6 SMW-AUTOBLOK

RemoteBase

M30-IOL

Axial coupler

Application/customer benets

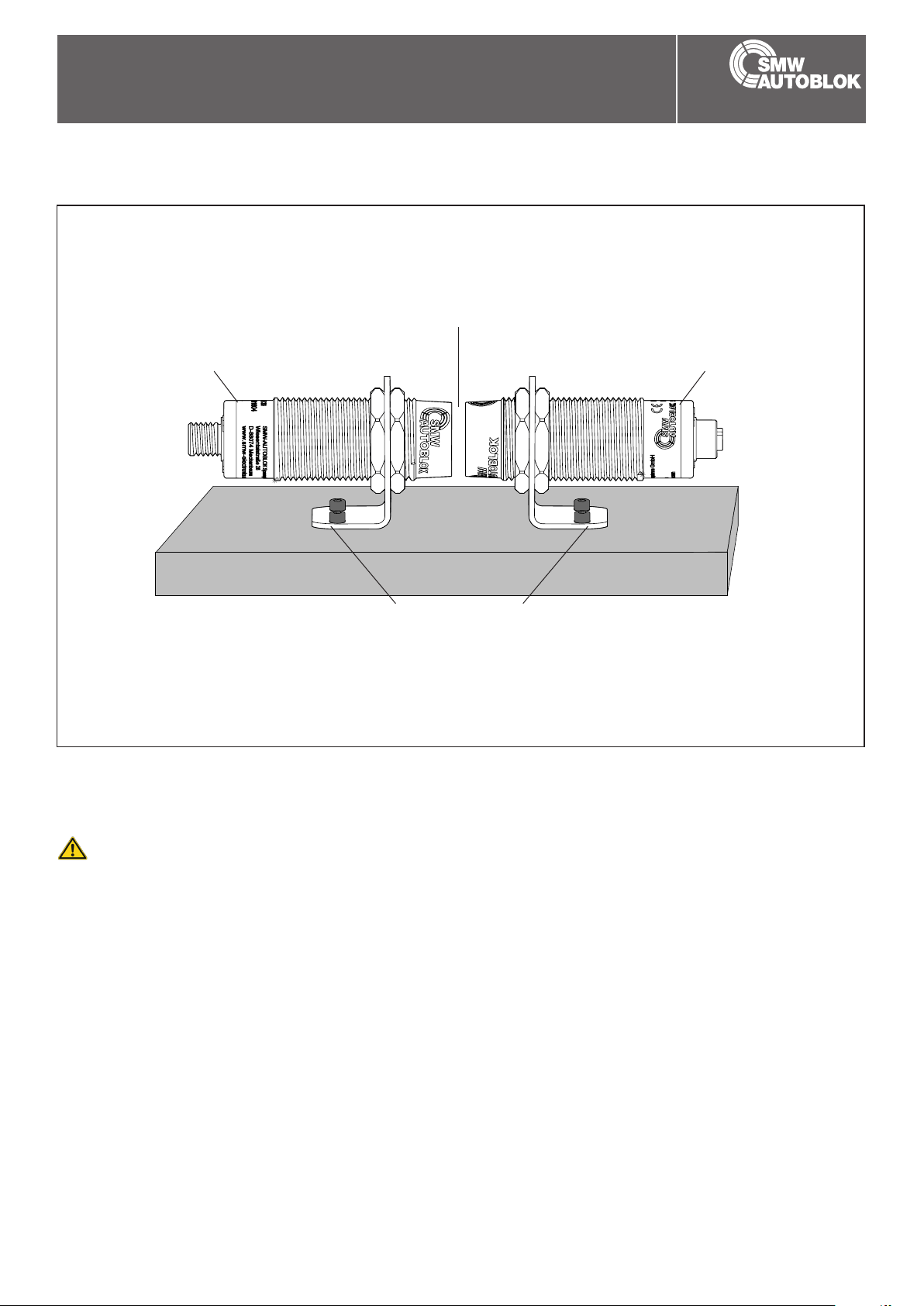

• Contact free, safe transmission of energy and signals

between moving / rotating and stationary components

• Application examples: Supply of sensors, Supply and monitoring of remote systems

• Dynamic Pairing

• Wear and maintenance free

• Protective function: Temperature monitoring, foreign object detection, reverse polarity protection

• Multi-level LED with good visibility

Technical features

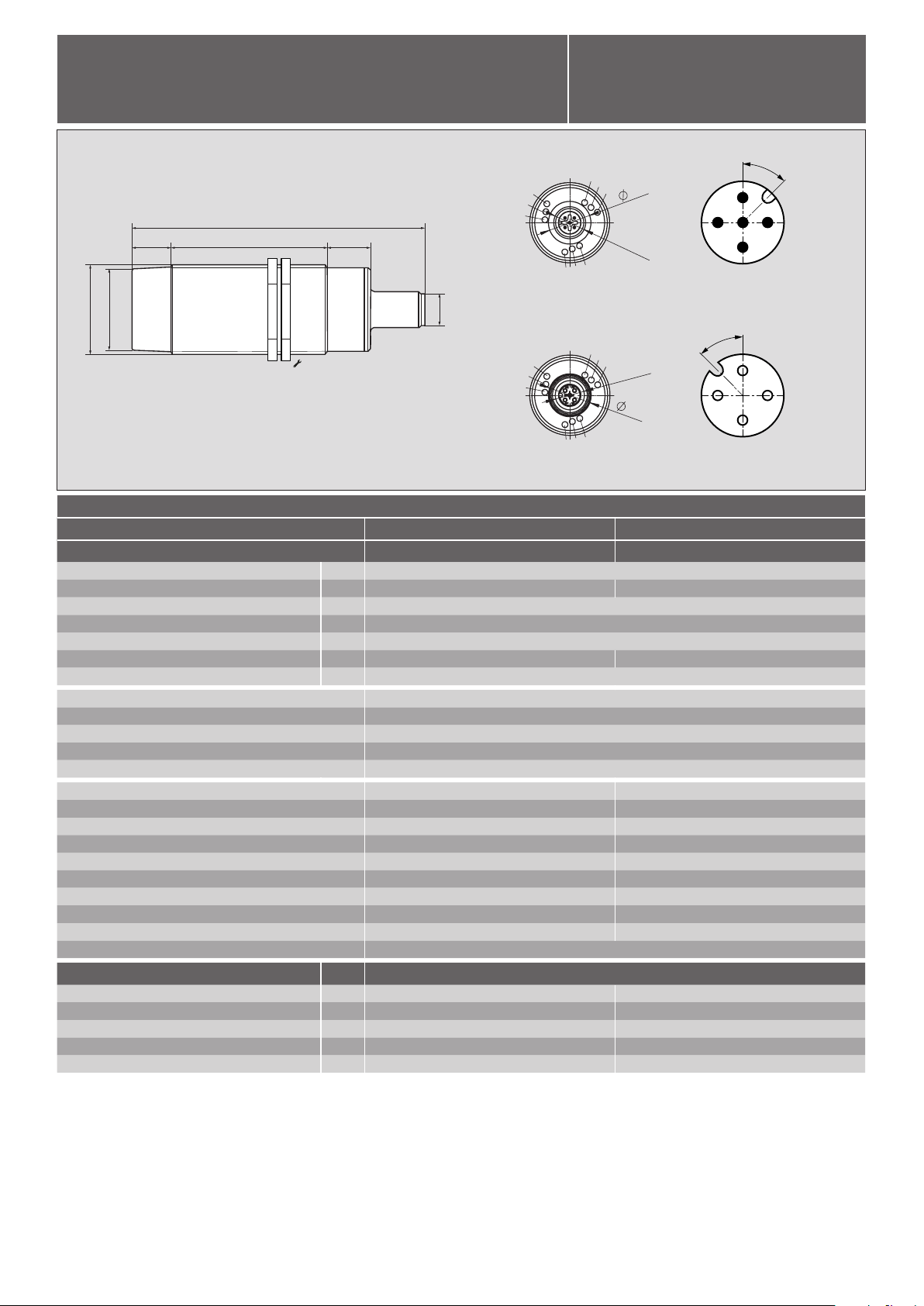

• Mounting M30 x 1.5

• Operating voltage 24 V (18 ... 30 V)

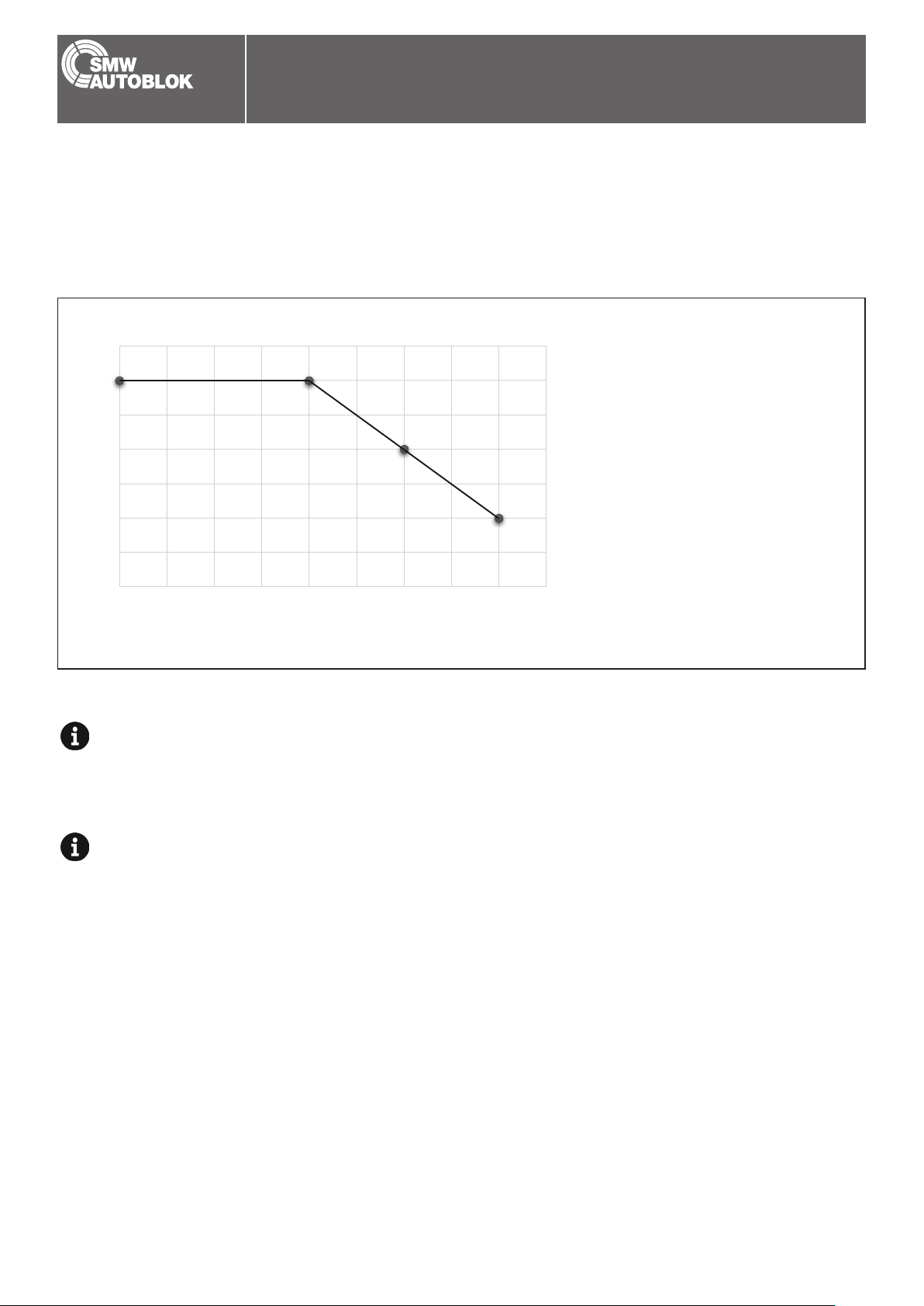

• Transmission distance 0 - 8 mm

• Transmission of energy: 24 V / 12 W (500 mA) with a distance of 0 - 4 mm

• Transmission of signals: IO-Link (COM1, COM2, COM3), 1 digital signal

• Connection: Base male connector M12 (5-pin), remote female connector M12 (4-pin)

• Protection class IP 67

• Id. No. Base: 0E011604, Id. No. Remote: 0E011605

Subject to technical changes.

For more detailed information please ask our customer service.

Inductive Coupling Sytem

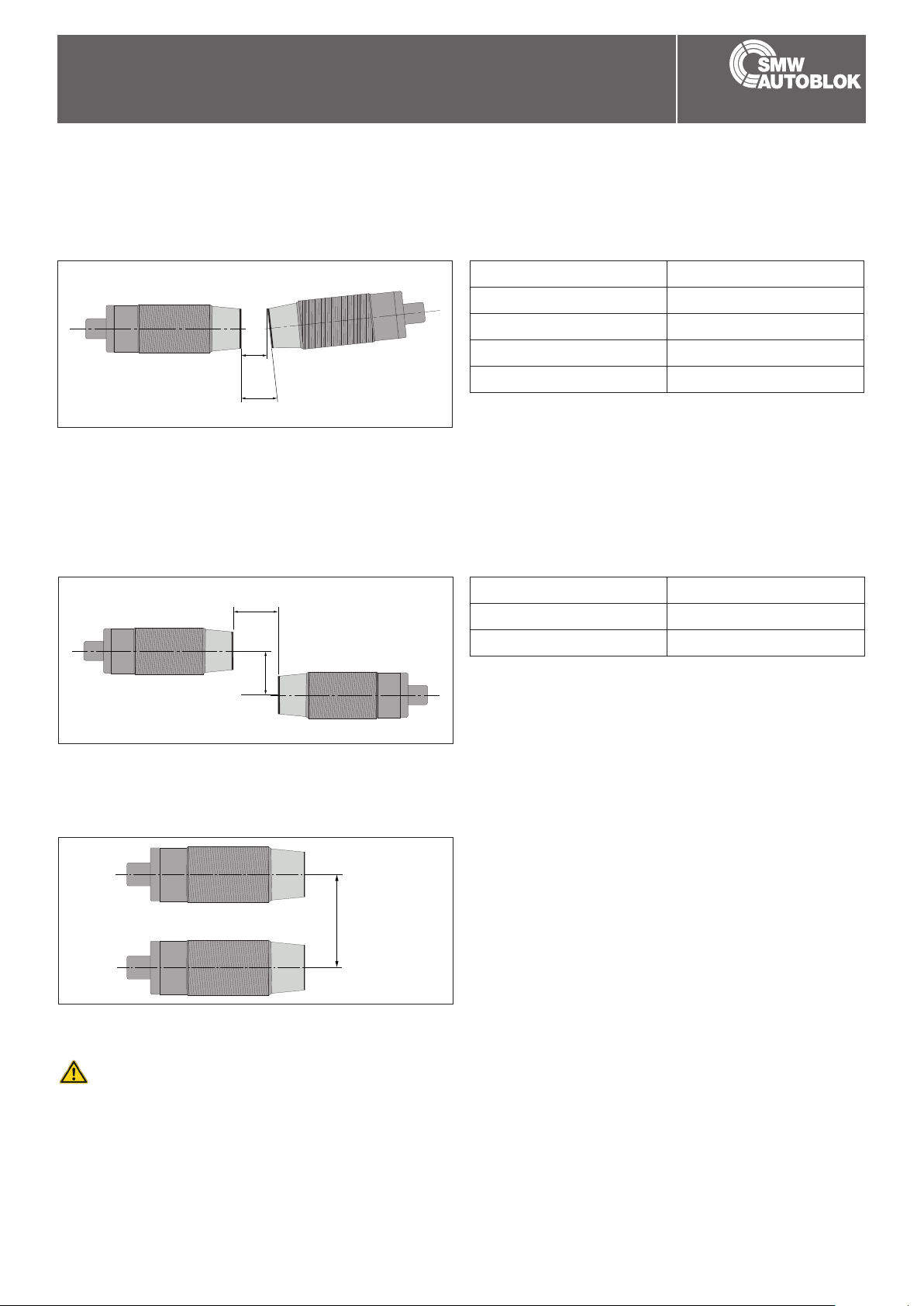

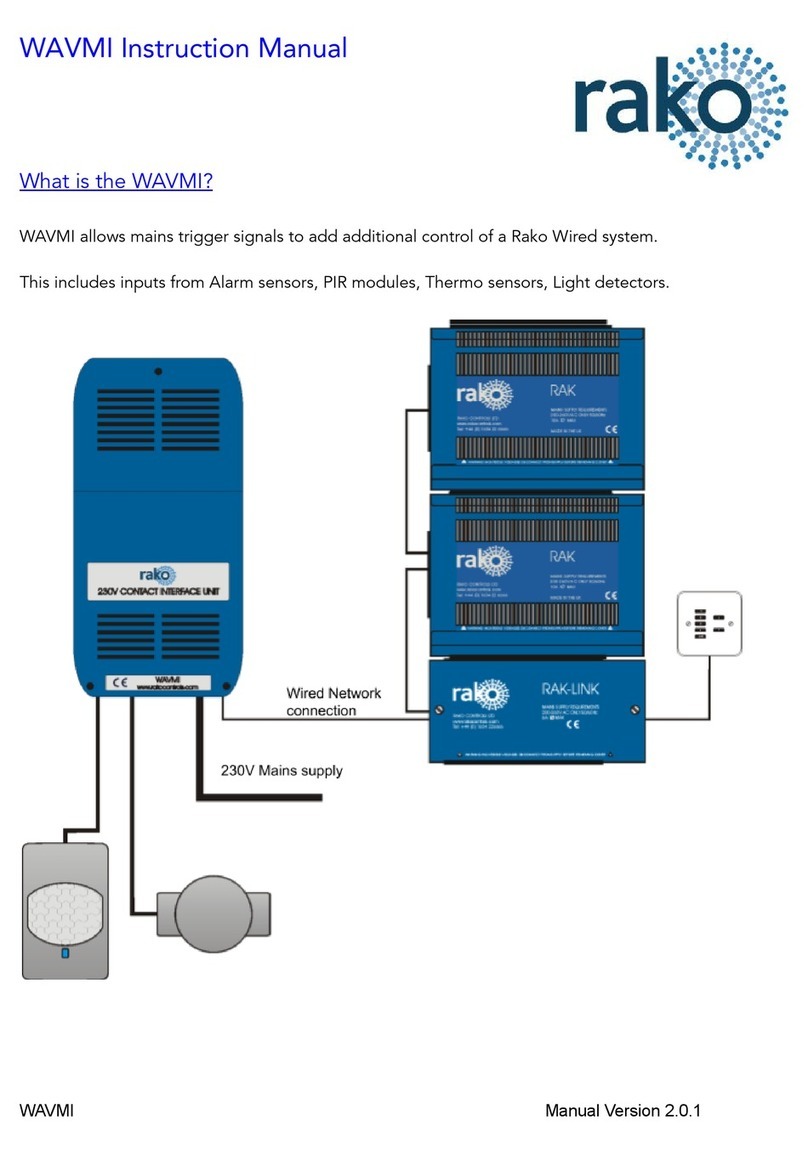

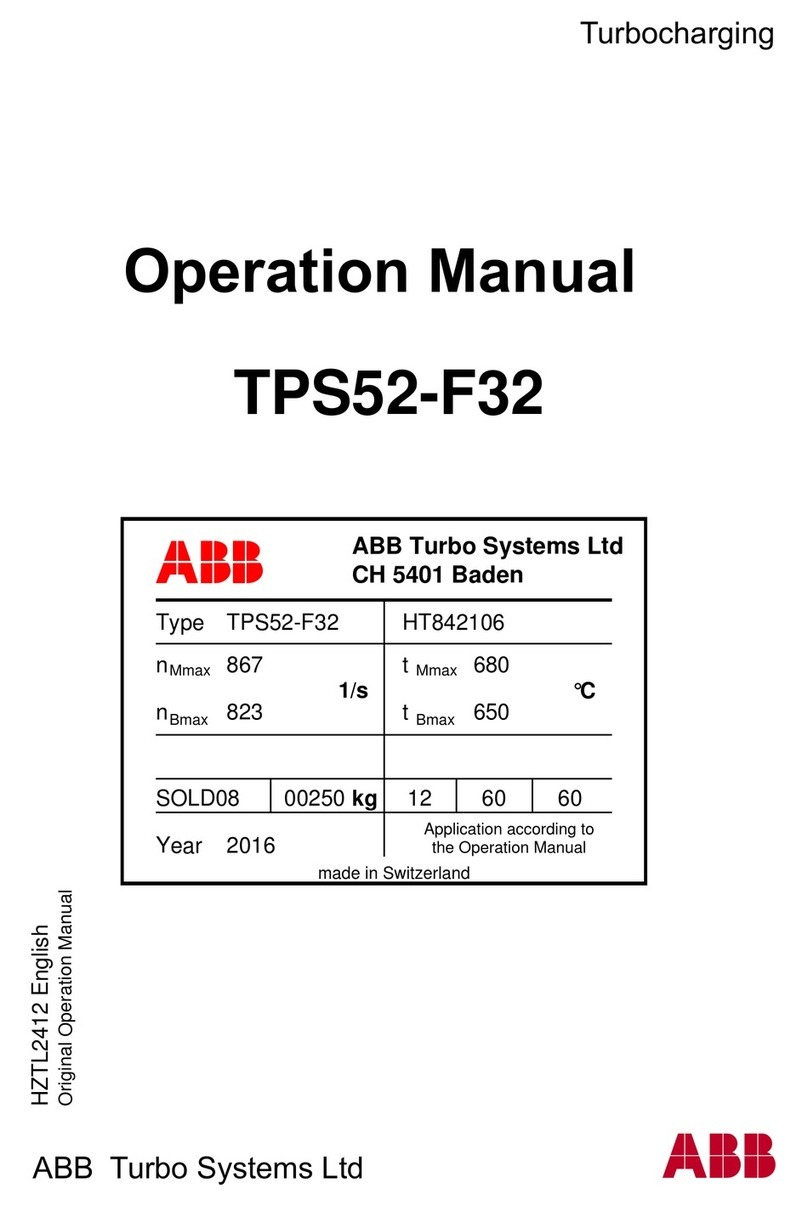

Block diagram:

IO-Link

Master

Energy

Signals

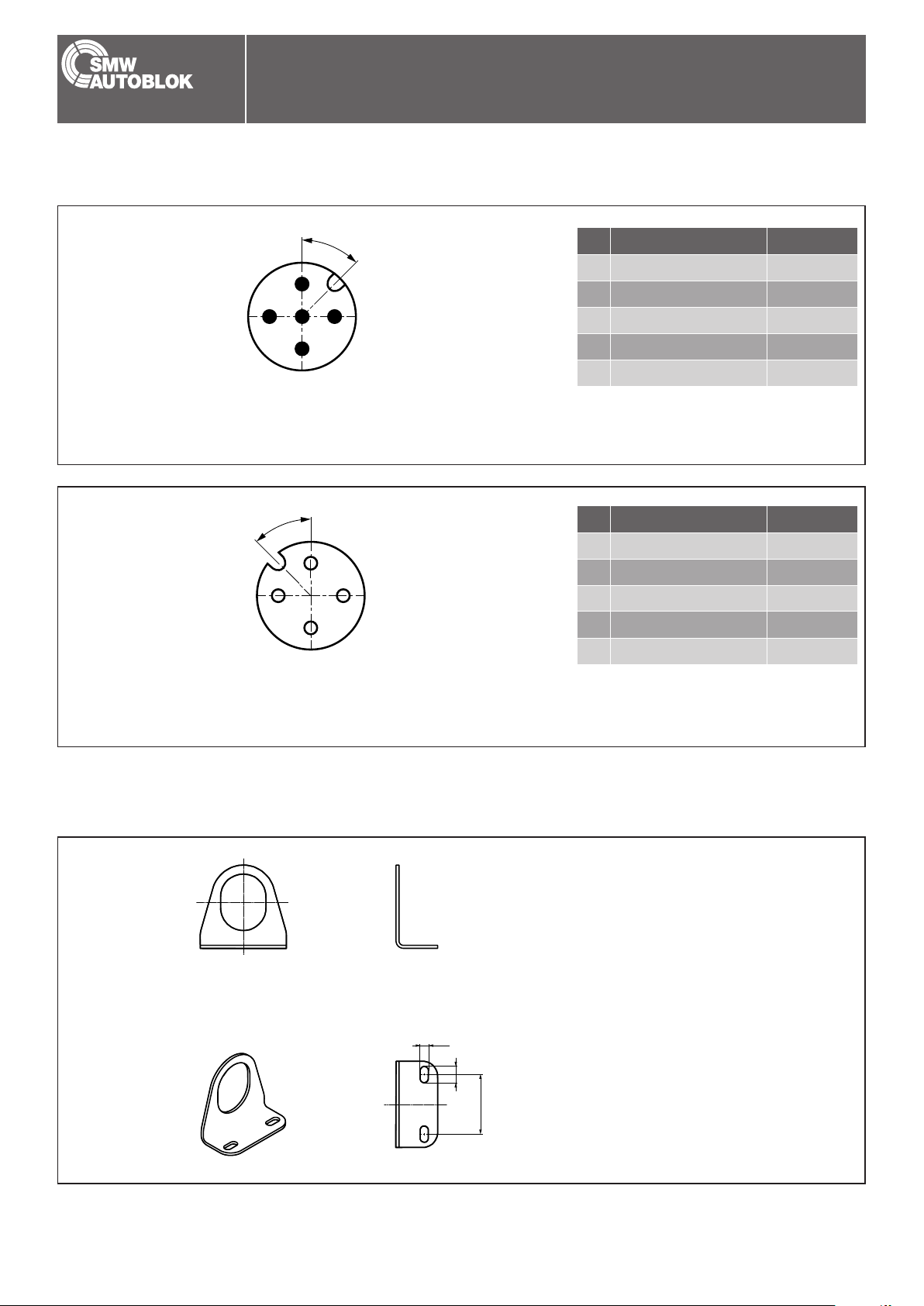

Function Base

LED Power

Color Green / red

Function

Off » Unit not supplied with voltage (or undervoltage)

On (green) » 24 V ok and mobile unit has been detected

Flashes 2 Hz green » 24 V ok but no mobile unit detected

Flashes 1 Hz red / green » Incompatible mobile unit detected

Flashes 2 Hz red » Foreign object detected

Flashes 5 Hz red » Internal error

LED IO-Link

Color Green / red

Function

Green » Signals IO-Link Operation

Green » On (SIO Mode Signal on)

Green » Off (SIO Mode Signal off)

Flashes 2 Hz red » Short circuit at the IO-Link PIN

Flashes 5 Hz red » Overload voltage output remote unit

LED Signal

Color Yellow

Function

Off » Digital input is not connected

or no mobile unit detected

On » Digital input is connected

Flashes 2 Hz » Digital input is connected

but short circuit at the output

Flashes 5 Hz » Overload voltage output mobile unit

Function Remote

LED Power

Color Green / red

Function

Off » Unit is not connected

On (green) » Unit coupled, voltage output DC 24 V ok

Flashes 2 Hz red » Connected but short-circuited at DC 24 V

Flashes 5 Hz red » Internal error

LED IO-Link

Color Green / red

Function

Green » Signals IO-Link operation according to IO-Link

specication (1000 ms on / 100 ms off)

Green » On (SIO Mode Signal on)

Green » Off (SIO Mode Signal off)

Flashes 2 Hz red » Short circuit at the IO-Link PIN

Flashes 5 Hz red » Overload voltage output mobile unit

LED Signal

Color Yellow

Function

Off » Digital input 2 is not connected

or no mobile unit detected

On / yellow » Digital input 2 is connected

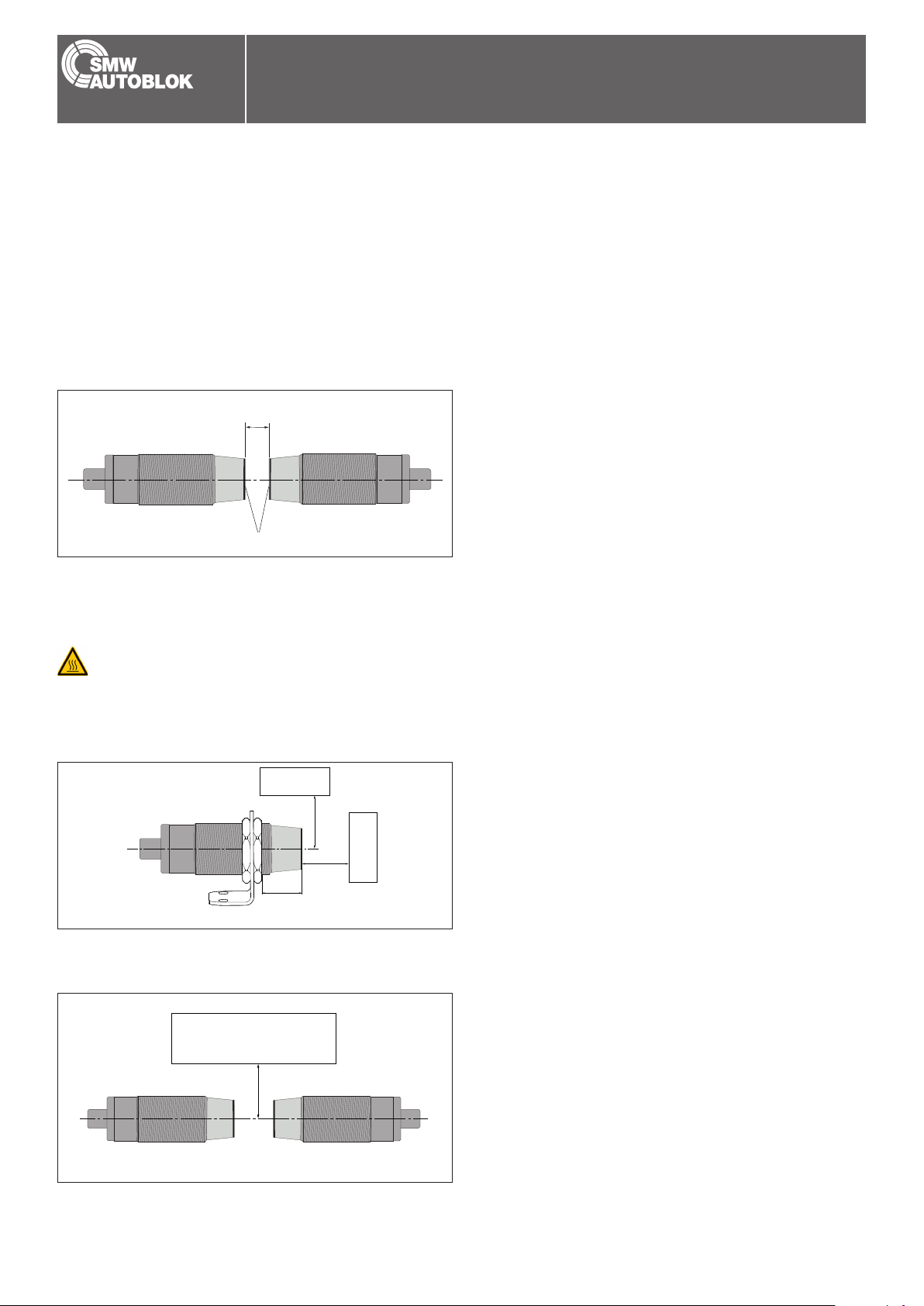

■ Contact free transmission of energy and signals

0 - 8 mm

IO-Link-Device

IO-Link

COM1, COM2, COM3

24 V / 12 W (12 W with a distance of 0 - 4 mm)