SMW Autoblok KNCS-NB User manual

KNCS-NBX - E - 2011-11 - 1

POWER CHUCK

Type KNCS-NB

Type KNCS-NBX

INSTRUCTION MANUAL

QUICK JAW CHANGE

SMW-AUTOBLOK 3

!

!

Danger of injury or danger to life if instructions

are not followed.

Please note especially the sections which are

marked with the following signs:

Please read this service manual carefully befo-

re installation and use and always follow the

regulations.

Instruction manual

Quick Change Jaw

Power Chuck

Type KNCS-NB

Type KNCS-NBX

Thank you for purchasing an original SMW-AUTOBLOK

quick jaw change chuck.

This service manual contains the installation, the use and the

maintenance instructions of the quick jaw change chucks, type

KNCS-NB / KNCS-NBX.

SMW-AUTOBLOK reserves the right to make changes without

notice.

This service manual may not be - in whole or in part - copied

without our written agreement.

The service manual is a part of the power chuck KNCS-NB/

KNCS-NBX and must be passed to the new owner in case of

sale.

Contents

Declaration of incorporation 4

General safety instructions 5

Description of function 6

Technical data KNCS-NB 8

Technical data KNCS-NBX 12

Installation 14

Operation 16

Maintenance 19

Disassembling / Repair 20

Spare parts 22

Trouble shooting 24

Calculation formulas for practical use 26

Warranty 12 and 24 months 28

Documentation of Maintanance 30

Confirmation of receipt of the manual 35

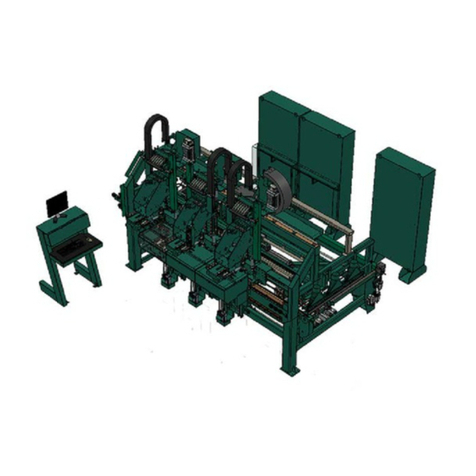

Overview

Danger of damage to the machine, the power

chuck or the components.

4SMW-AUTOBLOK

Signature of responsible person

Declaration of incorporation

for a partly completed machinery

to machine directive 2006/42/EC

The manufacturer: SMW-Autoblok Spannsysteme GmbH

Wiesentalstraße 28

D-88074 Meckenbeuren

Tel.: +49 (0) 7542 - 405 0

herby declares, that the following product:

Product description: Power chuck

Application range: Installation in machine tool

Type: KNCS-NB / KNCS-NBX

is intended to be installed into a completed machinery. It must not be put into service until the

final machinery into which the partly completed machinery it is to be incorporated has been

declared in conformity with the provisions of the EU machine directive (2006/42/EC) Annex II,B.

Applied harmonized norms: DIN EN 1550

Date: 29.12.2009

Declaration of incorporation

SMW-AUTOBLOK 5

!6. Remaining risks

The type of components (shape, weight, unbalance, ma-

terial etc.) has a big influence on the system “machine

tool - power chuck - component”. For that reason there

is always a residual risk.

These residual risks must be calculated by the user and

have to be eliminated by suitable actions.

7. Jaws

Always use original SMW-AUTOBLOK base jaws and

monoblock jaws. Jaws of other manufacturers can cause

damage to the chuck or accidents.

Top jaws must be mounted with head socket screws of

the class 12.9 only. Tighten with the specified torque.

Always ensure sufficient length of thread engagement

(min. 1,25 x thread dia.)!

If the jaw height of special jaws exceeds the height of

the standard jaws, the max. actuating force of the chuck

must be reduced in order to avoid an excessive lever ac-

tion and thus damage to the power chuck.

At reduced actuating force, the max. speed must also be

reduced accordingly!

8. Maintenance

The power chuck must be maintained at regular intervals.

Check the conditions by measuring the gripping force

with static gripmeter.

Replace damaged parts with

original SMW-AUTOBLOK spare parts only.

Maintenance must only be carried out at safe spindle stop

of the machine.

9. Actuating cylinder

The actuation of the power chuck must only be carried

out by suitable cylinders in accordance with safety pre-

cautions.

When installing the power chuck on the machine with an

existing cylinder be sure that the actuating force of the

cylinder does not exceed the max. permitted actuating

force of the chuck.

If necessary reduce the actuating force of the cylinder.

Connecting and adapter parts must be specified for per-

manent load. Adjust and check the proximity switches for

the stroke control before starting the production.

For any problems or questions please contact

SMW-AUTOBLOK directly or one of our authorized

offices.

General safety instructions

1. Correct use

SMW-AUTOBLOK power chucks work safely and trou-

blefree if they are used according to their specification i.e.

to clamp components on turning machines.

Any other use can cause hazards.

2. Personnel

Power chucks must be installed, operated and maintained

only by qualified and regularly trained personnel.

3. Safety precautions to the lathe

Machine spindle may only start if the clamping pres-

sure in the cylinder is fully reached and the compo-

nent is clamped within the permissible working ran-

ge.

Chuck can only be opened when machine spindle is

stopped.

A signal must stop the machine spindle in case of

failure in the clamping pressure and workpiece must

remain clamped safely until machine spindle stops.

Repowering after power failure must not change the

original clamping mode.

During machining the power chuck and the clamped

component must be protected by safety guards.

Open machine door only when machine spindle is

completely stopped.

Maintenance and actuation of the power chuck must

only be carried out when machine spindle is stopped.

4. Technical details

The max. data, max. actuating force F, max. spindle speed

n are engraved on the chuck body. They must not be

exceeded. Also the summary of the total static gripping

force ȈFsp at max. actuating force is engraved on the

chuck body.

5. Max. speed

The max. spindle speed is only valid at max. actuating

force using the standard hard stepped top jaws type GST,

which are not exceeding the outer diameter of the chuck.

If, for special applications, special top jaws are used clam-

ping force and the max. speed must be calculated accor-

ding to VDI 3106 but not exceeding the max. permitted

speed. Heavy special top jaws have an especially big influ-

ence on the max. speed. During the machining operation

the centrifugal force increases or decreases the gripping

force.

OD clamping = decreasing

ID clamping = increasing

The calculated values should be measured with a dynamic

gripmeter type GFT-X.

General safety instructions

!

!

!

!

!

!

!

!

!

6SMW-AUTOBLOK

KNCS-NB 210-52-3-Z170

Size of center mounting

Size of short taper

Z = Center mounting

A = Short taper mounting

Number of jaws

SMW-AUTOBLOK Type

Chuck o.d.

Through hole /

bore

The codes on the description of the type have the following meaning:

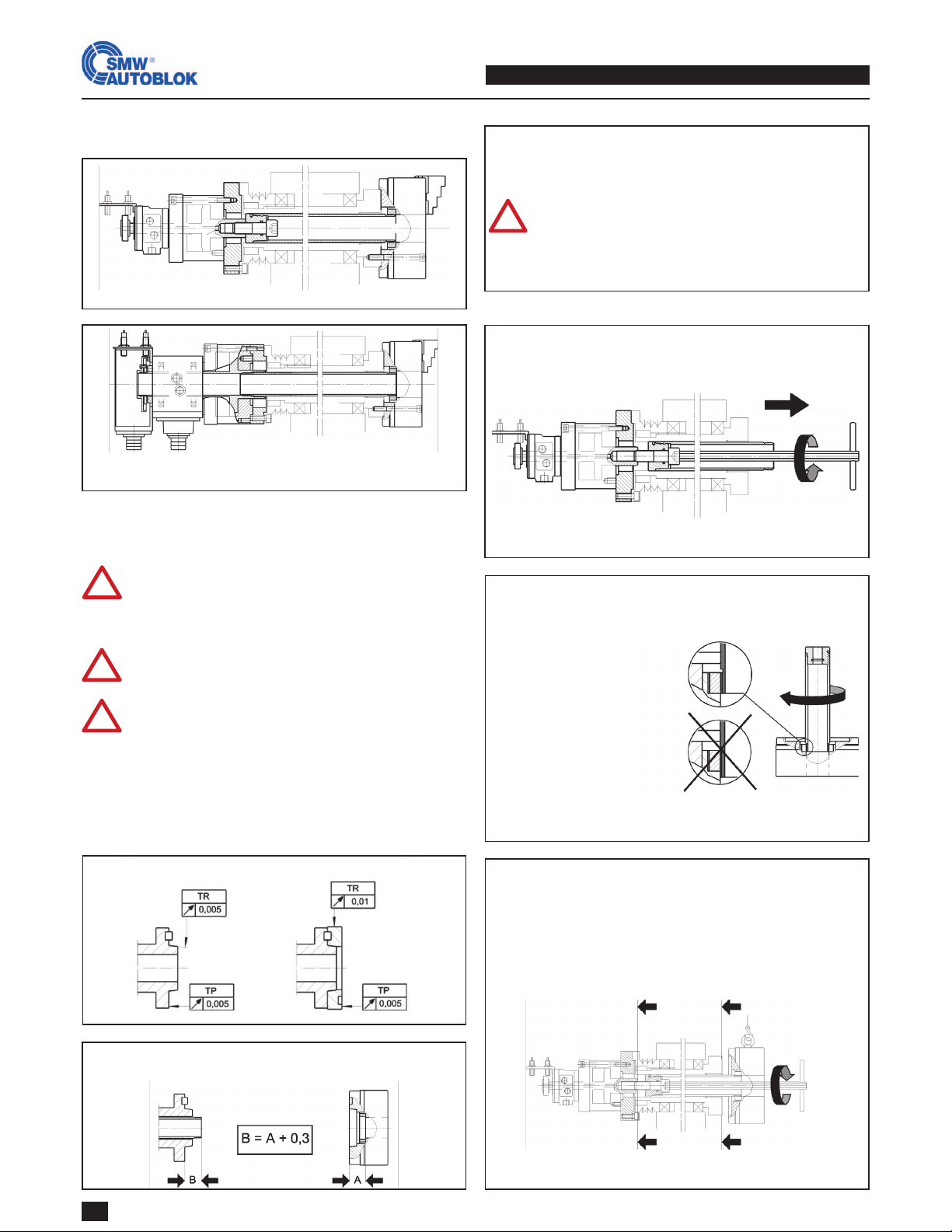

Description of function

Pos. II

jaw disengaged

Pos. I

jaw engaged

Transportation thread

Mounting

Safety pin

safety lock

mechanism

Jaw disengaging

key

Jaw guideway

No. 1

Thread for fixtures

etc.

Chuck type

Base jaw

(pointed serration or

tongue and groove)

Jaw guideway

No. 2

Serial No.

Dummy

Mounting key

Bright jaws

SMW-AUTOBLOK 7

up to nowWedge bar

Safety pin

Safety pin

Jaw is inserted correctly.

The jaw is positioned in the guideway

min. as far to the center that the sa-

fety pin is actuated. This insures that

the complete serration of the wedge

bar / jaw is engaged and the key can

be removed.

Jaw is inserted incorrectly.

No jaw is in the guideway

Safety pin locks the wedge bar

Key cannot be rotated back / re-

moved.

KNCS-NB / KNCS-NBX jaw safety interlock (patented)

Description of function

Power transmission by means of the unique and a thousand

times proven wedge bar design.

The axial draw / push force of the actuating cylinder is trans-

mitted to the radial jaw grip force by means of tangential

movement of the wedge bars.

Suitable for very high speed without centrifugal force

compensation due to superb design.

Case hardened chuck body. All function surfaces are hard

machined. This guarantees highest rigidity, precision, re-

peatability and service life.

Patented quick jaw change system. For changing the

jaws the wedge bars are moved tangentially via a key and

cambolts.

Single disengagement / engagement of jaws.

Patented safety interlock of the jaws ensures that all serra-

tion of the wedge bar/master jaw are fully engaged and the

gripping force is transmitted safely.

If jaws are not inserted correctly the jaws cannot be enga-

ged and the key cannot be removed (see below). KNCS-NB / KNCS-NBX wedge bar design

8SMW-AUTOBLOK

KNCS-NB 210-52 KNCS-NB 225-66 KNCS-NB 260-78 KNCS-NB 275-86 KNCS-NB 325-104

Z170 A6 A8 Z170 A6 A8 Z170 Z220 A6 A8 Z220 A6 A8 Z220 Z300 A8 A11

A215 225 260 275 324

B105 122 124 105 122 124 120 120 137 139 120 144 139 130 130 149 151

H6 D170 106.39 139.73 170 106.39 139.73 170 220 106.39 139.73 220 106.39 139.73 220 300 139.73 196.88

E168 180 210 210 268

F85 95 111 122 144

G1M60 x 1.5/16 M75 x 1.5/16 M90 x 2/20 M95 x 2/20 M115 x 2/22

G2M75 x 2/19 M85 x 2/19 M102 x 2/23 M110 x 2/23 M132 x 2/25

K22 22 25 25 25

max. L25 42 44 25 42 44 28 28 45 47 28 52 47 28 28 47 49

M52 66 78 86 104

N133.4 133.4 171.4 133.4 133.4 171.4 133.4 171.4 133.4 171.4 171.4 133.4 171.4 171.4 235 171.4 235

OM12 M12 M16 M12 M12 M16 M12 M16 M12 M16 M16 M12 M16 M16 M20 M16 M20

P72 82 95 105 130

Q261 271 318 322 376

R1M10/12 M10/12 M10/12 M10/18 M10/12

R2M6/10 M6/10 M8/14 M8/14 M10/12

S6 6 6 6 6

a28 28 35 35 50

-4.7 4.7 5.5 5.5 5.5

r28.3 33 33 38.5 49.5

6 7 6 7 9

Į° 60 60 60 60 60

ȕ°60 60 60 60 60

mm 6.0

22

6.0

22

7.0

25

7.0

25

7.0

25

kN 53 53 70 70 95

kN 100 100 135 135 180

5000 5000 4000 4000 3300

kg 24 26 26 26 29 29 40 40 43 43 48 53 50.7 65 65 68 68

kg·m

2

0.11 0.21 0.38 0.41 0.85

SIN-S 125/150 SIN-S 125/150 SIN-S 150/175 SIN-S 150/175 SIN-S 150/175/200

VNK 130-52 VNK 150-67 VNK 170-77 VNK 225-95 VNK 250-110

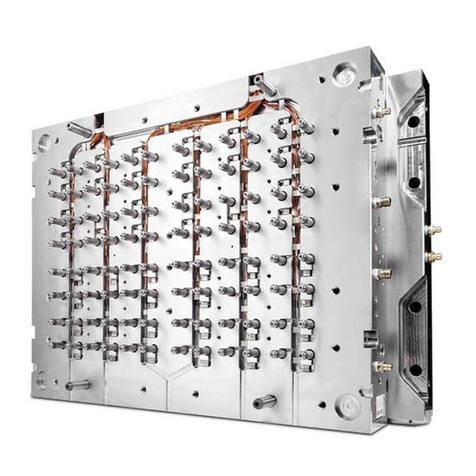

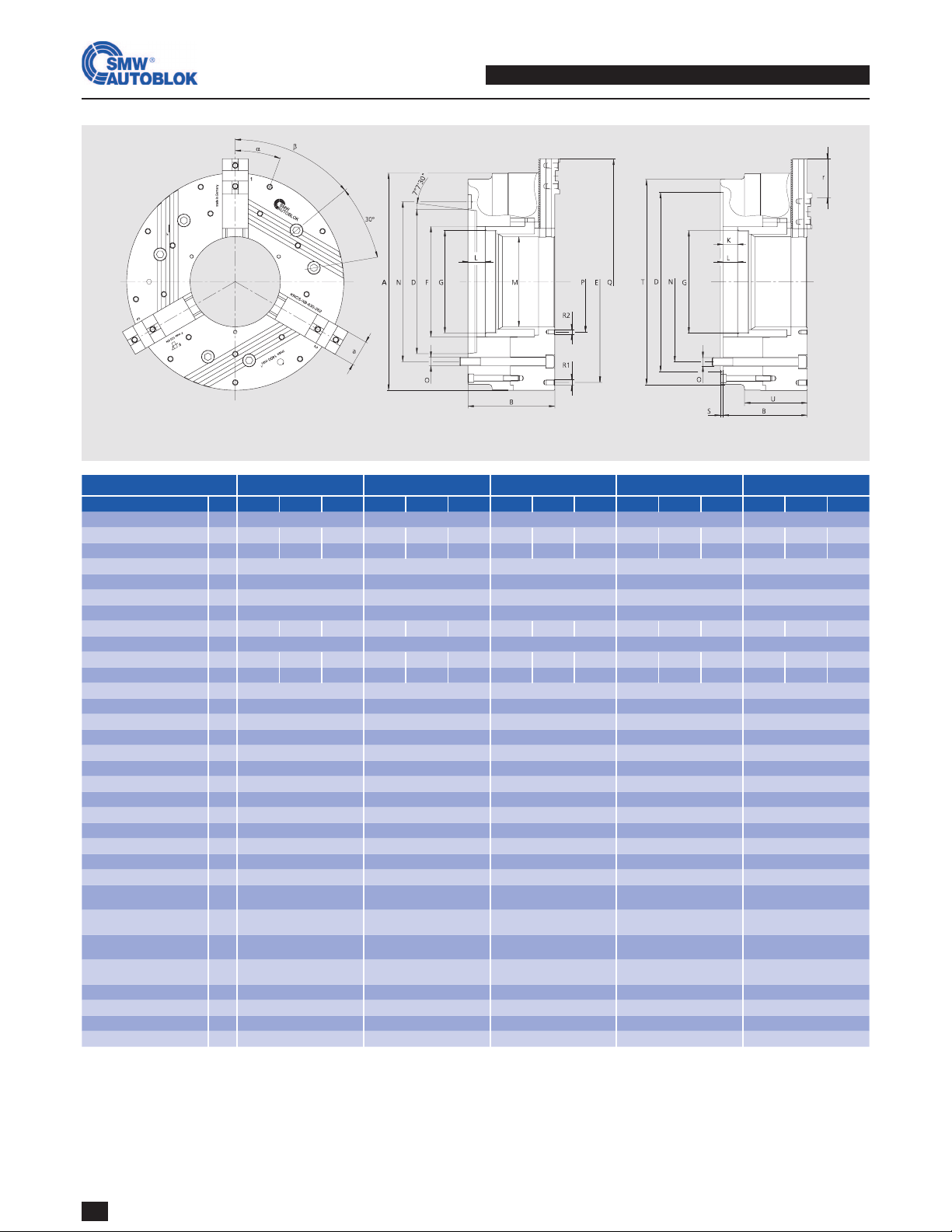

Technical data KNCS-NB

Subject to technical changes

Dimensions and position of base jaws are depending on top jaw type

SMW-AUTOBLOK Type

Mounting Size

Threaded ring / depth

Piston thread / depth

Piston stroke

Fixing bolt circle

Fixing bolt

Thread / thread depth

Thread / thread depth

Base jaw tooth pitch

Base jaw offset

Base jaw offset teeth

Stroke per jaw at

piston stroke Kmax.

max. actuating force

3-jaw chuck

max. total gripping force

3-jaw chuck

max. speed

3-jaw chuck rpm

Weight without jaws

Moment of inertia

rec. closed center cylinder Type

rec. open center cylinder Type

* Indirect mounting by reducing flange

SMW-AUTOBLOK 9

KNCS-NB 340-117 KNCS-NB 400-128 KNCS-NB 500-155 KNCS-NB 630-165 KNCS-NB 800-165

Z300 A8 A11 Z300 Z380 A11 A15 Z380 A11 A15 Z380 A11* A15 Z520 A15* A20

A340 400 500 630 800

B130 160 151 140 140 161 163 174 195 197 174 214 197 174 214 199

H6 D300 139.73 196.88 300 380 196.88 285.77 380 196.88 285.77 380 196.88 285.77 520 285.77 412.8

E270 330 420 420/585 420/585/750

F160 180 207 217 217

G1M125 x 2/22 M138 x 2/22 M165 x 2/25 M175 x 2/25 M175 x 2/25

G2M146 x 2/25 M160 x 2/25 M185 x 2/28 M195 x 2/28 M195 x /2/28

K25 32 42 42 42

max. L28 58 49 32 32 53 55 42 63 65 42 82 65 42 82 67

M117 128 155 165 165

N235 171.4 235 235 330.2 235 330.2 330.2 235 330.2 330.2 235* 330.2 463.6 330.2* 463.6

OM20 M16 M20 M20 M24 M20 M24 M24 M20 M24 M24 M20* M24 M24 M24* M24

P140 152 180 195 195

Q380 455 554 650 817

R1M10/16 M12/18 M16/25 M16/25 M16/25

R2M10/16 M12/18 M12/18 M12/18 M12/18

S6 8 8 8 8

a50 50 62 75 75

mm 5.5 5.5 7 7 7

r49.5 60.5 77 91 91

9 11 11 13 13

Į°60/35 60 60 20/9 x 40 20/9 x 40

ȕ°60 60 60 60 60

mm 7.0

25

8.0

32

10.0

42

10.0

42

10.0

42

kN 95 115 120 120 120

kN 180 240 250 250 250

3300 2750 1800 1500 1200

kg 77 88.5 82.5 111 111 116 116 225 231 231 390 411 398 620 660 635

kg·m

2

1.24 2.5 6.5 18 27

SIN-S 150/175/200 SIN-S 175/200 SIN-S 175/200 SIN-S 175/200 SIN-S 175/200

VNK 320-127 VNK 320-127 VSG 450-165 VSG 450-165 VSG 450-165

210-52

260-78

325-104

FG

F

800-165

630-165

500-155

400-128

FG

F

340-117

Technical data KNCS-NB

For highest speeds: flat gripping force curve

SMW-AUTOBLOK Type

Mounting Size

Threaded ring / depth

Piston thread / depth

Piston stroke

Fixing bolt circle

Fixing bolt

Thread / thread depth

Thread / thread depth

Base jaw tooth pitch

Base jaw offset

Base jaw offset teeth

Stroke per jaw at

piston stroke Kmax.

max. actuating force

3-jaw chuck

max. total gripping force

3-jaw chuck

max. speed

3-jaw chuck rpm

Weight without jaws

Moment of inertia

rec. closed center cylinder Type

rec. open center cylinder Type

The data in the diagrams refer to 3-jaw-chucks, newly maintained according to their

service manuals using SMW-AUTOBLOK K05 grease. The static and dynamic gripping

forces have been measured using standard soft top jaws, placed in a position not ex-

ceeding the outer diameter of the chuck.

FG Total grip force at 3 jaws [kN]

FG Total grip force at 3 jaws [kN]

Speed (rpm) Speed (rpm)

Safety advice / danger of damage:

When using taller / heavier jaws and / or clamping on a bigger dia-

meter reduce draw pull / rotating speed accordingly.

!

10 SMW-AUTOBLOK

L

B

N

G

S

Ha

a

b

L

B

N

G

S

Ha

a

b

KNCS-NB

210-52

KNCS-NB

225-65

KNCS-NB

260-72

KNCS-NB

275-86

KNCS-NB

315-91

KNCS-NB

340-117

KNCS-NB

400-128

KNCS-NB

500-155

KNCS-NB

630-165

KNCS-NB

800-165

- - Z170

064330 -Z220

064613 -Z300

064303

Z300

064306 - -

Z170

064334

Z170

069790

Z220

064331

Z220

069660

Z300

063852

Z300

069665

Z380

063950

Z380

064307

Z380

064548

Z520

064579

A 05 - - - - - - - - - -

A 06 064610 069791 064612 069661

A 08 064611 069792 064333 069662 064614 069666

A 11 - - - - 064302 069667 064304 064308 064577 -

A 15 - - - - - - 064305 064309 064549 064615

A 20 - - - - - - - - - 064616

KNCS-NB 210-52/225-65 260-72/275-86 315-91/340-117 400-128 500-155 630-165 800-165

138494 039624* 039626* 039629* 035565 035902 064604

B 28 35 50 50 62 75 75

H 32 40 45.8 45.8 57 57 57

L 85 104 115 125 160 200 287

N 20 20 20 26 30 30 30

S 10 12 12 12 18 18 18

M8 M12 M12 M12 M16 M16 M16

a 40 40 40 54 60 60 60

KNCS-NB 210-52/225-65 260-72/275-86 315-91/340-117 400-128 500-155 630-165 800-165

036292 035704 036167 036293 036294 036295 036296

B 28 35 50 50 62 75 75

H 32 40 45.8 45.8 61 61 61

L 85 104 115 125 160 200 287

N 1/16“x90° 1/16“x90° 1/16“x90° 3/32“x90° 3/32“x90° 3/32“x90° 3/32“x90°

17 21 21 25.5 25.5 25.5 25.5

G M12 M16 M16 M20 M20 M20 M20

a 2 x 23 30/28 30/28 2 x 38 3 x 38 4 x 38 6 x 38

b 11 14 14 17 17 17 17

KNCS-NB 210-52/225-65 260-72/275-86 315-91/340-117 400-128 500-155 630-165 800-165

- - 039628* 039631* 060561 060562 064590

B - - 50 50 62 75 75

H - - 45.8 45.8 57 57 57

L - - 120 146 168 203 287

N - - 19.02 19.02 19.02 19.02 19.02

S - - 12.7 12.7 12.7 12.7 12.7

- - 5/8-11 3/4-10 3/4-10 3/4-10 3/4-10

a - - 63.5 76.2 76.2 76.2 76.2

KNCS-NB 210-52/225-65 260-72/275-86 315-91/340-117 400-128 500-155 630-165 800-165

035566 035567 035568 035569 035570 035917 036708

B 28 35 50 50 62 75 75

H 32 40 45.8 45.8 61 61 61

L 85 104 115 125 160 200 287

N 1.5 x 60° 1.5 x 60° 1.5 x 60° 1.5 x 60° 3 x 60° 3 x 60° 3 x 60°

S 14 16 21 22 25 25 25

M12 M12 M16 M20 M20 M20 M20

a 2 x 25 2 x 30 2 x 30 2 x 45 1x50/1x60 2 x 60 4 x 60

b 11 11 14 17 17 17 17

KNCS-NB 260-72/275-86 315-91/340-117 400-128 500-155

UVB-B 250 UVB-B 315 UVB-B 400 UVB-B 500

238910 238911 238740 238912

B 35 50 50 62

H 110 115 125 160

h 81 81 91 113

L 109.5 170.5 148 175

5.9 11.9 17.6 32

Metric serration

3 x 60°

(Japanese standard)

Tongue and groove

American standard

Inch serration

3/32“ x 90°

Tongue and groove

KNCS-N

Chuck face

GBK-B

KNCS-N standard tongue & groove

Existing top jawBase jaw type

Supply range:

Chuck + disengaging key + mounting bolts + mounting key + set of coverplates without base jaws, without top jaws

Technical data KNCS-NB

Size

Spindle

mounting

Centering

rim small

Centering

rim large

GBK-BD

Inch serrated (for SMW-AUTOBLOK standard jaws)

Existing top jawBase jaw type

GBK-BA

American standard tongue & groove

Existing top jawBase jaw type

GBK-BM

Metric serration

Existing top jawBase jaw type

UVB-B

Soft wide monoblock jaws

Jaw type

Id. No.

Id. No.

G (metric)

S (ridge)

Id. No.

G (inch)

Id. No.

G (metric)

Jaw type

kg/set

Id. No.

SMW-AUTOBLOK 11

VNK

130/52

VNK

170/77

VNK

225/95

VNK

320/127

VSG

450/165

SIN-S

125

SIN-S

150

SIN-S

175

SIN-S

200

SIN-HL

100

SIN-HL

125

SIN-HL

150

SIN-HL

175

kN 58 76 100 123 138 71 108 150 196 49 77 108 154

6300 5000 4000 3200 2000 6000 6000 5000 4000 7000 6000 6000 5000

mm 52.5 77 95.5 127.5 165 - - - - - - - -

2 s

Actuating cylinder KNCS-NB / KNCS-NBX

Actuating cylinders with and without through hole

Examples for assembly

High-low clamping for thin-walled components

solid component

high gripping force

thin-walled component

low gripping force

roughing

finish

machining

chuck gripping force

without “high-low“ clamping with “high-low“ clamping

Principle

Function

Result

Open center with VNK Partial open center with SIN-S / SIN-HL

For easily deformed components SMW-AUTOBLOK offers

”high-low“ clamping. The gripping force of the chuck can be

reduced from a large amount of gripping force used in roug-

hing, to a smaller amount of gripping force for a finishing cut

without unclamping the component. The SMW-AUTOBLOK

closed center cylinder type SIN-HL and a modification of the

machine hydraulic are necessary.

In combination with a SMW-Autoblok ”high-low“ hydraulic

cylinder SIN-HL and suitable machine hydraulics, the KNCS-

NB / KNCS-NBX wedge bar system allows a monitored reduc-

tion of gripping force.

The component remains clamped in the chuck safely, howe-

ver, the stress of the component can be released. The ”high-

low“ cycle is programmable and is finished completely within

2 - 4 sec.

The result are round components with a minimum of defor-

mation.

For additional information please ask our engineers.

time

SIN-HL

Hydraulic closed center

cylinder for high-low clam-

ping with built-in safety

valves and piston stroke

control. Central through-

hole for air, oil or coolant

(pmax. = 70 bar)

SIN-S

Hydraulic closed center

cylinder with built-in safety

valves and piston stroke

control. Central through-

hole for air or coolant

(pmax. = 70 bar)

VNK

Hydraulic open center

cylinder with built-in safety

valves, piston stroke control

and coolant collector

(pmax. = 45 bar)

Type

Draw pull P

max

n

max.

r.p.m.

Through-hole

12 SMW-AUTOBLOK

KNCS-NBX 425-170 KNCS-NBX 530-210 KNCS-NBX 630-262 KNCS-NBX 800-262 KNCS-NBX 1000-262

Z380 A11 A15 Z380 A11 A15 Z520 A15 A20 Z520 A15 A20 Z520 A15 A20

A425 530 630 800 1000

B197 237 220 244 284 267 244 284* 269 244 284* 269 244 284* 269

H6 D380 196.88 285.77 380 196.88 285.77 520 285.77 412.77 520 285.77 412.77 520 285.77 412.77

E330.2 420 420/585 420/585/750 420/585/750/915

F222 262 320 320 320

GM202 x 2/25 M240 x 2/28 M297 x 2/33 M297 x 2/33 M297 x 2/33

K32 42 42 42 42

max. L32 72 55 42 82 55 42 82 67 42 82 67 42 82 67

M170 210 262 262 262

N330.2 235.0 330.2 330.2 235.0 30.2 463.6 330.2* 463.6 463.6 330.2* 463.6 463.6 330.2* 463.6

OM24 M20 M24 M24 M20 M24 M24 M24* M24 M24 M24* M24 M24 M24* M24

P194 235 292 292 292

Q487 598 745 915 1107

R1M12/16 M16/25 M16/25 M16/25 M16/25

R2M12/16 M16/25 M12/18 M12/18 M12/18

S8 8 8 8 8

T412 490 595 600 600

U137 167 182 182 182

a50 62 75 75 75

-5.5 7 7 7 7

r49.5 70 119 133 133

9 10 17 19 19

Į° 15°/12x30° 20°/9x40° 20°/9x40° 20°/9x40° 20°/9x40°

ȕ° 60 60 60 60 60

mm 8

32

10

42

10

42

10

42

10

42

kN 115 120 120 120 120

kN 240 250 250 250 250

2500 1500 1400 1000 850

kg 164 320 395 635 985

kg·m

2

4.3 13 23 54 125

SIN-S 175/200 SIN-S 175/200 SIN-S 175/200 SIN-S 175/200 SIN-S 175/200

VSG 450-165 VSG 550-205 VSG 550-205 VSG 550-205 VSG 550-205

Subject to technical changes

Dimensions and position of base jaws are depending on master jaw type

SMW-AUTOBLOK Type

Mounting

Size

Piston thread / depth

Piston stroke

Fixing bolt circle

Fixing bolt

Thread / thread depth

Thread / thread depth

Base jaw tooth pitch

Base jaw offset

Base jaw offset teeth

Stroke per jaw at

piston stroke K max.

max. actuating force

3-jaw chuck

max. total gripping force

3-jaw chuck

max. speed

3-jaw chuck rpm

Weight without jaws

Moment of inertia

rec. closed center cylinder Type

rec. open center cylinder Type

Technical data KNCS-NBX

* Indirect mounting by reducing flange

SMW-AUTOBLOK 13

L

B

N

G

S

Ha

a

b

L

B

N

G

S

Ha

a

b

KNCS-NBX

425-170

KNCS-NBX

530-210

KNCS-NBX

630-262

KNCS-NBX

800-262

KNCS-NBX

1000-262

Z380

160080

Z380

160090

Z520

069760

Z520

069770

Z520

069780

A 11 160081 160091 - - -

A 15 160082 160092 069768 069778 069788

A 20 - - 069769 069779 069789

KNCS-NBX 425-170 530-210 630-262 800-262 1000-262

035569 035570 035917 036708 -

B 50 62 75 75 -

H 45.8 61 61 61 -

L 125 160 200 287 -

N 1.5x60° 3x60° 3x60° 3x60° -

S 22 25 25 25 -

M20 M20 M20 M20 -

a 2 x 43 1 x 50/1 x 60 2 x 60 4 x 60 -

b 17 17 17 17 -

KNCS-NBX 425-170 530-210 630-262 800-262 1000-262

036631 060561 060562 064590 069807

B 50 62 75 75 75

H 45.8 57 57 57 57

L 146 168 203 286 384

N 19.02 19.02 19.02 19.02 19.02/3x

S 12.7 12.7 12.7 12.7 12.7

3/4-10 3/4-10 3/4-10 3/4-10 3/4-10/4x

a 76.2 76.2 76.2 76.2 76.2/3x

KNCS-NBX 425-170 530-210 630-262 800-262 1000-262

036293 036294 036295 036296 -

B 50 62 75 75 -

H 45.8 61 61 61 -

L 125 160 200 287 -

N 3/32“x90° 3/32“x90° 3/32“x90° 3/32“x90° -

25.5 25.5 25.5 25.5 -

G M20 M20 M20 M20 -

a 2 x 38 3 x 38 4 x 38 6 x 38 -

b 17 17 17 17 -

KNCS-NBX 425-170 530-210 630-262 800-262 1000-262

039629 035565 035902 064604 069806

B 50 62 75 75 75

H 45.8 57 57 57 57

L 125 160 200 286 384

N 26 30 30 30 30

S 12 18 18 18 18

M12 M16 M16 M16 M16

a 54 60 60 60 60

KNCS-NBX 425-170 530-210

UVB-B 400 UVB-B 500

238740 238912

B 50 62

H 125 160

h 91 113

L 148 175

17.6 32

Technical data KNCS-NBX

Metric serration

3 x 60°

(Japanese standard)

Tongue and groove

American standard

Inch serration

3/32“ x 90°

Tongue and groove

KNCS-N

GBK-B

KNCS-N standard tongue & groove

Existing top jawBase jaw type

Supply range:

Chuck + disengaging key + mounting bolts + mounting key + set of coverplates without base jaws, without top jaws

Size

Spindle

mounting

Centering

rim large

GBK-BD

Inch serrated (for SMW-AUTOBLOK standard jaws)

Existing top jawBase jaw type

GBK-BA

American standard tongue & groove

Existing top jawBase jaw type

GBK-BM

Metric serration

Existing top jawBase jaw type

Id. No.

Id. No.

G (metric)

S (ridge)

Id. No.

G (inch)

Id. No.

G (metric)

Chuck face

UVB-B

Soft wide monoblock jaws

Jaw type

Jaw type

kg/set

Id. No.

14 SMW-AUTOBLOK

!

!

!

!

3

4A

2

4A

2

1

3

1

4A

Insert draw tube with chuck into the machine spindle. Use

mounting belt or eye screw. KNCS-NB chucks carry a transpor-

tation thread from size 260 on.

Tighten draw bolt and push chuck onto the centering rim /

short taper.

Installation of chuck

Chuck without rotating ring nut

Partial open center

Wrong:

Draw tube not flush with

adaptor. Length of thread

engagement too deep

Correct:

Draw tube flush with

adaptor

Thread of draw tube / adaptor must be treated with copper pas-

te to avoid rust / seizing. Screw in draw tube into chuck

Check draw bar length with cylinder in frontend positi-

on. If necessary correct draw tube / adaptor!

Check spindle nose!

Open center

Partial open center

Installation of draw tube

Chuck without rotating ring nut

Partial open center

Also see page 17 Operating.

Move chuck piston into frontend position (chuck posi-

tion: OPEN). Release jaws by means of key and remove

one after another.

Check: All connecting and adaptor parts must be

calculated for continous operation!

Check: The max. draw pull of the actuating cylinder

must not exceed the max. actuating force of the

chuck! If necesary limit the pressure and secure the

limitation!

Before installing:

Installation

Examples for installation

Chuck with rotating ring nut:

Important: All rotating ring nut parts are highly-

loaded safety parts made of special steel!

When using special threaded rings use only origi-

nal SWM-AUTOBLOK blanks. Lock retaining ring

against loosening with screw in the proper way

(see page 21, pic. 5).

Always use SWM-AUTOBLOK special key (included

in delivery).

If there is no jaw in the guideway the key can

only be removed if the safety pin is actuated by

means of the dummy pin!

Cylinder in position “chuck OPEN”

Unscrew draw bolt and remove the draw tube from the spindle.

Removing draw tube

Chuck without rotating ring nut

Partial open center

Installation

SMW-AUTOBLOK 15

!

4B

!

4B

!

5

6

8

!

7

Danger of damage!

Never actuate the chuck when key is inserted!

Lubricate chuck at position ”chuck OPEN” . Always use SMW-

AUTOBLOK grease K05.

Lubrication see page 16.

Ordering no. 016440 K05 cartridge 500 g.

Ordering no. 011881 K05 can 1000 g.

Insert jaw 1, 2, 3 one after another into the guideways 1, 2, 3.

For jaw change please refer to page 17 / 18.

Check gripping force with gripmeter (GFT-X) at different actu-

ating pressures.

Lubrication

Insert mounting bolts ISO 4762 10.9 and thighten by hand. Ad-

just to lowest operating pressure and actuate cylinder: Position

“chuck CLOSED”.

Tigthen the mounting bolts with a torque wrench gradually one

after another. Do not exceed torque!

Mounting of chuck

Danger of damage to the chuck!

Do not tilt thread!

Do not apply force!

Never rotate spindle!

Rotate spindle by hand at adaptor or drive belt and screw in the

draw tube into the chuck to its end position. Push the chuck

onto the centering rim / short taper.

Cylinder in position “chuck OPEN”. Thread of draw tube/

adaptor must be treated with copper paste to avoid rust/seizing.

Position chuck concentric in front of the machine spindle by

means of suitable lifting equipment. Use mounting belt or eye

screw. KNCS-NB chucks carry a transportation thread from size

260 on.

Chuck without rotating ring nut

Open center

Observe correct length of thread engagement!

Draw tube face flush with adaptor

Installation of chuck

Installation of chuck

Chuck with rotating ring nut

Partial open center / Open center

Cylinder in position “chuck OPEN”. Thread of draw tube/

adaptor must be treated with copper paste to avoid rust/seizing.

Position chuck concentric in front of the machine spindle by

means of suitable lifting equipment. Use mounting belt or eye

screw. KNCS-NB chucks carry a transportation thread from size

260 on.

Insert the chuck key (standard equipment at option rotating nut)

through the chuck bore until the cams engage into the slots of

the rotating ring nut and screw the ring nut onto the draw tube

to its axial stop. Push the chuck onto the centering rim / short

taper.

Control

Check easy movement of the chuck. Chuck must open / close

easily at lowest clamping pressure.

Adjust the proximity switches on the actuating cylinder for stro-

ke control according to service manual of the cylinder.

Check jaw stroke.

Jaw stroke see technical details page 8 + 12.

Re-tighten the bolts with a torque wrench in position chuck

closed.

Danger of damage to the chuck!

Do not tilt thread!

Do not apply force!

Never rotate spindle!

Check radial and face runout

Bolt 10.9 ISO 4762 M10 M12 M16 M20 M24

Md (Nm) 48 70 170 300 500

Chuck type TR TP

KNCS-NB 210 0,02 0,03

KNCS-NB 260 - 400 0,03 0,03

KNCS-NB 500 - 630 0,05 0,05

Installation

16 SMW-AUTOBLOK

3

21

!

!

!

!

!

!

!

KNCS-NB/NBX 210 260 315 400 500 630 800 1000

GBK-B M8 M12 M12 M12 M16 M16 M16 M16

GBK-BD M12 M16 M16 M20 M20 M20 M20 -

GBK-BM M12 M12 M16 M20 M20 M20 M20 -

GBK-BA - - 5/8-11 3/4-10 3/4-10 3/4-10 3/4-10 3/4-10

Md (Nm) 35 65 65 65 170 170 170 -

Mounting surfaces of the top jaws must be straight

and on the same level. Otherwise the master jaw

gets distorted and locks in the guideway.

Boring ring

Boring ring

i.d. clamping

o.d. clamping

Highest repeatability can be achieved if you follow the following points:

Boring of soft jaws

Never grip boring ring with master jaw.Boring ring must be gripped as close to the grip-

ping area as possible.

For repeating jobs store top jaws with master

jaws as one unit.

Always machine top jaws under gripping force.

Use rigid boring ring.

Jaws of other manufacturers:

Safety risks due to wrong material or heat treatment

Danger of damage of your KNCS-NB / KNCS-NBX chuck due to wrong dimensions / tolerances

No warranty from SMW-AUTOBLOK

Use mounting bolts 12.9 ISO 4762 only. Always check correct length of thread engagement! Use torque

wrench and tighten gradually one after another.

Do not exceed torque (Md) otherwise master jaw gets distorted.

Use original SMW-AUTOBLOK master jaws GBK only! They

are marked on their face with the logo.

Mounting of top jaws on master jaws GBK

Operation

SMW-AUTOBLOK 17

1 3

24

!

!

!

Do not actuate foot pedal

Danger of damage to the

chuck!

Clean guideway and

lubricate. Lubricate

new jaw set in the

guideway and in the

serration.

Insert key and rotate

against spring tension

to pos. II and hold in

position.

Remove / reposition

jaw 1.

Changing / repositioning of the jaws is possible only in chuck

position “OPEN”.

Changing or re-positioning of the jaws

Do not actuate foot pedal

Danger of damage to the

chuck!

Do not actuate foot pedal

Danger of damage to the

chuck!

Jaw change

Foot pedal

chuck: OPEN

18 SMW-AUTOBLOK

7

86

5

!

!

!

!

!

!

!

!

Jaw change

Do not actuate foot pedal

Danger of damage to the

chuck!

Do not actuate foot pedal

Danger of damage to the

chuck!

Jaw safety interlock:

Key can only be removed in pos. I.

Key can only be rotated back from pos. II into

pos. I if a jaw is inserted correctly into the

chuck and the safety pin is actuated via the

jaw.

For installation and maintenance the key can be

removed in pos. I if the safety pin is actuated via

the dummy pin.

Danger of damage to the chuck!

Never actuate foot pedal (chuck) when key is

engaged for jaw change.

Never apply force!

Danger of damage to the chuck and actuating

cylinder!

Rotate key against spring tension to pos. II and hold in position.

Insert new jaw at least as far as necessary for the jaw to actuate

the safety pin.

Rotate key back to pos. I and remove. Jaw change of jaw 1 is

finished.

If no jaw is inserted, as example for maintenance or disassemb-

ling the chuck from the machine spindle, the key can be rotated

back to pos. I and removed if the safety pin is actuated via the

dummy pin.

For changing /

re-positioning

jaw No. 2 and jaw No. 3

repeat steps 2-6

Maintenance / disassembling / installation

Pos. II

Safety pin

Safety interlock: Key can only be removed in pos. I!

Do not actuate foot pedal

Danger of damage to the

chuck!

Pos. I

Pos. I

Safety pin

SMW-AUTOBLOK 19

1

3

2

!

!

!

!

!

Maintenace / Lubrication

Do not actuate foot pedal

Danger of damage!

Regular maintenance is the basis for correct func-

tion, high service life, precision and clamping

force of the clamping chuck.

Check gripping force regularly with gripmeter

(GFT-X)!

Never use coolants which dissolve the grease!

Maintenance intervals

at normal conditions / using coolant

Measurement Lubricate with

K05 grease

Disassemble + clean

see page 20 + 21

after operating

hours 20 1000

Lubrication of the chuck

Maintenance intervals

at rough conditions / using coolant

Measurement Lubricate with

K05 grease

Disassemble + clean

see page 20 + 21

after operating

hours 8 600

For optimal distribution of the grease do multiple jaw strokes

opening and closing.

At jaw change always clean and grease the guideway and the

serration.

Lubrication via 3 ball type grease nipples DIN 71412.

Can 1000 g

Id.No. 011881

Cartridge 500 g

Id.No. 016440

Grease gun for 14 Oz. cartridges to DIN 1284. (also refil-

lable from grease can 1000 g.)

Lubrication set

Id.No. 083726

Use original SMW-AUTOBLOK K05 grease!

The use of unsuitable lubricants can cause con-

siderable losses in clamping force or damage to

the clamping chuck.

Foot pedal

chuck:

CLOSED

First lubricate in chuck

positon “OPEN”...

1-2 strokes up

to size 275

2-3 strokes

from size 325

... then lubricate

in chuck position

“CLOSED”

1-2 strokes

up to size 275

2-3 strokes

from size 325

Foot pedal

chuck:

OPEN

20 SMW-AUTOBLOK

1

2

3

3A

3B

4

5A

5B

!

!Do not actuate foot pedal

Danger of damage to the

chuck!

Disassembling / Repair

Removal of the chuck from the machine spindle

Remove jaw 1 to 3. Key can be removed by actuating the safety

pin via dummy pin.

Use mounting belt to lift chuck. From size 260 mm on the

chucks carry a transportation thread for an eye bolt.

Close the chuck and remove the mounting bolts.

Open the chuck and release from centering rim dia./short taper

by means of light hit with a plastic hammer.

If the chuck does not release from the spindle:

Insert jaws again and do I.D. gripping on a solid ring or com-

ponent. The chuck is pushed off the spindle by means of the

actuation cylinder.

Partial open center

Unscrew draw bolt and remove chuck with draw tube from the

machine spindle.

Open center

Chuck without rotating ring nut:

Rotate spindle by hand at the flange or drive belt and screw out

the draw tube.

Open center

Chuck with rotating ring nut:

Insert key (standard equipment) through the chuck bore until

the cams engage into the slots and unscrew the threaded ring.

Never apply force!

Danger of damage to the chuck and actuating

cylinder!

This manual suits for next models

11

Table of contents

Other SMW Autoblok Industrial Equipment manuals

SMW Autoblok

SMW Autoblok Mario Pinto LT Operation instructions

SMW Autoblok

SMW Autoblok F180 User manual

SMW Autoblok

SMW Autoblok APS User manual

SMW Autoblok

SMW Autoblok VNK 70-37 Operation instructions

SMW Autoblok

SMW Autoblok M30 IOL User manual

SMW Autoblok

SMW Autoblok W-215 User manual

SMW Autoblok

SMW Autoblok SLX e-motion User manual

SMW Autoblok

SMW Autoblok ZHVD-SZ User manual