SMW Autoblok F180 User manual

F180 Ethernet

Inductive coupler system

DEUTSCH

INSTRUCTION MANUAL

Date:

Version:

Language:

COPY OF THE

ORIGINAL

2022-10

P2

English

Preliminary

SMW-AUTOBLOK 3

5

6

8

10

17

18

Übersicht

INSTRUCTION MANUAL

Inductive coupler system

F180 Ethernet

Thank you for purchasing your F180 Ethernet inductive coupler

system.

.

This instruction manual contains the installation, the functional

description and the operation of the „F180 Ethernet“.

SMW-AUTOBLOK reserves the right to make changes without

notice.

This instruction manual is a part of the „F180 Ethernet “ and

must be passed to the new owner in case of sale.

This instruction manual may not be -in whole or in part- copied

without our written agreement.

Content

Overview

Safety instructions

Tecnical data

Description of function

Installation

Typeplate

Warranty

Maintenance

Troubleshooting

Accessories

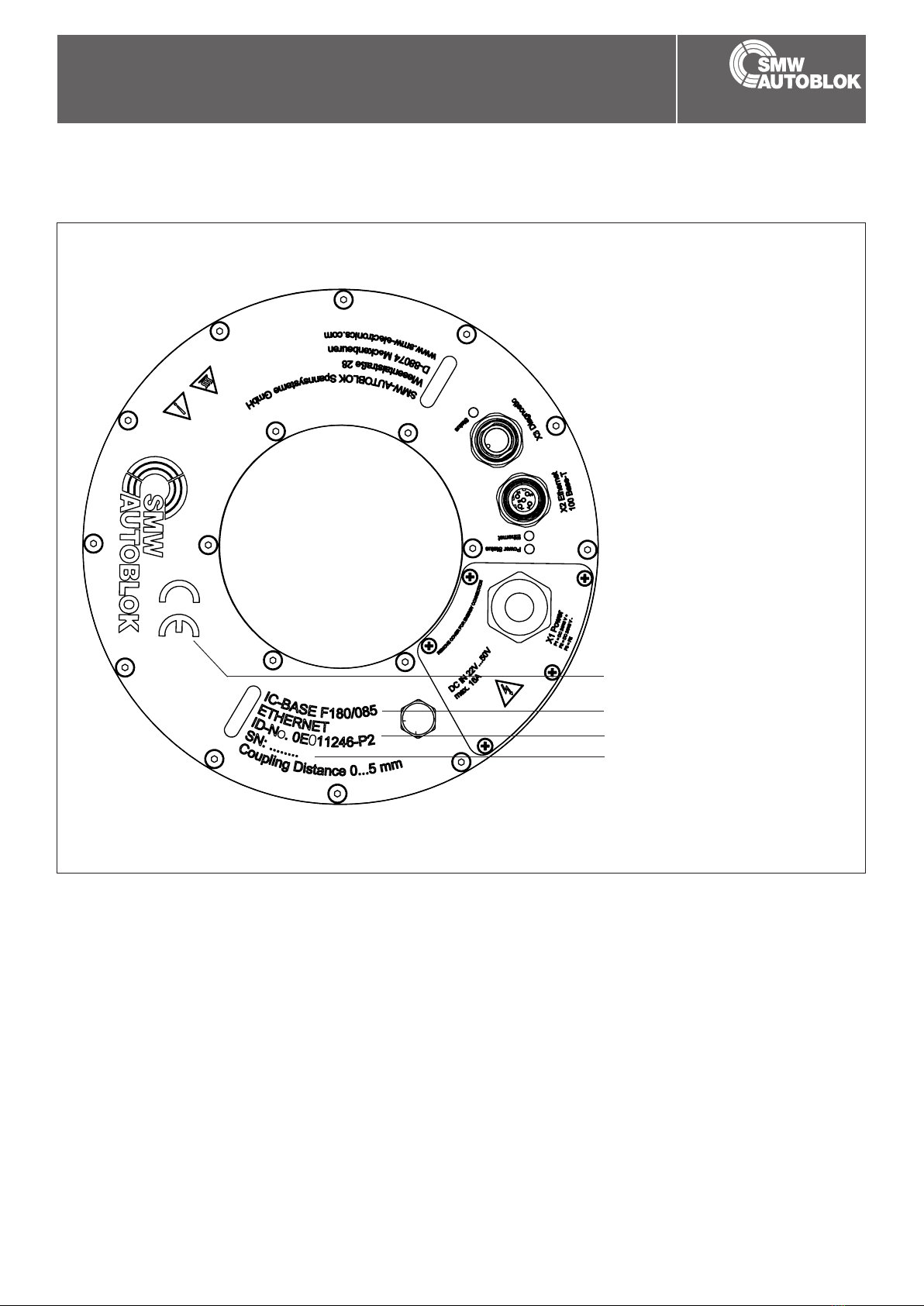

Typeplate

Warranty

Conrmation of receipt of the manual

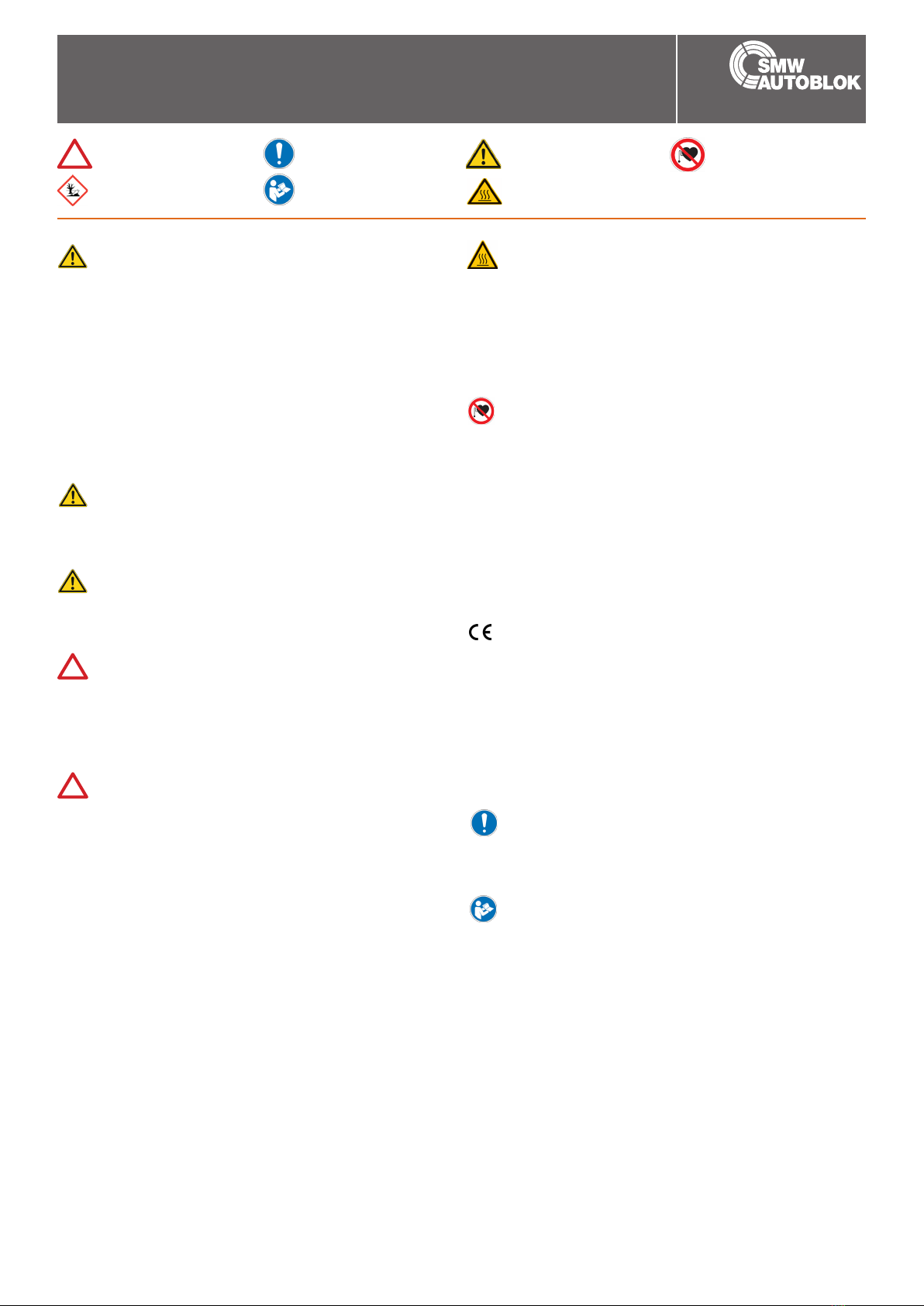

&Please read the instruction manual carefully

before installation and use and always follow the

regulations.

Please note especially the sections which are

marked with the following signs:

•Danger of injury or danger to life if instructions

are not followed.

•Danger of damage to the sensor, the machine or

the components.

0E011246-P2 Inductive coupler F180 Ether-

net Base

28.02.2022 V1 EN

0E011247-P2 Inductive coupler F180 Ether-

net Remote

28.02.2022 V1 EN

Validity:

4 SMW-AUTOBLOK

Einbauerklärung

SMW-AUTOBLOK 5

Allgemeine Sicherheitshinweise

!

Englisch

In case of doubts or questions please ask SMW-

AUTOBLOK or one of our authorized ofces.

7. Protection against electromagnetic elds during

operation and assembly

The permissible values according to VDE 0848 Part 3-1 are

observed from a distance of > 3 mm. Persons with physical

aids (e.g. pacemakers) may be exposed to health hazards

due to the magnetic elds emitted by the coupler system.

The minimum distance for this group of persons is > 5

mm. The operator must ensure that this minimum distance

is also maintained during operation by taking suitable

measures.

6. Caution: Hot surface!

Danger of burns from hot surfaces!

The active surface heats up even under normal operating

conditions.

Keep hands and objects away from the active surface.

Avoid contact of metallic objects on the active surface.

Fire hazard!

5. Operating faults

In case of defective and unrecoverable device malfunctions,

put the device out of operation and secure it against

unauthorized use.

4.

Duties of the operator

The operator must ensure that the locally applicable

national and international safety regulations are observed.

The unit may only be operated with an approved power

supply.

2. Authorized personnel

Installation and commissioning are only permitted by

trained specialist operators.

1. Intended use

The device is designed to transmit energy and signals

without contact. The system must not be used in

applications where the safety of persons depends on the

device function.

Liability claims against the manufacturer expire in the event

of damage caused by:

• unauthorized tampering

• use not in accordance with the intended purpose

• use, installation, handling contrary to the regulations of

these operating instructions.

3. Visual inspection

Please check the product for visible damage prior to use!

8. Certication

With the CE mark we conrm that our products comply

with the requirements of the EC Directives 2004/108/EC

(EMC) and the EMC Act.

In an accredited EMC laboratory, proof was provided that

the products meet the EMC requirements of the basic

technical standards:

• EN 61000-6-4 (emitted interference) and

• EN 61000-6-2 (immunity to interference)

General safety instructions

Danger!

Danger to the environment!

General precept sign!

Follow the instructions! Caution: Hot surface!

General warning sign!

!

!

Before the start up, the operating instructions must be

read carefully.

No access for persons with

pacemakers

6 SMW-AUTOBLOK

0 - 20 mm

24 V / 240 W

48 V / 400 W

-20° C ... +60° C -20° C ... +60° C

-20° C ... +60° C -20° C ... +60° C

0 mm ... 5 mm (24 V)

0 mm ... 3 mm (48 V)

0 mm ... 5 mm (24 V)

0 mm ... 3 mm (48 V)

24 V / 48 V -

-24 V DC / 10 A

48 V DC / 8,3 A

- 24 V DC / 4 A

15 A (24 V)

12 A (48 V) -

- < 50 mV

max. 100 mA -

< 1 s < 1 s

Base Remote

0E011246 0E011247

F180 Ethernet

Base Remote

Ethernet

Axial coupler

Application/customer benets

• Contact free, safe transmission of energy and signals

between moving / rotating and stationary components

• Application examples: Packaging machines, special machines,

Automation, Machine Tools, Printing Machines

• Substitution of slip ring / connector

• Dynamic Pairing

• Wear and maintenance free

• Protective functions: temperature monitoring, foreign object detection,

reverse polarity protection

• Multi-level LED with good visibility

Technical features

• Diameter 180 mm / Inner diameter 85 mm

• Supply voltage 24V / 48V

• Transmission distance 0 - 20 mm

• Transmission of energy 24V / 250W or 48V / 400W (selectable)

• Transmission of signals Ethernet 100 Base-T

• Transmission bandwidth Ethernet < 100 MBit

• Protection class: IP 67

Subject to technical changes.

For more detailed information please ask our customer service.

Block diagram:

Operating temperature (body surface)

Stocking temperature

Transmission distance

Operating voltage

Output voltage (Actuator supply)*

Output voltage (Sensor supply)*

Signal transmission Ethernet 100 Base-T Ethernet 100 Base-T

LED function display 3 LEDs 2x 3 LEDs 2x

Current consumption (base)

Overload protection / short-circuit protection

Reverse polarity protection

Data valid output

Ready for Operation

Inductive coupler F180 Ethernet

SMW-electronics Type

Id. No.

PLC

Energy

Signals

Inductive coupler system

■Contact free transmission of energy and signals

Signal transmission

Control

Power electronic

Signal transmission

Control

Rectier

Controller

24 V / 48 V

Controller

24 V

24 V / 10 A

Actuator

24 V / 2 A

Sensor

DAV /

Diagnosis

Ethernet

100BaseT

Galvanic

Isolation

Galvanic

Isolation

Galvanic

Isolation

DAV /

Diagnosis

Ethernet

100BaseT

Actuator

OFF

24 V /

48 V

48 V / 8,3 A

Actuator

SMW-AUTOBLOK 7

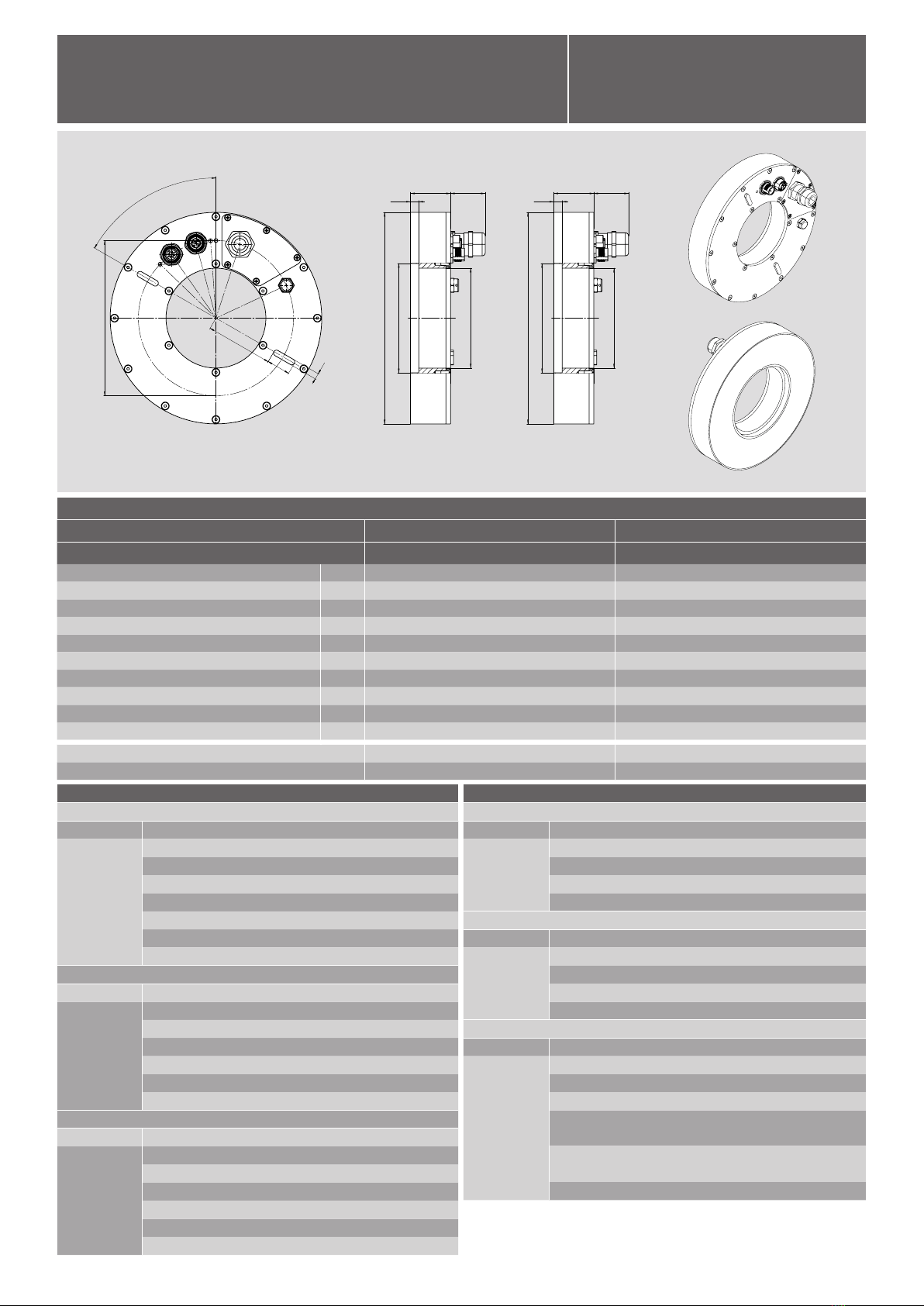

Base:Base / Remote: Remote:

60°

E

D

F

TK- Ø

132

H

H1

A

B

B1

C

60°

E

D

F

TK- Ø

132

H

H1

A

B

B1

C

Base Remote

0E011246 0E011247

Amm 180 180

Bmm 85 85

B1 mm 93 93

Cmm 29.5 29.5

Dmm 57 57

Emm 20 20

Fmm 5 5

Hmm 34 34

H1 mm 7 7

ɑ60 60

Al, GFK Al, GFK

IP 67 IP 67

F180 Ethernet

Axial coupler

Function Base

LED Power

Color Green / red

Function

Off » Unit not supplied with voltage (or undervoltage)

On (green) » Voltage ok and mobile unit has been detected

2 Hz green 50/ 50% » Operating temperature in critical range

1 Hz green 25/ 75% » Voltage ok but no mobile unit detected

1 Hz red/ green » Incompatible mobile unit detected

2 Hz red » Foreign element detected

5 Hz red » Internal error

LED Signal transmission Ethernet

Color Yellow / red

Function

Off » No mobile unit detected

On / yellow » Signal transmission ready

1 Hz yellow » Data packets are being transmitted

3 Hz yellow » 50% of the transmission bandwidth used (10 s)

8 Hz red » Data packets were discarded (in the last 10 s)

On / red » Error in data transmission (internal error)

LED Energy transmission

Color Yellow / red

Function

Off » No mobile unit detected

On (yellow) » Unit coupled, voltage output ok

1 Hz red/ yellow » Short circuit at voltage output sensor

3 Hz red/ yellow » Short circuit at voltage output actuator

3 Hz red » Short circuit at both voltage outputs

5 Hz red » Internal error

Function Remote

LED Actuator

Color Green / red

Function

Off » Unit not paired

On (green) » Unit paired, voltage output actuator ok

Flashes 2 Hz red » Unit paired but short circuit on actuator

Flashes 5 Hz red » Internal error

LED Sensor supply

Color Green / red

Function

Off » Unit not paired

On (green) » Unit paired, voltage output sensor (24 V) ok

Flashes 2 Hz red » Unit paired but short circuit on sensor (24 V)

Flashes 5 Hz red » Internal error

LED Signal transmission

Color Yellow / red

Function

Off » No mobile unit detected

On / yellow » Signal transmission ready

Flashes 1 Hz yellow » Data packets are being transmitted

Flashes 3 Hz yellow » 50% of the transmission bandwidth

used (10 s)

Flashes 8 Hz red » Data packets were discarded

(in the last 10 s)

On / red » Error in data transmission (internal error)

Subject to technical changes.

For more detailed information please ask our customer service.

Inductive coupler system F180 Ethernet

SMW-electronics Type

Id. No.

degree

Housing material

Protection class

Inductive coupler system

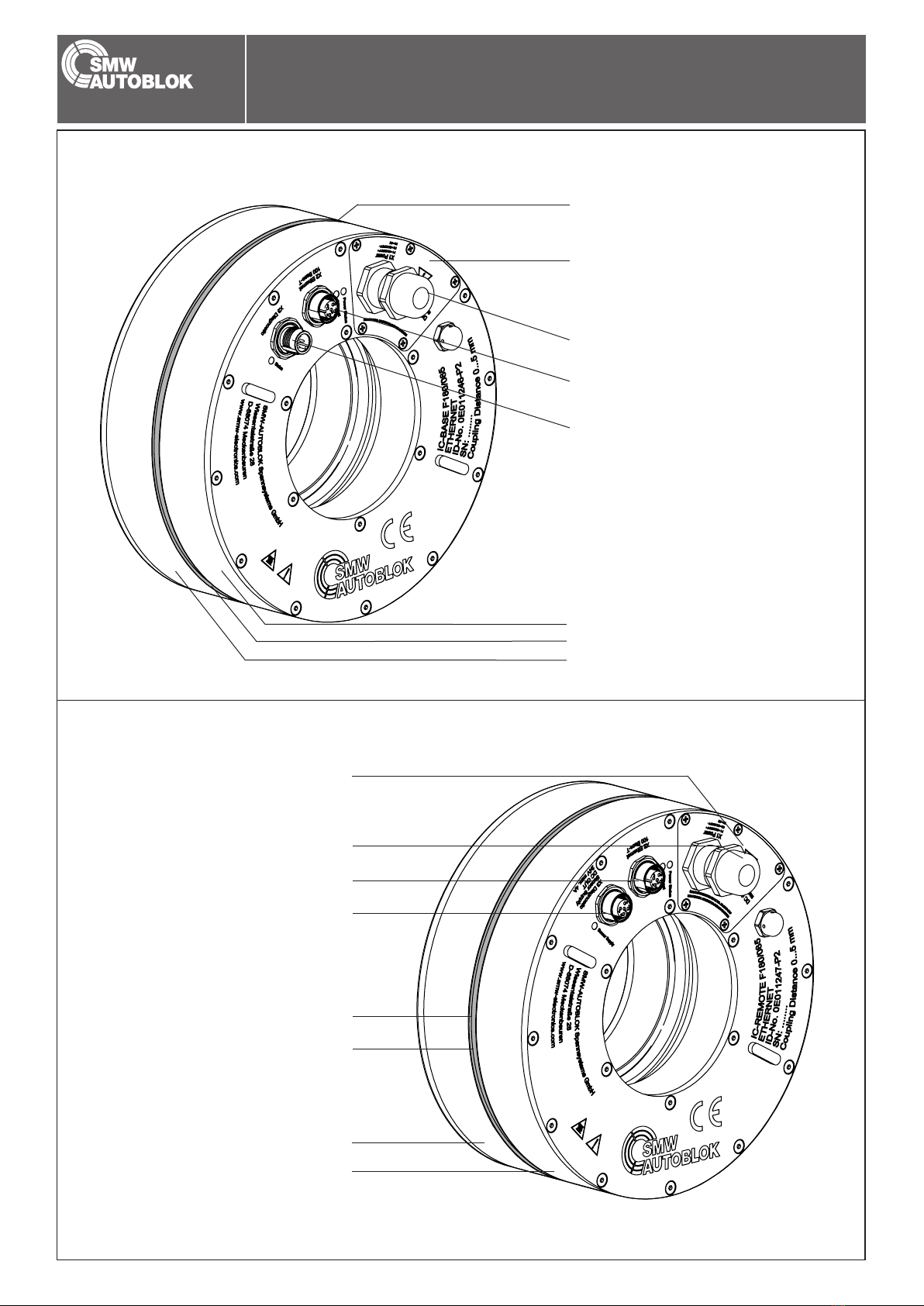

■ Stationary unit - Base

■ Mobile unit - Remote

8 SMW-AUTOBLOK

Description of function

Cable tting power cable M16

Transmission distance

Ethernet connection M12, female, D-coded

Diagnostic connection M12, plug, A-coded

Remote

Base

Coverage Energy

Coupler surface

View Base

View Remote

Cable tting power cable M16

Transmission distance

Ethernet connection M12, female, D-coded

Diagnostic connection M12, female, A-coded

Coverage Energy

Remote

Base

Coupler surface

SMW-AUTOBLOK 9

Description of function

The innovative F180 inductive coupling system is used to operate electronic components of automation technology such as eldbus gate-

ways, sensors or actuators on moving, dynamically variable machine and systems parts.

For this purpose, the coupling system transmits electrical energy and the necessary signals by using magnetic elds across an air gap.

This method is independent of movement and allows contact-free power and signal transmission into fast rotating system parts.

The inductive coupling system is designed for high power, so that it can operate a huge number of suitable actuators, such as, for example

magnet valves, servomotors or linear drives.

Description

10 SMW-AUTOBLOK

Installation

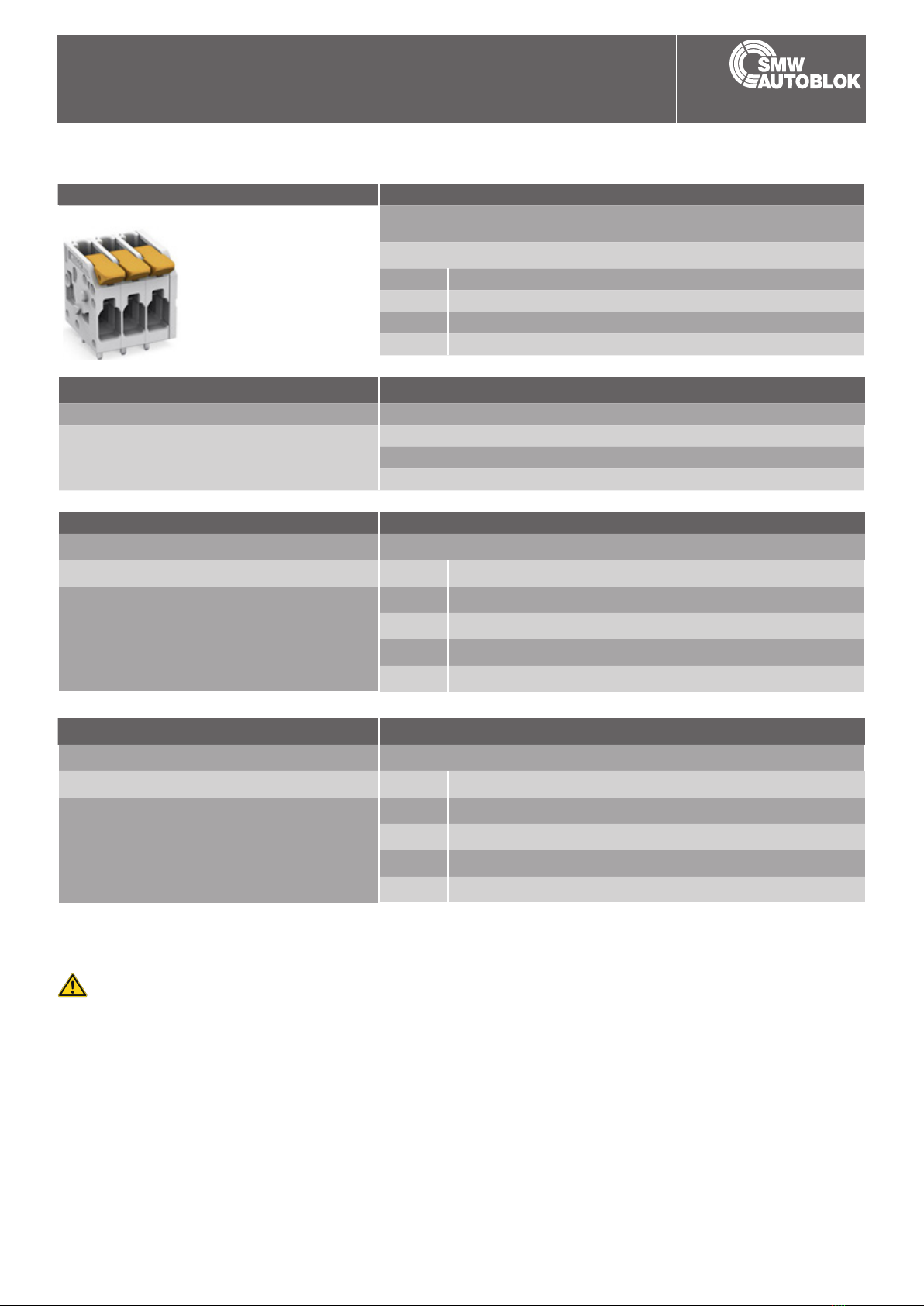

Terminal block inside the device

Screws for cover

Screws for cover

Socket screwed into housing

Lead through for electric line

Cap nut

Power connection

Cable tting M16

Cable tting M16 suitable for cable diameters from 5 bis 10 mm.

Note the specied tightening torque, 8 Nm for the cap nut.

The terminal block is accessible by removing the ve screws under the coverage energy.

1 - Vin

2 - GND

3 - FE

SMW-AUTOBLOK 11

Installation

Notice

Use base coupler 0E011246-P2 only with remote coupler 0E011247-P2.

The start-up can only occur after the entire transmission chain of base and remote has been comletely set up. The installation of the

components must always be performed in a (electrical) power-free state.

Operation can only be performed with a power supply limited to 15 A at a voltage up to 24 V/ 12 A at a voltage up to 48 V + or

another overcurrent protection device.

A correct coupling between Base and Remote is indicated by the Data Valid signal.

Start-up

12 SMW-AUTOBLOK

1 2 3

Installation

Connectors Base

Power supply

Terminal inside the unit (sealed) Terminal block with screw terminal (plug-in terminal) for 2.5mm² wires with

PG tting connection

PIN Function

1 DC 24/48 V +

2 DC 24/48 V -

3 FE (Functional ground)

Diagnose

Plug type M12 male 4-pin, A-coded

Pin assignment PIN Function

1 DC 24 V + (IN)

2 IN Actuator voltage ON/OFF

3 DC 24 V -

4 OUT Data Valid

Ethernet

Plug type M12 female, D-coded, inside the housing

Pin assignment PIN Function

1 TX +

2 RX +

3 TX -

4 RX -

SMW-AUTOBLOK 13

1 2 3

Installation

Actuator supply

Terminal inside the unit (sealed) Terminal block with screw terminal (plug-in terminal) for 2.5mm² wires with

PG tting connection

PIN Function

1 DC 24/48 V +

2 DC 24/48 V -

3 FE (Functional ground)

Output voltage selection

Switch inside the device Terminal block with screw terminal (plug-in terminal) for cable bridge (small) 2 pin

PIN Function

1 Sel 1 jumper set actuator U = 48 V

2 Sel 2 jumper not set actuator U = 24 V

Sensor supply diagnostic

Plug type M12 female 4-polig, A-coded

Pin assignment PIN Function

1 DC 24 V + sensor supply (OUT)

2 nc.

3 DC 24 V - sensor supply (OUT)

4 OUT Data Valid

Ethernet

Plug type M12 female, D-coded, inside the housing

Pin assignment PIN Function

1 TX +

2 RX +

3 TX -

4 RX -

Attention!

Damage to the remote unit due to overvoltage peaks if the cables are too long!

In order to meet the EMC requirements, the receiver cable must not be longer than 15 m. If a longer cable is nevertheless used,

take all steps to protect the receiver from overvoltage peaks.

Connectors Remote

14 SMW-AUTOBLOK

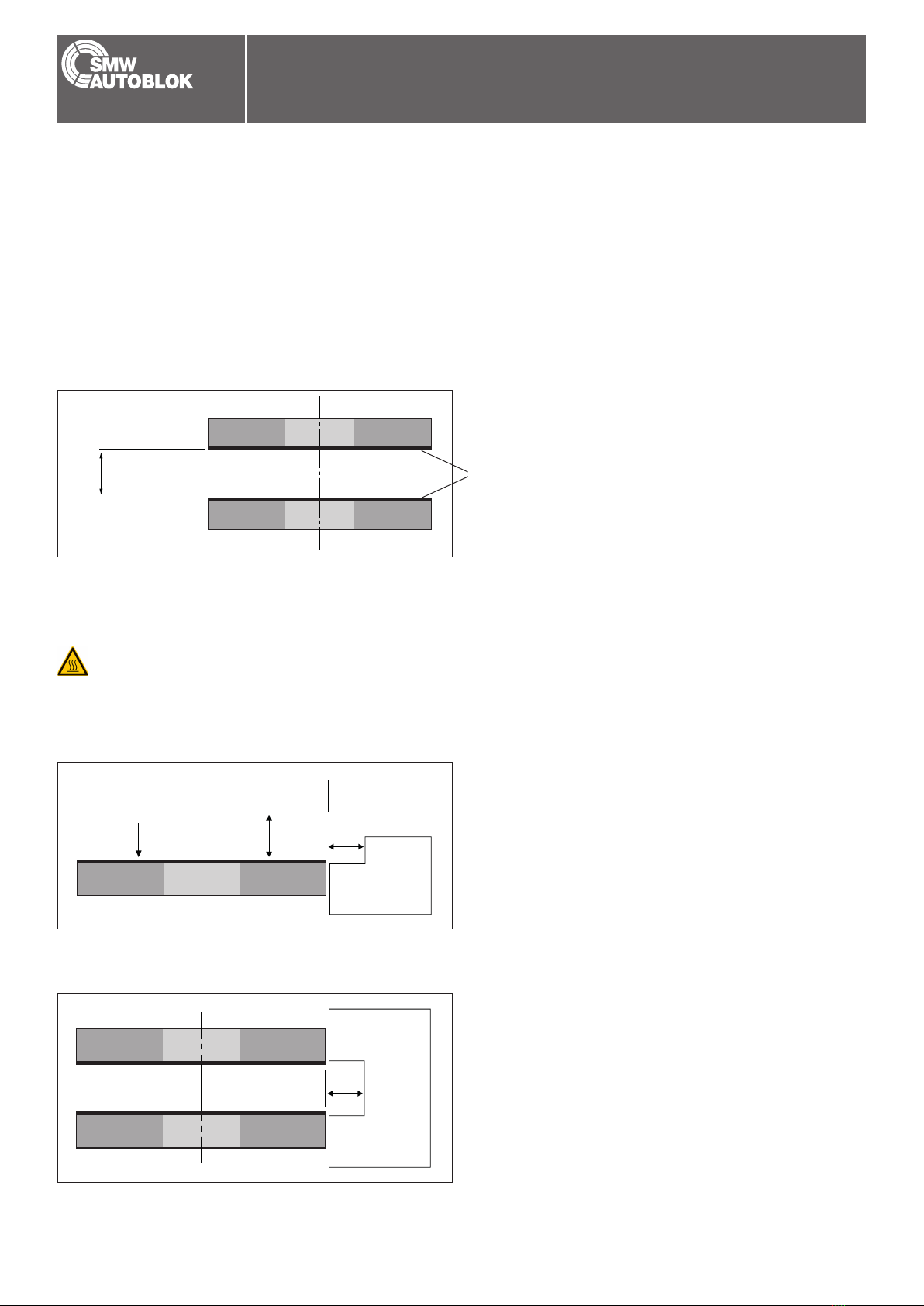

G

B

A

A

Installation

Operating voltage 24 V distance G ≤ 6 mm

Operating voltage 48 V distance G ≤ 3 mm

Distance A > 1 mm

Distance B > 30 mm

The base and remote units of the contactless transmission are integrated by mounting them in axial alignment in compliance with the

installation specications. The assembly must be performed in a (electrical) power-free state. The following sections describe valid instal-

lation instructions that must be strictly followed for correct operation.

We recommend to use the coupler with a coupling distance of 2 mm.

Distance to each other

Installation in metall

Metal objects in the area near the active coupling surfaces can heat up strongly due to the magnetic eld generated by the coupler.

Therefore, the specied minimum distances must be strictly followed when installing in metal.

Integration

Attention!

Active coupling surface

Not coupled state

Distance A > 1 mm

Coupled state

F180 Base

F180 Remote

Active coupling surface

SMW-AUTOBLOK 15

E

D

D

C

Installation

Permissible side offset

The maximum side offset between base and remote unit is ±1 mm.

Side offset E < 1 mm

Permissible angle offset

The permissible angle offset allows function in special mounting positions.

Attention!

The factors like enviroment temperature, distance, angle offset and side offset can affect the amount of energy transfer.

The coupler works optimal centric at D = 1 to 2 mm.

Distance D Angle °

0 mm

2 mm

< 2°

< 1°

16 SMW-AUTOBLOK

IO-Link Process Data Structure and Parameters

Notes

Englisch

SMW-AUTOBLOK 17

Typeplate

CE Label

Item Number

Type Information

Serial Number

Typeplate and contact

If you have any questions about the product or if you wish to place order, please specify the type and item number on the typeplate of

the inductive coupling system.

Contact:

SMW-AUTOBLOK Spannsysteme GmbH

Postfach 1151 • D-88070 Meckenbeuren

Wiesentalstraße 28 • D - 88074 Meckenbeuren

Tel.: +49 (0) 7542 - 405 - 0

Vertrieb Inland:

Fax: +49 (0) 7542 - 3886

Sales International:

Fax: +49 (0) 7542 - 405 - 181

18 SMW-AUTOBLOK

12 months warranty

Product:

SMW-AUTOBLOK guarantees the proper function of the inductive coupling system, if the operation and storage are in accordance

with the technical specifi cations of this operating manual.

In the case that the inductive coupling system does not meet the specifi ed requirements and values, after checking the facts, repair

or replacement will be carried out.

In case of production defects, the inductive coupling system will be repaired free of charge within the warranty period.

The warranty period will be 12 months starting from the date of purchase.

In order to maintain the warranty, the return must be carried out in the original packaging.

In addition, a description of the malfunction must be included.

The manufacturer otherwise retains the right not to admit warranty claims.

Warranty

Englisch

Inductive coupler system F180 Ethernet

SMW-AUTOBLOK 19

AUTOBLOK s.p.a.

Via Duca D‘Aosta n.24

Fraz.Novaretto

I-10040 Caprie - Torino

Tel. +39 011 - 9638411

Tel. +39 011 - 9632020

Fax +39 011 - 9632288

SMW-AUTOBLOK Spannsysteme GmbH

Postfach 1151 • D-88070 Meckenbeuren

Wiesentalstraße 28 • D-88074 Meckenbeuren

Tel. +49 (0) 7542 - 405 - 0

Vertrieb Inland: Fax +49 (0) 7542 - 3886

Sales International: Fax: +49 (0) 7542 - 405 - 181

SMW-AUTOBLOK Telbrook Ltd.

7 Wilford Industrial Estate

Ruddington Lane, Wilford

GB-Nottingham, NG11 7EP

Tel. +44 (0) 115 - 982 1133

SMW-AUTOBLOK

17, Avenue des Frères Montgoler - Z.I Mi-Plaine

F-69680 Chassieu

Tel. +33 (0) 4 - 727 - 918 18

Fax +33 (0) 4 - 727 - 918 19

SMW-AUTOBLOK Japan Inc.

1-56 Hira, Nishi-Ku

461-Nagoya

Tel. +81 (0) 52 - 504 - 0203

Fax +81 (0) 52 - 504 - 0205

SMW-AUTOBLOK Corporation

285 Egidi Drive - Wheeling, IL 60090

Tel. +1 847 - 215 - 0591

Fax +1 847 - 215 - 0594

SMW-AUTOBLOK IBERICA, S.L.

Ursalto 4 – Pab. 9-10 Pol. 27

20014 Donostia - San Sebastián (Gipuzkoa) (Spain)

Tel. +34 943 - 225 079

Fax +34 943 - 225 074

SMW-AUTOBLOK Poland Sp. z.o.o.

Ul Ligocka 103 - Building 8

40-568 Katowice

Tel. +48 (0) 664 673 428

SMW AUTOBLOK Makina San, Ve Tic. Ltd. ti.

Yeni ehir Mah, Osmanli Blv, Volume Kurtkoy Os

No: 9, Kat:1, D:4, 32912, Pendik Istanbul

Tel. +90 216 629 - 2019

SMW-AUTOBLOK Workholding Pvt. Ltd.,

Plot No. 4, Weikeld Industrial Estate,

Gat No. 1251, Sanaswadi, Tal – Shirur,

Dist – Pune. 412 208

Tel. +91 2137 - 616 974

Fax +91 2137 - 616 972

SMW-AUTOBLOK Mexico, S.A. de C.V.

Pirineos No. 515-B, Nave 16

Col. Industrial Benito Juarez

Micro Parque Industrial Santiago

Queretaro, Qro. C.P. 76130

Tel. +52 (442) 209 - 5118

Fax +52 (442) 209 - 5121

SMW-AUTOBLOK (Shanghai) Work Holding Co.,Ltd.

Building 6, No. 72, JinWen Road, KongGang

Industrial Zone, ZhuQiao Town, Pudong District

201323, Shanghai P.R. China

Tel. +86 21 - 5810 - 6396

Fax +86 21 - 5810 - 6395

AUTOBLOK Company Ltd.

NO.6, SHUYI RD., SOUTH DIST.,

TAICHUNG, TAIWAN

Tel. +886 4-226 10826

Fax +886 4-226 12109

SMW-AUTOBLOK s.r.o.

Merhautova 20

CZ - 613 00 BRNO

Tel. +420 513 034 157

Fax +420 513 034 158

SMW-AUTOBLOK KOREA CO., LTD.

1108 ho, Baeksang Startower 1st,

65, Digital-ro 9-gil, Geumcheon-gu

Seoul, ROK-08511, Korea

Tel. +82 2 6267 9505

Fax +82 2 6267 9507

SMW-AUTOBLOK Scandinavia AB

Kasernvägen 2

SE - 281 35 Hässleholm

Tel. +46 (0) 761 420 111

www.smw-autoblok.de

Spain

Mexico

Sweden / Norway

Korea

India

China

Japan

U.S.A.

Turkey

France

Great Britain

Taiwan

Czech Republic / Slovakia

Germany Italy

Poland

Table of contents

Other SMW Autoblok Industrial Equipment manuals

SMW Autoblok

SMW Autoblok W-215 User manual

SMW Autoblok

SMW Autoblok M30 IOL User manual

SMW Autoblok

SMW Autoblok VNK 70-37 Operation instructions

SMW Autoblok

SMW Autoblok Mario Pinto LT Operation instructions

SMW Autoblok

SMW Autoblok APS User manual

SMW Autoblok

SMW Autoblok ZHVD-SZ User manual

SMW Autoblok

SMW Autoblok KNCS-NB User manual

SMW Autoblok

SMW Autoblok SLX e-motion User manual