Softing TH LINK User manual

© Copyright 2014 - 2017 Softing Industrial Automation GmbH

TH LINK Industrial Ethernet

TH LINK PROFINET

TH LINK EtherNet/IP

TH LINK Modbus TCP

Installation Manual

Version: EN-062017-4.10

The information contained in these instructions corresponds to the technical status at the time of printing of it and is passed on with the

best of our knowledge. The information in these instructions is in no event a basis for warranty claims or contractual agreements

concerning the described products, and may especially not be deemed as warranty concerning the quality and durability pursuant to Sec.

443 German Civil Code. We reserve the right to make any alterations or improvements to these instructions without prior notice. The

actual design of products may deviate from the information contained in the instructions if technical alterations and product improvements

so require.

It may not, in part or in its entirety, be reproduced, copied, or transferred into electronic media.

Disclaimer of liability

Softing Industrial Automation GmbH

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial.softing.com

The latest version of this manual is available in the Softing download area at: http://industrial.softing.com/en/downloads.html

+ 49 89 4 56 56-0

+ 49 89 4 56 56-488

info.automation@softing.com

support.aut[email protected]

Copyright 2017 Softing Industrial Automation GmbH 3

Table of Contents

Table of Contents

Chapter 1 ............................................................................................ 5

Introduction

...................................................................................................................... 5

1.1 About TH LINK

...................................................................................................................... 5

1.2 Before you connect TH LINK

Chapter 2 ............................................................................................ 6

TH LINK design

...................................................................................................................... 6

2.1 Start-up guideline

...................................................................................................................... 6

2.2 Connections and display elements

...................................................................................................................... 8

2.3 Mount device

...................................................................................................................... 9

2.4 Connect to network

...................................................................................................................... 9

2.5 Connecting power supply and relay contact

Chapter 3 ............................................................................................ 10

Configuring the device in the network

...................................................................................................................... 10

3.1 Configuration requirements

...................................................................................................................... 10

3.2 Network presettings

...................................................................................................................... 11

3.3 Web access and login

...................................................................................................................... 11

3.4 Network overview

...................................................................................................................... 12

3.5 Setting new IP and network address

...................................................................................................................... 13

3.6 Check the connection to the device

...................................................................................................................... 13

3.7 Firmware update

Chapter 4 ............................................................................................ 14

Troubleshooting

Chapter 5 ............................................................................................ 15

Technical Data

Chapter 1 - Introduction

Copyright 2017 Softing Industrial Automation GmbH 5

1Introduction

1.1 About TH LINK

TH LINK provides a secure access to the fieldbus network and forms the basis for the Softing

product TH SCOPE.

Intended use: The TH LINK is designed to be used as a secure access point to Industrial Ethernet

networks. Any other use is deemed non-intended use.

1.2 Before you connect TH LINK

Strictly observe the following safety instructions before connecting the TH LINK:

Note

Small objects or liquids must not enter the case of the TH LINK (e.g. through the ventilation

slots). This may damage the device. Never cover the ventilation slots on the device.

Note

Never open the case of the TH LINK or carry out any mechanical modifications on the

device. This may lead to damages on the device as well as to loss of warranty.

EMC note

The TH LINK contains electronic components sensitive to electrostatic discharges. Damages

due to electrostatic discharge can lead to premature failure of components or intermittent

faults at a later stage. Before installing the TH LINK, divert the electrostatic discharge away

from your body and the tools used.

The TH LINK may only be installed or uninstalled by qualified, trained electrical engineering

personnel. When installing the TH LINK, observe the regulations for handling electric components in

accordance with VDE 0100. In addition, you must also observe the valid safety and accident

prevention regulations (UVV) when operating the device within the jurisdiction of the Federal

Republic of Germany.

High temperature differences between the storage site and installation site can result in

condensation within the case, which may cause the TH LINK to become damaged. In case of high

temperature differences, wait at least three hours before operating the device.

WEEE

Electrical and electronic equipment must be disposed of separately from normal waste

at the end of its operational lifetime.

Please dispose of this product according to the respective national regulations or

contractual agreements. If there are any further questions concerning the disposal of

this product, please contact Softing Industrial Automation.

TH LINK Industrial Ethernet - Installation Manual

6Copyright 2017 Softing Industrial Automation GmbH

2TH LINK design

2.1 Start-up guideline

The following steps are required for start-up:

1. Mounting

2. Plug-in SD card (recommended).

3. Connect to network (see Connect to network).

4. Connect to the power supply (see Connecting the power supply).

5. Configure network (see Configure the device in the network).

2.2 Connections and display elements

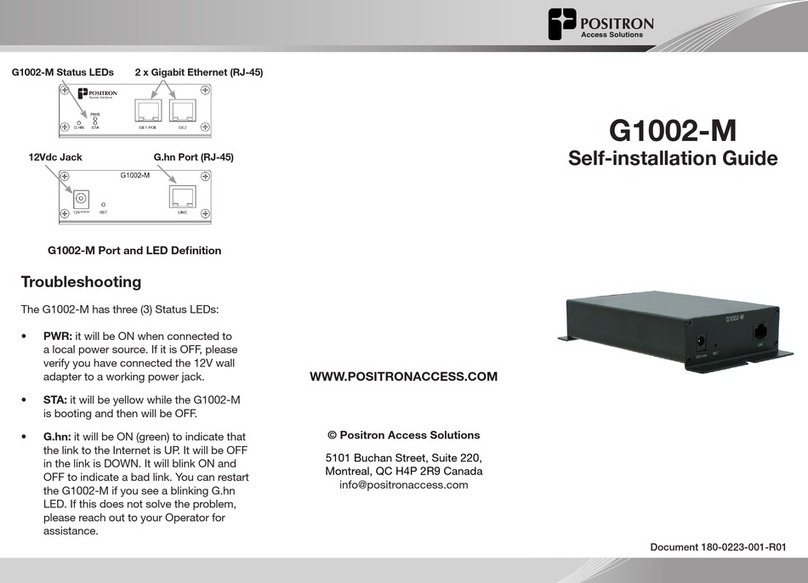

Figure 1: TH LINK (front and lateral view)

[1] Ethernet interface for office network

olights yellow: Ethernet data communication

olights green: physical connection available

Chapter 2 - TH LINK design

Copyright 2017 Softing Industrial Automation GmbH 7

[2] LED ETH

olights red: boot procedure

olights green: firmware update in progress

ois off: boot procedure is completed

[3] LED RUN

olights red: internal error

olights green: power supply is applied

ois off: device is not powered

[4] LED BUS

olights red: relay contact active (error occurred in the bus)

olights green: TH SCOPE measurement is running

ois off: TH SCOPE measurement is stopped

[5] Ethernet interface for automation network

olights yellow: Ethernet data communication

olights green: physical connection available

[6] Terminal strip for +24 V DC power supply

oA: 24 V (+)

oB: 0 V (-)

oC: Relay contact - input

oD: Relay contact - output

oE: Protective earth

[7] SD card slot

oYou can save data on the SD card to have the data available even after voltage recovery.

oInsert the SD card before installing the device or putting it into operation. Thus you make sure

the card is recognized during boot procedure.

oNow go to TH LINK Settings TH SCOPE and set the parameter Data restore after voltage

recovery to Yes.

oFollowing the initial device commissioning the SD card is formatted automatically. From this

time on you can save data independently from power interruptions.

Note

If the SD card is not recognized during boot procedure, restart the TH LINK.

[8] Type label

TH LINK Industrial Ethernet - Installation Manual

8Copyright 2017 Softing Industrial Automation GmbH

2.3 Mount device

Note

Make sure you have a minimum of 5 cm below and above the TH LINK in order to ensure

heat dissipation.

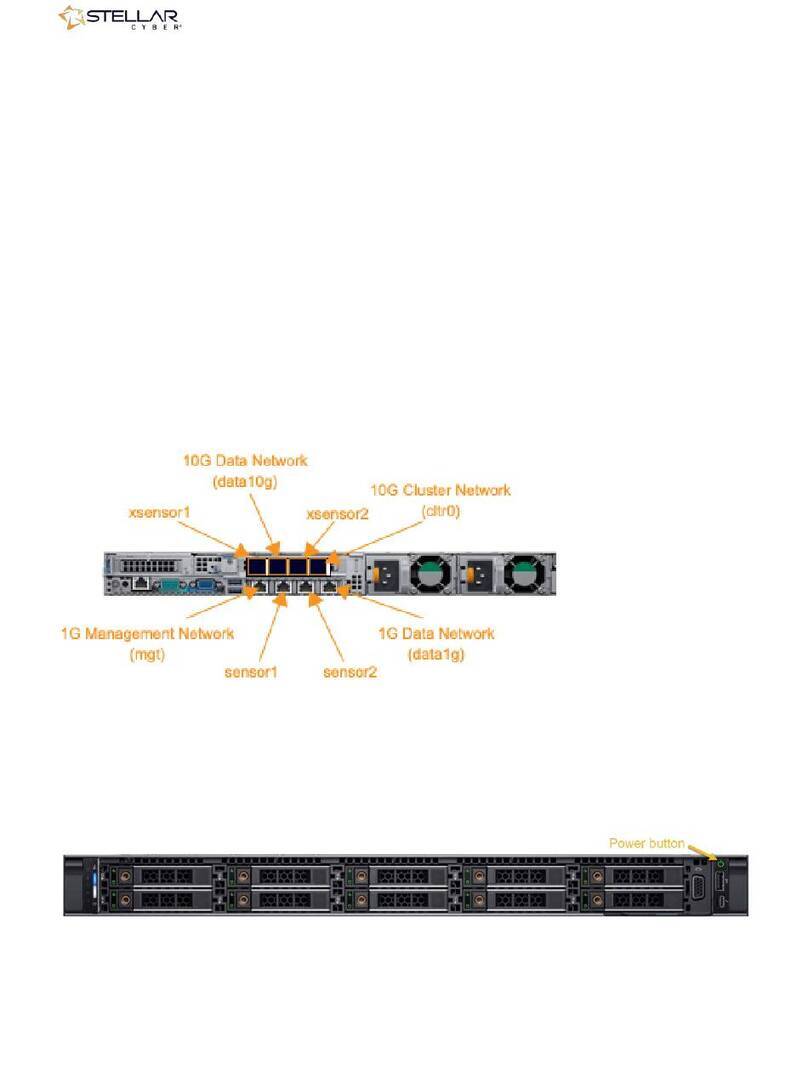

Figure 2: Mount and unmount the TH LINK

[1] Device with notch on DIN rail

[2] DIN rail

[3] Device on DIN rail

[4] Stop lever

1. Place the device with its notch on the DIN rail.

2. Move the device downwards until the stop lever locks into place on the DIN rail.

Unmount TH LINK:

1. Remove the connected supply and signal lines (Ethernet, power supply).

2. Place the screwdriver into the stop lever on the device (see figure above).

3. Press the screwdriver in the direction of the device and simultaneously swing the device off the DIN

rail.

Chapter 2 - TH LINK design

Copyright 2017 Softing Industrial Automation GmbH 9

2.4 Connect to network

1. TH LINK can either be accessed using the upper port (desktop icon) of the TH LINK or accessing the

network directly, which then has to be connected to the lower port (factory icon) of the TH LINK.

2. The bottom port (factory icon) should be connected to the automation network.

Note

There must be no firewall between the TH LINK and the Industrial Ethernet devices.

Note

The green LED on the Ethernet socket lights as soon as the TH LINK is energized and a

network is available.

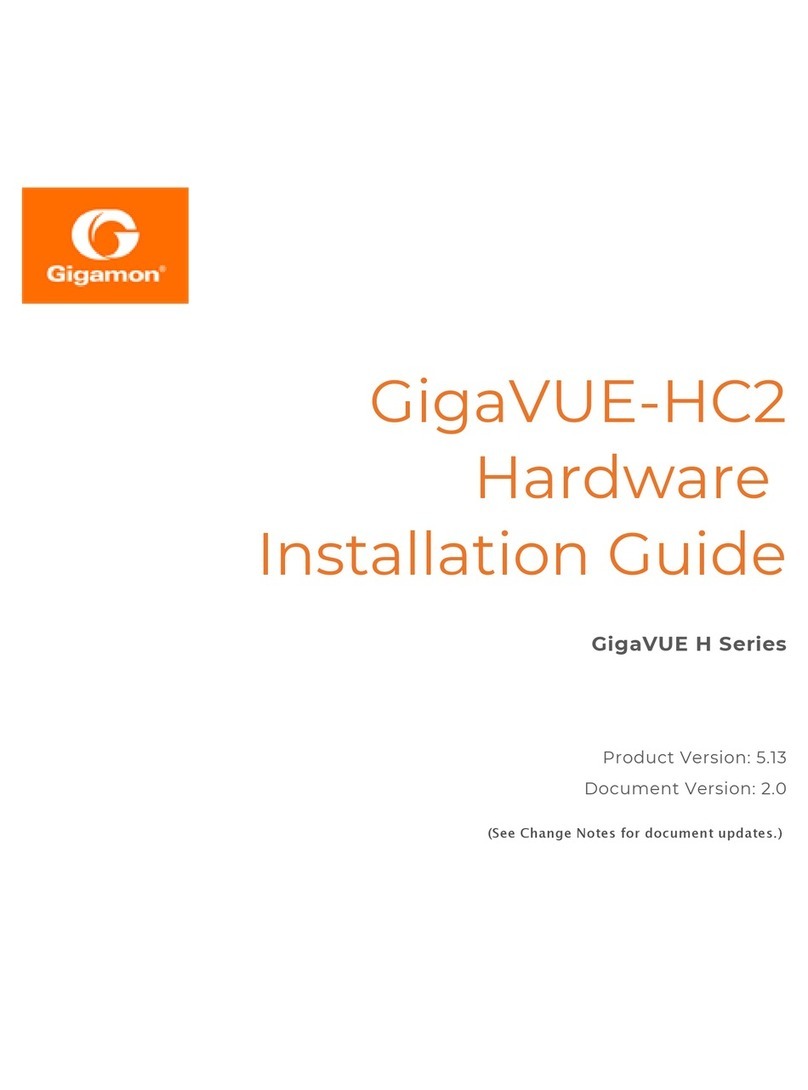

Figure 3: Connection options

2.5 Connecting power supply and relay contact

Electrical voltage

Only qualified electricians are allowed to work on the electrical equipment.

Danger due to incorrect earthing

Incorrect device earthing may cause injury to personnel or damage the device. Ensure

correct and proper earthing of the device.

Note

Reverse polarity in the power supply can damage the device. Make sure the power supply is

connected with correct polarity.

TH LINK Industrial Ethernet - Installation Manual

10 Copyright 2017 Softing Industrial Automation GmbH

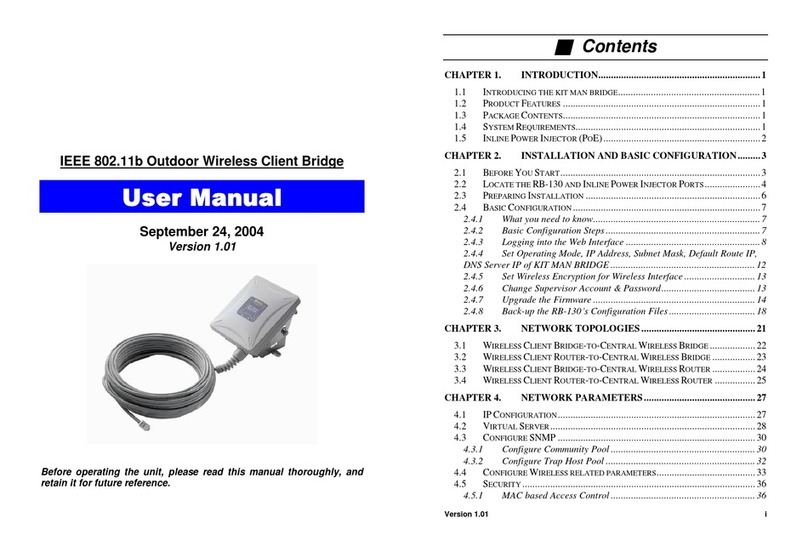

Figure 4: Terminal strip for power supply of the device

1. Connect the cable of a 24 V power supply and the earth conductor (earth terminal) to the terminal

strip on the device. The terminal strip can be plugged and lifted out for installation using a

screwdriver.

2. Connect the cable of the circuit that should be closed by the relay contact to the terminal strip on

the device.

3. Switch on the power supply. The LED RUN is green and the LED ETH flashes red until the device's

boot procedure is completed. Afterwards the LED RUN and BUS light green.

3Configuring the device in the network

3.1 Configuration requirements

The following ports have to be enabled in the firewall:

Protocol/purpose

Port

HTTP

80 TCP

Firmware update

1100 TCP

TH LINK communication with each other

1123, 1124, 2364 UDP

TH LINK communication with TH SCOPE

via Multicast

via Unicast

2364 UDP

1151, 2365, UDP

3.2 Network presettings

The device is preset to network operation with a DHCP server. No network configuration settings

are required in this operating mode.

In case of manual allocation of IP addresses the device can be reached via the following IP

addresses (Factory setting):

Note

TH LINK can be accessed from office network via IP 169.254.0.1 (default). To access TH LINK

from the automation network, you would choose IP 169.254.0.2 (default).

Chapter 3 - Configuring the device in the network

Copyright 2017 Softing Industrial Automation GmbH 11

3.3 Web access and login

After TH LINK has been successfully configured in the network, please go to Windows start >

Program > Softing > TH LINK > TH LINK to open the TH LINK web interface.

To log in as an administrator, go to the top right of the page and enter the password.

Note

The default password is the 9-digit serial number of the TH LINK. We recommend changing

the password after initially setting up the device.

Figure 5: Access and log in to the TH LINK web interface

3.4 Network overview

When opening the TH LINK web interface, a network overview will be provided, giving essential

information on all necessary diagnostic data of the network.

Figure 6: TH LINK network overview tab

TH LINK Industrial Ethernet - Installation Manual

12 Copyright 2017 Softing Industrial Automation GmbH

3.5 Setting new IP and network address

For configuration of IP-address of the TH LINK, please perform the following steps:

1. Inside the web interface, click on Settings and then on TH LINK.

2. In menu Network configuration switch the configuration method for office networks and/or

automation networks from DHCP to Manual.

3. Enter the new IP address.

Note

Note down the IP address. You can only access the device's configuration page by using this

IP address.

4. Enter the new addresses for Subnet mask and Default gateway.

5. Enter the IP address of the DNS server.

6. Click on the floppy disk sign to save the settings. The device then performs a restart.

Note

The default password can be changed on the TH LINK 's settings page. One the web

interface, click Settings > TH LINK and change the password under "User administration".

Click "Change password" to finalize.

Note

The device is preset to network operation with a DHCP server and in this case it is

automatically assigned an IP address. No network configuration settings are required in this

operating mode. The routine for the DHCP identification only runs during device start-up.

Briefly switch off the power supply for a new DHCP identification.

Chapter 3 - Configuring the device in the network

Copyright 2017 Softing Industrial Automation GmbH 13

Figure 7: Settings page of TH LINK web interface

3.6 Check the connection to the device

You can check the device's connection in the network. Start a web browser on your PC/notebook.

For DHCP: Enter the hostname http://THLINK-serial number (e.g.: http://THLINK-143500067) and

press Enter.

For manual IP configuration: Depending on the network in which your PC/notebook is installed,

enter the specified IP address of the office or automation network (basic setting: 169.254.0.1 or

169.254.0.2) and press Enter.

Now the website of the TH LINK should be displayed in the web browser.

3.7 Firmware update

Firmware updates for the TH LINK are available free of charge from our website. Proceed as follows:

1. Click Settings and then Firmware Update.

2. Check if the requirements for a firmware update are met. Stop the current measurement.

3. Download the latest firmware version from (http://industrial.softing.com/en/downloads.html) and

save it to a local directory.

4. Click [...] and then select the firmware file.

5. Click Start.

TH LINK Industrial Ethernet - Installation Manual

14 Copyright 2017 Softing Industrial Automation GmbH

Note

Do not turn off the power during the entire firmware update process! After the firmware

update the TH LINK restarts automatically.

Figure 8: Firmware update

4Troubleshooting

TH LINK is not found in the Ethernet network

Check the power supply (LED RUN must light green).

Check for correct connection (RJ-45, see Connecting to Ethernet).

The device is preset to network operation with a DHCP server (IP address for the device is assigned

by the DHCP server. If your network server does not support DHCP, you need to set the IP address

for the TH LINK manually (see Connection in a network with manual IP address assignment).

When a crossover cable is used between PC/notebook and TH LINK, both devices must be in the

same subnet.

LED RUN lights red – internal error

Reset password

In case you forgot the password to log in to the TH LINK, you can either

have the password reset with the help of the Softing Support team. The device must be remotely

accessible by a Softing staff.

send in the device to reset the password. The procedure is described on Softing's website (http://

industrial.softing.com/en/services/support/netzdiagnose.html).

Chapter 5 - Technical Data

Copyright 2017 Softing Industrial Automation GmbH 15

5Technical Data

Electrical data

Nominal supply voltage (limit

values)

V DC

24 (18 ... 32)

typical current consumption

mA

150

continuous current

consumption

mA

180

maximum current

consumption relay contact

mA

100

Protection class

IP

20

Note

The maximum current consumption on turn on is limited to 8 A in the TH LINK

Operating conditions

Ambient temperature range

(*)

°C

-40…+75

Relative humidity

%

5 ... 95 (no condensation)

(*) Depending on the SD card used the ambient temperature range might deviate from the values

indicated here. Verify the ambient temperature range specified by the SD card manufacturer. You

can find a list of recommended SD cards in Release Notes on your installation CD or in the Softing

download area (http://industrial.softing.com/en/downloads.html).

Housing dimensions

Dimensions W × H × D

mm

22,5 × 99 × 114,5

Weight (approx.)

g

120

Other

Ethernet connection

Type

RJ-45 (10Base-T/100Base-TX)

Certificates

CE, UL

Tel: + 49 89 45 656-0

Fax: + 49 89 45 656-488

info.automation@softing.com

Richard-Reitzner-Allee 6

85540 Haar / Germany

http://industrial.softing.com

Softing Industrial Automation GmbH

Table of contents

Other Softing Network Hardware manuals