9. Pre-operational Inspection

Pre-operational Inspection Table ..........9-1

Engine Cover..........................9-2

Engine Fuel Level ......................9-2

Fuel Tank Cap.........................9-2

Fuel Leaks............................9-2

Engine Oil Level .......................9-2

Wiring Harnesses ......................9-2

Battery Terminals ......................9-2

Battery Fluid Level......................9-3

Hydraulic Oil Level .....................9-3

Hydraulic Oil Leaks .....................9-3

Bolts and Fasteners ....................9-3

Wheels and Tyres ......................9-4

Structural Damage and Welds ............9-4

Lanyard Anchor Points ..................9-4

Platform Gravity Gate ...................9-5

Platform Guardrails .....................9-5

Flashing Light (option)...................9-5

Ground Control Switches

Machines with Electric Controls ...........9-5

Emergency Lower

Machines with Electric Controls ...........9-6

Lower control box .....................9-6

Upper control box .....................9-6

Platform Control Switches

Machines with Electric Controls ...........9-6

Ground Control Switches

Machines with Hydraulic Controls ..........9-7

Emergency Lower

Machines with Hydraulic Controls ..........9-7

Lower control station...................9-7

Upper control station...................9-7

Platform Control Switches

Machines with Hydraulic Controls ..........9-8

AC Outlet RCD/ELCB (option) ............9-9

LV Insulated MHP15/44HD ...............9-9

Insulation Covers .....................9-9

Fibreglass Basket .....................9-9

Boom insulation Covering ...............9-9

Cleanliness ..........................9-9

Placards and Decals ....................9-9

Placards and Decals

Machines with Electric Controls ...........9-9

Standard placards and decals ...........9-9

Placards and Decals

Machines with Hydraulic Controls ..........9-9

Standard placards and decals ...........9-9

Placards and Decals

Low Voltage Insulated Machines ..........9-9

Standard placards and decals ...........9-9

Decal list

machines with electric controls ..........9-10

Decal inspection drawing

machines with electric controls ..........9-11

Decal list

machines with hydraulic controls ........9-12

Decal inspection drawing

machines with hydraulic controls ........9-13

Decal list

low voltage insulated machines .........9-14

Decal inspection drawing

low voltage insulated machines .........9-15

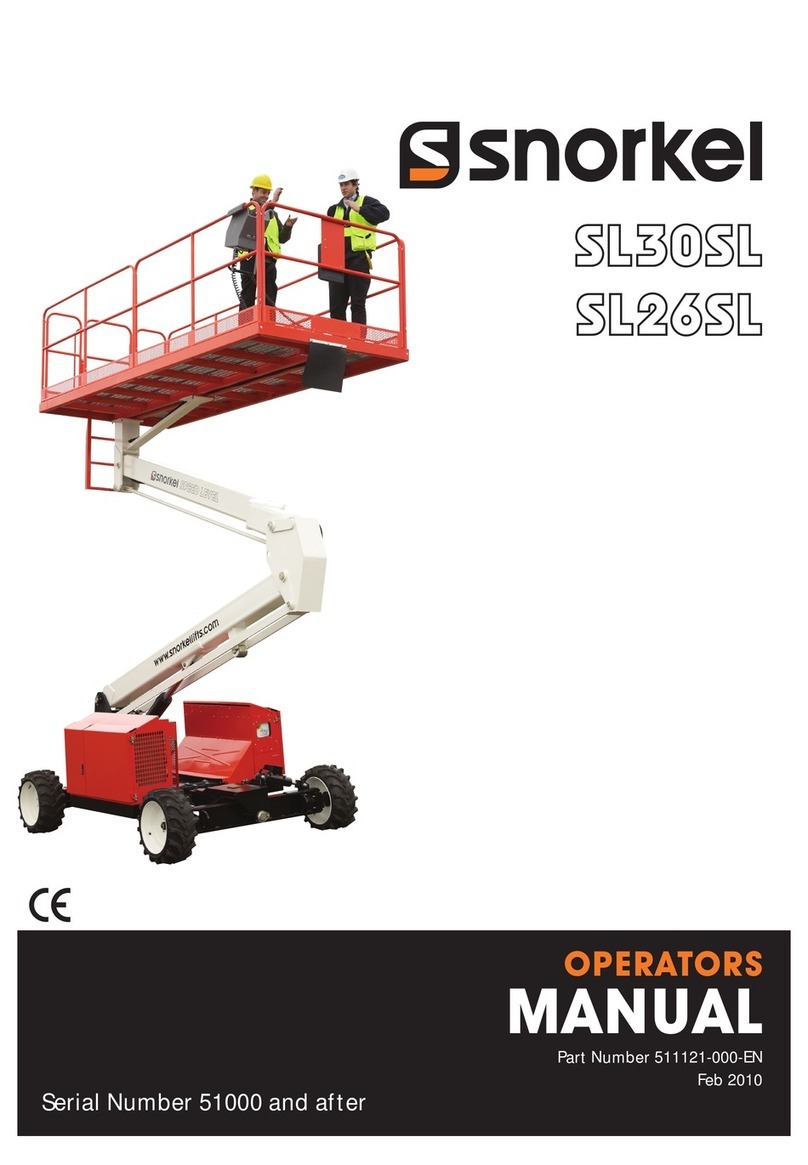

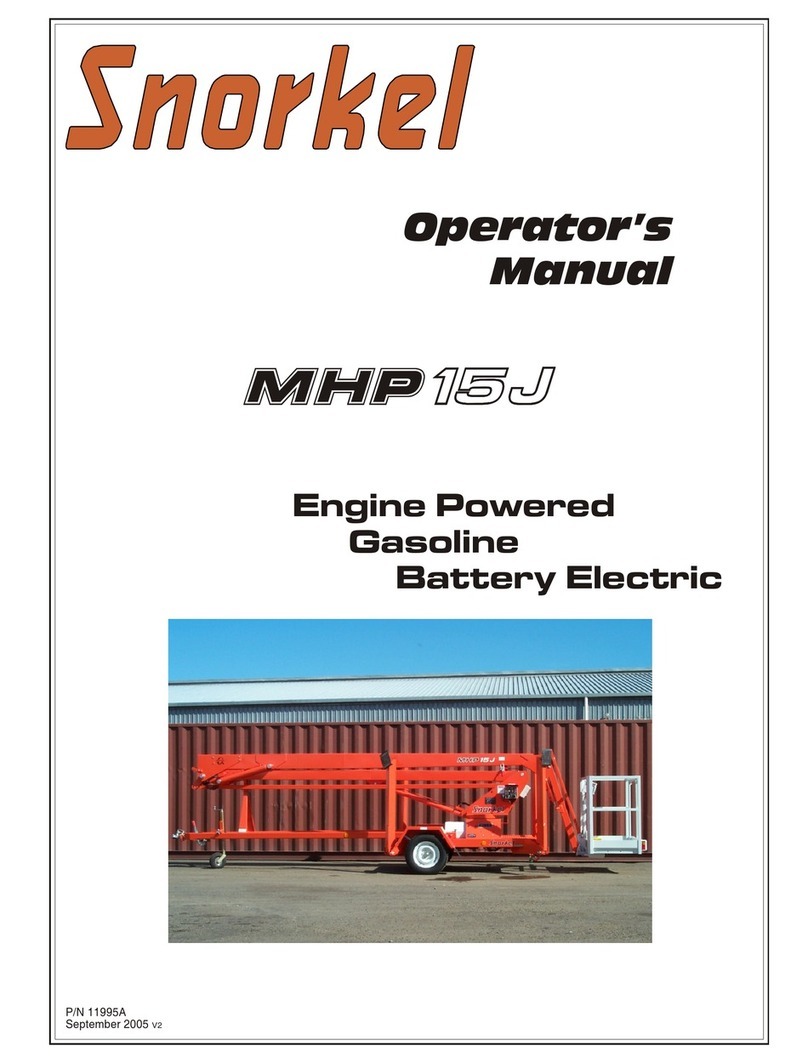

10. Operation

Operating Procedures ..................10-1

Control Stations.......................10-1

Emergency Stopping ...................10-1

Emergency Stopping

Machines with Electric Controls ..........10-1

Emergency Stopping

Machines with Hydraulic Controls .........10-1

Operation Considerations ...............10-2

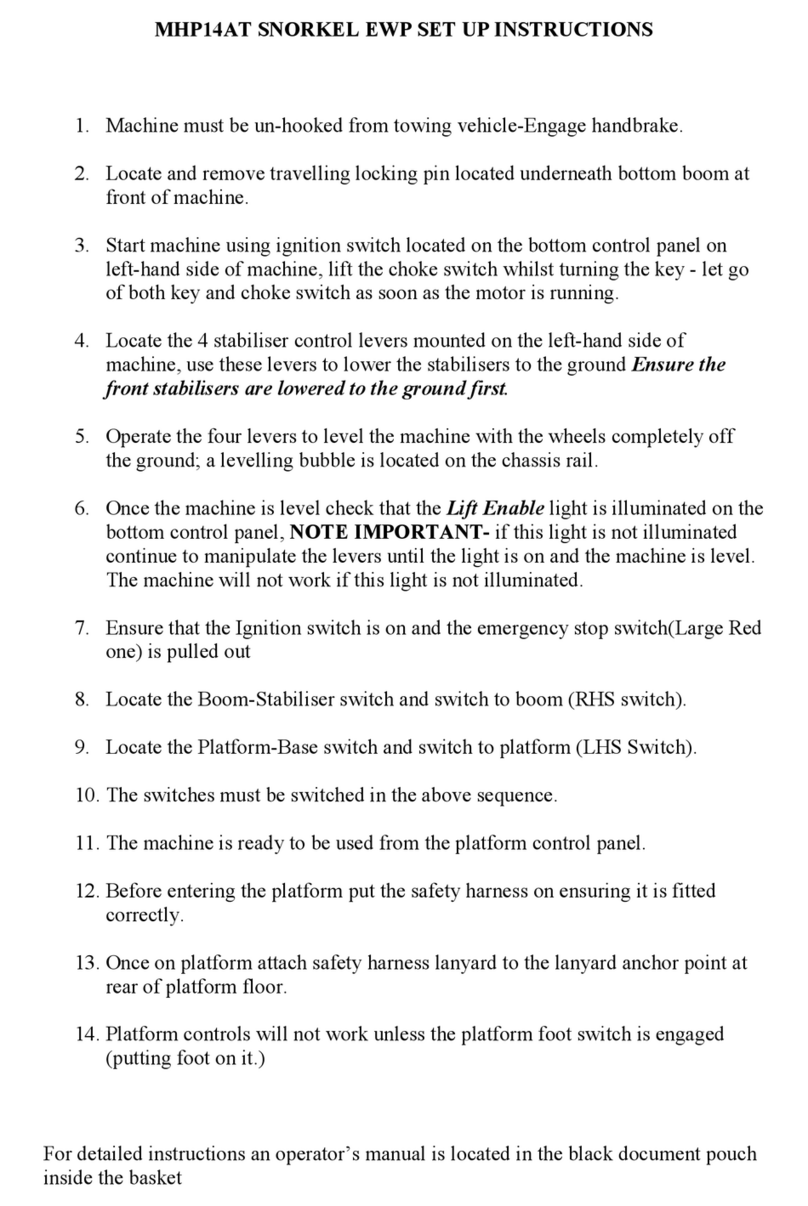

Stabiliser Operation....................10-2

Using the manual stabiliser valves .......10-2

Raising the manually operated stabilisers .10-3

Self levelling stabilisers (Optional) ........10-3

Setting the stabilisers manually .........10-3

Unlocking the booms...................10-3

Starting From Ground Control Box

Machines with Electric Controls ..........10-4

Starting From Platform Control Box

Machines with Electric Controls ..........10-4

Moving The Platform

Machines with Electric Controls ..........10-5

From ground control box...............10-6

From platform control box ..............10-6

Starting From Ground Control Box

Machines with Hydraulic Controls .........10-7

Moving The Platform

Machines with Hydraulic Controls .........10-8

From ground control box...............10-8

From platform control box ..............10-8

Over-Centre valve .....................10-9

Securing for Day .....................10-9

11. Emergency Operation

Emergency Operation Procedures ........11-1

Emergency Operation Procedures

Machines with Electric Controls ..........11-1

Operation from platform control box ......11-1

Operation from ground control position ...11-2

Emergency Operation Procedures

Machines with Hydraulic Controls .........11-2

Operation from platform control station ...11-2

Operation from ground control station ....11-3

page - viii MHP15/44HD – 12885A

Table of Contents