Socket & See MFT5000 User manual

Table of contents

Other Socket & See Test Equipment manuals

Socket & See

Socket & See FFCB 100 User manual

Socket & See

Socket & See RCD PRO User manual

Socket & See

Socket & See PDL 234Plus User manual

Socket & See

Socket & See PDIT 360 User manual

Socket & See

Socket & See DIT 400 User manual

Socket & See

Socket & See VVD PRO User manual

Socket & See

Socket & See DRC430 User manual

Socket & See

Socket & See PDL PRO User manual

Socket & See

Socket & See SP200 User manual

Socket & See

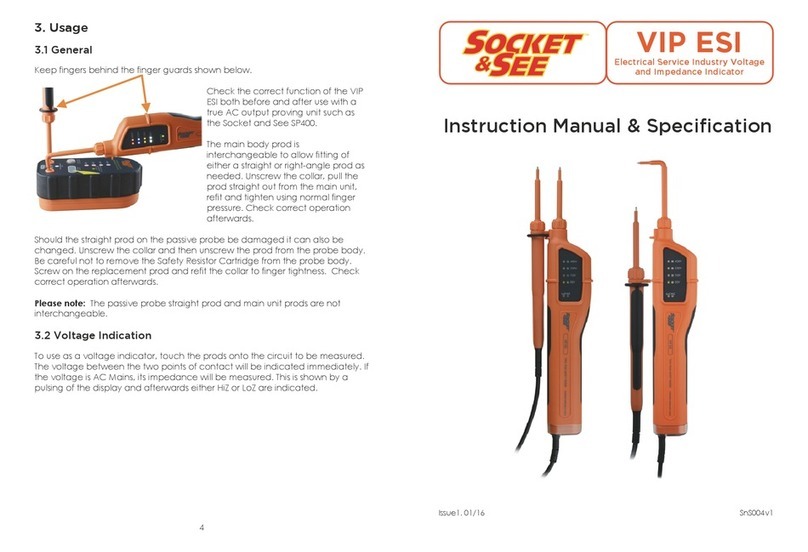

Socket & See VIP ESI User manual

Popular Test Equipment manuals by other brands

Tektronix

Tektronix 3B4 instruction manual

National Instruments

National Instruments PXIe-5160 Getting started guide

Tektronix

Tektronix 4 Series Declassification and security instructions

Icel Manaus

Icel Manaus TR-5300 manual

MARTINDALE

MARTINDALE PC104 instruction manual

Conrad

Conrad Nano V3 operating instructions

Adeunis RF

Adeunis RF LoRaWAN Europe EU863-870 user guide

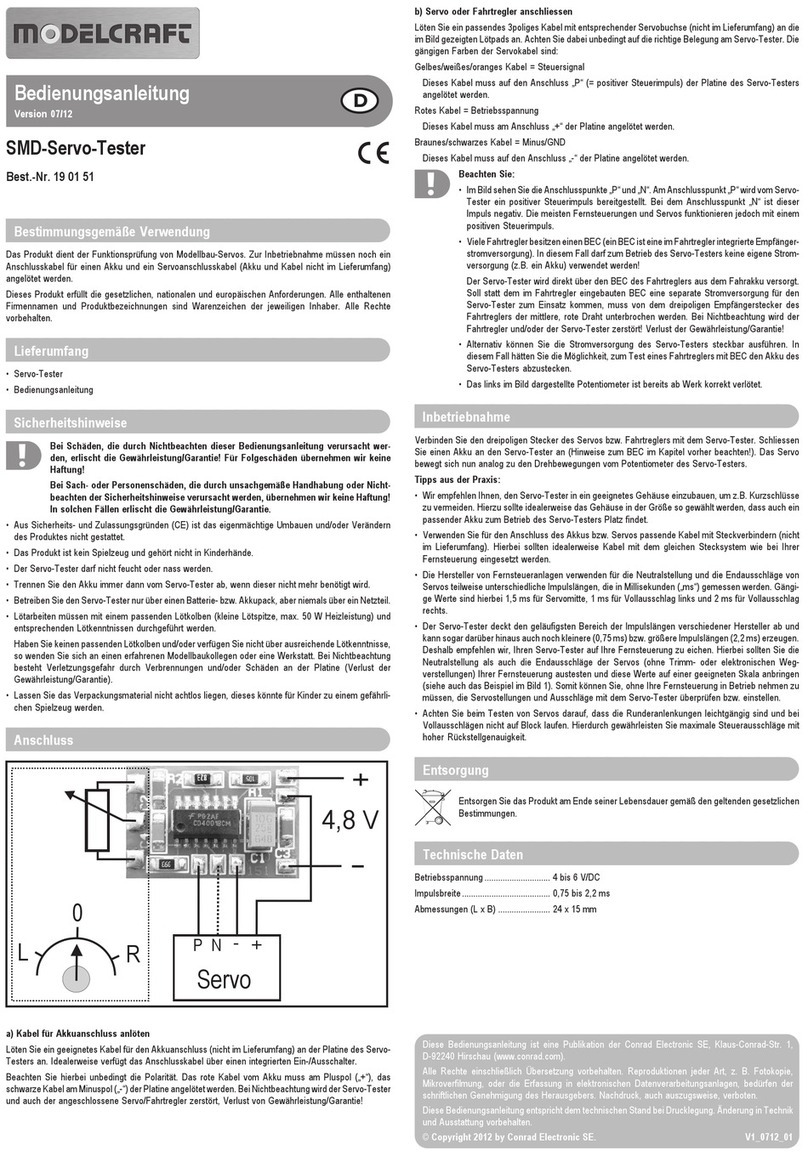

ModelCraft

ModelCraft 19 01 51 operating instructions

IET Labs

IET Labs PRS-200 Series Operation manual

Sanyo Denki

Sanyo Denki San Ace 9AT2560 Series instruction manual

Atlas Copco

Atlas Copco STbench System Overview Manual

PCE Instruments

PCE Instruments PCE-RTD 20 user manual