SolarGaps SGV1C80-6-W Series User manual

VENETIAN BLINDS WITH SOLAR PANELS

OPERATION MANUAL

EN

EN.2

Dear Customer!

SolarGaps would like to express its gratitude for your choice!

Our experts use best working practices and modern technologies to

ensure efficient utilisation of solar energy as you use our product.

We provide quality control at every production stage: from design of

engineering drawings and incoming control of materials and components to

outgoing control of finished products and packing of goods for further

transportation — with all operations performed by highly qualified personnel.

We strongly recommend you to read this manual carefully before installing

and using the product.

YOU CAN RELY ON THE TOP QUALITY OF SOLARGAPS PRODUCTS!

EN.3

CONTENTS

!

1.!

Functionality!and!field!of!application!...............................................................................................!EN.!4!

2.!

Reference!to!standards!................................................................................................................!EN.!5!

3.!

Technical!specifications!and!product!range!.................................................................................!EN.!6!

4.!

Delivery!set!...................................................................................................................................!EN.!8!

5.!

Product!description!and!operating!principle!...............................................................................!EN.!9!

6.!

Preconditions!for!installation!.....................................................................................................!EN.!11!

7.!

Product!installation!.....................................................................................................................!EN.!16!

8.!

Start-up!and!adjustment!works!..................................................................................................!EN.!22!

9.!

Product!testing!...........................................................................................................................!EN.!23!

10.!

Mobile!Application!instructions!...............................................................................................!EN.!24!

11.!

Transportation!rules!.................................................................................................................!EN.!37!

12.!

Storage!rules!.............................................................................................................................!EN.!38!

13.!

Safety!instructions!....................................................................................................................!EN.!39!

14.!

Fire!safety!instructions!.............................................................................................................!EN.!40!

15.!

Operation!conditions!and!useful!life!........................................................................................!EN.!41!

16.

!Maintenance!.............................................................................................................................!EN.!42!

17.!

Troubleshooting!.......................................................................................................................!EN.!43!

18.!

Warranty!obligations!................................................................................................................!EN.!44!

19.

!Disposal……………………………………………………………………………………………………………………………….EN.47!

Annexes:!!

!

1.

Warranty!Certificate.............................................................................................................!

EN.48!

2.

Declaration!of!Conformity....................................................................................................!

EN.49!

3.

Declaration!of!Performance.................................................................................................!

EN.50!

EN.4

1. Functionality and field of application

The SolarGaps solar panel blinds system (hereafter referred to as the BLINDS) is a smart

blinds system using built-in photovoltaic elements, which generate the electrical power. You

can use this electricity to power your home appliances, store it in batteries and/or sell the

excess amount to your energy supplier. SolarGaps blinds can automatically track the sun all

day long, adjusting their position to ensure optimum tilt angles for capture of solar rays and

maximum solar energy generation to provide power supply to various devices in your house,

apartment or office. SolarGaps blinds are mounted above window opening (outside of

apartment, house or office premises) and are capable to generate up to 100 W⋅h of energy

per 1 m2of the window area, which is generally enough to power 30 LED-lamps or three

MacBook laptops.

WARNING! Carefully study this Manual before starting installation (mounting) and

operation of the product.

Installation, maintenance and repairs of the product shall be performed only by

entities and organizations authorised (licensed) to perform such works or technicians

holding an appropriate certificate.

PROHIBITED! It is prohibited to carry out any works related to service and/or

repairs of the product without its prior disconnection from the power grid.

As a result of ongoing activities on improvement of the product by SolarGaps, this

document may not cover certain modifications in the design, though any such

modification shall by no means deteriorate neither technical specifications, nor design

and operational safety of the product.

EN.5

2. Reference to standards

EN 13561:2015 External blinds — Performance requirements including safety.

EN 13659:2015Shutters and external Venetian blinds. Performance requirements

including safety.

EN 60335-1:2012 Household and similar electrical appliances — Safety — Part 1: General

requirements.

EN 60335-2-97:2006 Household and similar electrical appliances — Safety — Part 2-97:

Particular requirements for drives for rolling shutters, awnings, blinds and similar

equipment.

EN 61000-3-2:2014 Electromagnetic compatibility (EMC) — Part 3-2: Limits — Limits for

harmonic current emissions (equipment input current ≤16 A per phase).

EN 61000-3-3:2013 Electromagnetic compatibility (EMC) — Part 3-3: Limits — Limitation

of voltage changes, voltage fluctuations and flicker in public low-voltage supply systems,

for equipment with rated current <= 16 A per phase and not subject to conditional

connection.

EN 55014-1:2006 Electromagnetic compatibility — Requirements for household

appliances, electric tools and similar apparatus — Part 1: Emission.

EN 55014-2:1997 Electromagnetic compatibility — Requirements for household

appliances, electric tools and similar apparatus — Part 2: Immunity.

EN.6

3. Technical specifications and product range

3.1. The BLINDS were designed and are manufactured according to the requirements of

EN 13561. The main technical specifications are presented in Table 1.

Table 1

Parameter

Value

Electrical energy generation:

- voltage, V

- frequency, Hz

- specific capacity, W/m2, minimum

- efficiency factor (EF), %, minimum

~ 230 and 110 ± 10%

50 or 60 ± 1

70

19

Adjustment of slat angle:

- slat angle adjustment range, degrees

- special software application for smartphone

70 to -30

SolarGaps

Power network:

- voltage, V

- frequency, Hz

- rated power consumption, W

207-244 and 110

50 or 60 ± 1

90 to 300

Operation conditions:

- working temperature, °C

- climate version, placement category 1

- shock resistance

-20 to +65

Moderately cold climate

group M3

Reliability indexes

- Mean time between failures, hours, min.

- total average useful life, years, min

20 000

10

Average specific weight, kg/m2

10±1

Notes:

Depends on the solar radiation intensity.

Power consumption during operation of the electric drive for adjustment of slats

position. It depends on power of the installed motor, which is determined by operational

load according to dimensions of the ordered product (length and number of salts).

EN.7

3.2. Product range of the BLINDS:

SGV1C80-6-W-(WxH)(color)(QM); SGV1C80-10-W-(WxH)(color)(QM);

SGV1C80-20-W-(WxH)(color)(QM); SGV1C80-6-R-(WxH)(color)(QM);

SGV1C80-10-R-(WxH)(color)(QM); SGV1C80-20-R-(WxH)(color)(QM);

EN.8

4. Delivery set

- SolarGaps BLINDS with solar panels .................................................................................1 set

- operation documents (Manual) ............................................................................................1 pcs.

- packing ...................................................................................................................................................1 pcs.

EN.9

5. Product description and operating principle

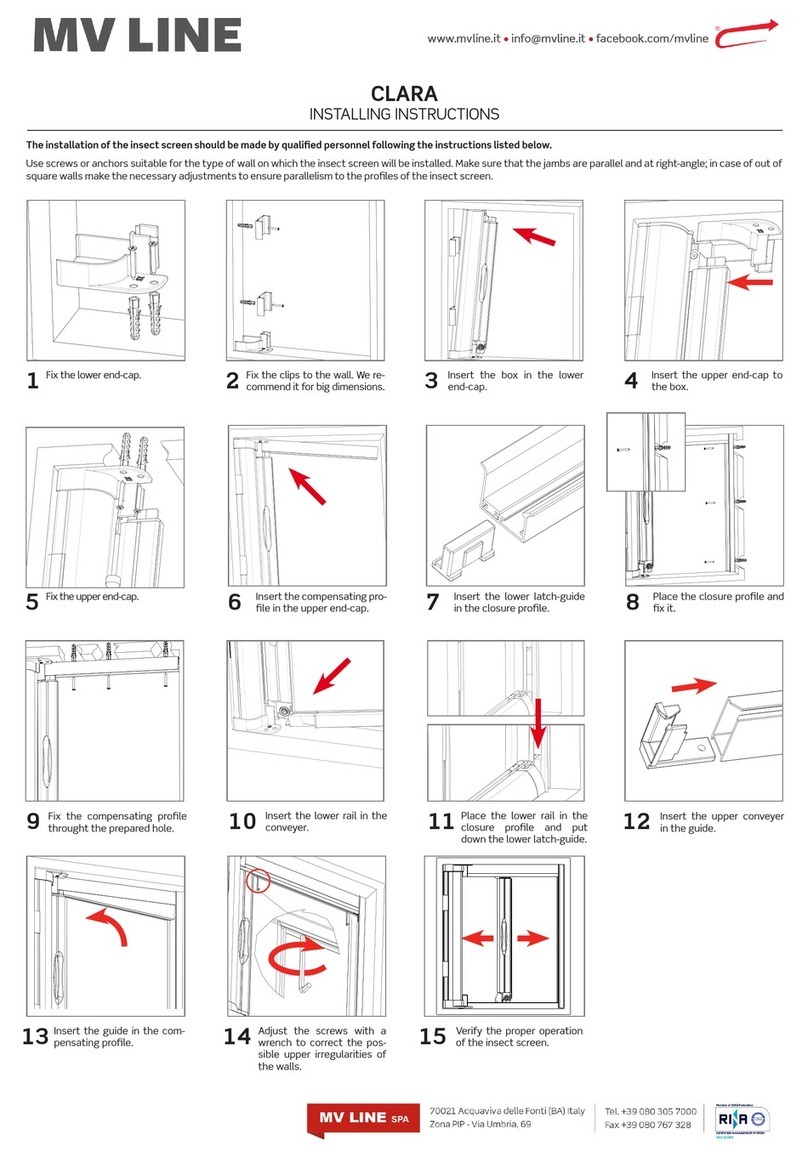

5.1. Product description

1– casing containing electric

drive motor, mechanisms

and control unit installed

under cornice;

2- mushroom-shaped

brackets;

3- slotted side guides;

4– slats with solar cells and

guiding rollers;

5- ladder cords (2 pcs.) — to

adjust the tilt angle of slats

with solar cells;

6- straps (2 pcs.) passing

through holes in slats with

solar panels to move the

entire blinds web up and

down;

7- bottom rail — to fix

cords and straps.

1

2

2

2

2

3

3

4

5

6

5

6

5

5

7

4

Figure 5.1. Product appearance

Figure 5.2. Arrangement of elements under the casing

5.2. Main elements of the BLINDS

5.2.1. Slats carrying attached solar panels that

convert solar energy into direct current electric

power. The number and length of slats depend on

the dimensions of ordered BLINDS.

Figure 5.3. Slats

5.2.2. Mechanism for moving slats with solar

panels up and down and adjusting the tilt

angle. The mechanism is mounted in the

cornice under the casing. It consists of electric

drive (motor), shaft and supports (number of

supports depends on the salt length, min. 2

pcs.)

Figure 5.4. Electric motor

EN.10

5.2.3. Slotted side guides (2 pcs.) ensure free

motion of slats with solar panels during operation

Figure 5.5. Slotted side guides

5.2.4. The electronic module installed in the casing

receives commands transmitted by a smartphone

via official application to control electric motor of

the BLINDS, controls output voltage of solar

panels and is connected to power consumption

and accumulation circuit for appliances, which use

the generated power.

Figure 5.6. Electronic module

5.2.5. The inverter converts generated power from DC to AC (~ 230 V 50 Hz) or

(~ 110 V 60 Hz) used as power supply for the majority of home appliances. Besides, if

needed, it allows connecting these consumers to the external power grid, or vice versa –

supplying the excess generated energy to the grid, which gives the right to respective

compensation according to the law. The connection cable for the inverter is attached

through cable duct QM.

5.2.6. The battery, which can be incorporated into the BLINDS system, allows optimizing

power supply of the house through redistribution of accumulated and consumed

electrical energy.

The BLINDS are controlled via Wi-Fi by using special mobile application and automatically

adjust the tilt angle of slats with solar panels, while tracking the sun position to ensure the

maximum power generation.

EN.11

6. Preconditions for installation

WARNING! It is recommend to read the technical description before proceeding

with the installation (mounting) and start-up and adjustment works to be performed

prior to operation of the BLINDS.

6.1. It is recommended to install the BLINDS outside of the building over a window or

any other transparent aperture. Only this mounting position together with appropriate

slat tilt angle adjustment can ensure optimum utilization of all advantages provided by

the BLINDS:

protection from direct sunlight by preventing the rays from entering the room;

conversion of solar radiation into electrical power for further consumption along

with the room dimming.

If you get professional advice on compatibility of equipment made by different

manufacturers, the BLINDS may be easily integrated into a single Smart House system,

in which multiple household processes are automated and controlled via centralized

services such as Google Home or Amazon Alexa.

During the purchase/sale of the BLINDS (before installation of the product) the

Buyer is recommend to:

check for absence of damages of the transportation packing by visual inspection;

carefully remove the packing material in a way not to damage components of the

BLINDS;

check the received product for conformity with the order;

check the completeness of the product;

make sure that the Warranty Certificate is properly filled, free of alterations, has an

indication of the date of sale, bears the Seller’s stamp and signature of the sales person;

check the availability of a document confirming the fact of purchase-sale of the

BLINDS;

record information on all revealed discrepancies, damages or missing components

of the BLINDS in the delivery receipt or delivery note;

file a claim to the transportation company, if any discrepancies and/or violations have

been found. If the product was received from a distributor, the claim shall be presented

directly to the distributor.

NOTE: The Manufacturer will not accept any claims relating to missing components

and physical damages to the product, as well to the absence of abovementioned

documents or their incorrect or unclear wording after installation of the BLINDS.

WARNING! Install the BLINDS according to legal and construction requirements for

installation of sun louvres (external blinds) in effect in your country.

Design, materials and components used in the product exclude the option

of indoor installation and operation of the BLINDS.

EN.12

CAUTION! The BLINDS contain components supplied by electrical power (~230 V 50

Hz and ~110 V 60 Hz) or generating it. Therefore, wiring and connection to the grid shall

be performed by an authorised electrical technician having an appropriate permit.

6.2. The Buyer is recommended to take into account the following factors prior to

installing the product:

6.2.1. In case of a new construction, it is desirable to include installation of the BLINDS in

the construction project in advance. In this case all installation and start-up issues will

be settled by the Constructor based on the contract with the End User/Buyer of our

product.

6.2.2. If a building already exists, it is recommended to order installation of the BLINDS

to companies that have permits (licenses) for such works (including Working At Height

Permit) or appropriately certified personnel.

6.2.3. If the Buyer intends to install the BLINDS and perform start-up works- to the

highest standard by himself, he will need:

advanced skills of using tools;

personal experience in performing elevated jobs and proper equipment;

favourable climate conditions (temperature, humidity, rain, snow, wind, dust rate,

smoke, natural lighting, etc.).

CAUTION!

All risks during the independent installation and start-up works performed by the

Buyer shall be borne by the Buyer, and the Manufacturer and/or Seller shall bear no

responsibility in this case.

Improper fixing and other installation errors, specifically under extreme

environmental conditions (icing, vibration, etc.) may cause product falling and

result in damage to property, health or even danger to lives of people or animals.

6.3. The Buyer/End User must choose the BLINDS installation option before ordering the

product model, since it is related to dimensions of the BLINDS. The main installation

options for the product include:

6.3.1.

If the building is already built, the BLINDS

may overlap the face of the building, as follows:

- slotted side guides are fixed at both sides of the aperture;

- the casing is fixed above the aperture.

This layout is easily implemented but is less resistant to external

impacts (natural disasters, vandalism).

6.3.2.

If the BLINDS are installed into the window aperture, a certain

useful light-transmitting window area is lost, as it is shielded by

the casing. Besides, the casing with mechanisms and slotted

side guides become visible from inside. However, this type of

installation is more resistant to external impacts.

6.3.3. The key factor of optimum installation is compliance of the ordered and received

model of the BLINDS with the chosen installation option.

EN.13

6.4. High-quality preparation of the window aperture is an essential precondition for

installation of the BLINDS with minimum expenses, namely:

the window aperture shall be rectangular in shape;

the working surface of aperture shall be plain and smooth without plaster sags and

cracks;

any deviation of the working surface area from vertical and horizontal position shall

not exceed 1.5 mm/m and 5 mm in total. The difference between lengths of diagonals

shall not exceed 5 mm.

Notes:

To perform exact measurements, use a metal tape measure. Take measurements in

millimetres in the width ×height format.

Measure each window since they may have slightly different dimensions.

Do not take measures from the building plan since they may be inaccurate.

Decide whether you prefer Overhung (larger that the window aperture) or Innerhung

(within the window aperture) BLINDS installation method.

Overhung

Innerhung

6.5. Taking measurements for the Innerhung (BLINDS within the window aperture)

installation method.

If you want to fit / fix / hang BLINDS within the window aperture, you have to measure

the internal size of the aperture (aperture size that is precise window height and width.)

EN.14

Measure the wall-to-wall window

width in three locations.

Record the shortest width

measurement

Measure the height from the upper

part of the windows aperture to the

window sill in three locations.

Record the shortest height/drop

measurement.

Tolerance to be taken into account

when taking width measurements.

Tolerance shall be at least 7 mm.

6.6. Taking measurements for the Overhung (BLINDS exceed the window aperture)

installation method.

Follow the instructions below if there is an architrave in the window aperture.

Measure the width from one architrave

edge to the opposite one.

Measure the height from the architrave

top to the location, which you plan to be

the lowest point for your BLINDS.

Record the measurement results.

EN.15

If there is no architrave, perform the

following steps

Measure the width from one edge of

the window aperture to the opposite one.

Measure the height from the window

aperture top to the location, which you

plan to be the lowest point for your

BLINDS.

Record the measurement results.

Notes:

Take into account different blind types. To ensure the maximum privacy and the

minimum light break, it is recommended that the BLINDS extend over the bottom and

both sides of the window opening.

CAUTION!

When making an order, be sure to specify the BLINDS installation method for which the

measurements were made.

EN.16

7. Product installation

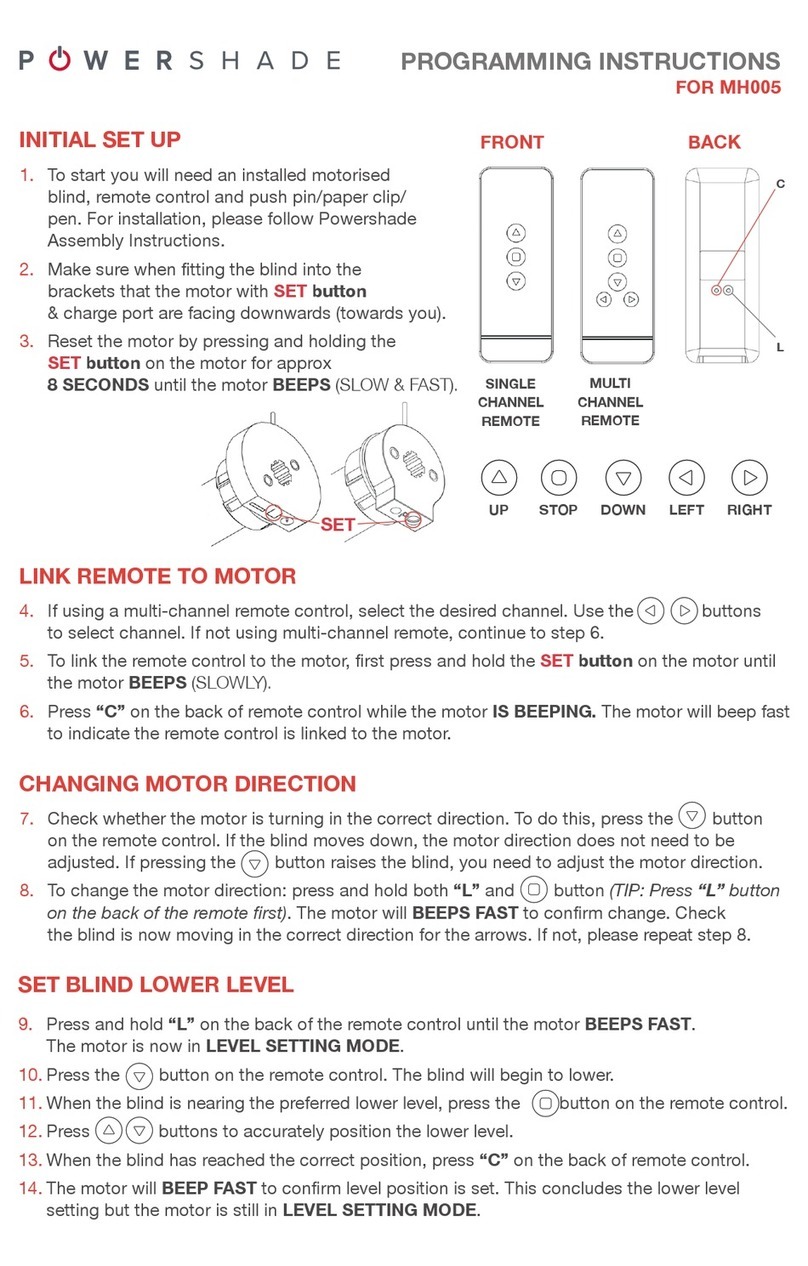

7.1. General sequence of operations for installation of the BLINDS is as follows:

install and fix the cornice that contains properly fixed casing with electric motor,

mechanisms and control unit with the help of latch brackets;

insert guiding rollers of slats with solar panels into slotted side guides;

install the slotted side guides and fix them with mushroom brackets;

drill holes for electrical cables;

install indoors and properly fix the inverter and battery (if a battery is incorporated

in the BLINDS system);

perform electric wiring according to the current standards.

CAUTION! Perform installation taking into account material properties of walls of the

building, where the BLINDS are to be mounted, as well as the window design and

materials, if the product is to be mounted into the window aperture. Therefore, use

proper tools and fixings (rods, anchors, screws, etc.) that are resistant to corrosion and

climatic impact to ensure secure attachment of the product under operation conditions.

7.2. Install the cornice with casing

containing electric motor,

mechanisms and control unit as

follows:

7.2.1. Mark out points for holes to fix latch

brackets on the prepared working

surface making sure to locate them at

equal intervals and ensuring

horizontal position of the casing and

cornice.

Casing containing electric motor,

mechanisms and control unit

located under cornice

Fixing screw

Hooking bracket for installation of

cornice and casing

Slotted side guides

Mushroom corbel for installation

of side guiding groove

Slats with solar cells

ламелі зсонячними елементами

Slats with solar cells

7.2.2. Make holes to fix the latch brackets depending -on the installation place, i. e.:

for concrete, stone or solid brick walls — Ø 8 mm holes using a

rotary hammer, e. g. REDIBOLT-N 8x120/M6/75 anchor and a

yellow zinc plated nut or equivalent;

for aerated concrete walls — Ø 6 mm holes using a drill for a

sleeve anchor used together with a screw, e. g. TGS 8x60/5.0-

6.0 anchor (yellow zinc plated) and DIN571 6.0x100 screw or an

equivalent set of fixing elements of a proper material;

for wooden walls — Ø 4 mm holes using a drill for a stainless

steel screw, e. g. DIN571 6.0x100 screw for Group 6 A2 wood or

equivalent;

for metal window frames — use a self-tapping screw without

drilling a hole;

e. g. for frames made of stainless steel, use TEX-Him 6.3x38C1

screw as per ISO 15480 or equivalent.

7.2.3. Fix the latch brackets to the working

surface using an appropriate fixing method

EN.17

(by anchor or screw) in accordance with

para. 7.3.2 of this Manual.

See Figure on the right →

кронштейни

-зачіпи

Latch

brackets

7.2.4.

кронштейни

-зачіпи

Latch

brackets

Hang up the cornice with casing on the

latch brackets.

←See Figure on the left.

NOTE: The package of BLINDS includes a hard casing made of extruded aluminium

alloy and a cornice made of high strength aluminium section. Therefore, installation is

highly simplified since the latch brackets can be fixed on walls or window frames in

convenient places.

7.3. Install the slotted side guides as

follows:

7.3.1. Mark out points for holes to fix the

mushroom brackets taking into

account the following requirements:

offset from the end of a guide ~

100 mm;

equispaced locations of brackets;

vertical position of the guides.

Casing containing electric motor,

mechanisms and control unit

located under cornice

ламелі зсонячними елементами

Fixing screw

Mushroom corbel for installation

of the slotted side guide

Slotted side guide

ламелі зсонячними елементами

Slats with solar cells

7.3.2. Drill holes to fix the mushroom brackets -the

same way as in para. 7.2.3 of this Manual.

7.3.3. Fix the mushroom brackets to the working

surface using an appropriate fixing method (by

anchor or screw) in accordance with para. 7.2.3 of

this Manual.

See Figure on the right →:

7.3.4. Insert guiding rollers of slats with solar cells

into slotted side guides in a way to ensure free

motion of the slats under operating conditions.

7.3.5.

EN.18

Insert caps of the mushroom -brackets into

respective slots in the slotted side guides

and fix them on the mushroom -brackets

with fixing screws.

←See Figure on the left.

NOTE:

Mount the slotted side guides made

of aluminium section with inserts for

smoother sliding of rollers of the slats

with solar cells with blind plugs

facing down.

Blind plug

Bottom rail

Slats with solar cells

Slotted side guide

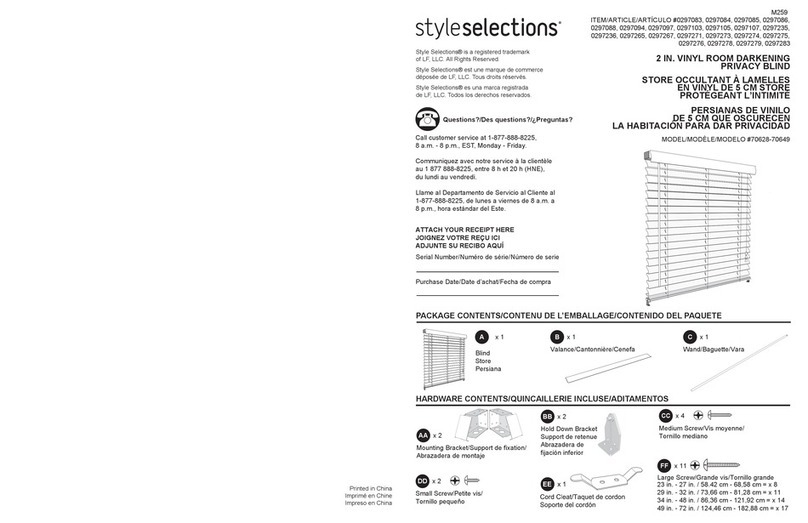

7.4. Connect the BLINDS to the grid, inverter and battery (if the latter is incorporated

into the BLINDS system) as follows:

7.4.1. Mark out a point for a wiring hole to bring electrical cables into the room in

which the following items are to be installed:

sockets for connecting the BLINDS to the grid;

inverter from the product set;

battery, if the latter is incorporated into the BLINDS system.

7.4.2. Drill a Ø 8-10 mm hole for

electrical cables as described in

para. 7.2.2 of this Manual.

7.4.3. Bring the above-mentioned

electrical cables into the room

and fit them with appropriate

connectors (plugs) supplied as

part of the set.

EN.19

7.4.4. Connect the motor cable to

a plug from the product delivery

set (see figure to the right).

7.4.5. Connect the electric cable to inverter connectors from the product delivery as

follows:

Strip off insulation at the end of each wire.

Slip the plug pin onto the striped wire end.

Crimp the pin using a special tool.

Force the plug onto the pin until you hear a distinctive click. Make sure the pin is

firmly fixed in the plug.

Put the cap onto the plug housing and tighten it firmly.

Slip the socket pin onto the striped wire end.

Crimp the pin using a special tool.

Force the socket onto the pin until you hear a distinctive click. Make sure the pin is

firmly fixed in the socket.

Put the cap onto the socket housing and tighten it firmly.

EN.20

Put heat shrink tube of appropriate diameter (5 mm) on wires with connectors.

Put on heat shrink tube of appropriate diameter (9.5 mm) on the wire to be

connected to MC4 connectors.

Solder plug connector (marked with ‘+’ on the housing) to core marked with ‘2’ on

the insulation.

Solder socket connector (marked with ‘-’ on the housing) to core marked with ‘1’ on

the insulation.

Pull on heat shrink tube over the soldered joints and heat up using a hot air gun.

Pull on heat shrink tube (9.5 mm in diameter) over the soldered joints (to improve

the appearance) and heat up with a hot air gun again.

7.4.6. Install and properly fix the

inverter and battery in the room in

places chosen taking into account

the length of respective electrical

cables (DC).

Diagram for connection of the product

* - Depending on the country of delivery, the system may be fitted with different

plugs or adapters.

** - The system may be optionally equipped with a rechargeable battery.

7.4.7. Attach the connectors, fitted in accordance with

para. 7.4.3 of the Manual, as follows:

DC output of the BLINDS — to the inverter and

battery;

AC input of the BLINDS and AC output of inverter —

to the grid using plugs.

This manual suits for next models

5

Table of contents

Popular Window Blind manuals by other brands

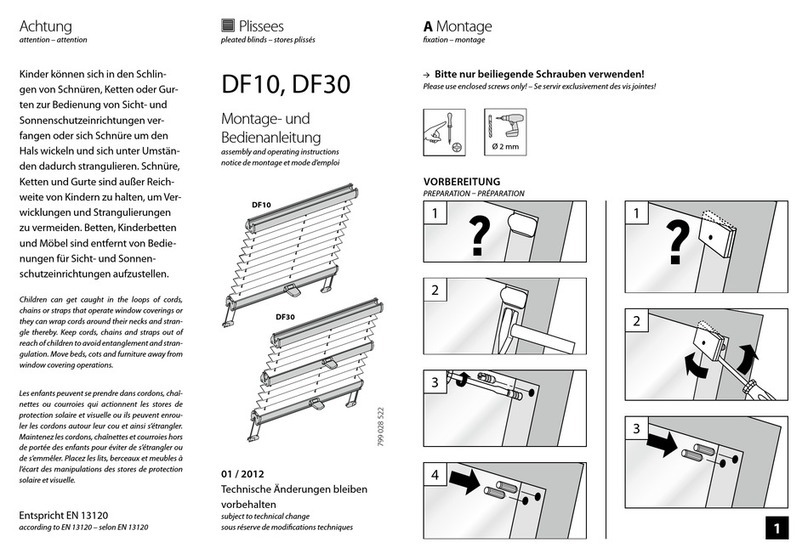

Plissees

Plissees DF10 Assembly and operating instructions

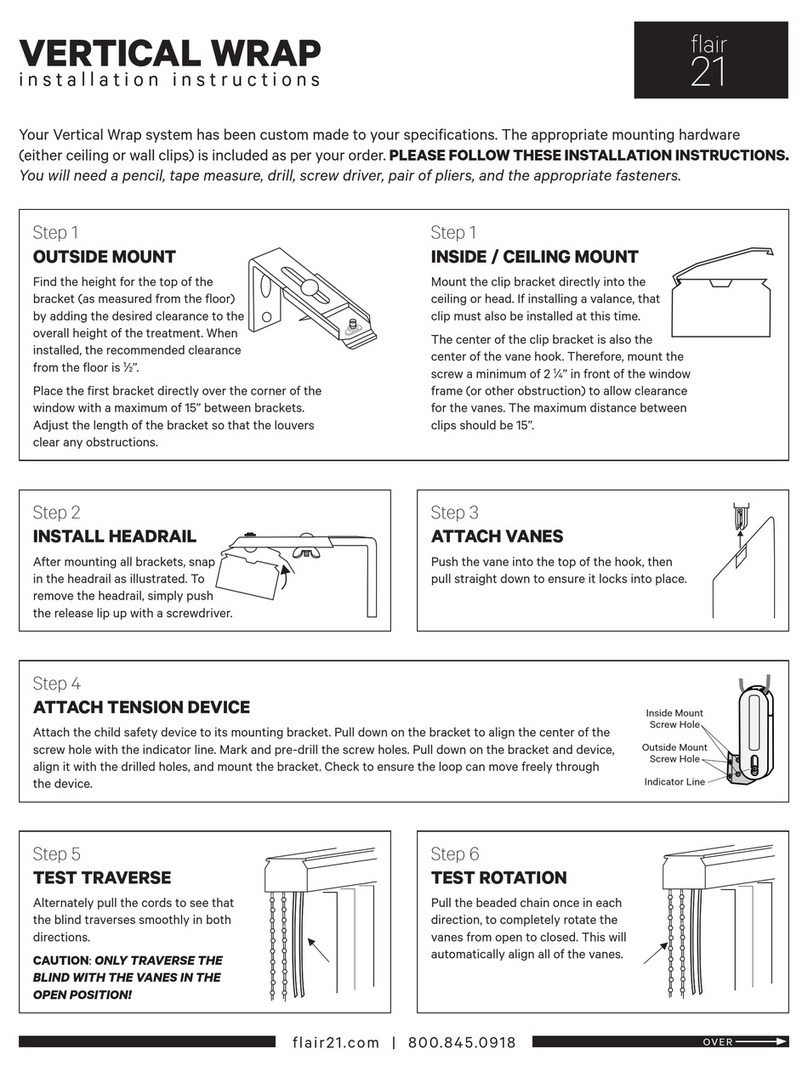

flair21

flair21 VERTICAL WRAP installation instructions

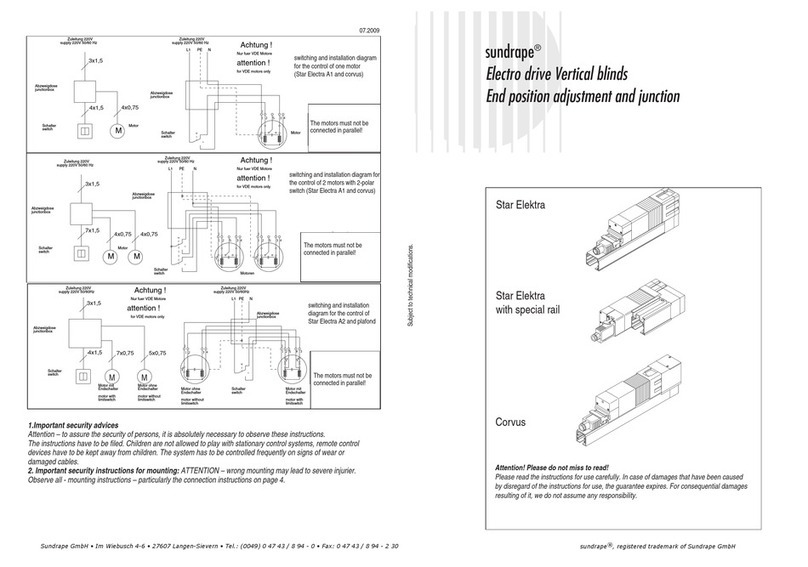

Sundrape

Sundrape Star Elektra instructions

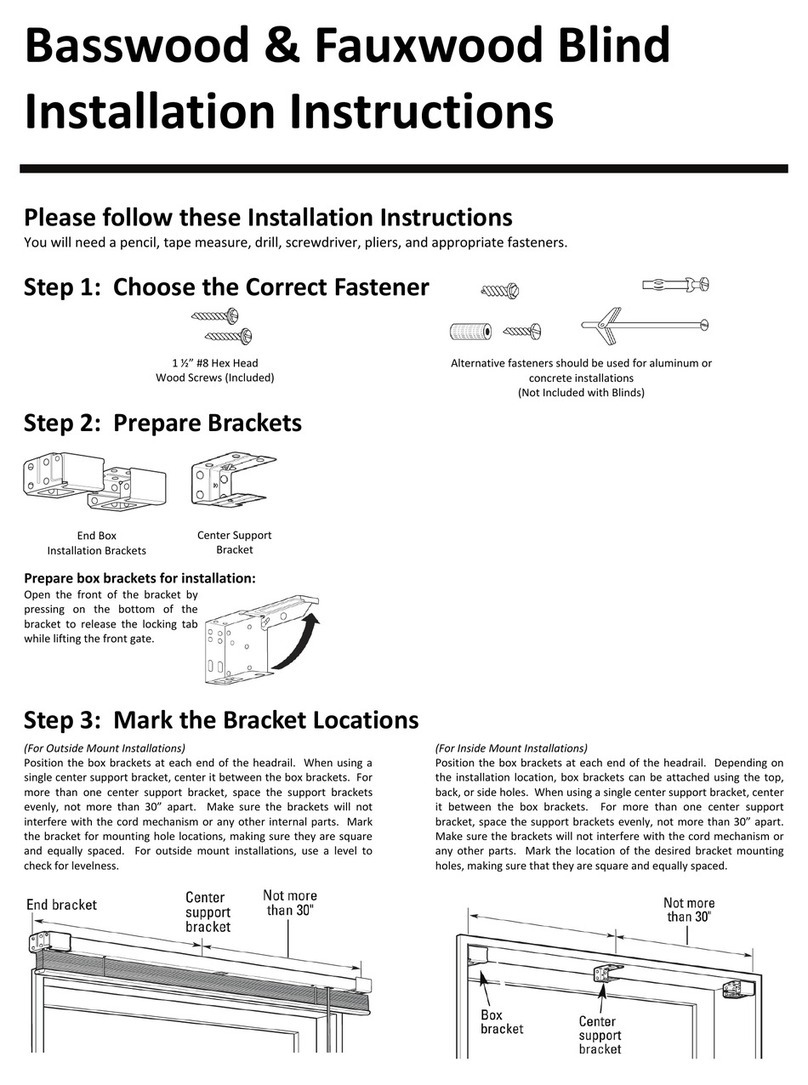

SelectBlinds

SelectBlinds Fauxwood Blind installation instructions

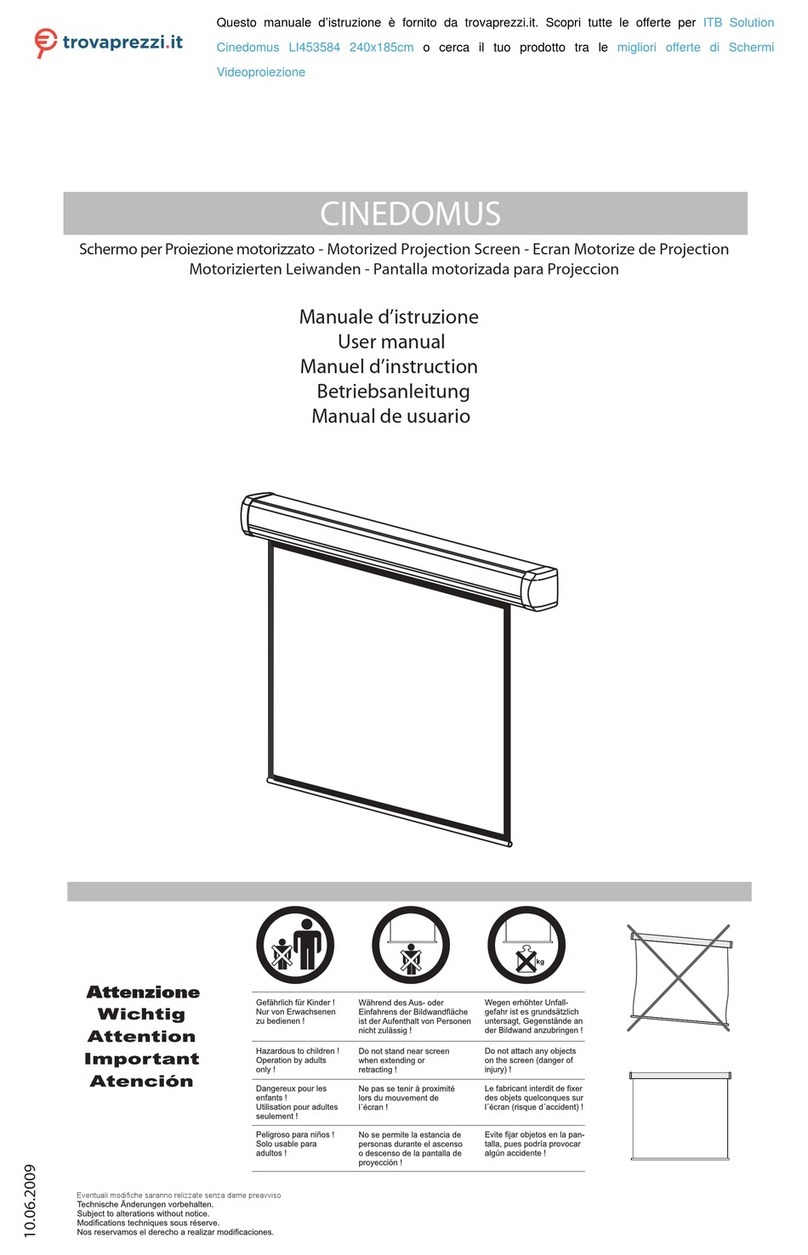

ITB

ITB CINEDOMUS LI453584 user manual

Victoria M

Victoria M SYSTEM VS 2 Original instructions