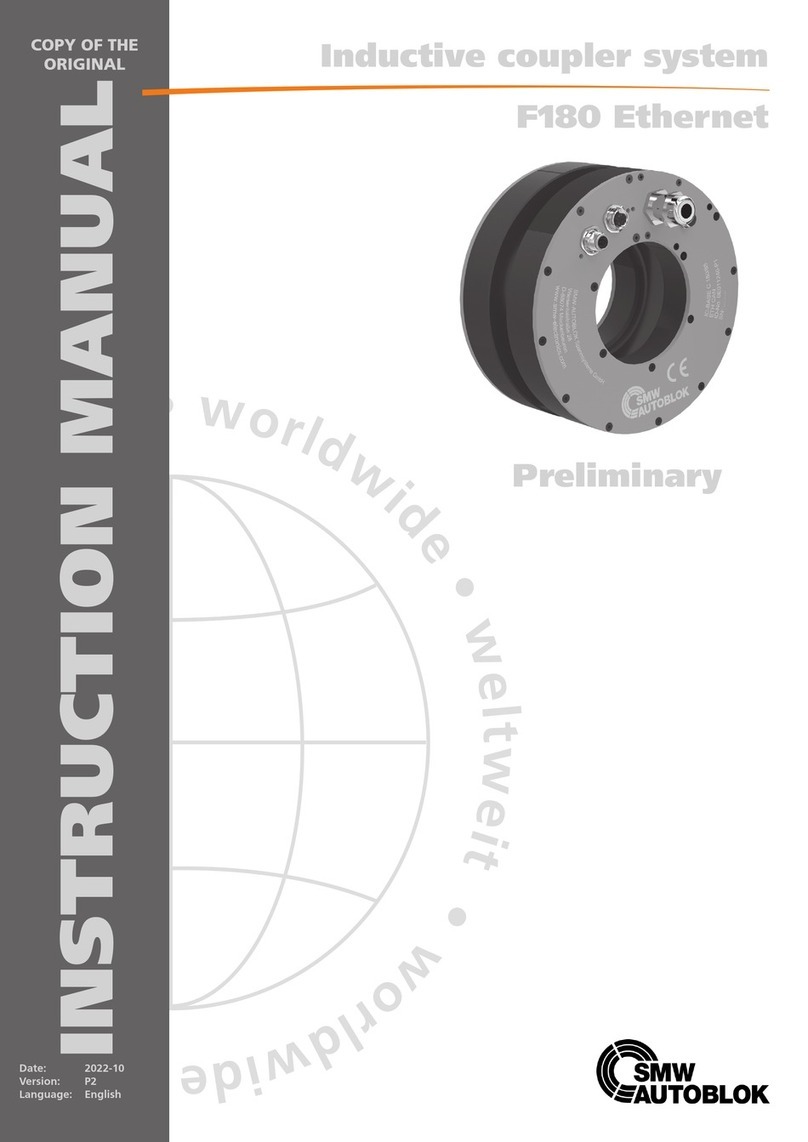

SMW Autoblok W-215 User manual

INSTRUCTION MANUAL

Date:

Version:

Language:

Type W

SHAFT CHUCK

COPY OF THE

ORIGINAL

2018-01

11

English

SMW-AUTOBLOK 3

4

5

6

7

8

10

10

10

10

11

12

13

14

15

15

16

17

19

20

20

20

21

25

31

32

38

39

40

42

45

INSTRUCTION MANUAL

Shaft chuck

Type W

Thank you for purchasing an Original-SMW-AUTOBLOK chuck

type W.

This instruction manual contains the installation, the use and the

maintenance instructions of the work holding „W“.

SMW-AUTOBLOK reserves the right to make changes without

notice.

This instruction manual is a part of the work holding and must

be passed to the new owner in case of sale.

This instruction manual may not be -in whole or in part- copied

without our written agreement.

Content

Please read the instruction manual carefully

before installation and use and always follow the

regulations.

Please note especially the sections which are

marked with the following signs:

• Danger of injury or danger to life if instructions

are not followed.

• Danger of damage to the work holding, the

machine or the components.

Overview

Declaration of incorporation

General safety instructions

Technical data

Ordering review

Description of function

Installation

Check the spindle flange adapter

Check draw tube position (chuck)

Mounting chuck size 215

Mounting chuck from size 260 up

Concentricity / adjustment of the chuck

Mounting the push rod / refilling the oil

Balancing

Operation

Mounting the face driver and jaws

Dismounting the face driver

Adjustment of the face driver

Checklist

Maintenance

Maintenance plan

Checking of oil level

Disassembling the chuck

Assembling the chuck

Views

Spare part list

Calculation formulas for practical use

Trouble shooting

Warranty 12 and 24 months

Documentation of maintenance

Confirmation of receipt of the manual

!

4 SMW-AUTOBLOK

W

29.12.2009

Eckhard Maurer

• DIN EN 1550 (2008)

• DIN ISO 13857 (2008)

Responsible for documentation:

SMW-AUTOBLOK Spannsysteme GmbH

Wiesentalstrasse 28

88074 Meckenbeuren

Deutschland / Germany

Schilling Rainer

Chief designer

Product description:

Application range:

Declaration of incorporation

for an incomplete machine

Machinery Directive 2006/42/EC, Annex II, B

Date:

is intended to be installed into a completed machine. It must not be put into service until the final machine into which

the partly completed machinery it is to be incorporated has been declared in conformity with the provisions of the EU

machine directive (2006/42/EC) Annex II, B.

Applied harmonized norms:

Installation in machine tool

The manufacturer:

herby declares, that the following product:

The following basic requirements of

Annex I, 2006/42/EC are complied with:

• No. 1, 1.1, 1.1.1, 1.1.2, 1.1.3

• No. 1.3.2, 1.3.3, 1.3.4, 1.3.7, 1.3.8

• No. 1.5, 1.6.1

• No. 1.7.1, 1.7.3, 1.7.4

The special technical documents have been created in accordance with Annex VII, Part B. These documents will be

made available electronically on a reasoned request by the national authorities.

Place: Meckenbeuren (Germany)

Declaration of incorporation

President

Type:

Shaft chuck

SMW-AUTOBLOK 5

!

In case of doubts or questions please ask SMW-AUTOBLOK or

one of our authorized offices.

11. Maintenance

The power chuck must be maintained at regular intervals. Check

the conditions by measuring the gripping force with a grip force

meter (e.g. GFT-X with head M4 for 6 jaws).

Replace damaged parts with original SMW-AUTOBLOK spare parts

only.

Maintenance must only be carried out at spindle stop of the

machine.

10. Residual risks

The type of components (shape, weight, unbalance, material

etc.) has a large influence on the system “machine tool - chuck -

component”. For that reason there is always a residual risk.

These residual risks must be considered by the user and must be

eliminated by suitable actions.

9. Crash / damages of the clamping chuck

In case of damage to the chuck, for example, after a collision, use

of wrong top jaws or actuation with unpermitted operating data

the chuck has to be returned immediately for safety reasons to

SMW-AUTOBLOK for inspection.

8. Actuating cylinder

The actuation of the chuck must only be carried out by suitable

cylinders in accordance with safety precautions and regulations.

When installing the chuck on the machine with an existing

cylinder, be sure that the actuating force of the cylinder does not

exceed the max. permitted actuating force of the chuck.

If necessary, reduce the actuating force of the cylinder. Connecting

and adapter parts must be specified for permanent load. Adjust

and check the proximity switches for the stroke control before

starting production.

The adjusted operating pressure / actuating force must be secured

against unauthorized change (for example with a lockable pressure

regulator).

7. Jaws

Always use original SMW-AUTOBLOK top jaws. Jaws of other

manufacturers can cause damage to the chuck or accidents.

SMW-AUTOBLOK top jaws are permanently marked with the max.

allowed actuating force F and the max. speed n.

These values must not be exceeded due to the danger of accidents!

Top jaws must be mounted with socket head cap screws of class

12.9 only. Tighten with the specified torque.

Always ensure sufficient length of thread engagement (min.

1.25 x thread dia.)!

The mounting bolts must be checked for damage and wear in

regular intervals, and have to be replaced if necessary. They have

to be replaced not later than after maximum 100000 clamping

cycles!

At reduced actuating force, the max. speed must also be reduced

accordingly!

6. Max. data for actuating force F and speed n

The data for maximum actuating force F and maximum spindle

speed n are engraved on the chuck body.

5. Safety precautions for the machine

• The machine spindle must only start if the hydraulic pressure

in the cylinder is fully reached and the component is clamped

within the permissible working range.

• Chuck can only be opened when the machine spindle is

stopped.

• A signal must stop the machine spindle in case of a failure of

the clamping pressure and the workpiece must remain safely

clamped until the machine spindle stops.

• Repowering after a power failure must not change the original

clamping mode.

• During machining, the chuck and the clamped component must

be protected by safety guards of the machine.

• Opening the machine door must be possible only when the

machine spindle is completely stopped.

• Maintenance and actuation of the chuck must only be carried

out when the machine spindle is stopped.

2. Demands on operators

SMW-AUTOBLOK chucks must be installed, operated and

maintained only by qualified and regularly trained personnel.

1. Correct use

SMW-AUTOBLOK chucks work safely and trouble free if they are

used according to their specifications i.e. to clamp components on

turning machines.

Any other use can be hazardous.

12. Environment protection

Danger for environment when handling incorrect!

Incorrect handling of environment hazardous materials, especially

the disposal, may result in environmental damage.

• Always follow below instructions.

• In case environmentally hazardous material polluted the

environment always take suitable actions immediately. If in

doubt, inform the local authority about the pollution.

The following hazardous materials are used: Lubricants such as oil

and grease can contain poisonous agents. They must not pollute

the environment. The disposal must be carried out by a suitable

waste management company.

For a proper function of the work holding, use original SMW-

AUTOBLOK lubricant only.

4. Transport

Please use suitable lifting gear for product heavier than 16 kg!

3. Visual inspection

Please check the product for visible damage prior to use!

General safety instructions

Englisch

Danger!

Danger to the environment!

General precept sign!

Follow the instructions! Warning of risk of crushing!

Warning of hand injuries!General warning sign!

Warning of suspended load!

!

!

!

!

!

6 SMW-AUTOBLOK

M=LN

UR

G1

S

G

H

d

b

B

ØC

ØA

G3

a2

a1

Z

h

h1

LN

U

R

M

P

G2

G1

G

ØH

ØE

T

ØS

ØD

W-215 W-260 W-325 W-460

A6 A8 A6 A8 A8 A11 A11 A15

A215 260 325 460

B176 211 238 213 285 251 344 309

CR92 R115 R143 R205

D145 175 220 335

E133.4 171.4 133.4 171.4 171.4 235 235 330.2

GM34 x 1.5 M33 x 1.5 M45 x 1.5 M85 x 2

G1M12 M16 M16 M55 x 2

G2M12 M16 M12 M16 M16 M20 M20 M24

G3M12 x 20 M16 x 24 M20 x 30 M24 x 45

H42 54 70 110

L55/40 20/5 96.5/51.5 121.5/106.5 106/91 140/125 119/104 154/139

M55/-4 20/-39 96.5/26.5 121.5/51.5 106/26.8 140/60.8 119/24.4 154/56.5

N30 42 42 42

P15.5 22 18 21 24 26 26 34

R30 45 50 50

Sf6 15 16.5 16.5 56.5

T22 29 46 60

U10 15 15 15

Z44 53 58 65

Z115 17 22 32.5

a1/a24.5°/1.5° 4.5°/1.3° 4.5°/1.3° 5°/2°

4.0/1.3 4.5/1.3 5.7/1.9 7.7/3.1

5.3 5.8 7.6 10.8

± 0.6 ± 1.0 ± 1.5 ± 3.3

30 36 44 52

65 78 96.5 150.5

50 57 72 88

0.25 0.50 0.75 1.50

0.50 1.00 1.50 3.00

5000 4000 3200 1800

30 55 75 100

60 110 150 200

0.236 0.271 0.639 0.606 1.872 1.734 9.35 8.91

40 45 75 70 140 127 364 336

W

Shaft chuck with retractable jaw carrier

Face driver

Shaft chuck Ø 215 - 460 mm

Piston of

W-215

* When exceeding distance h gripping force/speed must be reduced accordingly.

Subject to technical changes.

For more detailed information please ask our customer service.

SMW-AUTOBLOK Type

Mounting

Chuck outside dia.

Chuck height

In clamping position (radius)

Max. clamping dia.

Push rod face driver min./max.

Min./max.

Push rod pos. check dimension

Axial movement/jaw carrier

Piston stroke for jaw clamping

Opening/residual stroke angle

Opening/residual stroke at distance h1 h1

Max. jaw stroke at distance h* mm

Max. compensating / jaw Type C mm

b

d

Reference height h

Oil volume horizontal use l

Oil volume vertical use l

Max. speed r.p.m.

Max. draw pull kN

Max. grip force at reference distance h* kN

Moment of inertia kg·m2

Weight (without top jaws) kg

Englisch

Main dimensions and technical data

Request or

download:

www.smw-autoblok.de

JAWS-CATALOG

SMW-AUTOBLOK 7

W-215 W-260 W-325 W-460

A6 069930 069527

A8 069932 069444 069525

A11 069815 068981 069602

A15 069600

W-215 W-260 W-325 W-460

A6 069934 069542

A8 069936 069546 069552

A11 069817 069554 069606

A15 069604

W-215 W-260 W-325 W-460

ZHVD-SZ 68-17 110-25 110-25/240-40 240-40

044429 045297 045297/045298 045298

DCN 170-40/95-50

33705215

CGLP ISO VG 68

197859

SMW

AUTOBLOK

Oil: C GLP ISO VG 68

SMW

AUTOBLOK

Oil: C GLP ISO VG 68

W

Type C

Spindle

mounting

Type S

Spindle

mounting

Type

Double

piston cylinder

Id. No.

Id. No.

Oil for permanent oil bath lubrication

Oil specification

Contents 1 liter/1.05 quart (U.S.)

Id. No.

Shaft chuck with retractable jaw carrier

Face driver

Shaft chuck Ø 215 - 460 mm

Supply range:

Self centering clamping (Type S) chuck with mounting bolts and mounting keys, oil*

Actuating cylinder

Oil

* Attention:

The W-chucks in this ordering review are for the use of power operated face drivers only (Type 1).

To use face drivers with spring loaded center, a different chuck (Type 2) has to be used.

Please ask our engineers for the corresponding Id. No. and the matching cylinders.

Power operated face drivers and face drivers with spring loaded center cannot be used alternating on the same chuck.

Attention:

Shaft chuck for vertical machines on request.

Compensating clamping (Type C) chuck with mounting bolts and mounting keys, oil*

Supply range:

Englisch

Ordering review

8 SMW-AUTOBLOK

Description of function

Pushrod for face

driver Chuck piston

Stop bolt (3x) to refill oil in

vertical use (inverted spindle)

Oil fill plug

(horizontal position)

Oil refill plug for vertical

use

Plug for spring

Base jaw

Chuck body

Jaw carrier

Oil level control plug horizontal position

Oil level control plug only at

chucks for vertical use

Mounting key (from chuck size 260 up)Power operated face driver (Version Morse taper, only W-215 /

W-260) with fixed center

SMW-AUTOBLOK 9

W-215 W-260 W-325 W-460

< 0.6 mm < 1 mm < 1.5 mm < 4 mm

Description of function

The shaft chuck type W is available as a compensating or as a self

centering jaw version.

The shaft chuck type W has a retractable jaw carrier to allow

complete machining of shafts in one operation.

It is completely sealed and permanently lubricated by an oil bath.

The face driver is quick change with a taper for centering.

The chuck and the power operated face driver are actuated by a

double piston cylinder.

Conditions:

• The work pieces need to be faced and centered before loading

into to the chuck.

• Runout of the center bores to the clamping dia. can be max. (at

compensating jaw chuck).

The application: Complete machining of shafts in one setup

1. Machine clamping dia. (only necessary when using the self centering chuck):

The jaws are retracted. The component is clamped between centers and driven by the face driver. This operation can be eliminated if

the clamping dia. is already machined when the center bore is manufactured. This operation is not necessary when using the chuck

with fl oating jaws.

2. Rough machining:

The part is driven with the high gripping force of the jaws. High chip removal is possible.

3. Finish machining:

The chuck body is retracted. The part is clamped between centers and driven by the face driver. The complete outline can be

machined with perfect concentricity.

Chuck size

Center offset

10 SMW-AUTOBLOK

3B

3A

21

Installation

Check the spindle flange adapter

Check draw tube position (chuck)

Mounting chuck size 215

Draw bar position!

• The chuck is in a transport position with the jaw carrier

advanced, and the master jaws in a intermediate position.

Check the spindle nose!

• Spindle adapters need to be dialed in to these max. values.

Attention!

• For the chuck W-215, this alternative procedure is valid.

• This chuck size has a different method of installation not requiring the use of a mounting wrench.

• See fig. 3A and 3B only.

Preparation to install W-215

Connect the draw bar thread W-215

• Lift the chuck and position it concentrically in front of the

spindle.

• Remove all plugs with the spring packs from the chuck.

• Rotate the spindle by hand to connect the thread of the draw

bar and the thread of the chuck piston.

• The actuating cylinder has

to be in complete forward

end position (drawtube

fully extended); machine

signal “chuck clamped”.

Check!

• The max. drawpull of the cylinder must not exceed the allowed max. drawpull of the chuck!

• If necessary, drawpull must be reduced and locked to that value.

Confirm prior to installation

Check!

• All adapter parts must be designed for permanet use!

SMW-AUTOBLOK 11

3C

5

4

!

Installation

Mounting chuck from size 260 up

Preparation for installation W-260 / W-325 / W-460

• Lift the chuck and position it concentrically in front of the

spindle.

• Remove all plugs with the spring packs from the chuck.

• Lock the spindle against rotation.

• Screw the rotating drawnut of the chuck into the thread of the

drawbar with the mounting key.

Pull the chuck onto the spindle

• Match the bolt pattern of the chuck mounting bolts to the

threads in the spindle.

• Observe the position of the drive button!

• Switch on the hydraulic power unit of the machine and set it to

the lowest possible pressure.

• Pull the chuck towards the spindle with the lowest force

possible.

Attaching the chuck to the spindle

• Use the long mounting key that comes with the chuck to put

the mounting bolts into the chuck.

• Loosely tighten the mounting bolts.

• Switch on the hydraulic power unit again, and pull the chuck

completely onto the spindle.

Attention!

• Always use safe and appropriate lifting tools!

• Danger of damage!

• Do not cross thread!

• Never apply force!

• Never switch on the spindle drive!

12 SMW-AUTOBLOK

8

10

7

6

W-215 W-260 W-325 W-460

M12 M16 M20 M24

125 250 400 500

W-215 W-260 W-325 W-460

35 35 35 65

9

Installation

Concentricity

Adjustment of the chuck

Insert the plugs with the springs

Attention!

• To dial in the chuck use the lowest actuating pressure possible for the cylinder.

Only low forces must act onto the chuck!

Check the chuck for concentricity

• Position the dial indicator at the outer rim of the body, and

check the chuck for concentricity.

Dial in the chuck

• Adjust in the chuck carefully with a rubber mallet.

TR should be = < 0.005

Mounting the chuck

• Tighten the mounting bolts of the chuck with the correct torque

one after another, after checking the concentricity (pic. 10).

Use the hexogonal bit that comes with the chuck.

• After that double check the concentricity.

• For best concentricity the torque for the individual mounting

bolts can be varieted.

Chuck size

Bolt

Torque (Nm)

Chuck size

Torque (Nm)

Locking the radial chuck runout

• Tighten the locking set screws for the taper locking system.

• Double check the concentricity.

SMW-AUTOBLOK 13

11

12A

215 260 325 460

~250 ml ~500 ml ~1.000 ml ~1.500 ml

~500 ml ~1.000 ml ~1.700 ml ~3.000 ml

W-215 W-260 W-325 W-460

22 29 46 60

20 85 85 85

215 260 325 460

~ 350 ml ~1.700 ml

12B

Installation

Mounting the push rod

Refilling the oil

• Mount the push rod to actuate the face driver with a suiltable

torque wrench. Observe the checking dimension T (see technical

details dim. T) from the front face of the push rod to the front

face of the chuck body. This must be measured with the small

piston of the double piston cylinder in its completet forward

end position.

Oil level control plug

horizontal position

Oil refill plug

horizontal position

Stop bolt (3x) to refill oil

in vertical use (inverted

spindle)

Mounting push rod

Filling the chuck with oil (horizontal, vertical use, inverted spindle)

Refilling of oil (vertical use; the chuck is a special vertical version with an additional oil level control plug)

• Fill the chuck with the oil supplied with the jaw carrier in the

retracted position, the cylinder in the rear position and with the

push rod installed.

• To refill oil put jaw No. 3 in 9.00 O`clock position (on horizontal

machines).

• Oil type: CGLP ISO VG 68

• Oil recommended by SMW-AUTOBLOK: Castrol Gleitbahnöl

Magnaglide D68

Chuck size

Oil qty.

(horizontal)

Oil qty. (vertical use,

inverted spindle)

Chuck size

Dimension (mm)

Torque (Nm)

• Remove one spring pack in position „chuck open“ (chuck piston and jaw carrier retracted

in left end position).

• Close the chuck (Jaws closed and jaw carrier in forward right end position), and fill in oil

according to the table, until oil flows out from the oil control plug.

• Open the chuck again, and install the spring pack again.

Oil control plug vertical use

Chuck size

Oil qty.

(vertical use)

on

request

on

request

Attention!

Information for oil level check can be found on page 20.

Attention!

Information for oil level check can be found on page 21.

14 SMW-AUTOBLOK

W-215 Ø14.0 = 0.6 g Ø16.2 = 0.8 g 13 g 117 g

W-260 Ø14.0 = 0.6 g Ø16.2 = 0.8 g 17 g 153 g

W-325 / W-460 Ø16.2 = 0.8 g Ø20.5 = 2.6 g 39 g 351 g

Installation

Balancing

Balancing weight chambers (9x)

Plug

• For high demands of accuracy and surface quality the chuck must be fine balanced after installation.

• Balancing only with the jaw carrier retracted!

• The chuck has 9 balancing weight chambers equaly spaced arround the jaw carrier.

• The balancing weight chambers are filled with washers.

• Check the imbalance of the chuck with a suitable balancing unit.

• Eliminate the imbalance measured by removing washers accordingly.

• Put a little grease into the chamber after removing the washers to eliminate rattling.

Weight per washer Weight per chamber Total weight

SMW-AUTOBLOK 15

3

2

1

W-215 W-260 W-325 W-460

M12 M16 M20 M24

100 200 400 500

Operation

Mounting the face driver

Attention!

• Always use a torque wrench.

• Original SMW-AUTOBLOK top jaws have capture bolts.

• Clean the mounting faces of the master jaws and the top jaws

thorougly. When bolting the top jaws to the master jaws the

spring loaded pin in the master jaw automaticly pushes the top

jaw against the radial location shoulder.

• Allways observe correct seating of the top jaws on the master

jaws.

Face driver (Version Morse taper)

• Clean the inside taper of the chuck and the outside taper of the

face driver thoroughly.

Even smallest particles can cause runout!

• Do not oil the taper!

• Mount the face driver to the chuck using the mounting

wrench that comes with the chuck. Observe the position of

the orientation slot. Tighten the locking nut with the mounting

wrench.

• Reachable runout on the center point 0.02mm TIR!

Mounting the face driver (Version Morse taper)

• To achive a perfect concentricity use a work piece to push

against the face driver using the force of the tailstock. After that

manually retighten the locking nut with the mounting wrench.

Do not use a hammer or extensions.

Mounting the top jaws W-215 / W-260 / W-325 / W-460

Mounting the face driver (Version Morse taper) and the top jaws W-215 / W-260

Chuck size

Bolt

Torque (Nm)

16 SMW-AUTOBLOK

2

1

Operation

Dismounting the face driver

Dismounting the face driver (Version Morse taper) W-215 / W-260

Face driver (Version Morse taper)

To remove the face driver, first remove the top jaws.

• Use the mounting wrench to open the locking nut.

• In order to help guid the mounting wrench, the jaw carrier can

be brought into its forward, end position.

Face driver and guide sleeve (Version Morse taper)

• In order to have a better guide for the wrench, especially when removing the face driver, use the guide sleeve on the outside dia. of

the face driver.

• The ID of the sleeve matched to the OD of the corresponding face driver.

Face driver

Guide sleeve

Wrench

SMW-AUTOBLOK 17

1

2

W-215 W-260 W-325 W-460

M6 M6 M8 M10

15 15 36 72

!

Operation

Adjustment of the face driver

(Standard)

Face driver (Version short taper not adjustable)

Standard: Mounting of the face driver: Version short taper, radialy not adjustable

(Radialy not adjustable = short taper of the face driver with tight fit to the short taper of the chuck for self centering installation)

Cover wedge

Power operated drive pin

Capture mounting bolts Removable center

Mounting of the face driver (Version short taper not adjustable)

• Tighten the bolts alternately. Double check the concentricity.

• Reachable runout on the center point 0.02mm TIR!

Chuck size

Bolt

Torque (Nm)

Attention!

• Danger of injury! Cover the driving pins / centerpoint or use suitable protection gloves when changing the face driver!

18 SMW-AUTOBLOK

4

2

3

1

W-215 W-260 W-325 W-460

M6 M6 M8 M10

15 15 36 72

!Attention!

• Do not overtighten the bolts of the locking wedges. The bolts can break! The face driver will be locked in the chuck!

• Danger of injury! Cover the driving pins / centerpoint or use suitable protection gloves when changing the face driver!

Face driver (Version short taper adjustable)

• Insert the face driver into the chuck and loosely tighten the

mounting bolts.

Option: Mounting and adjusting of the face driver: Version short taper, radialy adjustable

(Radialy adjustable = short taper of the face driver with clearence to the short taper of the chuck for manual radial fine adjustment)

Mounting and adjusting of the face driver (Version short taper adjustable)

• Check the runout of the center point with a dial indicator.

Adjust the runout by using a rubber mallet.

TIR=< 0.005 mm (Only when using the version for an adjustable

face driver).

Mounting and adjusting of the face driver (Version short taper adjustable)

Locking wedge

Power operated drive pin

Capture mounting bolts Removable center

Mounting and adjusting of the face driver (Version short taper adjustable)

• Tighten the bolts alternately. Double check the concentricity.

• Insert the locking wedges and tighten with max. 3.5 Nm torque.

Double check the concentricity.

Chuck size

Bolt

Torque (Nm)

Operation

Adjustment of the face driver

(Optional)

SMW-AUTOBLOK 19

Checklist

Before starting production check the following:

Top jaws

• Are the mounting bolts of the top jaws tightened properly?

• Retighten the mounting bolts with a torque wrench if needed!

• Does the clamping diameter of the jaws match the work piece dia.?

• Is there enough residual jaw stroke?

Clamping pressure

• Does the hydraulic pressure and the resulting grip force match the data engraved on the top jaws?

• Never exceed the values stated on the top jaws!

Speed

• Does the max. speed in the CNC program match the max. speed engraved on the top jaws?

• Never exceed the values stated on the top jaws!

Face driver

• Is the concentricity of the center point of the face driver correct?

• Is the locking nut tightened correctly?

• Retighten if necessary.

Imbalance

• Is there any vibration caused by imbalance?

• Increase the spindle speed to machining speed in small increments and eliminate imbalance if needed.

Operation

Checklist

20 SMW-AUTOBLOK

•

•

•

•

•

•

215 260 325 460

~ 250 ml ~ 500 ml ~ 1000 ml ~ 1500 ml

~ 500 ml ~ 1000 ml ~ 1700 ml ~ 3000 ml

100 ml 200 ml 400 ml 800 ml

Maintenance

Maintenance plan

Checking of oil level

Attention!

• Regular maintenance is important for the safe function, long lifetime, precision and grip force of the chuck.

• Check the grip force of the chuck regularly with the SMW-AUTOBLOK GFT-X grip meter!

• Do not use any liquids that can damage or destroy the chuck seals!

• Make sure the coolant used will not damage or destroy the chuck seals!

Maintenance plan

* Advice for checking method: At lowest hydraulic pressure possible, the jaw carrier and the master jaws must move smoothely

without chattering.

Checking of oil level (horizontal and vertical use)

Refill oil (on horizontal machines)

1. Bring the oil refill plug to the12.00 O`clock position.

Jaw No. 3 will be in 9.00 O`clock position.

2. Open the oil refill and the oil level control plug.

3. Refill oil (CGLP ISO VG 68) until it flows out from the oil control

plug port.

4. Close the oil refill and the oil level control plug.

Attention!

Checking the oil level must be carried out only when the jaw

carrier is fully retracted!

Refill oil (on vertical machines with inverted spindle)

1. Open one (only one out of the 3) stop bolts.

2. Refill oil (CGLP ISO VG 68) until it flows out from the oil refilling

plug port (bottom edge of port).

3. Close the stop bolt port.

Oil level control plug horizontal

position

Oil fill plug

horizontal position

Jaw 3 in 9:00

o‘clock position

In 12:00 o‘clock position

Stop bolt (3x) to refill oil

in vertical use (inverted

spindle)

Attention!

• Wear of the seals can increase normal oil consumption!

• In case the refill volume exceeds the max values in the table below, the chuck must be checked and the seals must be changed.

daily weekly monthly yearly

Visible leakage

Oil level check / refill oil

Measuring of grip force

Cleaning outside

Check jaw carrier and master jaws for smooth movement *

Revision consisting of: Disassembling the chuck, Changing all seals and

wear parts, Checking for cracks, Refilling with fresh oil

Chuck size

Oil qty. (horizontal)

Oil qty. (vertical use, inverted spindle)

Max. oil consumtion / refill volume

This manual suits for next models

3

Table of contents

Other SMW Autoblok Industrial Equipment manuals

SMW Autoblok

SMW Autoblok F180 User manual

SMW Autoblok

SMW Autoblok Mario Pinto LT Operation instructions

SMW Autoblok

SMW Autoblok VNK 70-37 Operation instructions

SMW Autoblok

SMW Autoblok M30 IOL User manual

SMW Autoblok

SMW Autoblok ZHVD-SZ User manual

SMW Autoblok

SMW Autoblok KNCS-NB User manual

SMW Autoblok

SMW Autoblok APS User manual

SMW Autoblok

SMW Autoblok SLX e-motion User manual