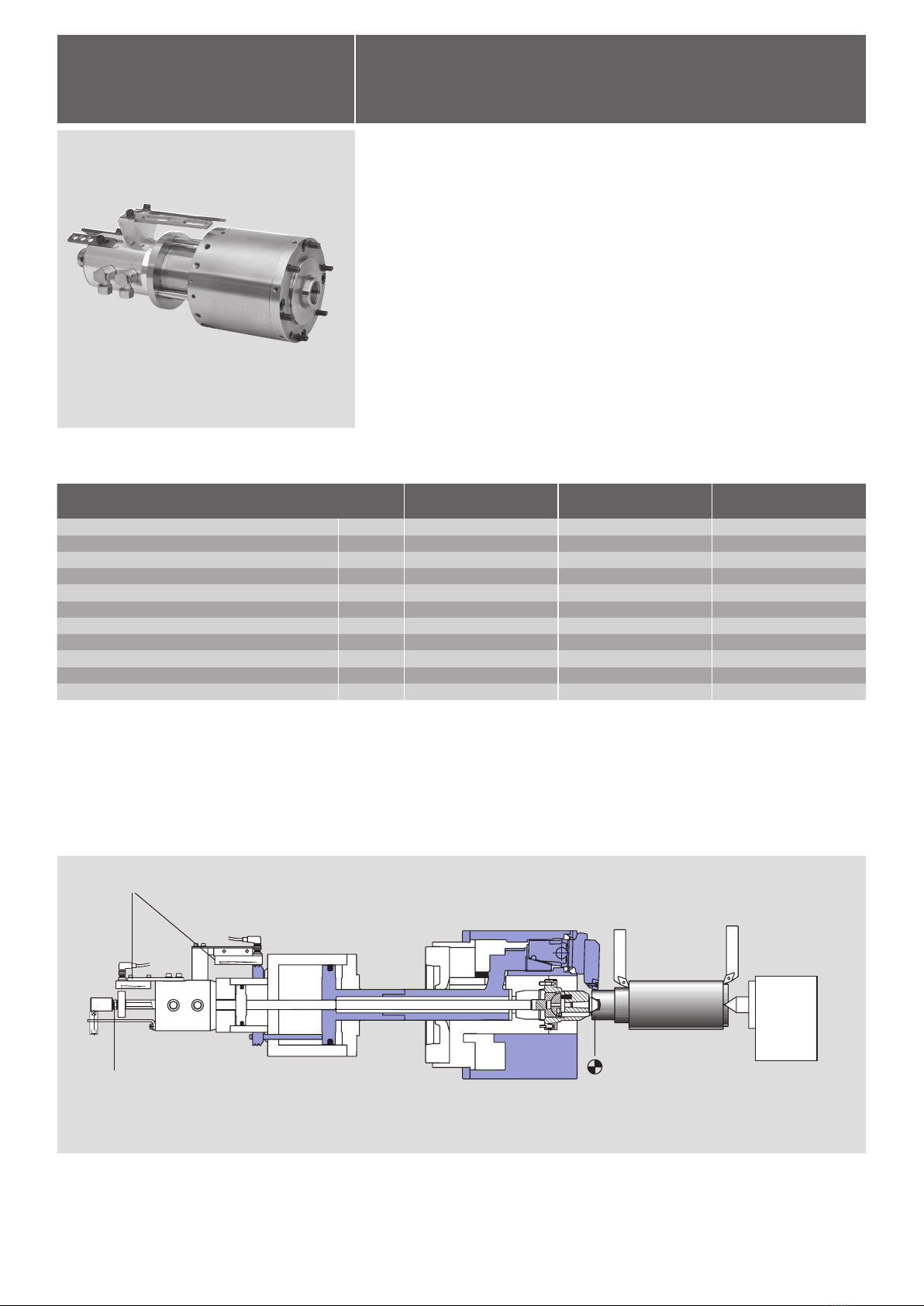

ZHVD-SZ

Rotating hydraulic cylinder

with 2 independent pistons

■ up to 80 bar

■ central bore for air/coolant/oil

■ stroke control via proximity switch or linear positioning system

Application/customer benefits

• Actuation of retractable jaw chuck with power operated face drivers

• Actuation of power chuck with part-ejector

• Actuation of power chucks with retractable axial stop/finger chucks with power

operated centering fixture

Technical features

• Double piston cylinder with 4 way oil manifold for separate actuation

of the cylinders

• Horizontal or vertical installation

• Stroke control on each cylinder, safety valves on the big cylinder

• Central bore for coolant, oil or air with thread for rotary union

• Mounting from the rear side with bolts

• A 10 μm filter in pressure line is requested. Use oil HM32 ISO 3448

• Pressure range 8-70 bar

Standard equipment Ordering example

Double piston cylinder Double piston cylinder ZHVD-SZ 068-17

Mounting screws or

Stroke control on each cylinder Double piston cylinder ZHVD-SZ 068-17

Proximity bracket (without proximity switch) with rotary union (optional)

Technical data

ZHVD-SZ cylinder with retractable jaw chuck

and power operated face driver

Piston 2

for actuation of the

driving pins in the face driver

Piston 1

for actuation of the chuck

and clamping jaws

SMW-AUTOBLOK Type

Id. No.

Piston stroke mm

Piston area A/piston force max. cm2/kN

Piston area B/piston force max. cm2/kN

Piston area C/piston force max. cm2/kN

Piston area D/piston force max. cm2/kN

Speed max. r.p.m.

Weight kg

Moment of inertia kg·m2

Operating pressure max. bar

Operating pressure min. bar

Oil leakage (*) dm3/min

Rotary union

(option)

Linear stroke control

LPS-XS/LPS-NT (option)

* Total at 30 bar / 50 °C

**At max. speed/ oil HM32 ISO 3448

Important: On higher pressure the leakage increases proportionally. On higher oil temperature the leakage increases over proportionally (the use of an oil cooler is

recommended). When designing/checking the hydraulic unit please ask for our data sheets

Englisch

SMW-AUTOBLOK 7

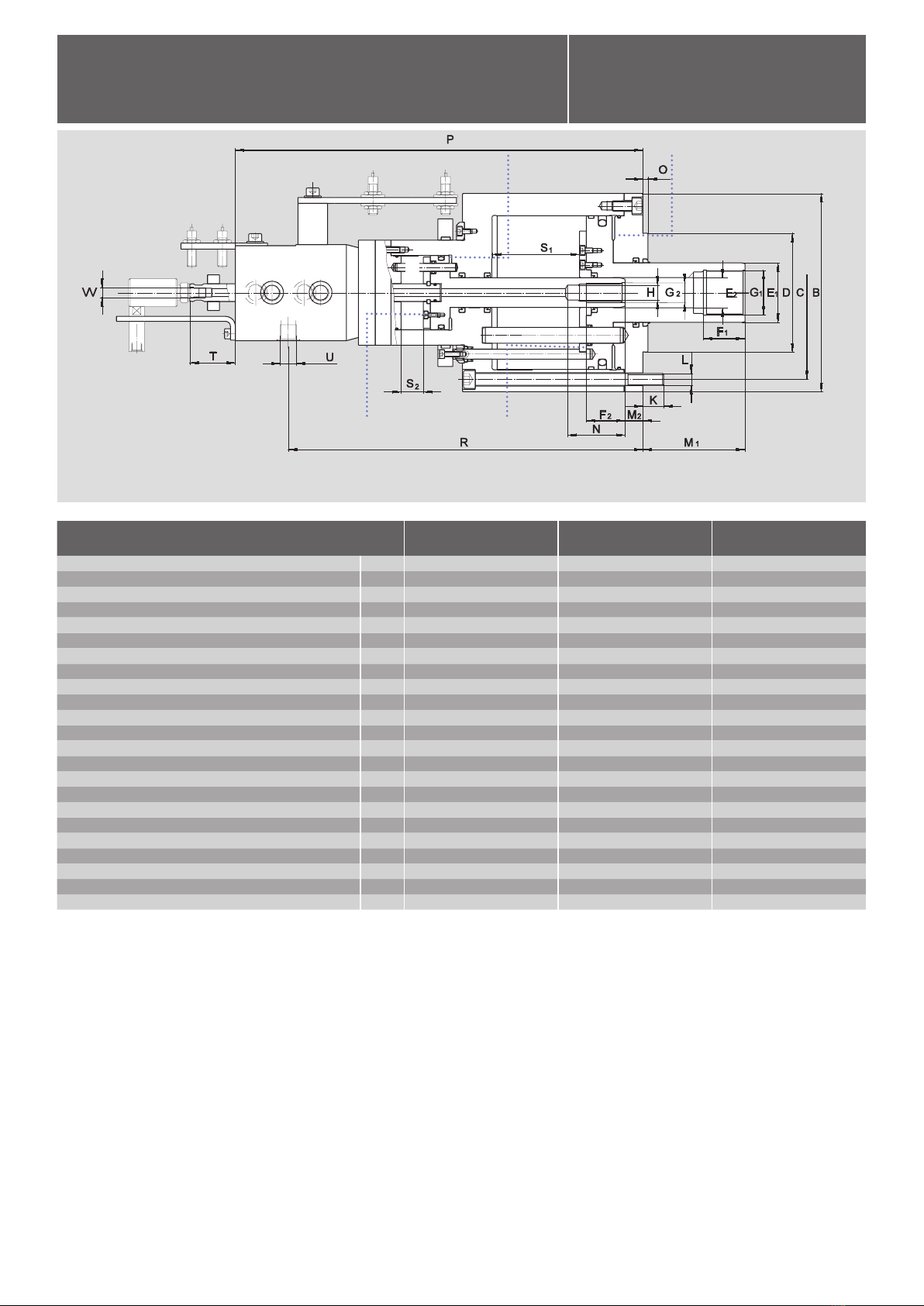

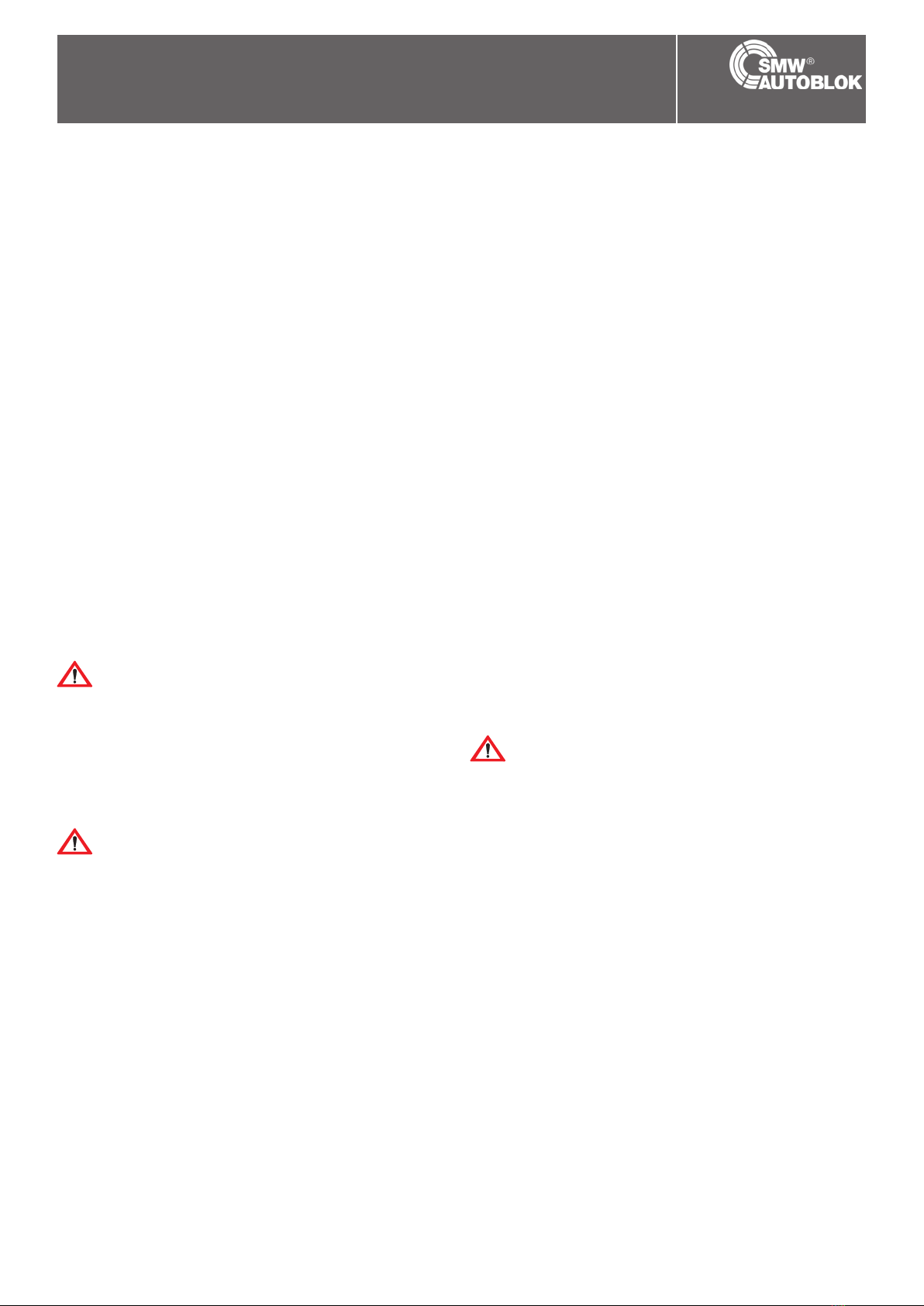

AB CD

1

2

ZHVD-SZ 068-17 ZHVD-SZ 110-25 ZHVD-SZ 240-40

044429 044577 045220

B165 198 230

C145 175 205

D h6 105 120 160

E145 60 60

E225 30 30

F133 42 42

F228 41 39

G1M36 x 1.5 M45 x 1.5 M50 x 1.5

G2M16 M20 M20

H13.5 15 15

K15 15 21

LM10 / 6x M12 / 6x M12 / 6x

M182/12 105/15 106/1

M233/18 33/18 67/47

N50 58 58

O555

P381 400 442

R329 348 389

S170 90 105

S215 15 20

T48/33 52/37 77/57

UG3/8” G3/8” G3/8”

WM10 x 1 M10 x 1 M10 x 1

ZHVD-SZ

Rotating hydraulic cylinder

with 2 independent pistons

■ up to 80 bar

■ central bore for air/coolant/oil

■ stroke control via proximity switch or linear positioning system

Option: LPS-NT Linear stroke control

Rotary union for oil/coolant/air

SMW-AUTOBLOK Type

Id. No.

mm

Fixing bolts circle mm

Centering rim mm

mm

mm

mm

mm

Piston rod thread 1 mm

Piston rod thread 2 mm

mm

mm

Fixing bolts/number mm

max./min. mm

max./min. mm

mm

mm

mm

mm

Stroke Piston 1 mm

Stroke Piston 2 mm

max./min. mm

mm

mm

Piston area C Piston area A

Piston area D Piston area B

Subject to technical changes.

For more detailed information please ask for customer drawing.

Englisch

8 SMW-AUTOBLOK

Description of function

• Double piston cylinders have 2 independent cylinder chambers

(for piston 1 and piston 2).

• Piston 1 is used for the chuck actuation piston 2 for the face

driver or movable centers.

Piston 1 has a built in safety valve for both functions open and

close.

• Piston 2 has no safety valves.

The hydraulic operation of cylinder 1 and cylinder 2 must be

carried out with 2 individual hydraulic circuits.

• Both pistons of the cylinder can be monitored by proximity

switches or a linear stroke control.

• A manifold for 1 media can be installed to the cylinder as an

option.

SMW-AUTOBLOK 9

0.005

0.015

A

0.03

AB CD

1

2

A

B

C

D

L

M8 16 23

M10 26 45

M12 38 77

M16 72 190

M20 100 370

Installation

Piston area B

Piston area D

Piston area A

Piston area C

Pic. 1

runout at

stationary

manifold

Rotary union for 1

medium RU-1-10

(optional)

Switch ring

Installation to the machine spindle

Do not expose the cylinder to any shocks during or after unpacking

or during installation!

Do not put the cylinder onto the switch ring or switch rods of the

stroke control and never use it to lift the cylinder. The switch ring

will get damaged!

Clean the cylinder.

Check the cylinder flange of the machine for face and radial run

out as well as for flatness. (Pic. 1).

Screw in the draw tube/bar and pressure bar into the cylinder using

Loctite lite. Never apply force.

Mount the cylinder and adjust it for run out according to pic. 1.

Tighten the mounting bolts with a torque wrench accoding to

below table.

The anti rotation bracket and the flexible hoses must not apply

any force onto the cylinders oil manifold. Use cylindrical fi tting of

correct lenght only.

Before connecting the hoses to the cylinder bleed and flush the

hoses to remove any contamination. Check all fittings for sealnes.

Connct the cylinder according to pic. 2.

All pressure lines must have filters with 10 micron (mm). Oil type

3° E (HLP-32) at 50 ° C oil temperature. Max oil temperature 55°C.

No additional parts must be attached to the oil manifold or the

coolant collector. Connect the manifold if mounted.

The drain hose has to have a constant decline towards the tank of

the power unit. It must not create any back pressure.

Pic. 2

Ports Description

chuck clamp

chuck open

face driver clamp

face driver open

leakage oil delivery

Boltsize F (kN) M (Nm)

10 SMW-AUTOBLOK

Installation / Operation

Installation of hydraulic double piston cylinder

Important:

Never allow the cylinder to rotate without oil pressure.

This will damage the bearings, cause seizure of the

distribution ring and the body.

Never rotate the cylinder at high speed with cold oil!

This could damage the bearings and the manifold ring.

We recommend making a few movements (opening/ closing)

at a low speed before starting.

The ZHVD-SZ cylinders consit of two parts:

one is fixed and one rotates at high speed.

As a consequence, there is the possibility of a seizure

between the two parts in case of non-compliance with the

correct installation and maintenance instructions.

When the cylinder is rotated for the first time, be careful that

all personnel stand well clear of the cylinder.

Start up:

• Actuate the cylinder approx 10 times at stopped spindle

and check if the oil is flowing.

• Stroke control via proximity switch or linear positioning

system LPS-LPS-X or LPS-XS).

• Rotate the spindle at 500 rpm. while applying the max.

allowed hydraulic pressure, and actuate the cylinder

several times.

• No the cylinder is ready for operation.

The max speed nmax must only be used when the oil

temperature has reached min. 30 ° C!

Danger of injury!

Never touch the cylinder when operating the cylinder or the

machine. Danger of squeezing in the switch ring area and

also the complete cylinder is rotating!

Only operate the machine with the safety covers of the

machine closed. No persons must stay in the hazardous

area!

Observe all safety instruction for the stroke and pressure

control.

Always observe all data on the cylinders label.

Operation

The operating pressure for the pistons 1 and 2 has to be according

to the technical data of the corresponding chuck (W or GSA).

The pressures and the resulting actuating forces are indicated on

the drawings of the corresponding top tooling drawings.

Never exceed these values!

SMW-AUTOBLOK 11

Maintenance

Maintenance

Cylinders need only little maintenance.

The maintenance needed is regular cleaning of the cylinder and

inspection for leakage and physical damages. The hydraulic oil

of the power unit of the machine must be refilled and changed

regularly. All filters need to be changed regularly.

The first oil change must be carried out after 1200 to 1500

operating hours, after that 1 time per year. Always use the correct

oil according the cylinders label.

Indirect risks

Indirect risks are the risks that can derive from improper working or

driving of the ZHVD-SZ-cylinder, when clamping components with

power chucks.

The machine must be allowed to rotate only under the following

conditions:

a) After having checked with a pressure gauge that the feeding

circuit has reached the requested pressure.

b) After the proximity switches (2 pcs or more) have confirmed the

position of “component clamped”.

The electric and hydraulic circuits of the machine must

guarantee that the component cannot move during the

spindle rotation (safety agaist an accidental opening / closing

of the workholding system).

It is necessary to use double-solenoid valves with detented positions,

to ensure that the position is kept in the case of lack of current (to

prevent the opening of the jaws of the chuck).

Annual:

Inspection of the safety valves of the cylinder.

For testing a grip force meter is clamped in a set of test jaws (do not

come with the chuck as a standard).

After switching off the pressure the grip force must not drop by

more than 1/3 within 4 minutes.

Hydraulic power unit and recommended oils

The unit’s tank capacity must be at least 4 times the nominal

output of the pump measured in litres/min. (eg; with a 12 l/min

pump the power unit tank must have a capacity of at least 45-50

litres). Should this be impossible, we recommend using oil-cooling

systems. The best operating temperature for hydraulic rotating

cylinders is between 35° and 60° C (even 70° C will not cause any

problem).

The hydraulic system must have an aspiration filter with links of

50-60 μ and a 10 μ feeding filter (we suggest to use filter efficiency

control systems). The delivery filter must be replaced every 6-8

months.

ZHVD-SZ-cylinders have large oil feeding holes; in order to take

advantage of this and achieve good piston speed, the pump of the

hydraulic power unit must have adequate delivery capacity.

The feeding circuit must have the shortest pipes possible, without

constrictions and the electrovalves must have a large cross section

for the oil flow.

Recommended oils

The oil to be used with hydraulic rotating cylinders is specified in

the ISO 3448 type HM 32 regulation. For example:

• Shell-Tellus 32

• Agip OSO 32

• ESSO NUTO H32 (or TERESSO 32)

• Mobil DTE 24 (or DTE light)

We do not recommend using higher density oils because

they could create serious problems in the cylinder’s rotation

at high speeds and with cold oil.

Disfunctions

Double piston cylinders consist of 2 assembly groups:

• Oil manifold

• Cylinder part

At loss of pressure, leakage or failure of the oil manifold the

complete cylinder needs to be replaced, since at a repair on site the

required test-bench run and balancing is not possible and thus also

safety risks exist.

Do not disassemble the oil manifold, since a correct assembling

without special tools is not possible.

In case of disfunctions our service or one of our worldwide

subsidiaries will be available for at any time.

12 SMW-AUTOBLOK

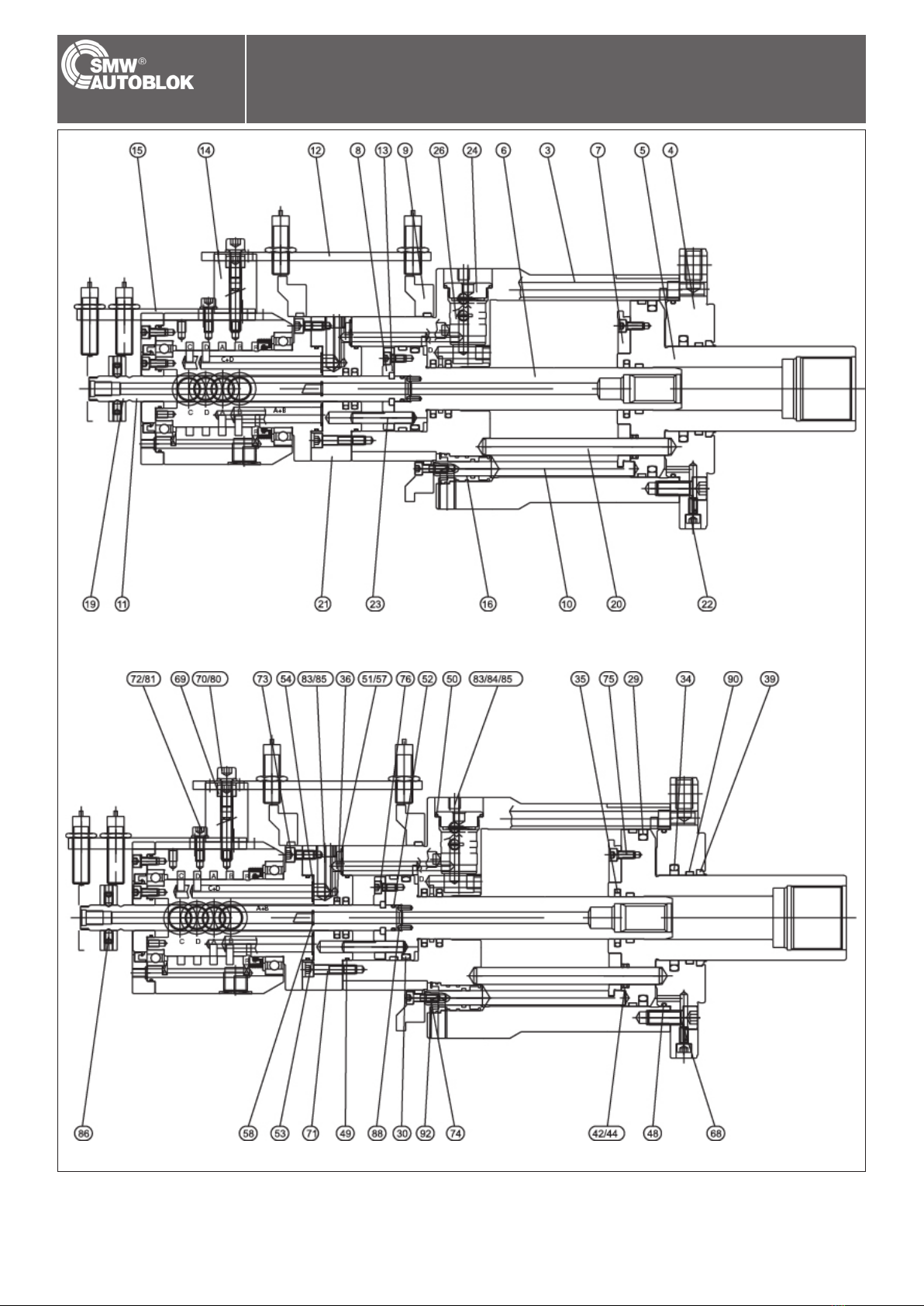

Spare parts

SMW-AUTOBLOK 13

3

4

5

6

7

8

9

10

11

12

13

14

15

16

19

20

21

22

23

24

26

29

30

34

35

36

39

42

44

48

49

50

51

52

53

54

57

58

68

69

70

71

72

73

74

75

76

80

81

83

84

85

86

88

90

92

Spare parts

No. Description

Cylinder body

Cylinder cover

Piston 1

Piston 2

Washer K1

Washer K2

Ring

Rod

Switchstick

Proximity switch bracket

Split ring

Proximity switch carrier

Short proximity switch carrier

Sleeve

Switch ring

Anti rotation pin

Intermediate flange

Hexagon head pipe plug

Cylinder pin

Cover

Valve cpl.

Piston seal

Piston seal

Rod seal

Rod seal

Rod seal

Scraper

Square ring

Support ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

O-ring

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Cylinder head screw ISO 4762

Washer

Washer

Set screw

Set screw

Set screw

Set screw

Pin

Piston ring

Seeger ring

14 SMW-AUTOBLOK

Garantie

12 months warranty

Product:

SMW-AUTOBLOK provides a warranty on the purchased product for 12 months from the date of purchase as stipulated in

our General Terms of Sale in the following cases:

• The defect was not known to the customer at the time of purchase.

• The defect is not due to wear as a result of use.

• The customer has not been negligent by improperly operating or incorrectly maintaining of our product. Refer to the

enclosed instruction manual for operation and maintenance information.

• It is not a wear part such as seals, rollers or valves.

• Especially work piece touching parts such as jaws, locators, inserts, rollers and face drivers are excluded from warranty.

• Only original SMW-Autoblok parts have been used such as spare parts, seals, rollers, valves, jaws, locators, inserts

and face drivers.

• There is evidence that the maintenance intervals in the operating instructions have been followed. The customer

must provide maintenance documentation for this purpose. The maintenance performed must be documented in the

maintenance section of the operating instructions and signed by a properly authorized person.

Please note that, if the above requirements are not met, the warranty is only invalid if the defect already existed at the time

of transfer of risk, which is usually upon delivery of the product, unless the customer was aware of the defect at the time

of transfer of risk.

Warranty

Englisch

Hydraulic double piston cylinder

SMW-AUTOBLOK 15

Garantie

24-months warranty

-optional-

Product:

Against additional fee, SMW-AUTOBLOK offers a warranty on the purchased product for 24 months from date of purchase

as a modification to the 12-month limitation period stipulated in our General Terms of Sale if the following conditions are

met:

• An extension of the warranty from 12 to 24 months has been agreed upon in writing with SMW-AUTOBLOK.

• There is no defect due to wear as a result of use.

• The defect was not known to the customer at the time of purchase.

• The customer has not been negligent by improperly operating or incorrectly maintaining of our product. Refer to the

enclosed instruction manual for operation and maintenance information.

• It is not a wear part such as seals, rollers or valves.

• Especially work piece touching parts such as jaws, locators, inserts, rollers and face drivers are excluded from warranty.

• Only original SMW-Autoblok parts have been used such as spare parts, seals, rollers, valves, jaws, locators, inserts

and face drivers.

• There is evidence that the maintenance intervals in the operating instructions have been followed. The customer

must provide maintenance documentation for this purpose. The maintenance performed must be documented in the

maintenance section of the operating instructions and signed by a properly authorized person.

• Paid inspection by or at SMW-AUTOBLOK is mandatory.

Minimum interval with maintenance documentation by SMW-AUTOBLOK.

Single shift operation once in 24 months

2- and 3-shift operation once in 12 months

The customer is responsible for having inspections performed on time.

• The delivery location and machine location are within Germany.

Warranty

Englisch

Hydraulic double piston cylinder

16 SMW-AUTOBLOK

Wartungsnachweis

Documentation of maintenance

Product:

Serialno.:

Regular and documented maintenance conserves the

value of your work holding, and ensures warranty!

!

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Englisch

SMW-AUTOBLOK 17

Wartungsnachweis

Documentation of maintenance

Product:

Serialno.:

!

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Regular and documented maintenance conserves the

value of your work holding, and ensures warranty!

Englisch

18 SMW-AUTOBLOK

Documentation of maintenance

Product:

Serialno.:

Regular and documented maintenance conserves the

value of your work holding, and ensures warranty!

!

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Englisch

SMW-AUTOBLOK 19

Documentation of maintenance

Product:

Serialno.:

!

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Maintained according

to instruction manual

YES

Operating hours

Name

Date

Signature

Remarks

Regular and documented maintenance conserves the

value of your work holding, and ensures warranty!

Englisch

This manual suits for next models

6

Table of contents

Other SMW Autoblok Industrial Equipment manuals

SMW Autoblok

SMW Autoblok M30 IOL User manual

SMW Autoblok

SMW Autoblok KNCS-NB User manual

SMW Autoblok

SMW Autoblok W-215 User manual

SMW Autoblok

SMW Autoblok VNK 70-37 Operation instructions

SMW Autoblok

SMW Autoblok F180 User manual

SMW Autoblok

SMW Autoblok SLX e-motion User manual

SMW Autoblok

SMW Autoblok Mario Pinto LT Operation instructions

SMW Autoblok

SMW Autoblok APS User manual