3

SUBJECT INDEX

1- INTRODUCTION................................................................................................................................................................................. 5

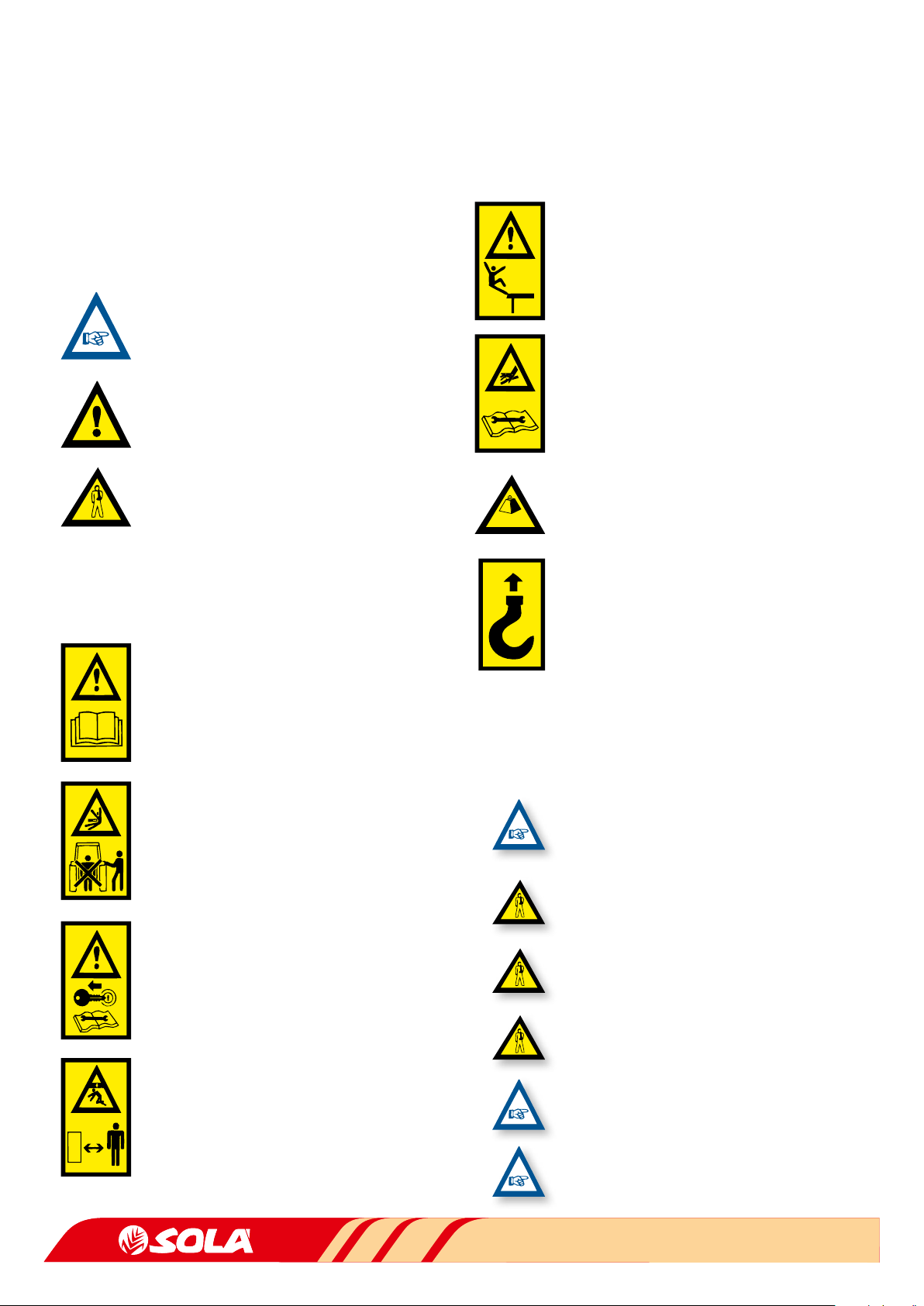

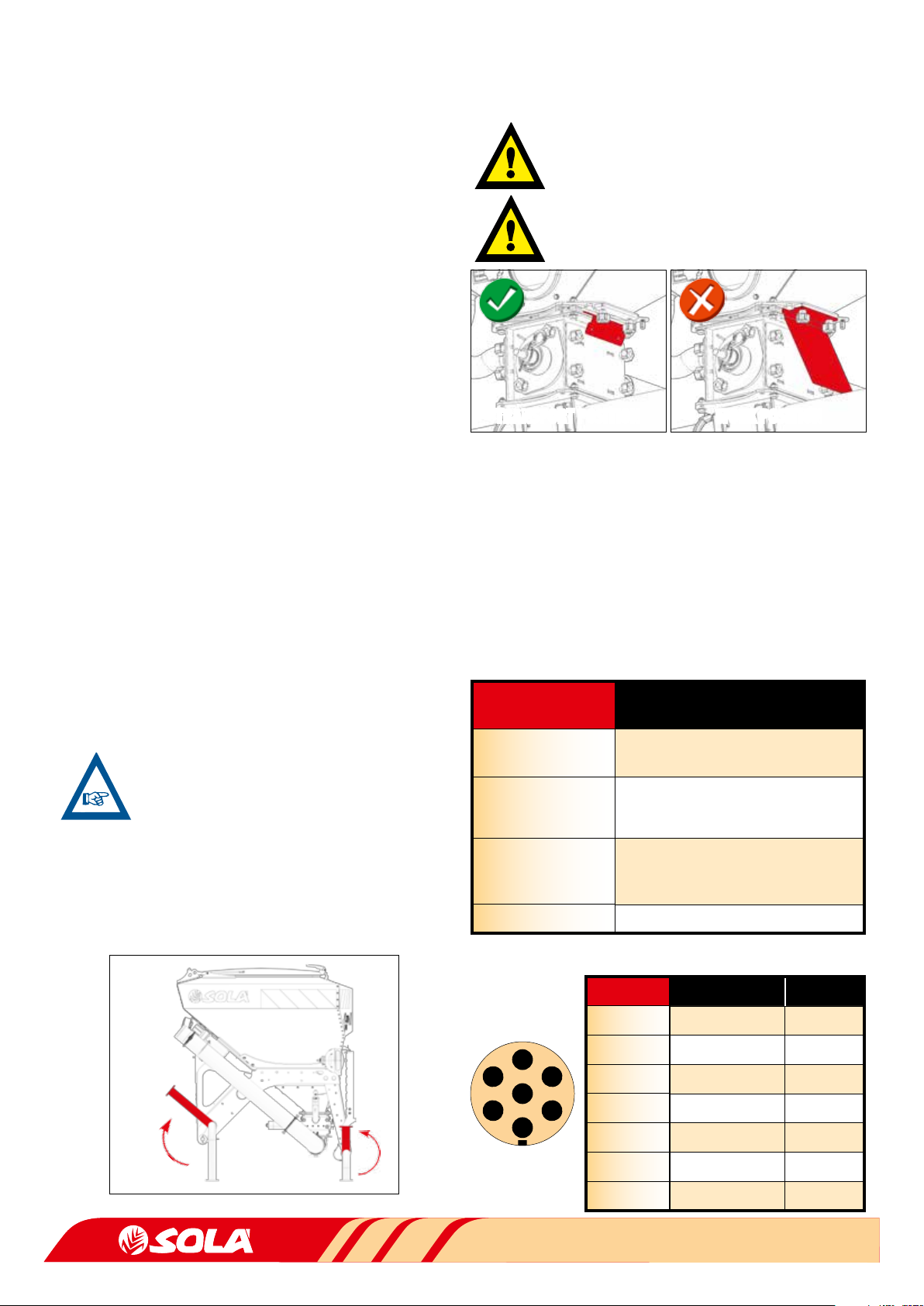

2- SAFETYINSTRUCTIONS..................................................................................................................................................................... 6

2.1 SAFETY SYMBOLS..........................................................................................................................................................................................................6

2.2 GENERAL SAFETY DISPOSITIONS..............................................................................................................................................................................6

2.3 USE DEPENDING ON DESIGN......................................................................................................................................................................................7

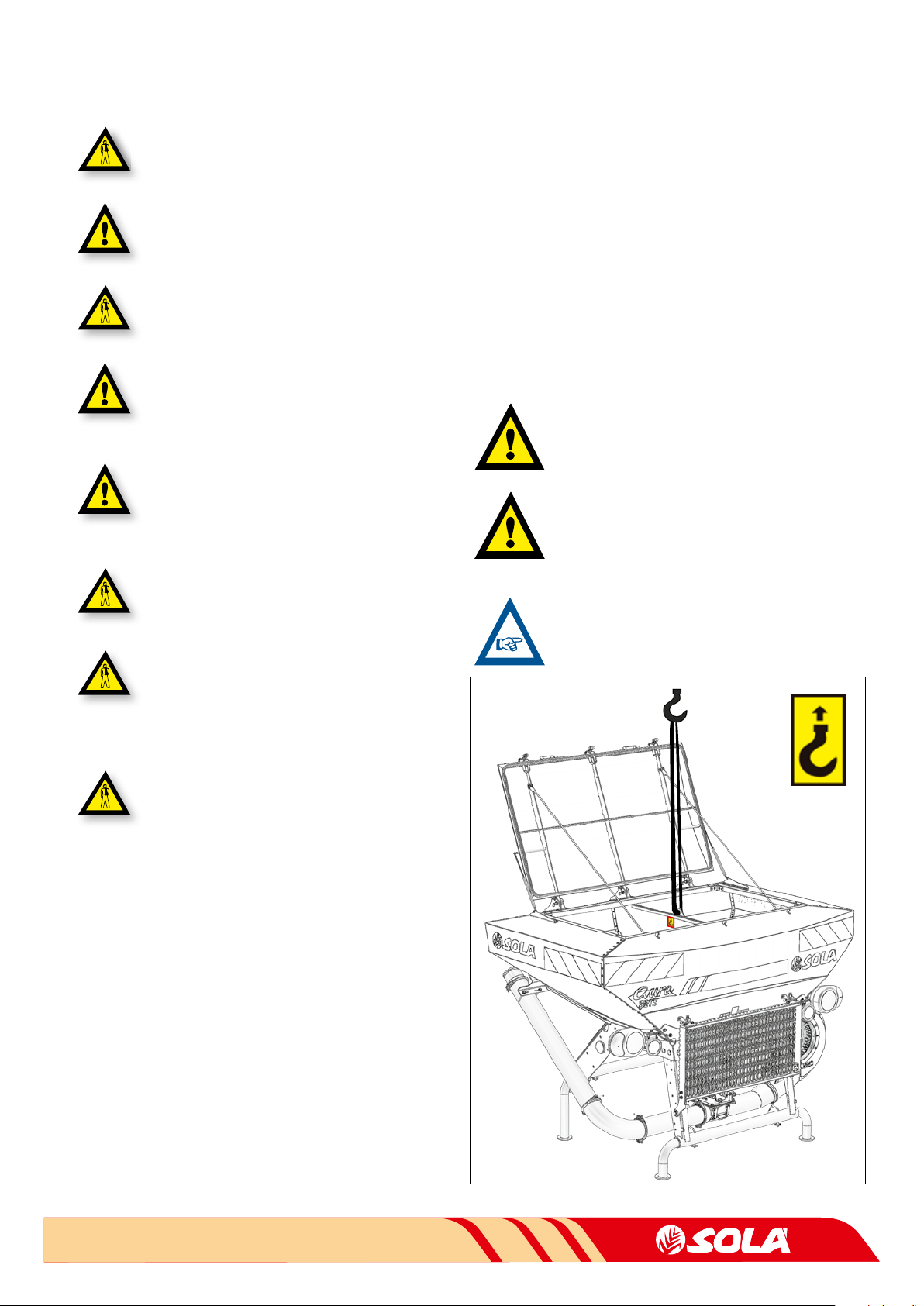

2.4 LOADING AND UNLOADING INSTRUCTIONS ..........................................................................................................................................................7

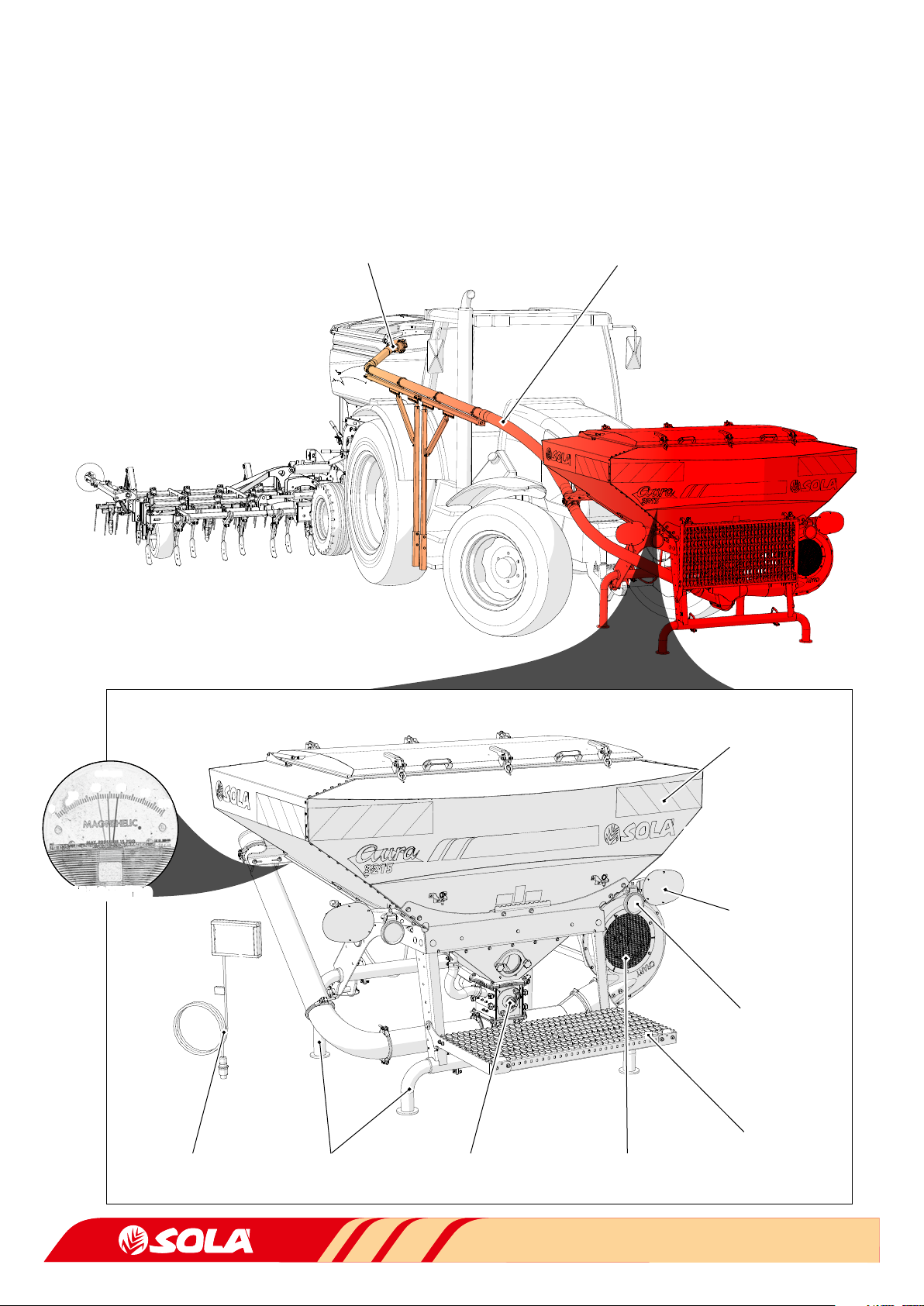

3. GENERALDESCRIPTION .................................................................................................................................................................... 8

3.1 GENERAL OVERVIEW ....................................................................................................................................................................................................8

3.2 TECHNICAL FEATURES .................................................................................................................................................................................................9

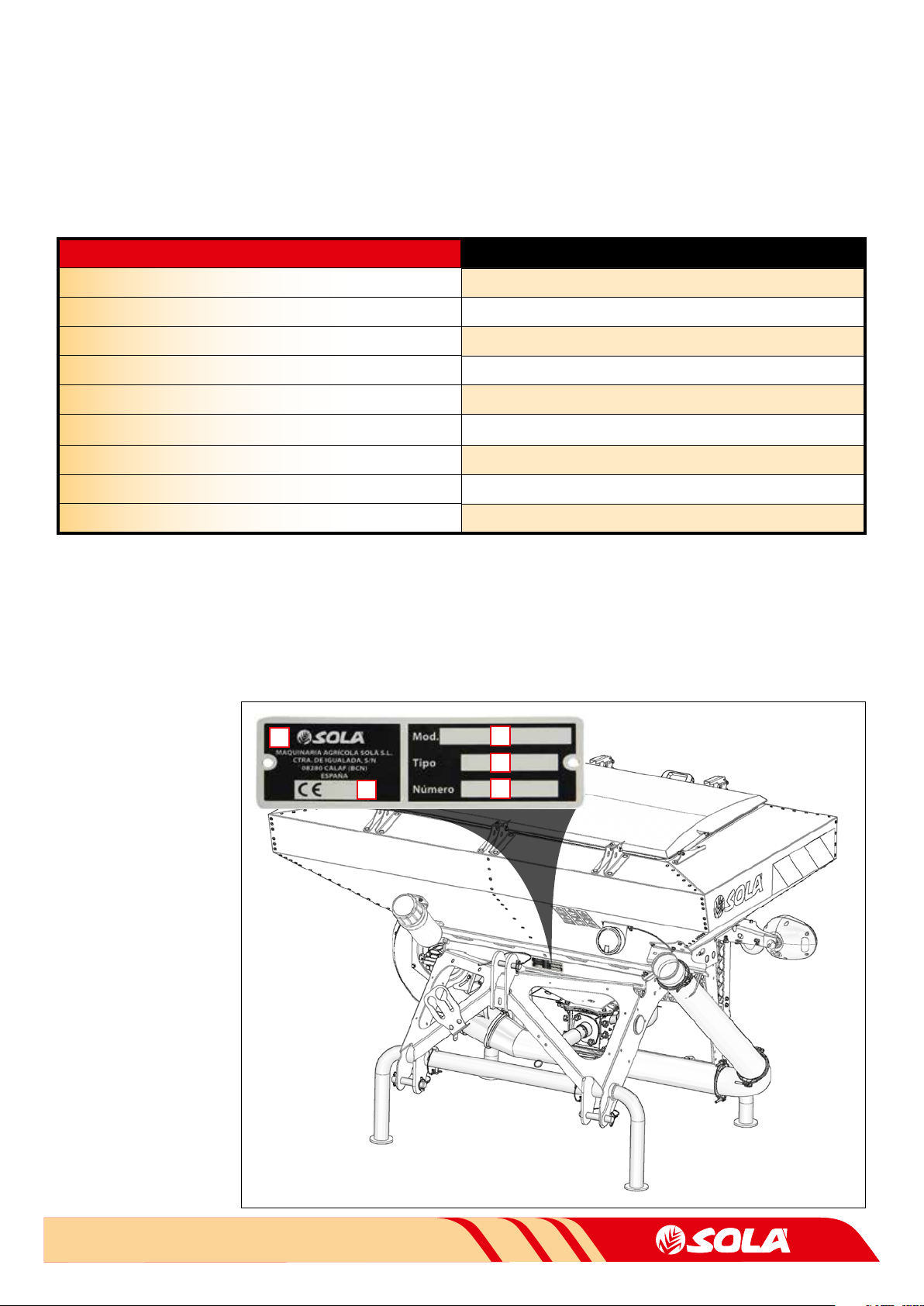

3.3 IDENTIFICATION OF THE MACHINE...........................................................................................................................................................................9

4. COMMISSIONING ............................................................................................................................................................................ 10

4.1 ASSEMBLY OF THE MACHINE TO THE TRACTOR...................................................................................................................................................10

4.2 TRACTOR'S REQUIREMENTS.....................................................................................................................................................................................10

5. DOSAGE............................................................................................................................................................................................11

5.1 DISPENSER TYPES........................................................................................................................................................................................................11

5.1.1 ROLLER DISPENSER ..........................................................................................................................................................................................11

5.1.2 ENDLESS DISPENSER........................................................................................................................................................................................12

5.1.3 TRANSFILLING DISPENSER .............................................................................................................................................................................13

5.2 CALIBRATION TEST .....................................................................................................................................................................................................13

5.3 DOSAGE GRAPHS ........................................................................................................................................................................................................14

5.3.1 ROLLER DISPENSER..........................................................................................................................................................................................15

5.3.1.1 ROLLER DISPENSER WITH A SINGLE OUTLET...................................................................................................................................15

5.3.1.2 ROLLER DISPENSER WITH TWO OUTLETS ........................................................................................................................................16

5.3.2 ENDLESS DISPENSER .......................................................................................................................................................................................17

5.3.2.1 ENDLESS DISPENSER WITH A SINGLE OUTLET................................................................................................................................17

5.3.2.2 TWO ENDLESS DISPENSERS WITH TWO OUTLETS ......................................................................................................................... 17

6. USAGE ADVICE ................................................................................................................................................................................ 18

6.1 AURA-3215 WITH PERFORMER .................................................................................................................................................................................18

6.2 AURA-3215 WITH ISOBUS..........................................................................................................................................................................................18

7. MAINTENANCE ................................................................................................................................................................................ 19

7.1 CHECK-UP FREQUENCY ..............................................................................................................................................................................................19

8. WARRANTY ..................................................................................................................................................................................... 21

SUBJECT INDEX