Soldron 385D Technical manual

Operation instruction

LEAD-FREE SOLDERING STATION

Model:385D

Thank you for purchasing LEAD-FREE SOLDERING STATION.

Please read this manual before use, and keep

it after reading it for future reference.

Applicable product model: 385D

This product is a fully automatic tin output device, you can choose one-hand

operation, foot pedal tin feeding operation; flexible tin output, fixed metal pipe

output tin multiple ways; efficient, simple and easy welding. The stepper motor

is controlled by the instruction of the single-chip microcomputer, and the tin

WARN

The definitions of "Warning" and "Caution" in this manual are as follows:

WARNING: Misuse can result in death or serious injury to the user.

ATTENTION: Abuse may result in injury to the user or substantial damage to

the objects involved. NOTICE

● when the power is turned on, the temperature of the soldering iron tip

is in a high temperature state.

● Since abuse may result in burns or fire, please strictly observe the following:

● Do not touch the metal parts near the tip of the soldering iron.

● Do not use the soldering iron tip near flammable objects.

● Notify other people in the factory that the tip of the soldering iron is very

easy to burn and may cause a dangerous accident. Power should be turned

off during breaks or after work.

● When replacing parts or installing the tip, turn off the power and allow

the tip to cool to room temperature.

● In order to avoid damage to the welding station and maintain a safe working

environment, the following items should be observed:

● This product uses a three-wire grounding plug, which must be inserted into

a three-hole grounding socket. Do not change the plug or use an ungrounded

three-prong adapter to make a poor ground. For extension cords, use a grounded

three-wire power cord.

● Do not use a soldering iron tip for work other than soldering.

● Do not knock the soldering station against the worktable to remove

the flux residue, which may seriously damage the heating core.

● Do not modify the welding station without authorization.

● When replacing parts, the original parts should be used.

● Do not get the soldering station wet, or use the soldering station with wet hands.

● Smoke will be emitted during welding, and the work should have good ventilation

facilities.

● When using the soldering station, do not do anything that may injure the body or

damage objects.

Product overview

1

2

Welding station

Soldering Iron handle

Product structure and components

Model

Power

Input voltage:

Temperature range:

Maximum ambient temperature:

Temperature stability:

Shell material ferro:

Tin wire diameter:

Appearance volume:

Weight:

385

60W

AC 220V +/- 10% 50Hz/60Hz

200-480°C

40°C

+2°C (still air, no load)

alloy paint

0.6-1.2MM

Length 200mm, width 140mm, height 130mm

2.5KG

Soldering iron tip to ground resistance:

Soldering iron tip to ground potential:

Heating element:

Wire device:

Length ( without wies ):

Weight:

Less than 2ohms

Less than 2 mV

Ceramic

1.2 meters

190mm

123 grams (including tin conduit)

1.Tin Spool

2.Out of the box

3.Out of the tin tube

locking screw one

4.Wire diameter ajustment Screw

5.Display window of tin

output parameters

6.Button for parameters of tin output

7.Catheter

8.Handle

9. Stand

10. Pressure adjustment screw

11. Clutch lever

12. Heating indicator light

13. Temperature adjustment knob

Figure (1) Whole machine (Type B)

output is precisely and flexibly controlled. The length, speed and amount of tin

returning can be adjusted. All parameters are digitally displayed, which is clear

at a glance. The welding effect of the product is stable, the work efficiency is

significantly improved, and the combined structure is optimized. The heating

element of the soldering iron is imported low-voltage ceramic heating element,

which is fast and stable in heating, safe and reliable.

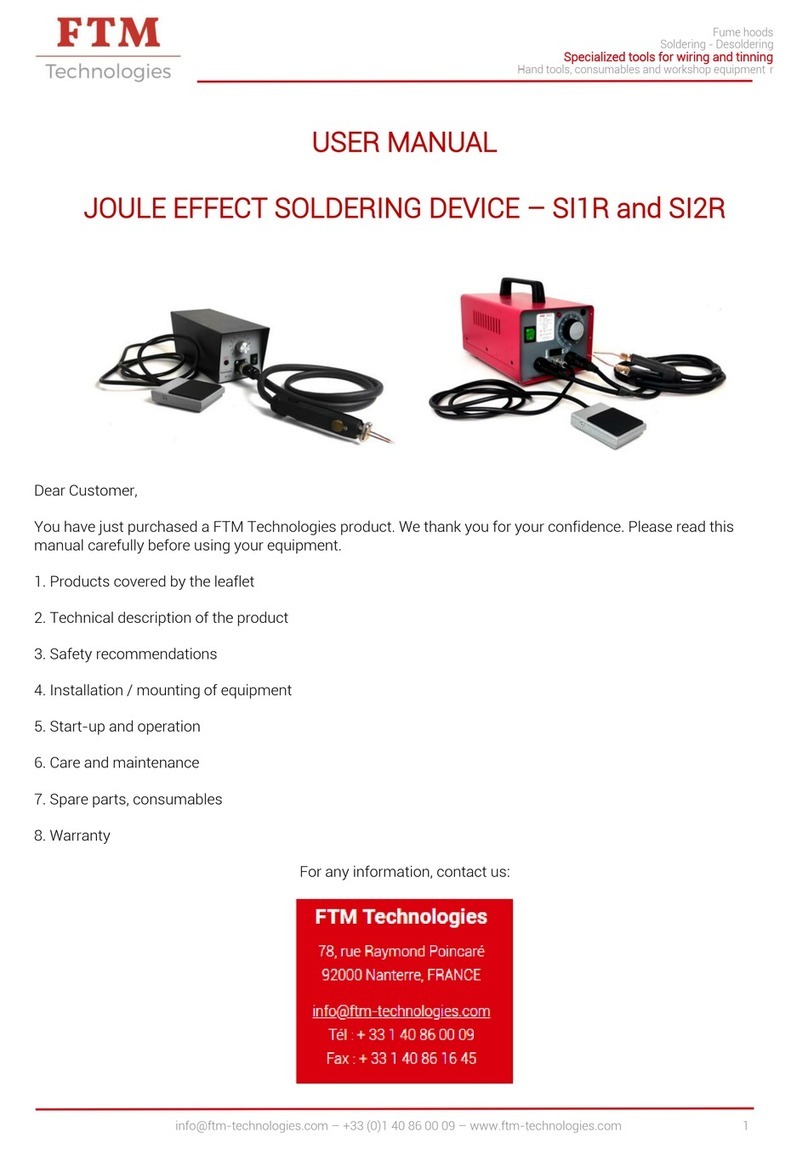

Figure (2) Rear panel

14. Handle interface

15. Foot pedal interface

16.Power switch

17.Ground

18.Power

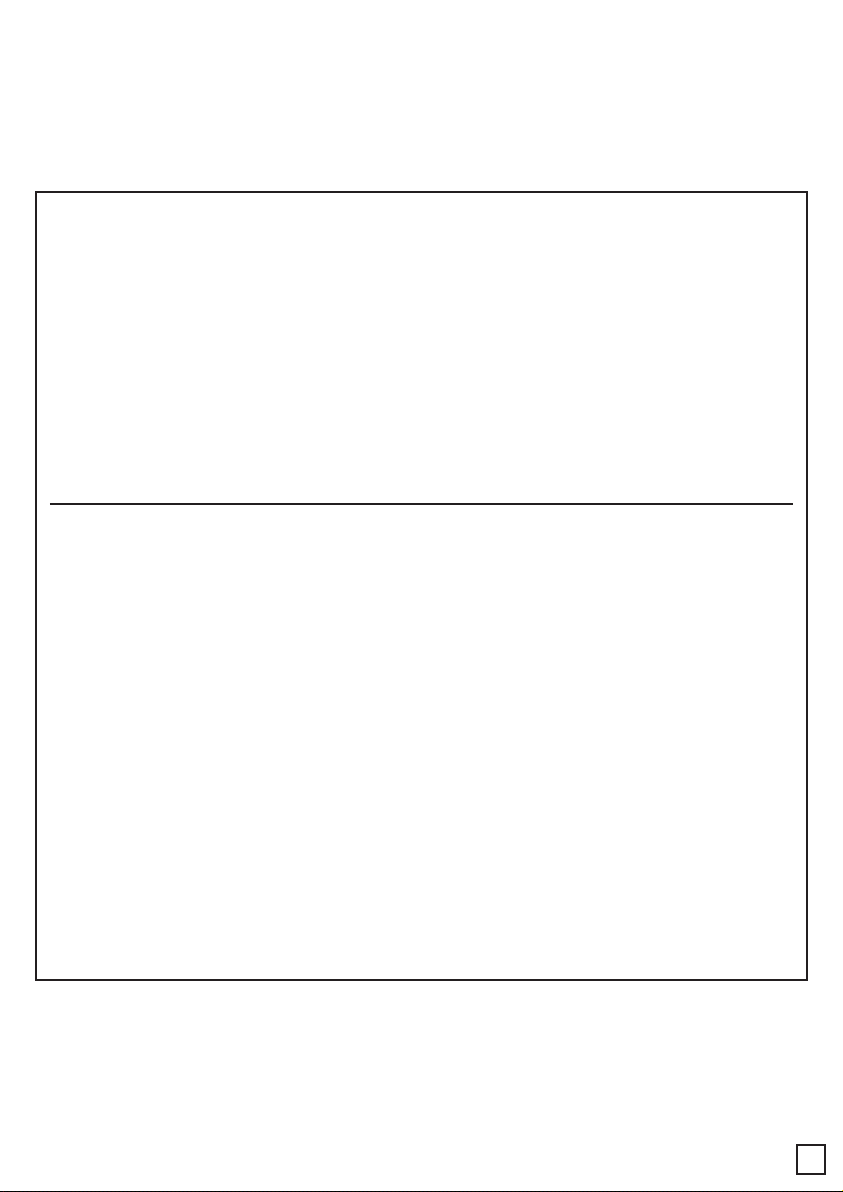

8.Soldering iron tip

9. Stainless Steel Sheath

10. Socket + Nut

11. Connect mesons

12. Handle sheath

13. Out tin button

14. Handle tube

15. Handle wire and sheath

(c-type handle has this equipment)

2. Stainless steel guide tube

3. Lock nut

4. Catheter set screw

5.(B type ) tin tube

6. Outlet tin pipe joint

7.Locating ring

1. Out of the tin nozzle

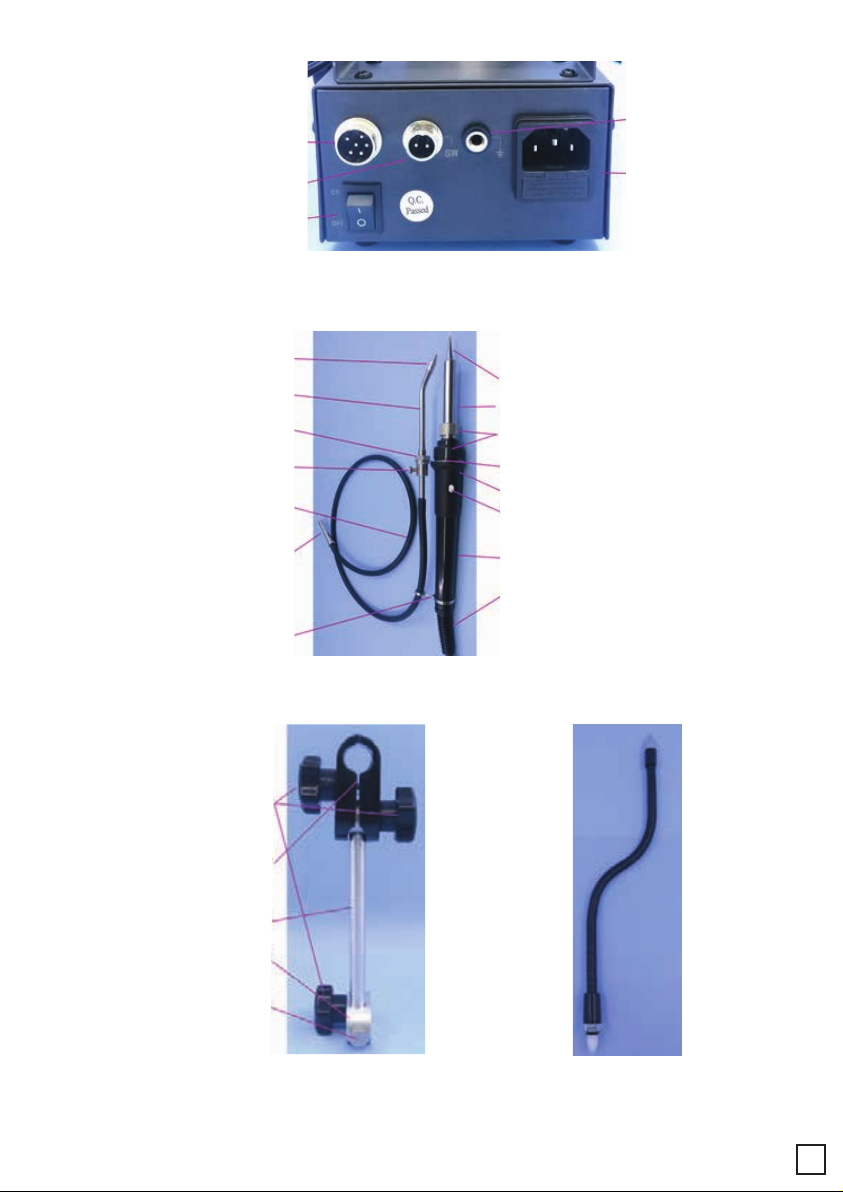

1.Hand nut

2. Handle clip

3. Stand rod

4. Fix the cluminum cake

5.Aluminum pie screw

Figure (3) Handle assembly

Figure (4) Bracket Figure (5) Optional universal metal hose

(Type A)

3

Set up and use the soldering station

A. Solder stand and solder wire installation

Note: Before installing and electrifying, check whether the power supply

voltage is consistent with the working voltage on the nameplate of the

machine ,After the power is turned on, the heating indicator (1)-12 will light

up, and the heat pipe of the handle will heat up. Operate carefully to avoid

burns.

Select the tin wire with the appropriate wire diameter according to the solder

joint, adjust the normal pressure (10. Pressure adjustment screw), set the gap

between the transmission wheels (4. Wire diameter adjustment screw), pay

attention to the tin wire from the downward penetration into the tin hole , after

the power is turned on, the mode is set to (0), press the manual switch or pedal

until the tin wire is sent to the tin outlet, and select the tin outlet as a fixed metal

pipe and a movable tin hose according to actual needs.

1. Connect the assembly wires to the socket of the soldering station.

2. Place the soldering station on the soldering station stand.

3. Insert the plug into the power outlet. Remember to ground.

4. Press the power switch.

B. Connect the handle

Fix the handle on the bracket clip (4) or the soldering iron seat, insert the

handle into the rear panel and connect the handle as shown in Figure (2) (14.

Handle interface), and lock it tightly

C. Connect the foot switch

D. Connect the power

Calibrate Solder Station Temperature

Note: When connecting or disconnecting the soldering station, remember

to turn off the power to avoid damage to the soldering station.

Insert the plug of the foot switch into the "SW" jack on the rear panel of the

machine

Recalibrate the soldering station temperature every time the handle heating

element or the soldering iron tip is replaced.

The way to recalibrate the soldering station temperature is to use a soldering

iron tip thermometer to calibrate. This method is more accurate.

Calibration with a soldering iron tip thermometer

1) Set the temperature to 350 degrees Celsius.

2) When the temperature is stable, use a thermometer to measure the actual

temperature of the current soldering iron tip.

3) Use Phillips screws at the "CAL" hole at the bottom of the machine to adjust

the actual temperature to be consistent with the set temperature.

4

Table of contents

Other Soldron Soldering Gun manuals