W21 Magnet Drive System®| 3

Quick Guide

1 - Technology

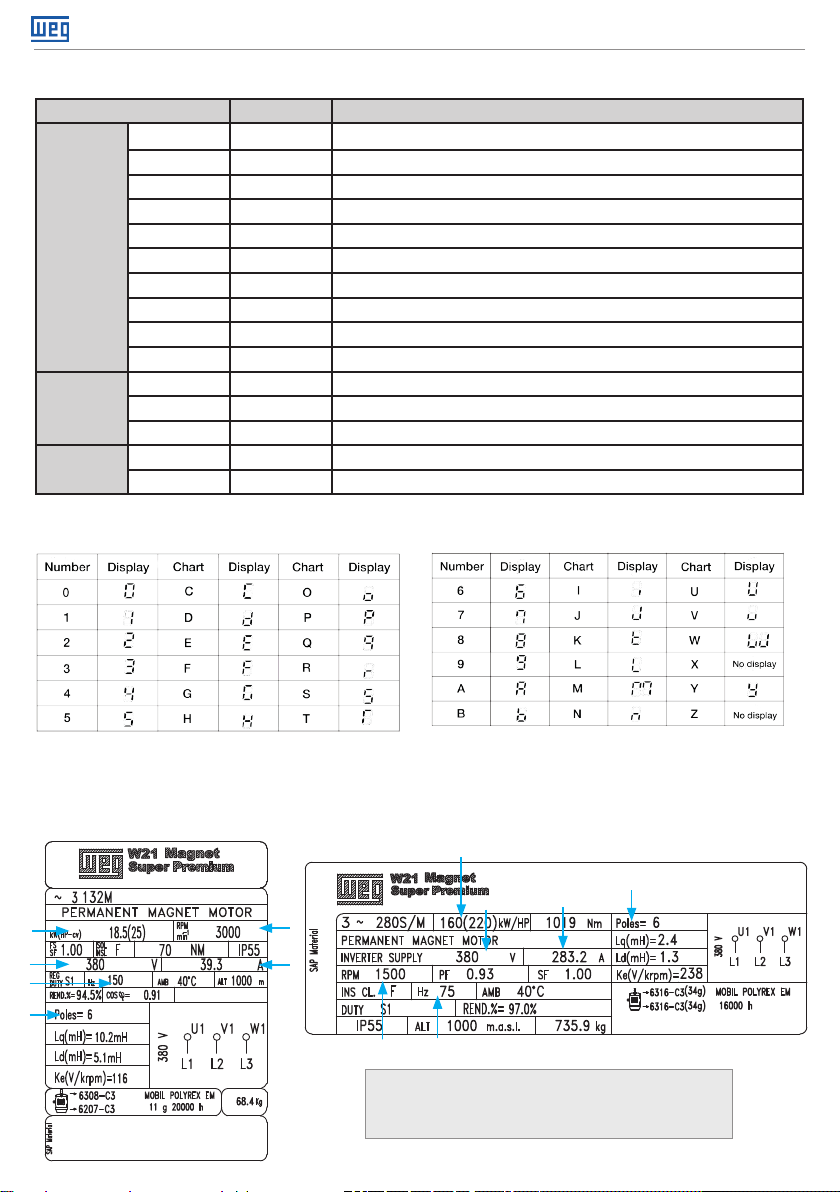

W21 Magnet Drive System is a system composed of the W21 Magnet permanent magnet synchronous

motor and the WEGPM frequency inverter.

The W21 Magnet motor features three-phase stator winding, similar to an induction motor, and rotor

assembled with permanent magnets instead of a squirrel cage. The permanent magnets eliminate the need

of current induction on the rotor (magnetizing current); therefore, with no load the motor presents a very low

current, just enough to make up for the losses. Besides the magnetizing current, the W21 Magnet does not

require slip compensation either, since the shaft speed does not vary with the load.

All W21 Magnet motors present a single configuration of six poles.

FNote!

Since this motor is not designed to be connected directly to the power line, all the motors of this line

present a single configuration of six poles and variable electric frequency. For example, the electric

frequency of the 1500 and 3000 rpm motors is:

1500 rpm x 6 poles = 75 Hz

120

3000 rpm x 6 poles = 150 Hz

120

FNote! W21 Magnet motors can be driven by the PM with encoder and Sensorless PM control options only.

2 - Safety measures

Any service on the internal parts of the motor must be performed by qualified personnel

only, since, due to the attraction between metallic parts caused by the magnets, risk of

accident is present both in the assembly and disassembly of the motor.

People that use pacemakers cannot handle these motors. The permanent magnets can

also cause disturbances or damages to other electric equipment and components during

service.

gBefore opening the terminal box of the motor, make sure the motor shaft is not spinning.

gNever touch the motor terminals while the rotor is spinning, because, even with the inverter shut down,

risk of electric shock is present. If it is observed the possibility of the load to accelerate the motor shaft, it

is necessary to install a disconnecting device between the inverter and motor terminals.

gW21 Magnet motors feature PTC temperature sensors which must be connected to the inverter so that

the motor will be shut down in case of overheating.

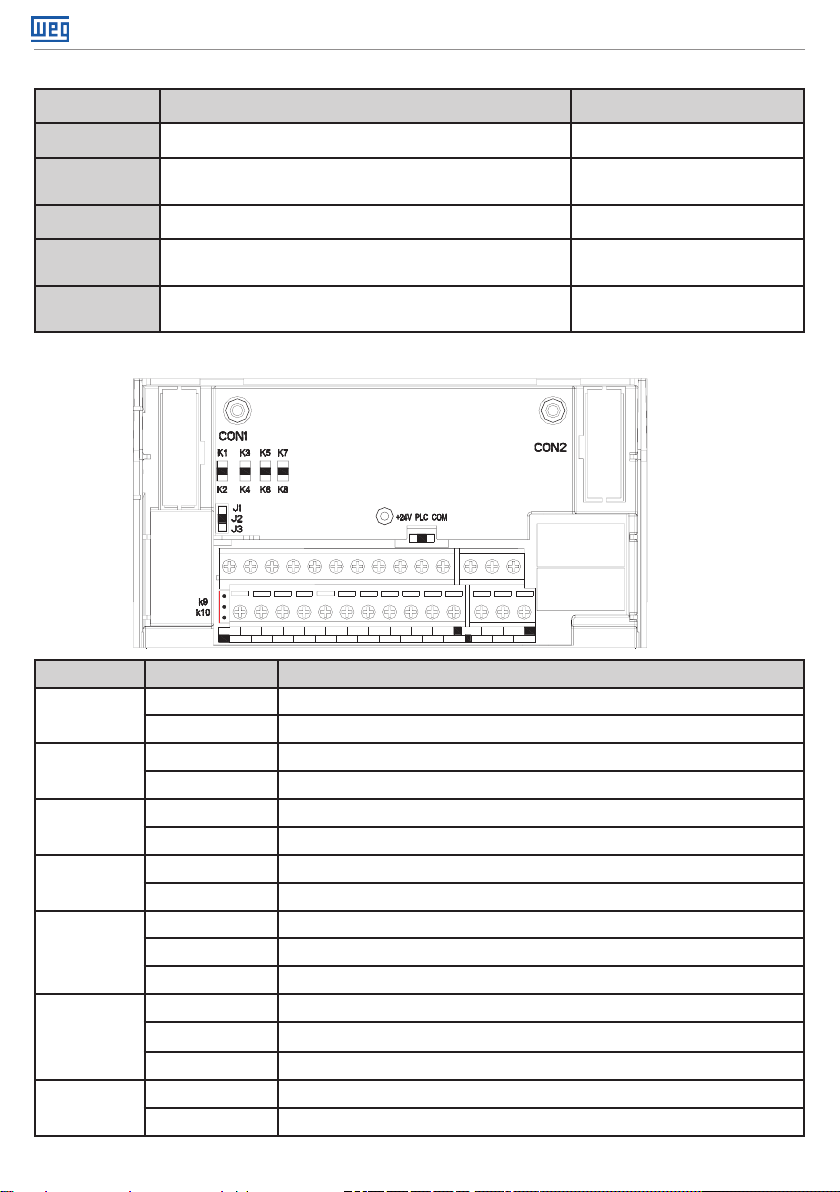

In order to connect the PTC temperature sensor, it needs to connect the input X7 & COM (refer to section

3 - Inverter Installation and Connections - Standard Connection Diagram) and setting the function F2.06 to

9: External Fault Input (refer to Section 4 - Configuration of the inverter) where X7 shall be set as Normally

Closed.

English

For further information on the motor installation and maintenance, refer to the instruction booklet supplied with it.

FNote!