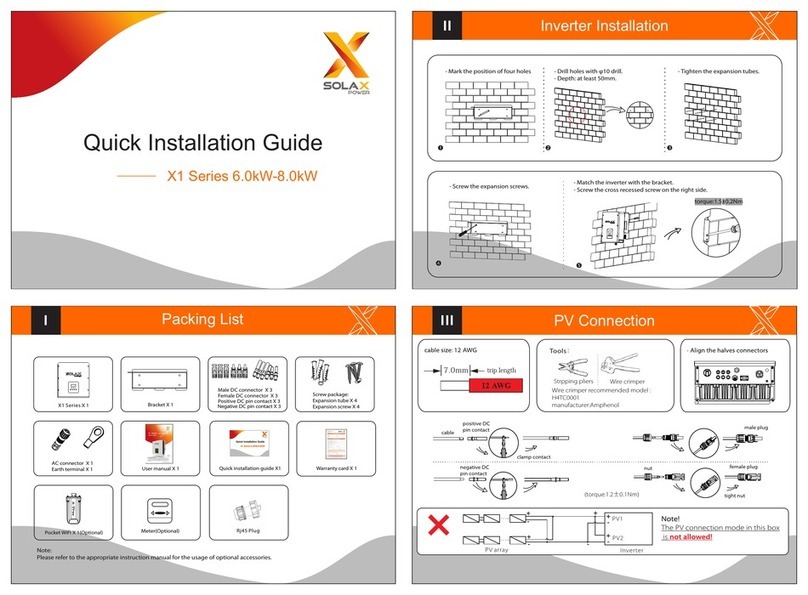

Quick Installation Guide

—— BMS Parallel Box-II

Packing List (BMS Parallel Box-II)

I

III

II

Battery Installation

IV

Overview of Installation

V

Installation Prerequisites

Terminals of the BMS Parallel Box-II

Note: The Quick Installation Guide briefly describes required installation steps. If you have any questions, refer to the Installation

Manual for more detailed information.

Ensure that the installation location meets the following conditions:

The building is designed to withstand earthquakes

The location is far from the sea to avoid salt water and humidity, over 0.62 miles/997.79 meters

The floor is flat and level

There are no flammable or explosive materials, at a minimum of 3 ft//0.91 m

The ambience is shady and cool, away from heat and direct sunlight

The temperature and humidity remains at a constant level

There is minimal dust and dirt in area

There are no corrosive gases present, including ammonia and acid vapor

Where charging and discharging, the ambient temperature ranges from 32°F/0℃ to 113°F/45℃

ŸŸŸŸŸŸŸŸŸŸ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

In practice, the requirements of battery installation may be different due to enviroment and locations.

In that case, follow up the exact requirements of the local laws and standards.

- Fix the box to the bracket with M4 screws.

- Drill two holes with driller (ø 0.39 inch/10 mm)

- Depth: at least 3.15 in/80.00 mm

- Lock the joint between hanging board and wall bracket

with M5 screws. (Torque: 1.2-1.5 N·m)

The bracket needs to be removed from the box.

Group 1

Group 2

+

-

+

-

+

-

Battery module Battery module Battery module Battery module

Battery module Battery module Battery module Battery module

Quick Installation Guide x 1

Power Cable (-) x 1 (6.56 ft/2 m)

Power Cable (+) x 1 (6.56 ft/2 m)

Ring Terminal x 1

Grounding Nut x 1 Installation Manual x 1

Rotation Wrench x 1

Expansion Screw x 2

Expansion Tube x 2

Quick Installation Guide

BMS Parallel Box-II

Power Cable (-) x 2 (3.28 ft/1 m)

Power Cable (+) x 2 (3.28 ft/1 m) BMS Cable x 1 (6.56 ft/2 m)

XII XIII

XIV

Object Mark Description

B1+

RS485-2

B2+

BAT-

BMS

/

Battery module communication of group 1

Battery module communication of group 2

Connector B2+ of Box to + of battery module of group 2

Connector BMS of Box to BMS of inverter

Air Valve

GND

RS485-1

XI

X

ON/OFF

POWER

Circuit Breaker

Power Button

DIP DIP Switch

XII

XIII

XIV

BAT+ Connector BAT+ of Box to BAT+ of inverter

Connector BAT- of Box to BAT- of inverter

B2- Connector B2- of Box to - of battery module of group 2

B1-

GND

Connector B1+ of Box to + of battery module of group 1

Connector B1- of Box to - of battery module of group 1

I II

VI

IV VII IX X

XIIII

IV V

VIII

Series-connected Plug x 2

BMS

Power Cable Disassembling

Tool x 1

Group 1

+

-

+

-

Battery module Battery module Battery module Battery module

(1)

(2)

Note!

- If the batteries have not been used for more than 9

months, these batteries must be charged to at least

SOC 50 % each time.

- If one of the batteries is replaced, the SOC of the

battery after replacement shall be consistent with those

of batteries that have not been replaced, with the

maximum difference of between -5% and 5%.

- If users want to increase their battery system capacity,

please ensure that the SOC of the existing system

capacity is about 40%. The manufacture date of the new

battery shall not exceed 6 months; in case of exceeding

6 months, please charge the new battery to around

40%.

- Before installation, please make sure that the wall can

bear the weight of the batteries installed. If not, please

take the mode of floor installation.

The recommended installation distance between the

box and the battery group (incl.group 1 and group 2)

is 11.81-23.62 inches/300-600 mm, and the distance

between the modules is 9.84 inches/250.00 mm.

The SolaX battery module is rated at IP55 and thus can be installed outdoors as well as indoors.

However, if installed outdoors, the battery pack shall not be exposed to direct sunlight and moisture.

Note!

If the ambient temperature exceeds the operating range, the battery pack will stop running to protect

itself.

The optimal temperature range for operation is 59℉/15℃ to 86℉/30℃. Frequent exposure to harsh

temperatures may deteriorate its performance and lifetime.

Note!

For the first installation, the interval among manufacture dates of battery modules shall not exceed 3

months.

Note!