SODECA VSD/A Instruction sheet

Code: 1127947

Doc. Num: 0000003909 (2016-05-06)

VSD/A

ES

EN

Wiring and Configuration Manual

Convertidor de Frecuencia

Variable Frequency Drive

Conversor de frequência

IP20 & IP66 (NEMA 4X)

0.37 – 22Kw (0.5 – 30HP)

110 – 480V

www.sodeca.com

PT

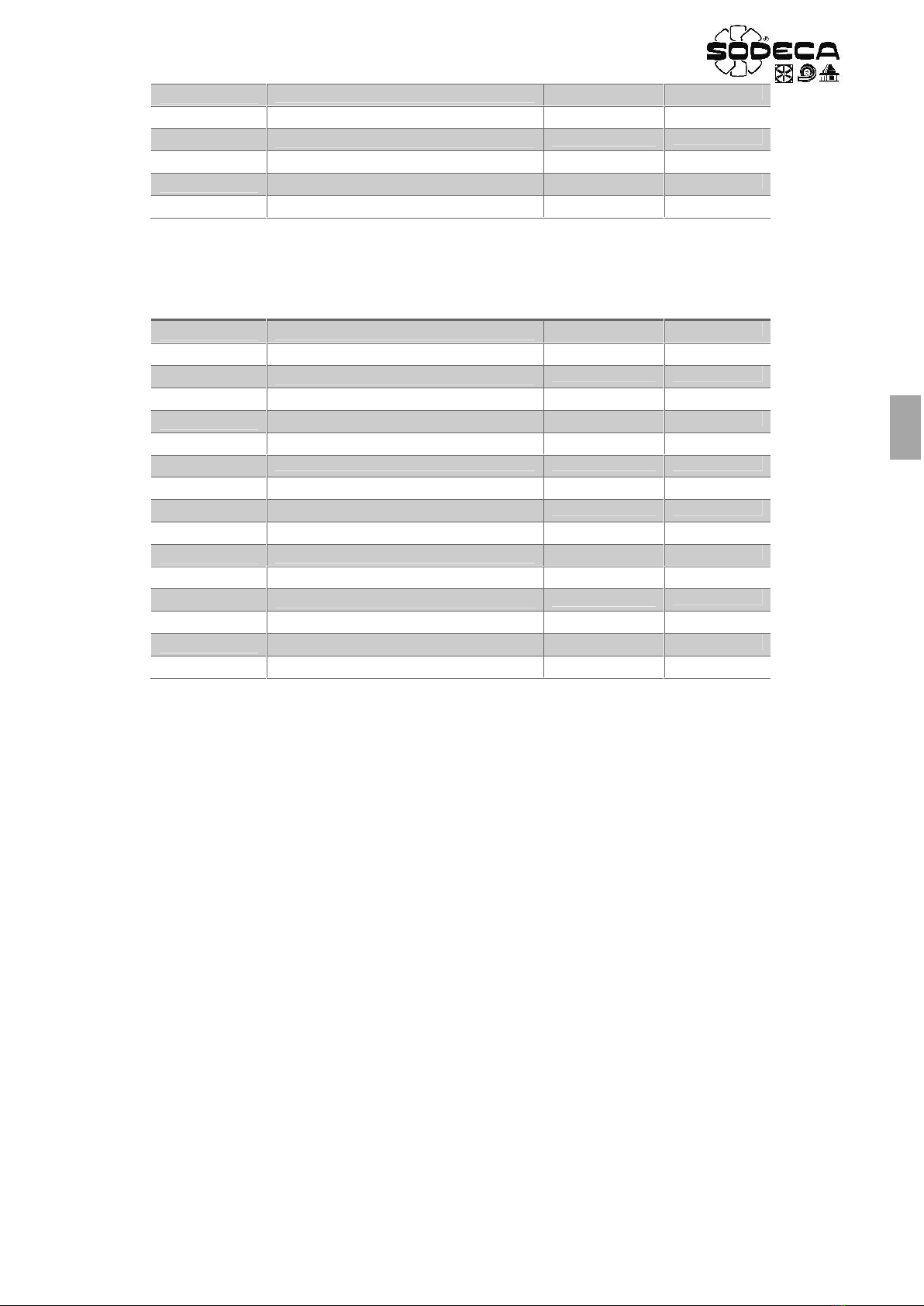

Fig. 6

Fig. 9

VSD/A

Fig. 11

A

ES

Transmisor de presión diferencial SI-PRESIÓN TPDA

EN

Differential pressure transmitter SI-PRESIÓN TPDA

PT

Transmissor de pressão diferencial SI-PRESIÓN TPDA

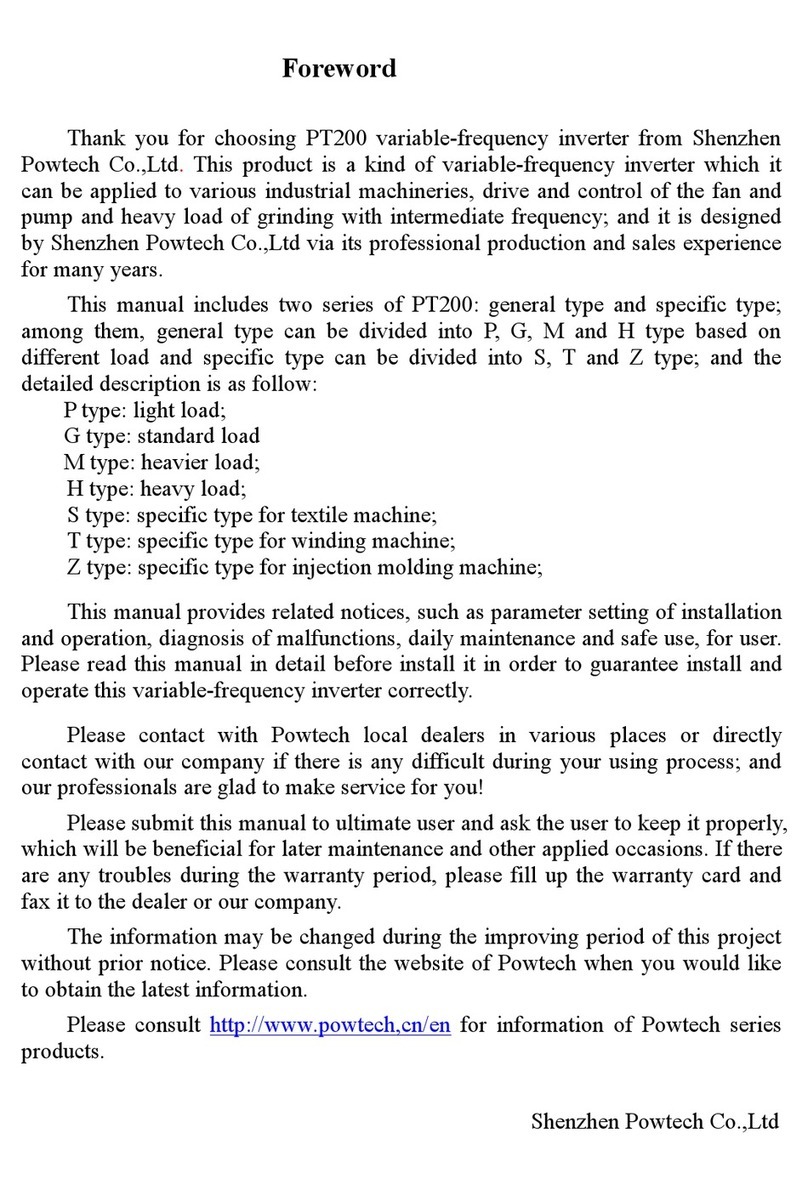

JP5

JP1

TERMINAL 1

TERMINAL 2

ES

Escala de medida sonda

Tipo de salida analógica

Salida analógica y bus

Alimentación sonda

EN

Measuring probe scale

Analog output type

Analog output and bus

Power supply probe

PT

Escala de medida da sonda

Tipo de saída analógica

Saída analógica e bus

Alimentação da sonda

Fig. 13

*Note 1

ES

Las unidades de medida pueden cambiarse solo con el jumper 5 instalado. Elimine el jumper al terminar

EN

The measurement units can be changed only with the jumper 5 installed. Remove the jumper at the end.

PT

As unidades de medida apenas podem ser alteradas com o jumper 5 instalado. Elimine o jumper ao terminar

Outlet

Inlet

1

EN

INDEX

WARNINGS 2

INTRODUCTION TO COMMON OPERATIONS WITH THE VSD*/A 2

AP1. BASIC CONFIGURATION – Drive control using the keypad – VSD1-D, VSD3-D 3

1.1 PROGRAMMING 3

1.2 WIRING 3

1.3 “BASIC CONFIGURATION” OPERATION MODE 3

AP2. EXTERNAL KIT MODE – Manipulate with the mtp 010 remote control 4

2.1 PROGRAMMING 4

2.2 WIRING 4

2.3 “EXTERNAL REMOTE CONTROL KIT” OPERATION MODE 4

AP3. MIXED MODE – External start, speed adjustment with the internal keypad. 5

3.1 PROGRAMMING 5

3.2 WIRING 5

3.3 “MIXED” OPERATION MODE 5

AP4. FIRE MODE WITH NO OR NC ACTIVATION SIGNAL – Preset speeds 6

4.1 PROGRAMMING 6

4.2 WIRING 7

4.3 “FIRE MODE with Preset Speeds” OPERATION MODE 7

AP5. FIRE MODE WITH NC ACTIVATION SIGNAL – Analog speed/potentiometer 8

5.1 PROGRAMMING 8

5.2 WIRING 8

5.3 “FIRE MODE with Analog Speed” OPERATION MODE 8

AP6. FIRE MODE + CO WITH NO OR NC ACTIVATION SIGNAL – Preset speeds 9

6.1 PROGRAMMING 9

6.2 WIRING 10

6.3 “FIRE MODE + CO with preset speeds” OPERATION MODE 10

AP7. CO2 MODE 11

7.1 PROGRAMMING 11

7.2 SETPOINT ADJUSMENT OF THE CO2 CONCENTRATION 12

7.3 WIRING 12

7.4 PROBE SI-CO2 IND CONFIGURATION 12

7.5 “CO2” OPERATION MODE 12

AP8. TEMPERATURE MODE 13

8.1 PROGRAMMING 13

8.2 PROBE SI-TEMP IND CONFIGURATION 13

8.3 SETPOINT ADJUSMENT OF THE CO2 CONCENTRATION 14

8.4 WIRING 14

8.5 “TEMPERATURE” OPERATION MODE 14

AP9. PRESSURE CONTROL MODE – VSD1-P, VSD3-P 15

9.1 PROGRAMMING 15

9.2 PRESSURE SETPOINT ADJUSTMENT 15

9.3 WIRING 16

9.4 PROBE SI-PRESSURE TPDA CONFIGURATION 16

9.5 “PRESSURE CONTROL” OPERATION MODE 16

2

EN

WARNINGS

The AC Variable Speed Drives (VSD*/A) supplied by SODECA are meant to be handled using the keypad, see “BASIC

CONFIGURATION” section. Other control ways are possible with simple and quick adjustments. Some of them are

explained in this guide. This guide is a summary from the complete VSD*/A guidebook and is meant to help with the

equipment’s installation and start-up of its most common operations. If the user’s needs aren’t properly fitted with any of the

operation modes found in this guide check the Installation and Operation Manual of the VSD/A (download it on

sodeca.com), or contact with our technic support SODECA.

It is recommended to read all the security information and obligations/recommendations that are instructed in the VSD*/A

User Guide. This is an instructive guide about the applications and does not replace the complete guide, it’s an addition. It

is the user responsibility to apply all the required measures needed for the correct installation and programming of the

VSD*/A as instructed in the user guide.

INTRODUCTION TO COMMON OPERATIONS WITH THE VSD*/A

The family of the AC Variable Speed Drive (from now on, “Drive”) is well-known for its easy and quick configuration, as

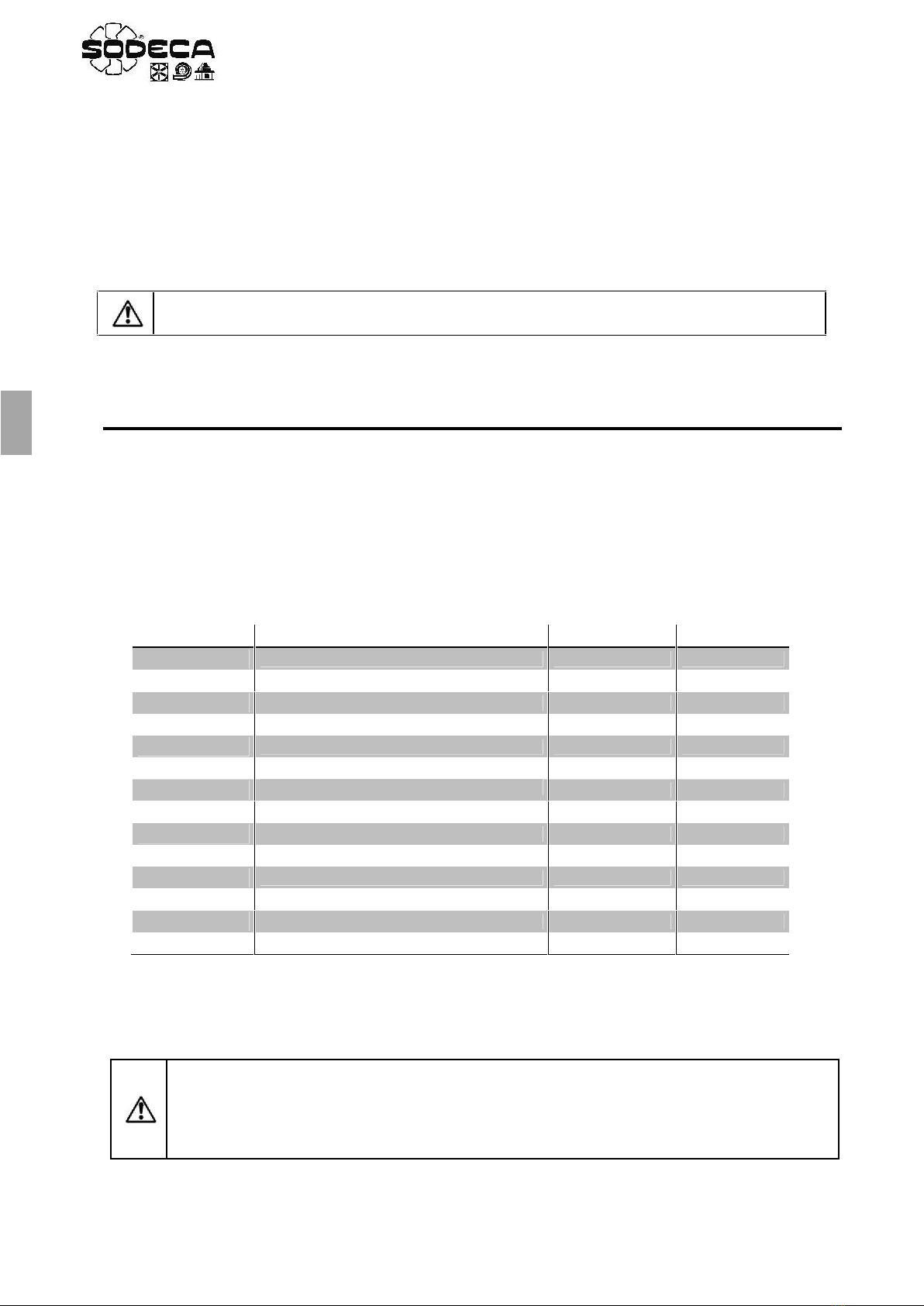

shown in the table below. Before the start of the programming or the start up, it is important to read carefully this page and

learn the four most common actions that the user may use during the adjustment process and start up.

In the next section it’s explained with detail the most common applications in a concise and practical way, which will make

the start up last only a few a minutes.

3

EN

AP1. BASIC CONFIGURATION – Drive control using the keypad – VSD1-D, VSD3-D

The AC Variable Speed drives (VSD*/A) supplied by SODECA are meant to be handled using the keypad.

This section explains how to configure the “BASIC CONFIGURATION” control mode. This basic control mode allows

to start and stop the drive using its keypad, START y STOP keys, and change the rotation speed of the motor

with the y keys, without using the exterior control KIT.

1.1 PROGRAMMING

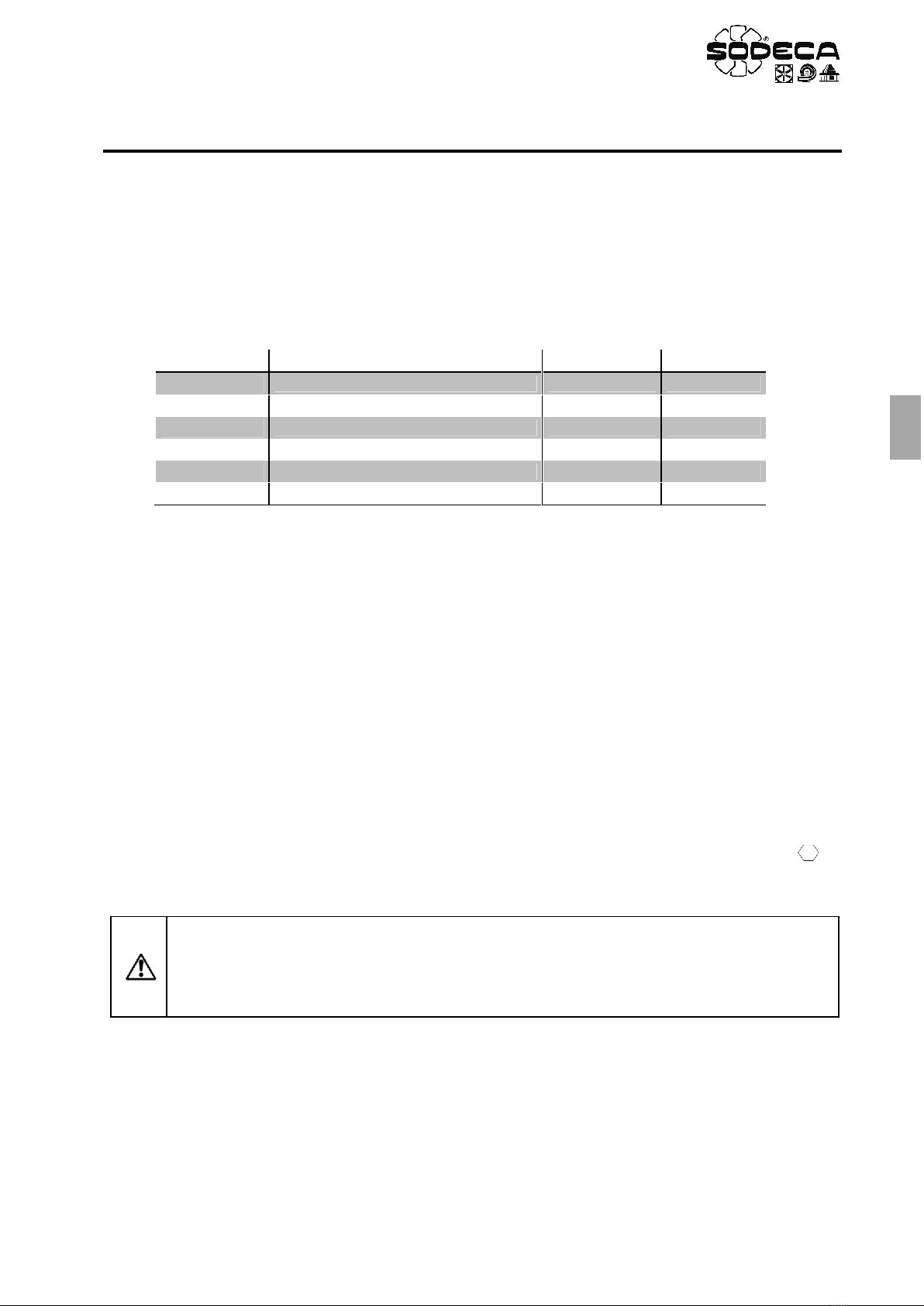

Use the next table to change to the basic configuration mode.

Table “BASIC CONFIRGURATION”

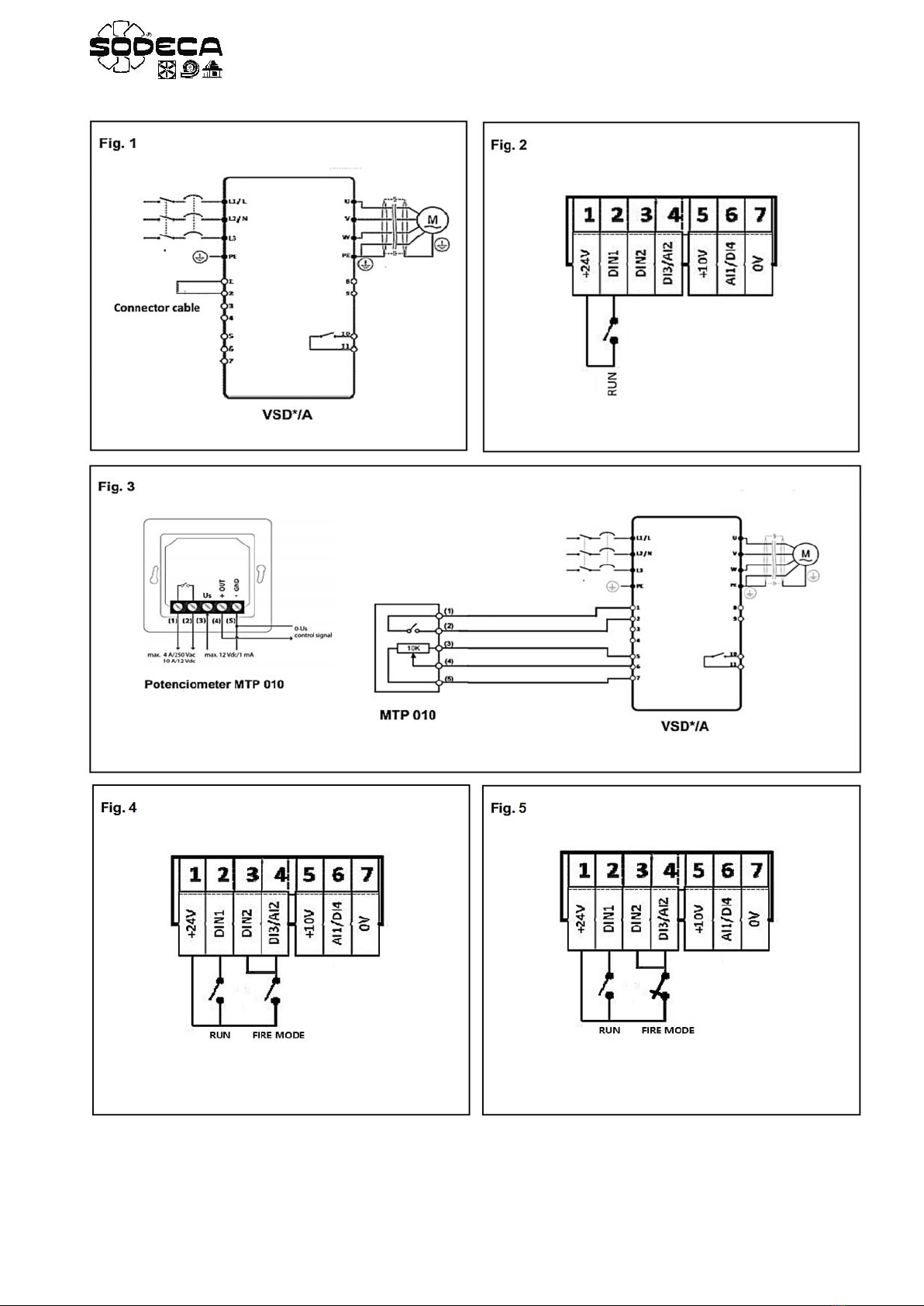

1.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “BASIC CONFIGURATION” control mode is selected, that is after introducing the parameters of the basic

configuration table (section 1.1), use a copper wire to short-circuit the terminals 1 and 2 of the VSD*/A. This short-circuit

enables the keypad control mode (See Fig. 1). This short-circuit can be changed with an external signal which would

prevent enabling the drive when the bridge between terminal 1 & 2 is open.

1.3 “BASIC CONFIGURATION” OPERATION MODE

1. Ensure the bridge between terminals 1 & 2 is closed. The display will show

2. Press the START key. The display will show and the drive will increase the speed until it reaches the

minimum speed programmed in the parameter.

3. Press to increase speed.

4. The drive will increase gradually, with the acceleration ramp previously programmed, until the key is no longer

pressed. The acceleration ramp is adjusted in theparameter, check before the start.

5. Press to decrease speed. The drive will decrease speed until the key is no longer pressed.

The acceleration ramp is adjusted in the parameter.

6. Press the STOP key. The drive will decrease its speed and stop. The acceleration ramp is adjusted in the

parameter.

7. The display will show . The drive is disabled.

8. In order to program the speed without pressing start, that is when the display is showing , press the STOP

key while the drive is disabled and the display will show the objective speed. Use the y keys to adjust the

wanted speed value. Press the STOP key to show on the display again.

9. Press START, the drive will accelerate towards the objective speed.

10. While the drive is enabled, we can visualize the consumption of the motor by pressing the navigator key >2

seconds.

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

1

4

EN

AP2. EXTERNAL KIT MODE – Manipulate with the MTP 010 remote control

This section explains how to proceed with the configuration of the “EXTERNAL REMOTE CONTROL KIT –

MTP010”control mode. This simple control mode allows to start the drive and adjust the speed from the exterior remote

control kit MTP010.

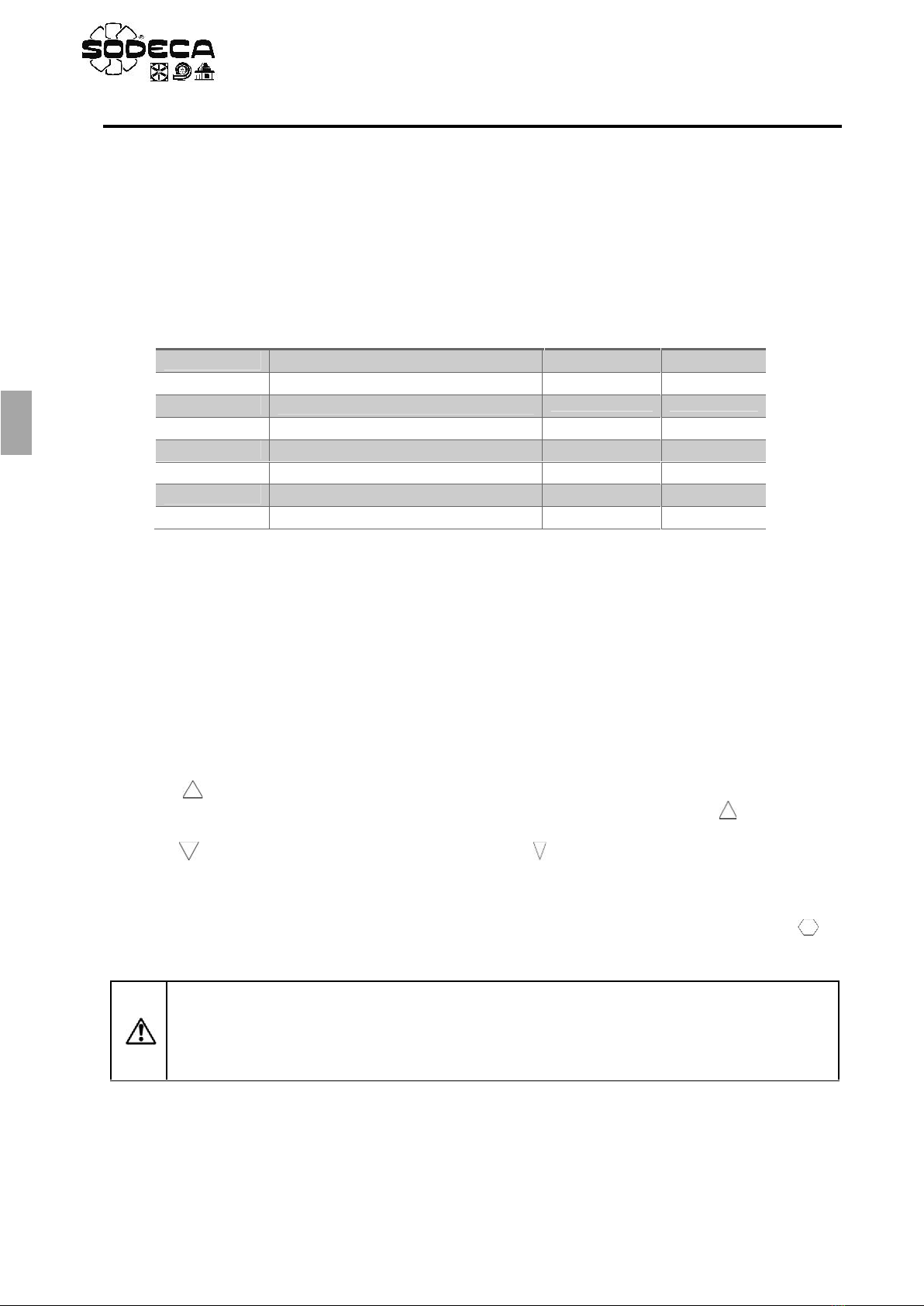

2.1 PROGRAMMING

Use the next table to change the mode to the external kit mode.

Table “EXTERNAL REMOTE CONTROL KIT”

2.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “EXTERNAL REMOTE CONTROL KIT” control mode is selected, that is after introducing the parameters of

the external remote control kit table (section 2.1), wire the remote control as seen in the picture. (See Fig. 3).

2.3 “EXTERNAL REMOTE CONTROL KIT” OPERATION MODE

1. To start the drive, close the built-in switch of the remote control (starting switch ON). The display will stop showing

and the drive will accelerate towards the speed adjusted by the potentiometer. If the potentiometer is in the

lower speed position, the drive will stay at minimum velocity, programmed in the P-02 parameter.

2. The speed can be increased or decreased with the potentiometer.

3. The drive will increase gradually, with the acceleration ramp programmed in P-03. Check before the start.

4. The drive will decrease gradually, with the deceleration ramp programmed in P-04. Check before the start.

5. When the starting switch is OFF, the drive will start to decelerate and stop, showing in the display. The drive

is disabled

6. While the drive is enabled, we can visualize the consumption of the motor by pressing the navigator key >2

seconds.

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

ATTENTION: If there’s a loss of the power supply while the ventilator is working with the starting

switch closed, the drive will be disabled with the display showing . Once the power supply

is restored, the drive will be disabled even with the starting switch ON. In order to start the drive

again, the switch must be changed to the OFF position and then changed again to the ON

position. See parameter to modify the configuration and change it to .

5

EN

AP3. MIXED MODE – External start, speed adjustment with the internal keypad.

This section explains how to configure the mixed control mode. This mode is a combination between the basic

configuration and the exterior remote control kit configuration. This mode allows to start the drive from an exterior switch

and adjust the speed with the internal keypad.

3.1 PROGRAMMING

Use the next table to change to the mixed mode.

Table “MIXED MODE”

3.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “MIXED” control mode is selected, that is after introducing the parameters of the mixed mode table (section

3.1), wire the remote control as seen in the picture. (See Fig. 2).

3.3 “MIXED” OPERATION MODE

1. To start the drive, close the built-in switch of the remote control (starting switch ON). The display will stop showing

and the drive will accelerate towards the minimum speed adjusted in the P-02 parameter.

2. Press to increase speed.

3. The drive will increase gradually, with the acceleration ramp previously programmed, until the key is no longer

pressed. The acceleration ramp is adjusted in theparameter, check before the start.

4. Press to decrease speed. The drive will decelerate until the key is no longer pressed.

The acceleration ramp is adjusted in the parameter.

5. When the starting switch is OFF, the drive will start to decelerate and stop, showing in the display. The drive

is disabled.

6. While the drive is enabled, we can visualize the consumption of the motor by pressing the navigator key >2

seconds.

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

1

Extended Menu Access code

101

Keypad Start Mode Select

3

ATTENTION: If there’s a loss of the power supply while the ventilator is working with the starting

switch closed, the drive will be disabled with the display showing . Once the power supply

is restored, the drive will be disabled even with the starting switch ON. In order to start the drive

again, the switch must be changed to the OFF position and then changed again to the ON

position. See parameter to modify the configuration and change it to .

6

EN

FIRE MODE

The Fire Mode function is designed to ensure continuous operation of the drive when an external alarm signal is activated

(fire alarm) until the drive is no longer capable of sustaining operation. This input may be linked to a fire control system

to allow maintained operation in emergency conditions, e.g. to clear smoke or maintain air quality within that building.

Fire Mode disables some protection features in the drive (Heat-sink Over-Temperature, 4-20mA fault, Faulty Thermistor

on Heat-sink…).

AP4. FIRE MODE with NO or NC activation signal– Preset speeds

This section explains how to configure the “FIRE”control mode with a normally open (NO) or a normally closed (NC)

activation signal and two operation speeds; the normal speed and the fire speed which can be adjusted as a preset

speed.

FIRE MODE with NO activation signal

When the free potential contact is open, which enables the Fire Mode, and the drive is receiving the RUN signal, the

drive will work at a preset speed with all the protections enabled. If the fire mode signal is active, that is when the

activation contact changes to closed position, and the drive is receiving the start signal (it can be the a contact of the fire

mode), the drive will work at a preset speed with all the protections disabled. (See Fig.4.)

MODO FUEGO with NC activation signal

When the free potential contact is closed, which enables the Fire Mode, and the drive is receiving the RUN signal, the

drive will work at a preset speed with all the protections enabled. If the fire mode signal is active, that is when the

activation contact changes to open position, and the drive is receiving the start signal (it can be a contact of the fire

mode), the drive will work at a preset speed with all the protections disabled. (See Fig.5.)

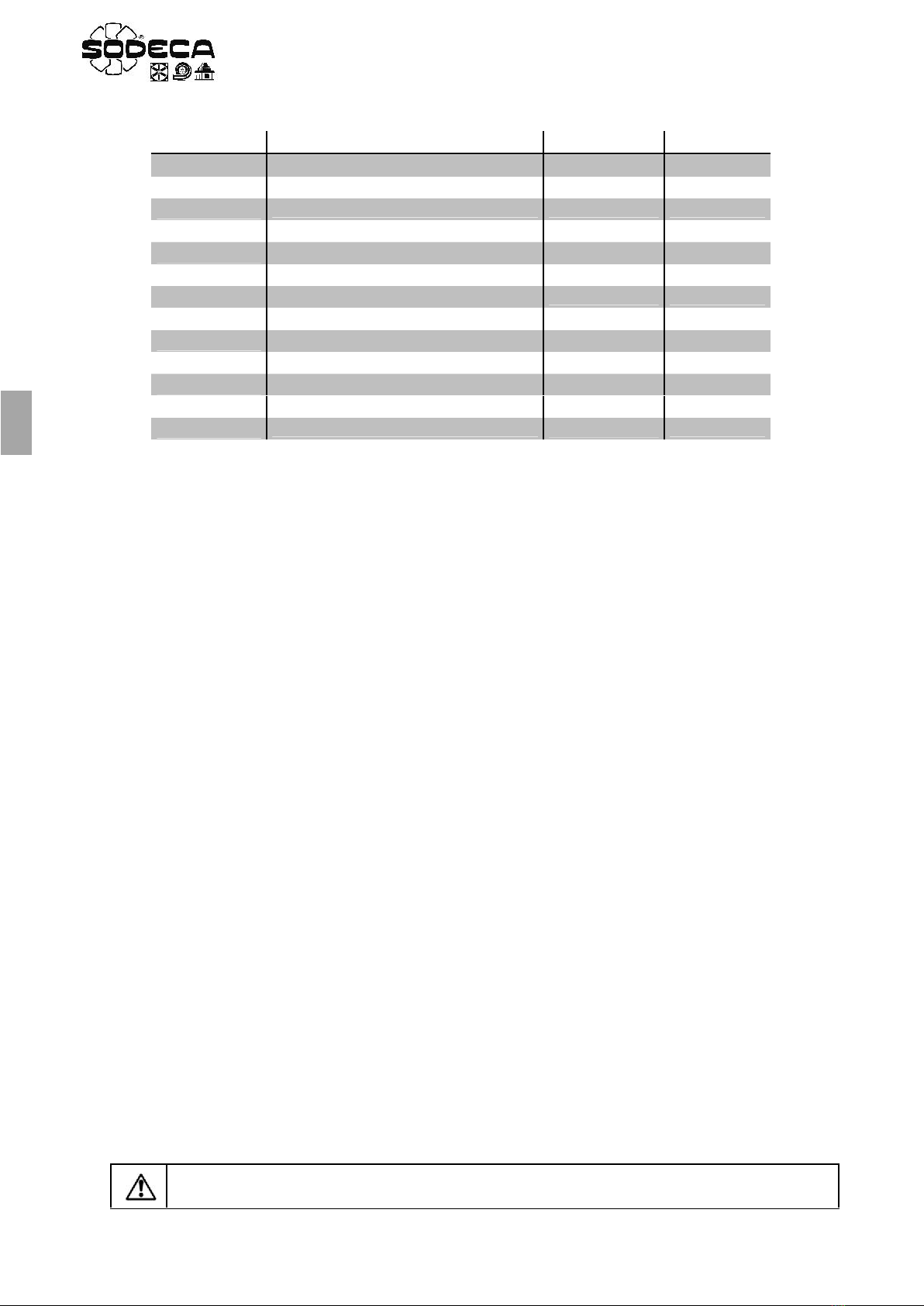

4.1 PROGRAMMING

Use the next table to change to, or modify, the Fire mode with normally open activation signal (NO) or with normally

closed activation signal (NC). The preset speeds can be adjusted to go forwards or reverse.

Table “FIRE MODE with NO contact, Preset Speeds”

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

0.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

Extended Menu Access code

101

Digital Input Function Select

16

Fire Speed

± xx.x

Hz

Normal Speed

± xx.x

Hz

Starting Mode

Fire Logic Input

1:

Latch Fire

0:

7

EN

Table “FIRE MODE with NC contact, Preset Speeds”

4.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “FIRE MODE with NC contact” or “FIRE MODE with NO contact” control mode is selected, that is after

introducing the parameters of the fire mode table (section 4.1), wire the drive as seen in the picture. (See Fig. 4 o 5.)

The Fire signal disables the protection features and maintains a constant speed. The Normal mode activates a constant

speed, distinct from the Fire speed. Both modes require a starting switch (Run), which can be replaced by a short-circuit

between terminals 1 & 2, or a contact related to the Fire and Normal mode activation.

In case the short-circuit is chosen, the drive will be always enabled and only will stop when the short-circuit is opened;

then display will show .

4.3 “FIRE MODE with Preset Speeds” OPERATION MODE

FIRE MODE with NO activation signal

1. Verify that the Fire mode signal triggers the Fire mode as well as the start signal (Run).If necessary use a two

contact Normally Open relay.

2. Verify that the Normal mode signal only triggers the start signal (Run).

3. When one of the two signal is active, the drive will accelerate towards de preset speed according to the normally

open contact table (see section 4.1)

4. When the two signals aren’t active, the drive will start to decelerate and stop, showing in the display.

5. The Fire signal disables the protection features so the drive will maintain continuous operation in emergency

conditions. The speed can be forward or reverse depending on the value set in the “Fire Speed” parameter.

FIRE MODE with NC activation signal

1. Verify that the Fire mode signal halts the Fire mode and activates the start signal (Run).If necessary, use a two

contact relay, one contact Normally Open and the other Normally Closed.

2. Verify that the Normal mode signal only triggers the start signal (Run).

3. When one of the two modes is triggered, the drive will accelerate towards de preset speed according to the normally

closed contact table (see section 4.1).

4. When the two modes aren’t active, the drive will start to decelerate and stop, showing in the display.

5. The Fire signal disables the protection features so the drive will maintain continuous operation in emergency

conditions. The drive can go forward or reverse depending on the value set in the “Fire Speed” parameter.

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

0.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

Extended Menu Access code

101

Digital Input Function Select

16

Normal Speed

± xx.x

Hz

Fire Speed

± xx.x

Hz

Starting Mode

Fire Logic Input

0:

Latch Fire

0:

The Fire Mode operation can affect the warranty of the drive and even nullify it. Contact with

SODECA for further information.

8

EN

AP5. FIRE MODE with NC activation signal – Analog speed/potentiometer

This section explains how to configure the “FIRE”control mode with a normally open (NC) activation signal and two

operation speeds; the fire speed is adjusted as a preset speed and the normal speed is adjusted with an analog signal.

FIRE MODE with NC activation signal

When the free potential contact is normally closed, which selects the operation mode, and the drive is receiving the RUN

signal, the drive will operate at a speed adjusted with an analog signal or a potentiometer, with all the protections enabled.

If the fire mode signal is active, that is when the activation contact changes to closed position, and the drive is receiving

the start signal (it can be the a contact of the fire mode), the drive will work at a preset speed with all the protections

disabled. (See Fig.6).

5.1 PROGRAMMING

Use the next table to change to, or modify, the Fire mode with normally closed activation signal (NC). The Fire mode

speed can be adjusted to go forwards or reverse.

Table “FIRE MODE with NC activation signal – Analog speed/potentiometer”

5.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “FIRE MODE with NC contact” control mode is selected, that is after introducing the parameters of the fire

mode table (section 5.1), wire the drive as seen in the picture. (See Fig. 6.)

The Fire signal disables the protection features and maintains a constant speed. The Normal mode activates a constant

speed, distinct from the Fire speed. Both modes require a starting switch (Run), which can be replaced by a short-circuit

between terminals 1 & 2, or a contact related to the Fire and Normal mode activation.

In case the short-circuit is chosen, the drive will be always enabled and only will stop when the short-circuit is opened;

then display will show .

5.3 “FIRE MODE with Analog Speed” OPERATION MODE

FIRE MODE with NC activation signal

1. Verify that the Fire mode signal halts the Fire mode and activates the start signal (Run).If necessary, use a two

contact relay, one contact Normally Open and the other Normally Closed.

2. Verify that the Normal mode signal only triggers the start signal (Run).

3. When one of the two modes is triggered, the drive will accelerate towards de preset speed according to the table

(see section 4.1).

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

x.x

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

Extended Menu Access code

101

Digital Input Function Select

15

Analog Input 1 Signal format

Fire Speed

± xx.x

Hz

Starting Mode

Fire Logic Input

0:

Latch Fire

0:

9

EN

4. When the two modes aren’t active, the drive will start to decelerate and stop, showing in the display.

5. The Fire signal disables the protection features so the drive will maintain continuous operation in emergency

conditions. The drive can go forward or reverse depending on the value set in the “Fire Speed” parameter.

AP6. FIRE MODE + CO with NO or NC activation signal – Preset Speeds

This section explains how to configure the “FIRE + co”control mode with a normally open (NO) or a normally closed

(NC) activation signal for the fire mode selection and a normally open (NO) activation signal for the CO mode. Each

mode has an operation speed; CO speed and fire speed adjusted as preset speed, as well as STOP via software in case

that neither of the signals are active (Fire or CO) and the RUN signal is active.

FIRE MODE + CO with NO activation signal

If the fire signal is active, that is when the activation signal goes from normally open to normally closed, and the RUN

signal is active (a fire mode contact can be used), the drive will operate at a preset speed with all the protections disabled

If the CO signal is active, that is when the activation signal goes from normally open to normally closed, the RUN signal

is active and the fire mode is not active, the drive will operate at a preset speed with all the protections enabled. (See

Fig.7)

When the drive receives the RUN signal but doesn’t receive the CO or FIRE signal, the drive will show STANDBY on the

display and will wait until it receives an order (CO or FIRE).

MODO FUEGO + CO with NC activation signal

If the fire signal is active, that is when the activation signal goes from normally closed to normally open, and the RUN

signal is active (a fire mode contact can be used), the drive will operate at a preset speed with all the protections disabled.

If the CO signal is active, that is when the activation signal goes from normally open to normally closed, the RUN signal

is active and the fire mode is not active, the drive will operate at a preset speed with all the protections enabled. (See

Fig.7)

When the drive receives the RUN signal but doesn’t receive the CO or FIRE signal, the drive will show STANDBY on the

display and will wait until it receives an order (CO or FIRE).

6.1 PROGRAMMING

Use the next table to change to, or modify, the Fire mode with normally open activation signal (NO) or with normally

closed activation signal (NC). The preset speeds can be adjusted to go forwards or reverse.

Table “FIRE MODE + CO with NO activation signal”

The Fire Mode operation can affect the warranty of the drive and even nullify it. Contact with

SODECA for further information.

WARNING: If the FIRE signal and CO signal are active simultaneously, the FIRE mode will prevail over

the CO mode, as long as the drive is set with the parameters shown in the section 6.1

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

0.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

Extended Menu Access code

101

Digital Input Function Select

17

Standby Speed

0.0

Hz

Fire Speed

± xx.x

Hz

10

EN

Table “FIRE MODE + CO with NC activation signal”

6.2 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “FIRE MODE with NC contact + CO” or “FIRE MODE with NO contact + CO” control mode is selected, that

is after introducing the parameters of the fire mode table (section 6.1), wire the drive as seen in the picture. (See Fig. 7

or 8.)

The Fire signal disables the protection features and maintains a constant speed. The CO mode activates a constant

speed, distinct from the Fire speed. Both modes require a starting switch (Run), which can be replaced by a short-circuit

between terminals 1 & 2, or a contact related to the Fire and Normal mode activation.

In case the short-circuit is chosen, the drive will be always enabled and only will stop when the short-circuit is opened;

then display will show .

6.3 “FIRE MODE + CO with preset speeds” OPERATION MODE

Fire Mode with NO activation signal

1. Verify that the Fire mode signal triggers the Fire mode as well as the start signal (Run).If necessary use a two

contact Normally Open relay.

2. Verify that the CO mode signal triggers the CO mode as well as the start signal (Run).If necessary use a two contact

Normally Open relay.

3. When one of the two signal is active, the drive will accelerate towards de preset speed according to the normally

open contact table (see section 6.1).

4. When the two signals aren’t active, the drive will start to decelerate and stop, showing in the display.

5. The Fire signal disables the protection features so the drive will maintain continuous operation in emergency

conditions. The speed can be forward or reverse depending on the value set in the “Fire Speed” parameter.

CO Speed

± xx.x

Hz

Fire Speed

± xx.x

Hz

Starting Mode

Fire Logic Input

1:

Latch Fire

0:

Standby Mode Timer

1.0

s

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

0.0

Hz

Acceleration Ramp Time

20

s

Deceleration Ramp Time

20

s

Motor Rated Current

x.x

A

Primary Command Source

0

Extended Menu Access code

101

Digital Input Function Select

17

Fire Speed

± xx.x

Hz

Standby Speed

0.0

Hz

Fire Speed

± xx.x

Hz

CO Speed

± xx.x

Hz

Starting Mode

Fire Logic Input

0:

Latch Fire

0:

Standby Mode Timer

1.0

s

11

EN

Fire Mode with NC activation signal

1. Verify that the Fire mode signal halts the Fire mode and triggers the start signal (Run). If necessary, use a two

contact relay, one contact Normally Open and the other Normally Closed.

2. Verify that the CO mode signal triggers the CO mode as well as the start signal (Run).If necessary use a two contact

Normally Open relay.

3. When one of the two modes is triggered, the drive will accelerate towards de preset speed according to the normally

open contact table (see section 6.1).

4. When the two modes aren’t active, the drive will start to decelerate and stop, showing in the display

5. The Fire signal disables the protection features so the drive will maintain continuous operation in emergency

conditions. The speed can be forward or reverse depending on the value set in the “Fire Speed” parameter.

AP7. CO2 MODE

This section explains how to configure the “CO”control mode. This mode allows the drive to regulate the speed of the

ventilator depending on the CO2level read by a probe.

7.1 PROGRAMMING

Use the next table to change to, or modify, the CO2 mode.

Table “CO2”

1. In order to make the regulation more dynamic, change the oparameters. Increase until the output

is fast enough. The increase as much as possible and stop before the system oscillates.

2. See section 7.2 for the setpoint configuration.

The Fire Mode operation can affect the warranty of the drive and even nullify it. Contact with

SODECA for further information.

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

10

s

Deceleration Ramp Time

10

s

Motor Rated Current

x.x

A

Primary Command Source

5

Extended Menu Access code

101

Analog Input 1 Signal format

U 0-10

V

PI Controller Proportional Gain

1.0

%

PI Controller Integral Time

1.0

s

PI Controller Operating Mode

1

PI Reference (Setpoint) Source Select

0

PI Digital Setpoint

xx.x

%

PI Feedback Source Select

1

ATTENTION: If there’s a power loss while the ventilator is working and the RUN switch is

closed, the drive will enter the stop stage and show on the display. Once the power is

restored, if the RUN switch is still closed, the drive will maintain the stop status. In order to start

again, the RUN switch must be opened and closed again. This operation can be modified

setting the mode in the parameter.

12

EN

7.2 SETPOINT ADJUSMENT OF THE CO2 CONCENTRATION

The setpoint is adjusted in the parameter. This parameter is shown as a percentage and will translate to a different

value of CO2concentration in ppm, subject to the chosen scale of the probe.

Scale

CO2concentration in ppm

per every 10% of the Setpoint

450-1850 ppm

140 ppm*

0-1000 ppm

100 ppm

0-1500 ppm

150 ppm

0-2000 ppm

200 ppm

(*) Increase for every 10%, add 450 ppm to obtain the real value

7.3 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “CO2” control mode is selected, that is after introducing the parameters of the CO2mode table (section 7.1),

wire the drive as seen in the picture. (See Fig. 9.).

The RUN signal must be connected between the terminals 1 & 2, and the switch is always closed, the drive will start

automatically when given power. If the user wants to stop the operation with a selector, timer, etc.… Set up a free

potential contact in series between the terminals 1 & 2.

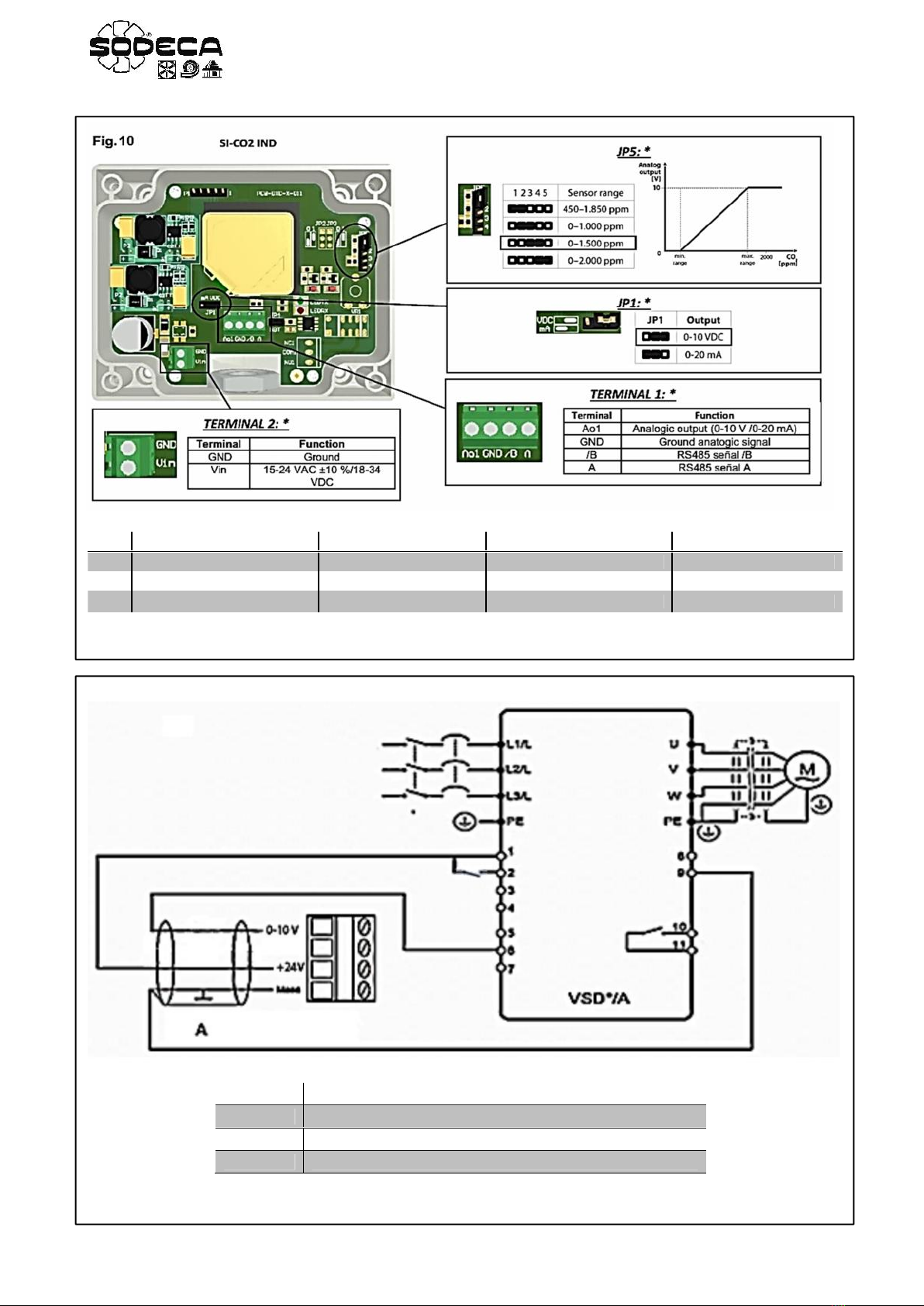

7.4 PROBE SI-CO2 IND CONFIGURATION

It’s advised to adjust the scale of the probe SI-CO2 IND between 0 and 1000 ppm and the output signal 0-10 V. This

adjustment by means of the jumpers JP5 and JP1 respectively. Remove the cover of the probe to find this jumpers. (See

Fig. 10)

7.5 “CO2” OPERATION MODE

1. Close the RUN switch connected between the terminals 1 & 2 to start the drive. The display will show and

the drive will increase the speed until reaching the objective speed. This speed is subjected to the CO2

concentration level detected by the probe and the setpoint adjusted in .

2. If the CO2 level goes over the setpoint adjusted in the drive will increase the speed in order to decrease the

CO2 level below the setpoint.

3. If the CO2 level goes below the setpoint adjusted in the drive will decrease the speed in order to keep the

CO2 level below the setpoint.

4. If the user wants the drive to be always working, short-circuit the terminals 1 & 2 with a copper wire.

5. If the parameter has a value >0.0s, the drive will disconnect automatically when the CO2 level goes below

the setpoint for a certain amount of time, adjusted in this parameter. If this feature is active and the CO2 level goes

below the setpoint for an amount of time higher than the one set in , the drive will stop even when the RUN

switch is closed and won’t start again until the CO2 level goes over the setpoint.

6. While the drive is ON, the user can see the motor consume pressing the Navigator key >2 seconds.

VSD*/A Wirings

Terminal VSD*/A

Description

L/N+PE

Single phase input, only for VSD1/A

L1/L2/L3+PE

Three phase input, only for VSD3/A

U/V/W+PE

Three phase motor output

1

+24 VDC (100 mA)

2

Run signal

6

Analog input 1

7

0 V analog input

9

0 V

10

Output relay

11

‘Drive OK’ = Closed

13

EN

AP8. TEMPERATURE MODE

This section explains how to configure the “TEMPERATURE” control mode. This mode allows the drive to regulate the

speed of the ventilator as well as the warm or cold air inlet through a frequency inverter VSD*/A depending on the

temperature detected by the analogic sensor. Inverter starting is done from an external control (selector).

8.1 PROGRAMMING

Use the next table to change to, or modify, the TEMPERATURE mode.

Table “TEMPERATURE”

1. In order to make the regulation more dynamic, change the oparameters. Increase until the output

is fast enough. The increase as much as possible and stop before the system oscillates.

2. If we need warm air inlet we should configure to 0, on the contrary, if we need cold air inlet we should

configure to 1.

3. See sections 8.2 and 8.3 for the setpoint configuration.

8.2 PROBE SI-TEMP IND CONFIGURATION

Is recommended to adjust the output signal to 0-10V and the sensor SI-TEMP IND measuring scale. This adjustment by

means of the jumpers JP1 and JP2 respectively. Remove the cover of the probe to find this jumpers. (See Fig. 15).

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

5

s

Deceleration Ramp Time

5

s

Motor Rated Current

x.x

A

Primary Command Source

5

Extended Menu Access code

101

Analog Input 1 Signal format

U 0-10

V

PI Controller Proportional Gain

0.2

%

PI Controller Integral Time

1.0

s

PI Controller Operating Mode

0 - 1

PI Digital Setpoint

xx.x

%

PI Feedback Source Select

1

ATTENTION: If there’s a power loss while the ventilator is working and the RUN switch is

closed, the drive will enter the stop stage and show on the display. Once the power is

restored, if the RUN switch is still closed, the drive will maintain the stop status. In order to start

again, the RUN switch must be opened and closed again. This operation can be modified

setting the mode in the parameter.

14

EN

8.3 SETPOINT ADJUSMENT OF THE CO2 CONCENTRATION

The setpoint is adjusted in the parameter. This parameter is shown as a percentage depending on the sensor SI-

TEMP IND scale chosen in JP2 it has a different temperature value in ºC (Fig. 15).

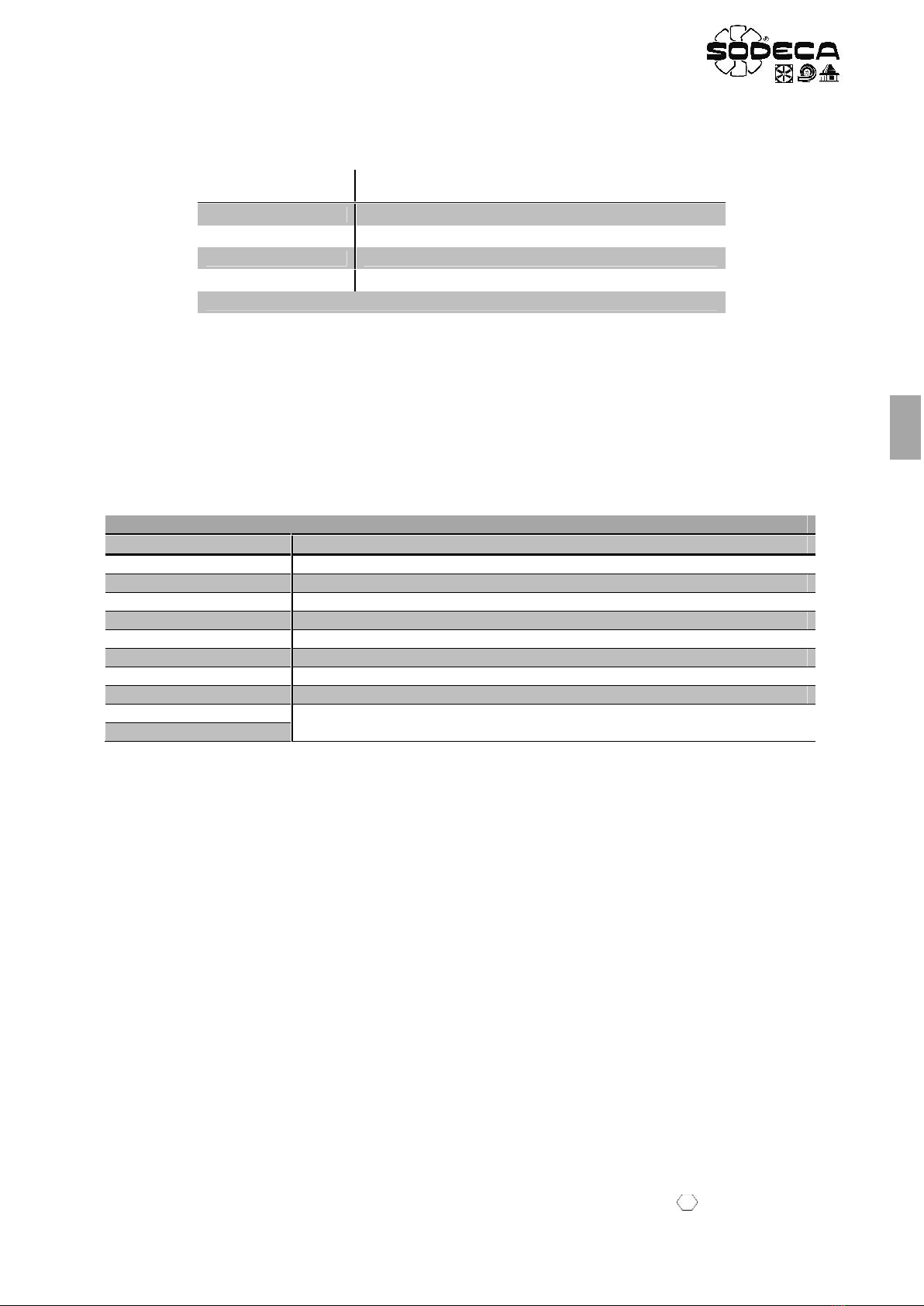

Scale

CO2concentration in ppm

per every 10% of the Setpoint

0 – 30ºC

0ºC 0% - 30ºC 100%

10 – 40ºC

10ºC 0% - 40ºC 100%

20 – 50ºC

20ºC 0% - 50ºC 100%

0 – 50ºC

0ºC 0% - 50ºC 100%

8.4 WIRING

Before the start of the programming, wire the L1-L2-L3 input phases when using three phase equipment and wire the

L1-L2/N input phases when using single phase equipment.

Once the “TEMPERATURE” control mode is selected, that is after introducing the parameters of the Temperature mode

table (section 8.1), wire the drive as seen in the picture. (See Fig. 14). The RUN signal must be connected between the

terminals 1 & 2, and the switch is always closed, the drive will start automatically when given power. If the user wants to

stop the operation with a selector, timer, etc.… Set up a free potential contact in series between the terminals 1 & 2.

8.5 “TEMPERATURE” OPERATION MODE

1. Close the RUN switch connected between the terminals 1 & 2 to start the drive. The display will not show to

start cold or warm air inlet, depending of the parameter configuration, until reaching the set point configured

in .

2. If the parameter is set at 0 and the temperature exceeds the set point value configured in ,the inverter

VSD*/A will decrease the speed in order to keep it on the configured value. On the contrary, if the temperature

decreases below the set point configured in ,the inverter VSD*/A will increase the speed in order to keep it

on the configured value.

3. If the parameter is set at 1 and the temperature exceeds the set point value configured in ,the inverter

VSD*/A will increase the speed in order to keep it on the configured value. On the contrary, if the temperature

decreases below the set point configured in ,the inverter VSD*/A will decrease the speed in order to keep it

on the configured value.

4. If the user wants the drive to be always working, short-circuit the terminals 1 & 2 with a copper wire.

5. If the parameter has a value >0.0s, the drive will disconnect automatically. In this way, even keeping the run

connection, if the temperature is the desired, the inverter will stop and will show in the display, starting

again when is necessary according to the set point value configured in .

While the drive is ON, the user can see the motor consume pressing the Navigator key >2 seconds.

VSD*/A Wirings

Terminal VSD*/A

Description

L/N+PE

Single phase input, only for VSD1/A

L1/L2/L3+PE

Three phase input, only for VSD3/A

U/V/W+PE

Three phase motor output

1

+24 VDC (100 mA)

2

Run signal

6

Analog input 1

7

0 V analog input

9

0 V

10

Output relay

11

‘Drive OK’ = Closed

15

EN

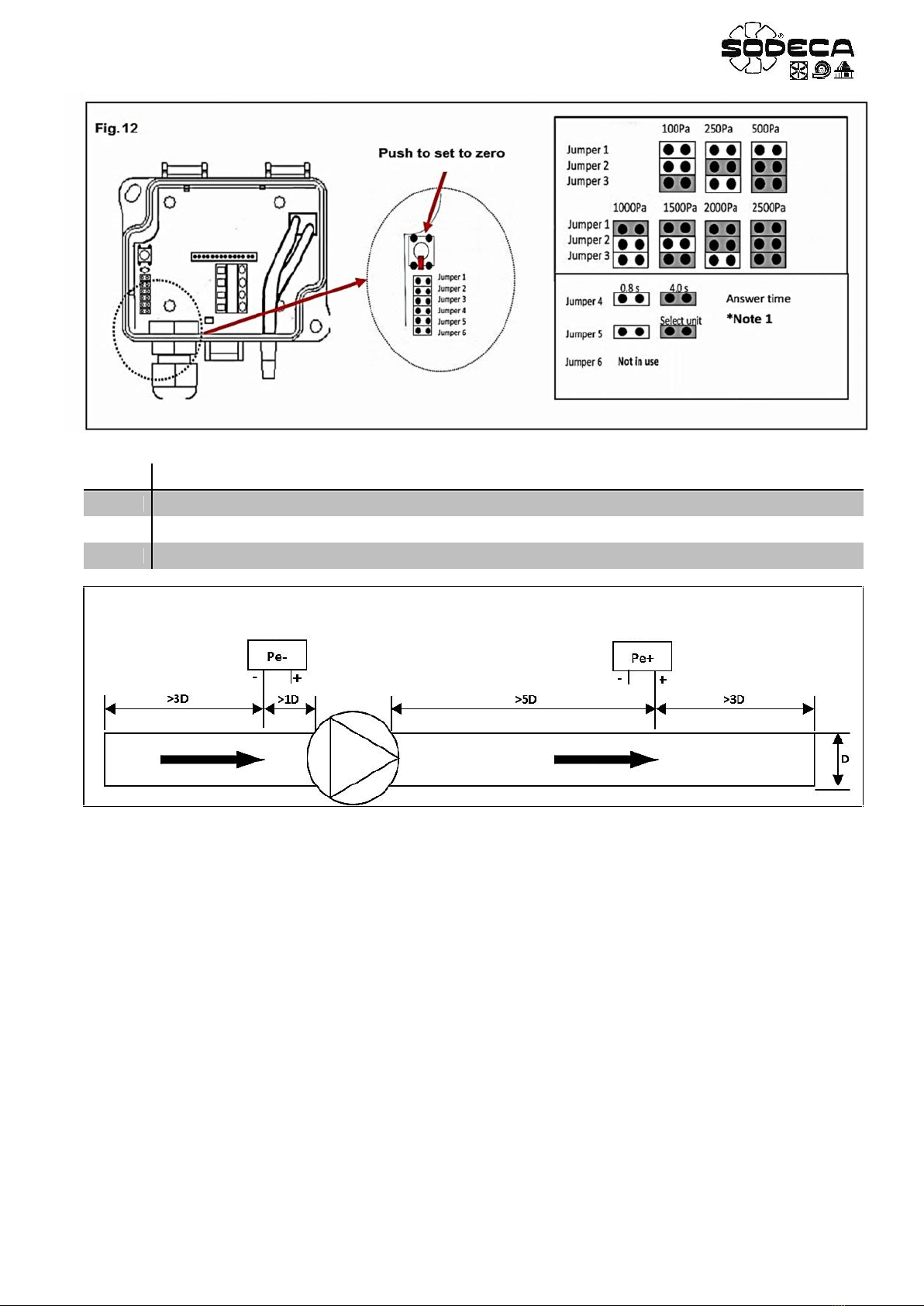

AP9. PRESSURE CONTROL MODE – VSD1-P, VSD3-P

This section explains how to configure the “PRESSURE CONTROL”control mode. This mode allows the drive to

regulate the speed of the ventilator depending on the overpressure between to places.

9.1 PROGRAMMING

Use the next table to change to, or modify the pressure control mode.

Table “PRESSURE CONTROL”

1. In order to make the regulation more dynamic, change the oparameters. Increase until the output

is fast enough. The increase as much as possible and stop before the system oscillates.

2. See section 9.2 for the setpoint configuration.

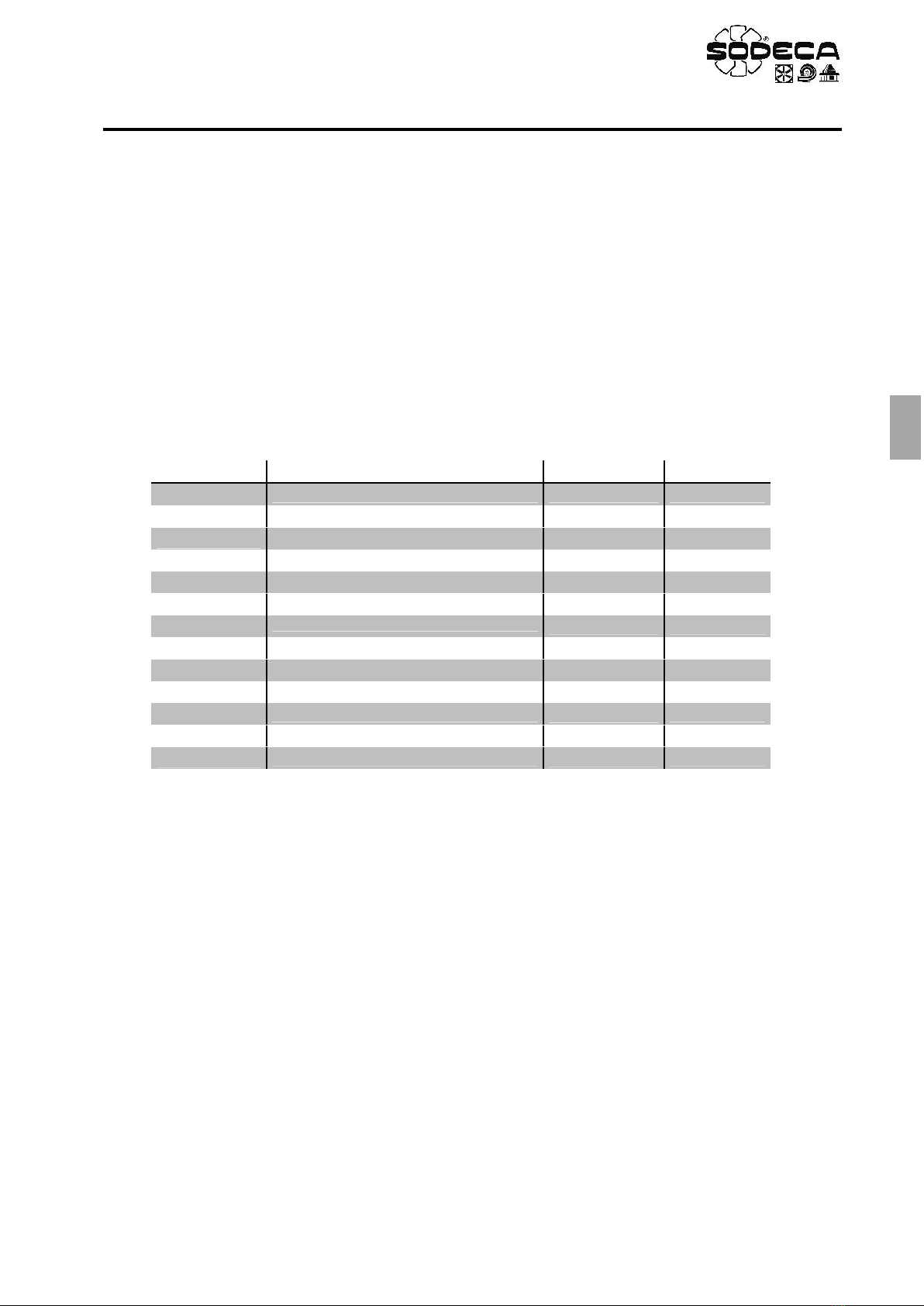

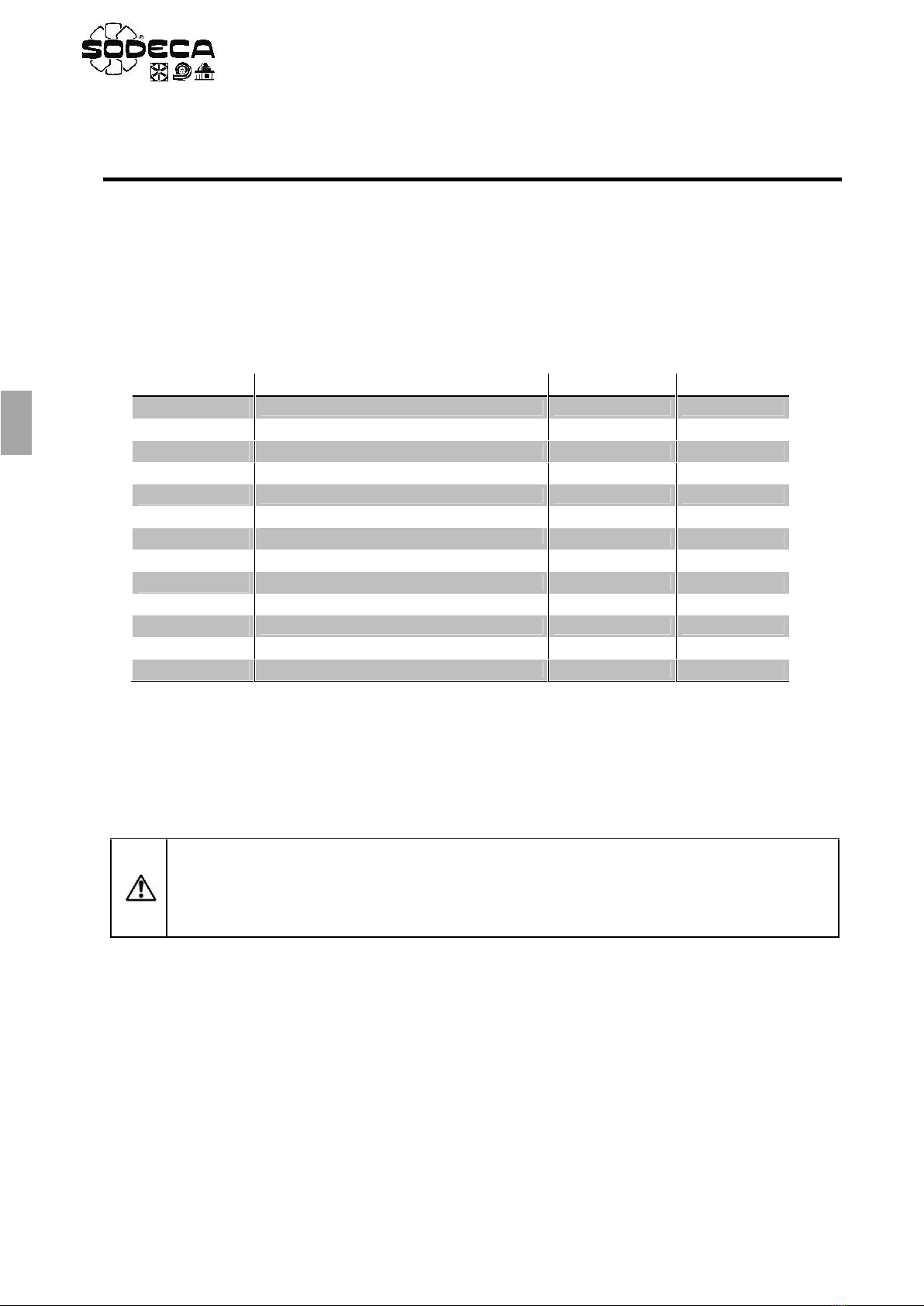

9.2 PRESSURE SETPOINT ADJUSTMENT

The pressure setpoint is adjusted in the parameter. The value read by the drive is shown in the only-read

parameter, if the probe has a display the user will be able to see the value directly. This parameters are shown

as percentages and will translate to a different value of Pa, subject to the chosen scale of the probe.

Scale

Pressure in Pa

for every 10% of the Setpoint

Scale

Pressure in Pa

for every 10% of the Setpoint

±100 Pa

20 Pa*

0-1000 Pa

100 Pa

0-100 Pa

10 Pa

0-1500 Pa

150 Pa

0-250 Pa

25 Pa

0-2000 Pa

200 Pa

0-500 Pa

50 Pa

0-2500 Pa

250 Pa

(*)Increase for every 10%, subtract 100 Pa to obtain the real value

Parameter

Description

Adjustment

Units

Maximum Frequency

50.0

Hz

Minimum Frequency

20.0

Hz

Acceleration Ramp Time

10

s

Deceleration Ramp Time

10

s

Motor Rated Current

x.x

A

Primary Command Source

5

Extended Menu Access code

101

Analog Input 1 Signal format

U 0-10

V

PI Controller Proportional Gain

0.2

%

PI Controller Integral Time

3.0

s

PI Controller Operating Mode

0

PI Reference (Setpoint) Source Select

0

PI Digital Setpoint

xx.x

%

PI Feedback Source Select

1

ATTENTION: If there’s a power loss while the ventilator is working and the RUN switch is closed,

the drive will enter the stop stage and show on the display. Once the power is restored, if

the RUN switch is still closed, the drive will maintain the stop status. In order to start again, the

RUN switch must be opened and closed again. This operation can be modified setting the

mode in the parameter.

Popular DC Drive manuals by other brands

SOMFY

SOMFY OXIMO BASIC WF RTS instructions

Danfoss

Danfoss VLT 6000 HVAC Series Design guide

Lenze

Lenze 8200 motec E82ZMFBC001 Mounting instructions

Vertiv

Vertiv Liebert GXT RT Series Quick installation guide

Delta Electronics

Delta Electronics AC Servo Drive ASDA-AB user manual

Deif

Deif IMD 100 CONFIGURATION AND VERIFICATION INSTRUCTIONS