Solex GAG-08DC User manual

- 1-

DC INVERTER

AIR TO WATER HEAT PUMP

User Manual

Model: GAG-08DC/12DC/16DC

- 2-

Contents list

1 GENERAL……………………………………………………………………………………………..……….3

2 SYSTEM DESCRIPTION……………………………………………………………...………..……………3

3 INSTALLATION………………………………………………………………………………………………...3

3.1 General points for installation engineer………………………………………………………………...3

3.1-1 Transport and storage………………………………………………..........................................3

3.1-2 Inspection of the installation…………………………………………........................................4

3.1-3 Sitting the heat pump…………………………………………………........................................4

3.1-4 Controller………………………………………………………………........................................5

3.2 Installation design…………………………………………………………………………………………5

3.3 Pipe Connection…………………………………………………………………………………………..8

3.4 Electrical Connection……………………………………………………………………………………..9

3.4.1 Installation Drawing…………………………………………………………………………….…11

3.4.2 Important: You need to install a separate circuit breaker in all installations………….….….11

3.4.3 Anti-freeze Function………..………………………….……………………………………….....11

3.5 Commissioning………..…………..………..………..………..………………………………..............11

3.5.1 Preparations…………………..………..………..…………………………….……………….….11

3.5.2 Inspection before Start up………..………..………..………..……………………...........….…12

3.5.3 Start up and Commissioning………...………..………..……………………............…………12

4 CONTROLLER MANUAL……..………...…………..………..……….………..…………………….…….12

4.1 Electric Parts Control Program working theory………..……..………..…………...........………….12

4.2 Operating Mode Principle………………………………………………………………………………13

4.3 Wire controller……………………………………………………………………………………………14

4.3.1 Controller……………………………………………………………………………..…………....14

4.3.2 Buttons definition………………………………………………………………………………….15

4.4 keys operation………………………………………………………………………………………...…15

4.4.1 Unlock screen……………………………………………………………………………...…...…15

4.4.2 Turn on/off………………………………………………………………………………...…..…...15

4.4.3 Change mode (5 modes) ………………………………………………………………….…….15

4.4.4 Modify the setting parameters…………………………………………………………………...15

4.4.5 Clock setting………………………………………………………………………..………..…....16

4.4.6 Timer setting……………………………………………………………………............…………16

4.4.7 Night mode…………………………………………………………………………………………18

4.4.8 Auto heat curve…………………………………………………………………………….......…18

4.4.9 Communication with LCD controller…………………………………………………………….18

4.5 System Protection and Error Codes……………………………………………………………….….18

4.6 System Adjustable Parameter Table………………………………………………………………..…20

4.7 Parameter check (Only checkable parameter list) ………………………………………………..…22

5 TECHNICALSPECIFICATION………………………………………………………………………...……24

5.1 Internal View…………………………………………………………………………………………..…24

5.2 System Drawing…………………………………………………………………………………………27

5.3 Dimensions(mm) ………………………………………………………………………………….........27

5.4 Specification…………………………………………………………………………………..…………29

6 Maintenance……………………………………………………………………………………………..……30

6.1 Maintenance and Cleaning for User……………………………………………………………...……30

7 How To Get The Most Out Of Your Heat Pump……………………………………………………………30

- 3-

1 GENERAL

The unit is an air source heat pump for space heating and sanitary water heater for houses,

apartment blocks and small industrial premises. Outdoor air is used as a heat source creating free

energy to heat your home.

2 SYSTEM DESCRIPTION

The unit is a monoblock (single unit) air/water heat pump, specially designed for the colder climate.

There is no need for bore holes and usually the system can be installed within 1 day.

The unit can both heat hot water effectively at high outdoor temperatures and give a high output to

the heating system at low outdoor temperatures. If the outdoor temperature drops to a level lower

than minus 0°C (factory setting), the auxiliary heater switches on to ensure the heat pump unit

works normally. The unit is also capable of cooling in the summer. The heat pump controller is an

intelligent wired system.

The unit is rated as 8KW/12KW/16KW. The Material/components are chosen to provide a long

service life and to fully withstand harsh outdoor conditions.

The unit has two different installation options:

1). Space heating/cooling + DHW (Domestic hot water)

2). Space heating/cooling only or DHW only

3 INSTALLATION

3.1 General points for installation engineer

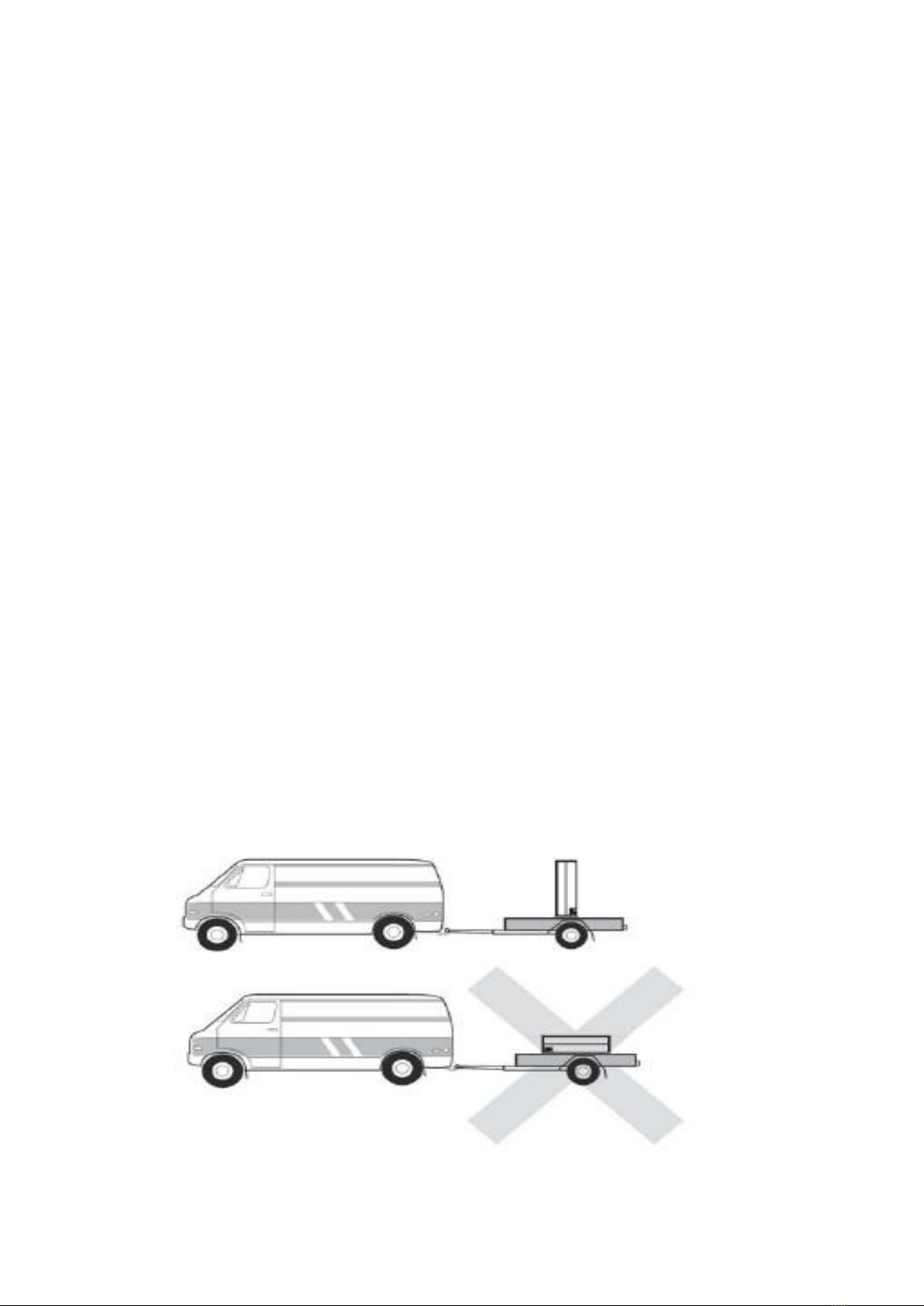

3.1-1 Transport and storage

The unit should be transported and stored vertically.

- 4-

3.1-2 Inspection of the installation

Current regulations require the heating installation to be inspected before it is commissioned .

The inspection must be carried out by a suitably qualified person and should be documented. If the

heat pump is replaced, the installation must be inspected again. In the event of installation with

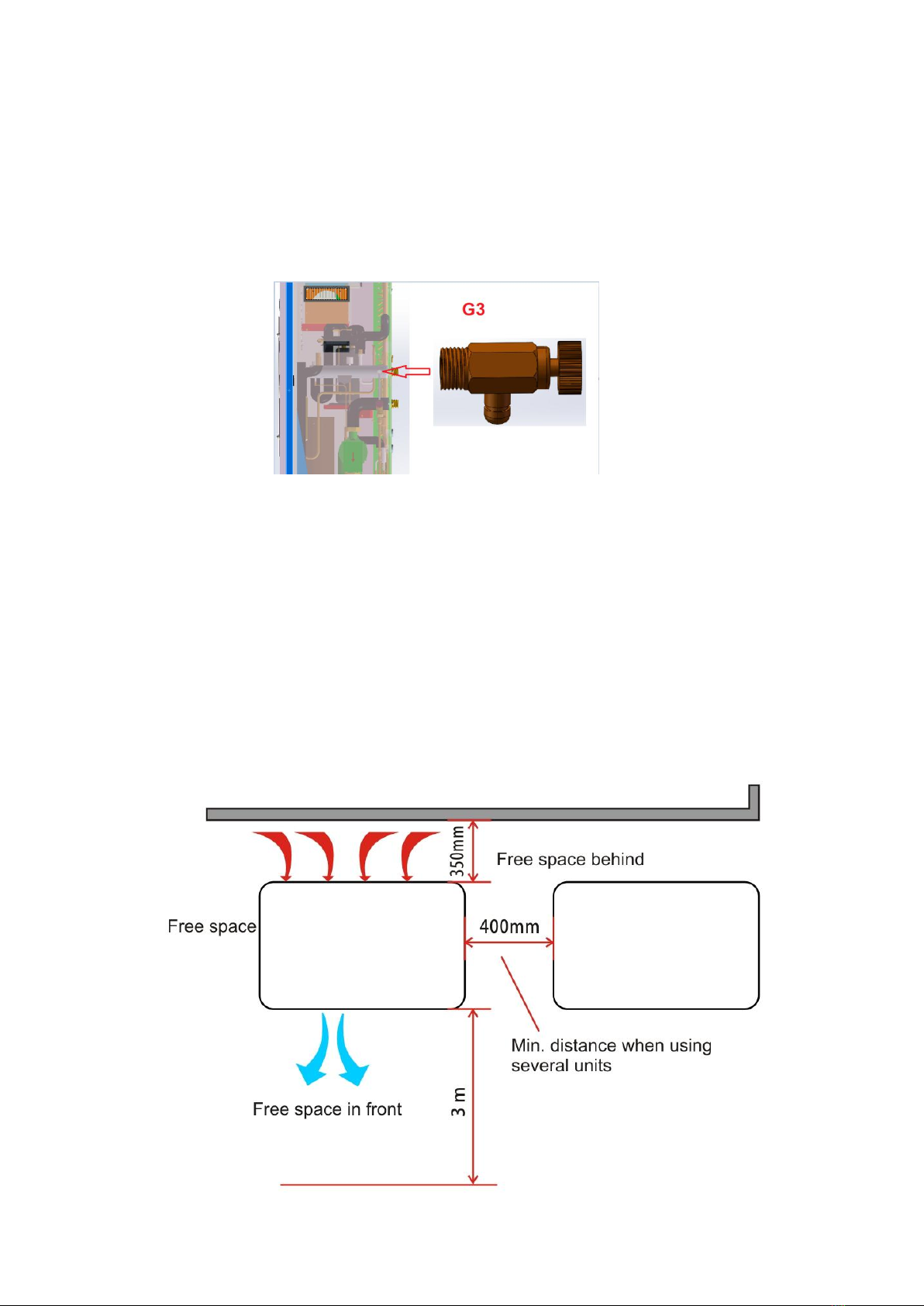

unvented (closed) heating systems, G3 unvented guidelines must be

followed during the install. It should be noted that the heat pump provides the first measure of

defense against high pressure/temperatures. A further 2 must be installed to comply with the G3

unvented procedures.

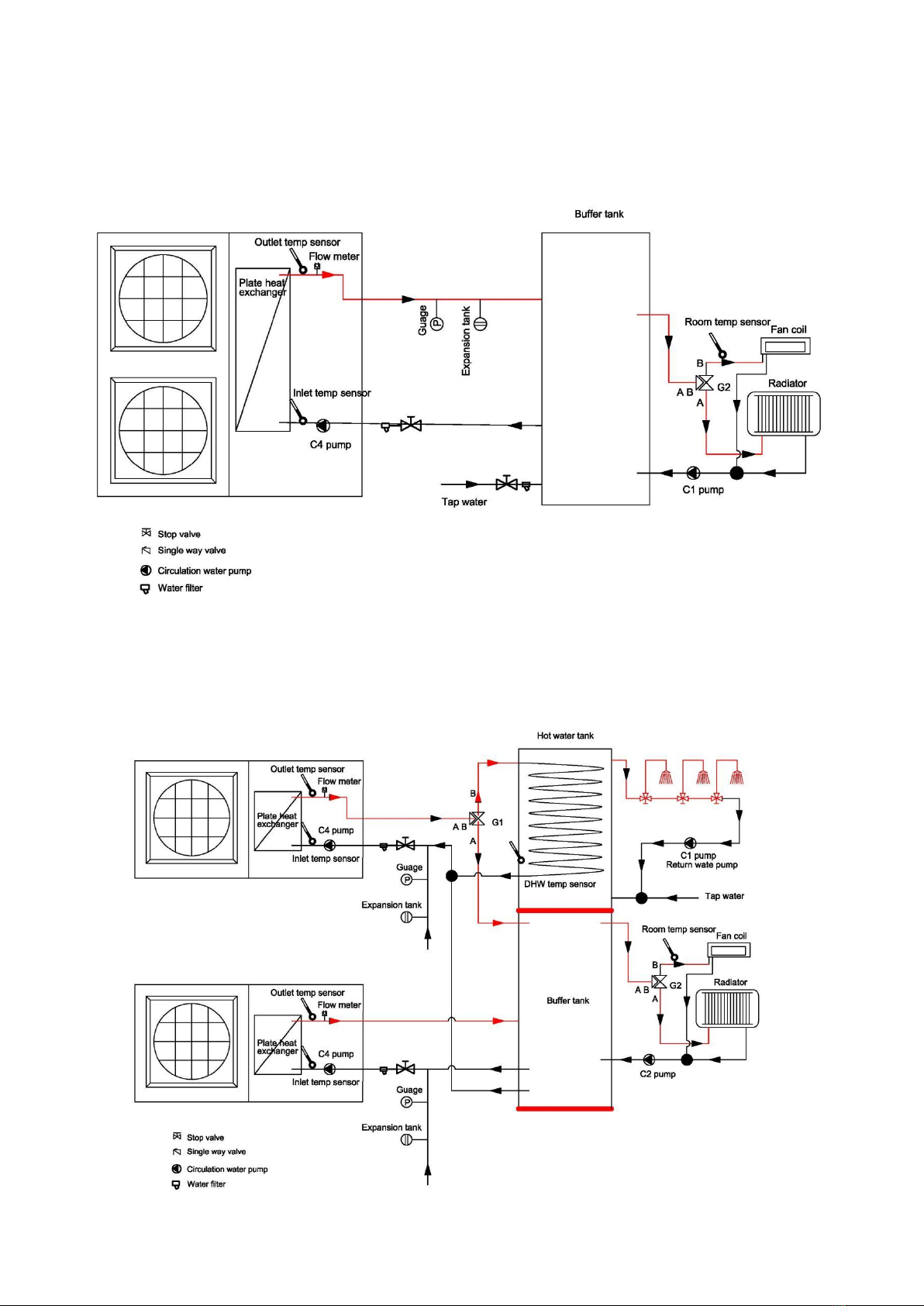

3.1-3 Sitting the heat pump

The unit is placed (securely fixed) outdoors on a firm base, preferably a concrete foundation. It

should not be positioned next to sensitive walls, for example, next to a bedroom. Also ensure that

the placement does not inconvenience any neighbors’.

Large amounts of condensation water as well as de-icing water from defrosting can be produced.

You must provide good drainage at the installation area and make sure the water cannot run out

onto paths or the like during periods that ice can form. Ideally, condensation water is led off to a

water drain or a suitable soak away. The distance between the unit and the exterior wall must be at

least 350 mm. The free space above must be at least one meter. The unit must not be placed in a

position so that air can re-circulate thus lowering the COP.

Care must be exercised so that the heat pump is not scratched during installation.

- 5-

3.1-4 Controller

The unit is equipped with an external electronic controller that handles all functions necessary for

heat pump operations. Defrosting, stop at max/min temperature, connection of the compressor

heater as well as enabling the aux electrical heater, monitoring of motor protection and pressure

switches are all controlled.

The number of starts and the operating time can also be read.

The controller is set during installation and can be used during a service.

Under normal operating conditions the home owner does not need to have access to the controller.

The unit has an integrated electronic outlet water temperature sensor that limits the outlet

temperature up to 60°C.

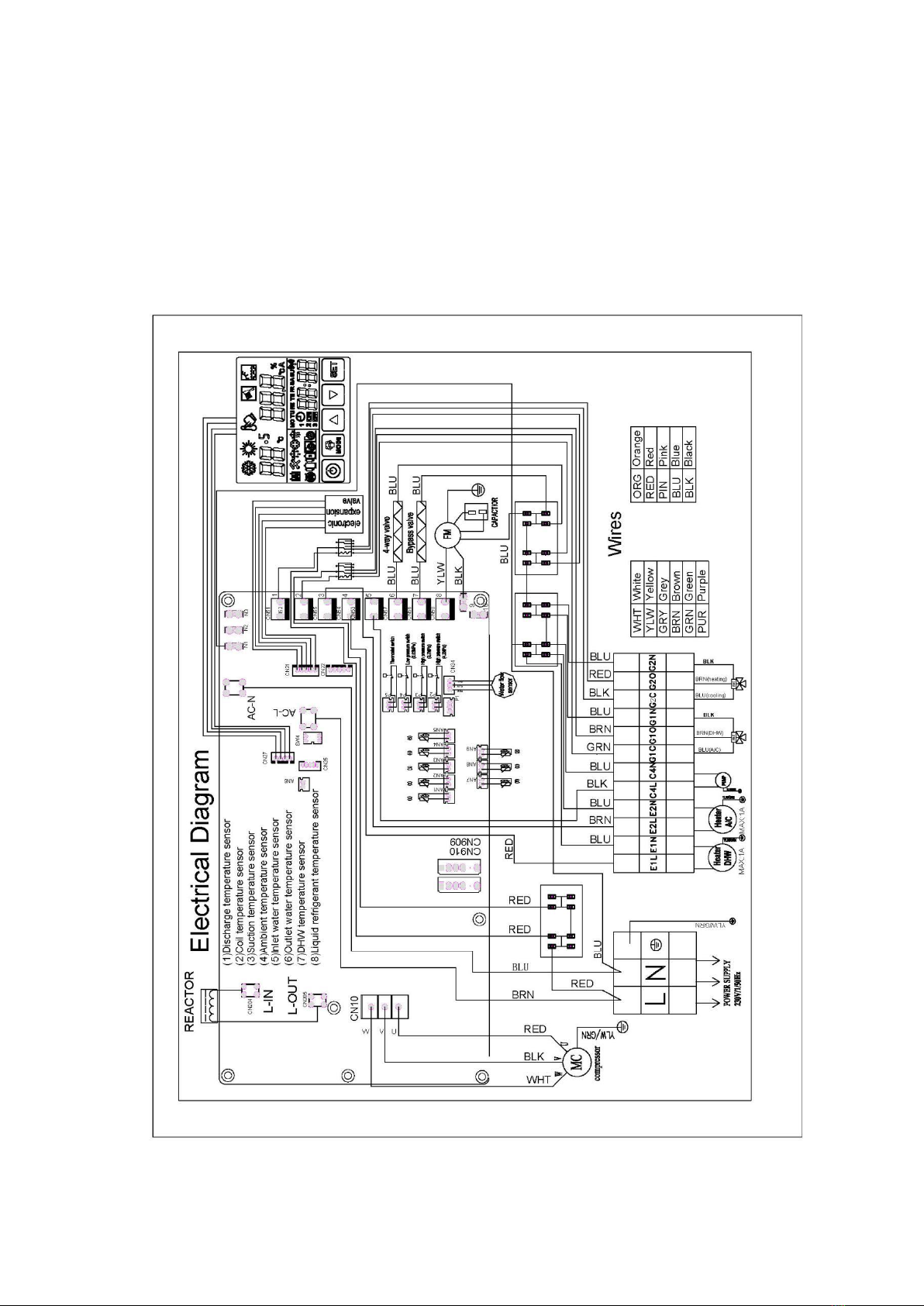

3.2 Installation design

The unit can be installed in several different ways.

The safety equipment must be installed in accordance with current regulations for all installation

options.

When connecting with the unit, the total water volume in the heat pump pipe system and buffer

tank must be at least 10 liters per KW of output.

A) Space Heating/Cooling + DHW

- 6-

B) Space Heating/Cooling Mode Only

C) 2x8/12/16 Installation. Space Heating/Cooling + DHW

- 7-

D)3x8/12/16 Installation. Space Heating/Cooling + DHW.

Solar Application 1

- 8-

Solar Application 2

3.3 Pipe Connection

28mm pipe is recommended.

The pipe work must be flushed before the heat pump is connected, so that any contaminants do

not damage the components parts.

The heating/cooling water inlet and outlet direction must be connected according to the marked

areas on the heat pump.

All outdoor pipes must be thermally insulated with at least 19 mm thick pipe insulation. The

insulation must also be vapor resistant.

The water circulation pump must at all times be operational (even if unit is not running) to prevent

any possible damage due to freezing. Even when in standby mode, the circulation pump is

controlled directly from the unit, which takes the outdoor temperature and temperature in pipe into

consideration to decide whether to circulate water within the system.

Shut-off valves and drain valves are fitted so that unit can be emptied in the event of prolonged

power failures.

The supplied flexible hoses act as vibration dampers. The flexible hoses are fitted so a slight bend

is created, thus acting as vibration dampening.

Important: Even though the unit has anti-freeze protection, if the circulation pump fails or there is

a problem with the power supply, there is still a risk of damage due to freezing. During the

installation Anti-freeze (Ethylene Glycol) is strongly recommended. If the air

temp is ever lower than 0c, it must use enough glycol.

- 9-

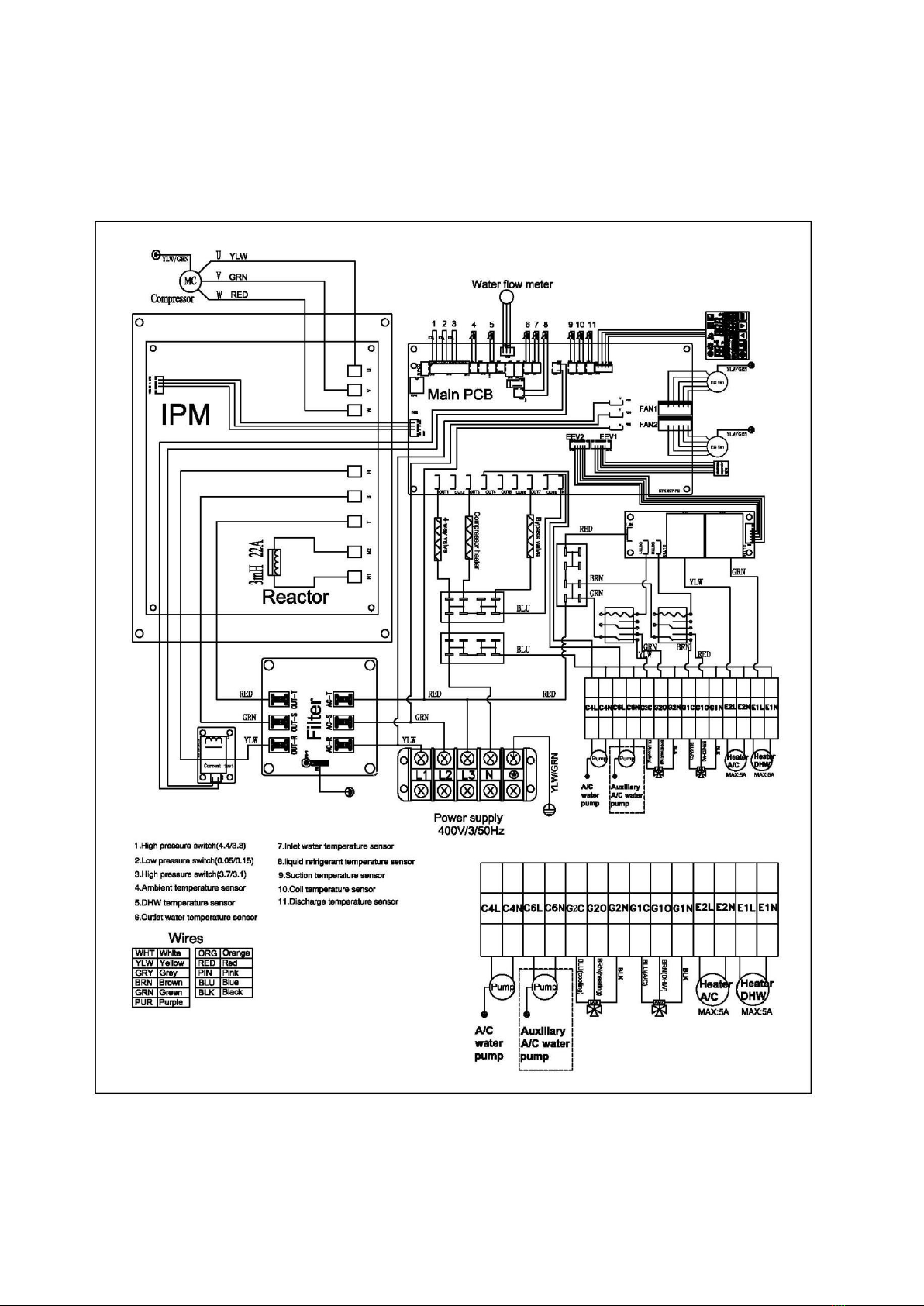

3.4 Electrical Connection

Electrical installation and service must be carried out under the supervision of a qualified

electrician. Electrical installation and wiring must be carried out in accordance with the stipulations

in force.

Wiring Diagram GAG-08DC/12DC

- 10-

Wiring Diagram:GAG-16DC

- 11-

3.4-1 Installation Drawing

3.4-2 Important: You need to install a separate circuit breaker in all installations.

3.4-3 Anti-freeze Function

DHW anti-freeze

When DHW water tank(AN8) temperature ≤ 4°C, system starts hot water antifreeze, start domestic hot

water mode and compressor, When hot water temperature is 12°C or higher, withdraw DHW antifreeze. If

the compressor starts over 30 minutes, withdraw DHW antifreeze.

AC anti-freeze

Air conditioning inlet (AN5) or outlet (AN7) water temperature is 4°C or lower, system starts AC antifreeze,

water pump C1 start。

When the input water temperature ≥ 12°C or compressor operates over 30 minutes , withdraw AC

antifreeze.

3.5 Commissioning

3.5.1 Preparations

Before commissioning, make sure compressor heater has already pre-heated for 3-10 minutes.

1) Compressor Heater

As mentioned above, if the temperature is lower than 10°C, it is important that the compressor heater can

heat the compressor before the first start up. In order to ensure this happens, please follow the

instructions below:

a. Disconnect the power connection of compressor, aux electric heater, circulation pump. (Due to

anti-freeze protection, the compressor, aux electric heater and circulation pump could start in

stand-by status.

b. Switch on the outside Isolator and power connection of the unit.

c. After 3-10 minutes, switch off the outside Isolator and re-connect the power connection of compressor,

aux electric heater and circulation pump.

2) Filling and Venting

Fill the system slowly ensuring bleed valves are open (if not automatic).

- 12-

3.5.2 Inspection before Start up

1) Mechanical Inspection:

a. Check the cabinet and inside pipe system for possible damage during transportation.

b. Check that the heating water circuit is filled and well vented. Check the pipe system for leaks.

c. Check the Fan making sure it can move freely.

2) Electric System Inspection

a. Check the power supply (voltage/frequency) matches the rating label and specification.

b. Check all the electrical connections for loose or damaged wires due to transportation.

3) Pipe Inspection

a. Check all the valves, and water flow directions.

b. Check for any possible leaks inside or outside of unit.

c. Check the insulation of all the pipes.

3.5.3 Start up and Commissioning

a. After the system inspection is finished, startup can begin.

b. Connect the power supply; switch on the isolator to turn on the heat pump.

c. The circulation pumps starts immediately. After 30 seconds, the fan motor starts. After another 10

seconds, compressor starts.

d. Air is initially released from the hot water and venting may be necessary. If bubbling sounds can be

heard from the heat pump, the circulation pump or radiators the entire system will require further venting.

When the system is stable (correct pressure and all air eliminated) the automatic heating control system

can be set as required.

e. Check heating water inlet/outlet temperature difference after the system is stable.

f. Check the compressor exhaust and suction temperature.

g. Adjust the parameters according to different weather conditions and user requirements.

4 CONTROLLER MANUAL

4.1 Electric Parts Control Program working theory

a) Compressor

After the compressor is shut down, it has a minimum interval of 3 minutes before the next start up

The initial "power-up" does not require the protection of three minutes;

During defrost, compress on/off interval is based on the defrost parameters.

b) Start up / Shut down Cycle

When the heat pump switches on, the water circulation pump and the fan will start 60 seconds before

compressor

When the heat pump switches off, the water circulation pump shuts down 30 seconds after the

compressor. The fan switches off 5 seconds after the compressor

During defrost, the water circulation pump does not stop running;

c) DHW Auxiliary Electric Heater E1

F08=0, E1 is not valid ; F08=1,E1 is valid.

E1 turns on as set out in the conditions below:

Ambient temperature ≤ set value (parameter F09,-20°C ~ 30°C, default 0°C);

- 13-

Compressor’s working time ≥set value (parameter F10,10 ~ 30min, default 15min);

DHW water tank temperature <setting temperature;

When DHW anti-freeze, E1 is on, when DH>15°C, E1 off.

When some error cause compressor stop, if DHW required, E1 will be on.

d) A/C Auxiliary Electric Heater E2

F05=0; E2 is not valid; F05=1,E2 is valid.

A, E2 turns on as set out in the conditions below:

The heat pump is running heating:

Ambient temperature ≤ set value (parameter F06,-20°C ~ 20°C, default 0°C);

Compressor’s working time ≥ 15minutes;

AC water inlet temperature <setting temperature;

B, When start defrost at AC heating mode, if inlet water temperature ≤39°C, E2 turns on. When Ac inlet

temp>45°C, E2 off.

C, During anti-freezing, the auxiliary electric heater E2 turns on.

D, If inlet or outlet temperature sensor breakdown, the auxiliary electric heater E2 turns on.

e) Motorized 3 way Valve G1

In DHW mode, the motorized 3 way valve is power on. In any other mode, it is power off.

4.2Operating Mode Principle

1) Space Cooling Mode

Temperature setting range is 10-25°C, the factory setting is 12°C;

2) Space Heating Mode

Temperature setting range is 10-55°C, the factory setting is 45°C;

3) Hot Water Mode

Temperature setting range is 10-60°C (50~60°C is increased by electric heater), the factory setting is

50°C;

4) Defrost Cycle

Auto Defrost mode (normal defrosting)

All heat pumps are fitted with intelligent defrost controls. A number of parameters are taken into account

before defrost begins and ends. The parameters should be set as per factory settings or otherwise set out

by an engineer. The defrost time will vary depending upon the conditions the heat pump is working in. The

length between defrosts will either extend or contract depending upon the parameters set.

- 14-

4.3 Wire controller

4.3.1 Controller

There are 5 keys for operation. Auto restart function,weekly timer.

Compresso

r1

Heating

Wifi

Anti-freeze

zeze

A/C heater

DHW temp/AC outlet

temp/parameter

value

Defrost

Cooling

DHW

Time/

Parameter

number

Timer point

Target temp setting

Mode

DHW pump

Up

Down

SET

Compressor

2

DHW

heater

A/C

pump

ON/OFF

Error

A/C inlet temp

Sterilization

Timer ON/OFF

- 15-

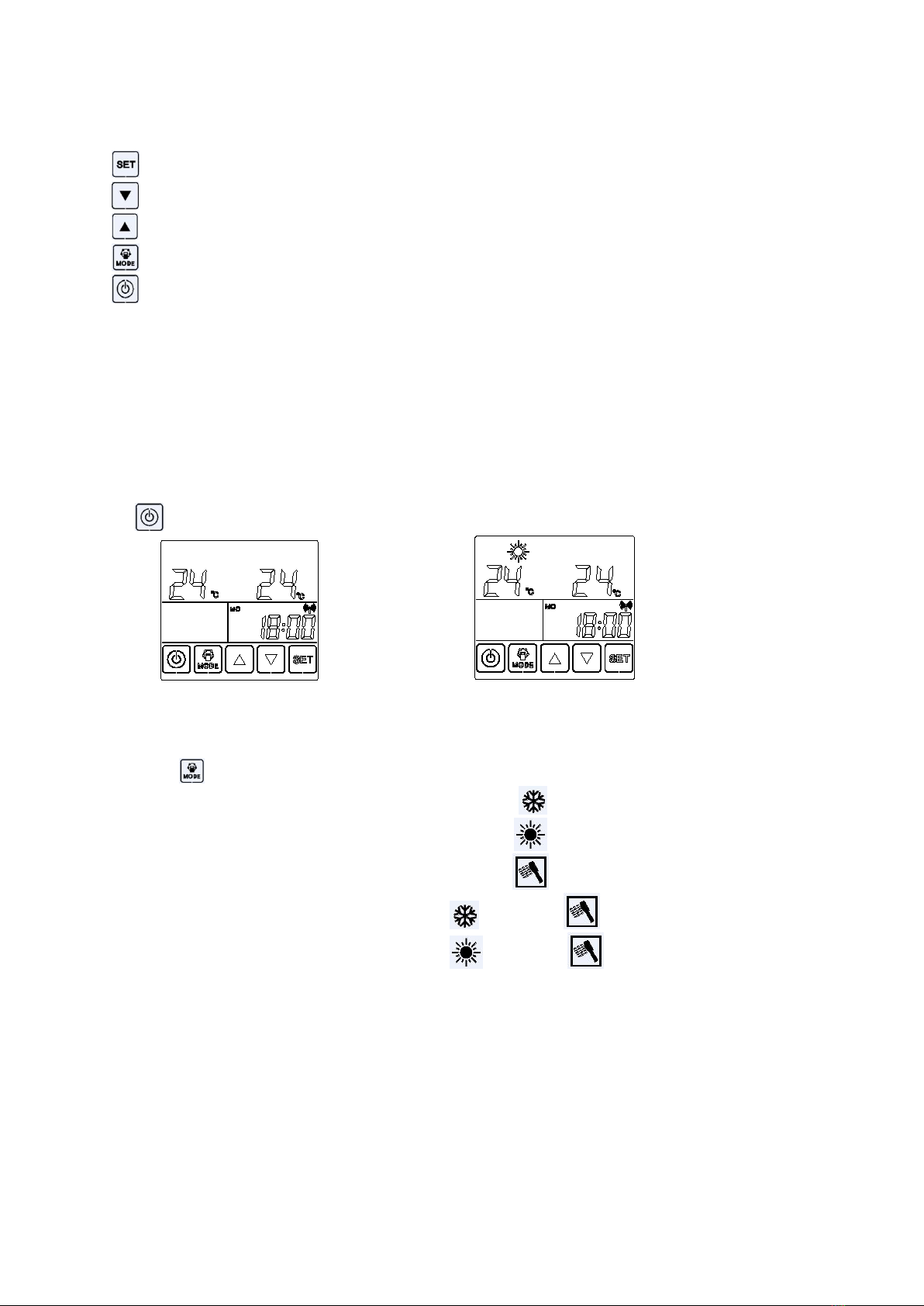

4.3.2 Buttons definition

(1) SET key: confirm the setting or check/set the parameter or manual defrost

(2) down key: reduce

(3) up key:increase

(4) mode key: change the mode or adjust time or timer setting

(5) On/Off key: Turn on or off heat pump or return the main window

4.4 keys operation

4.4.1 Unlock screen

When the screen’s light is off, the screen is locked. Touch any key, the screen is unlocked and the light on.

4.4.2 Turn on / off

Touch key.

OFF ON

4.4.3 Change mode (5 modes)

A, press the key repeatly, the mode icons will flash by recycling.

COOLING

HEATING

DHW

COOLING + DHW

HEATING + DHW

B, When selected cooling or heating plus DHW, DHW will be priority.

C, When selected DHW mode, only DHW operation, no cooling and heating.

D, Healthy sterilization is an independent automatic operation mode, if necessary, modify the parameters

individually.

4.4.4 Modify the setting parameters

A, When the selected mode is running, the unit will run in accordance with the factory set default values or

the last modification of the temperature.

- 16-

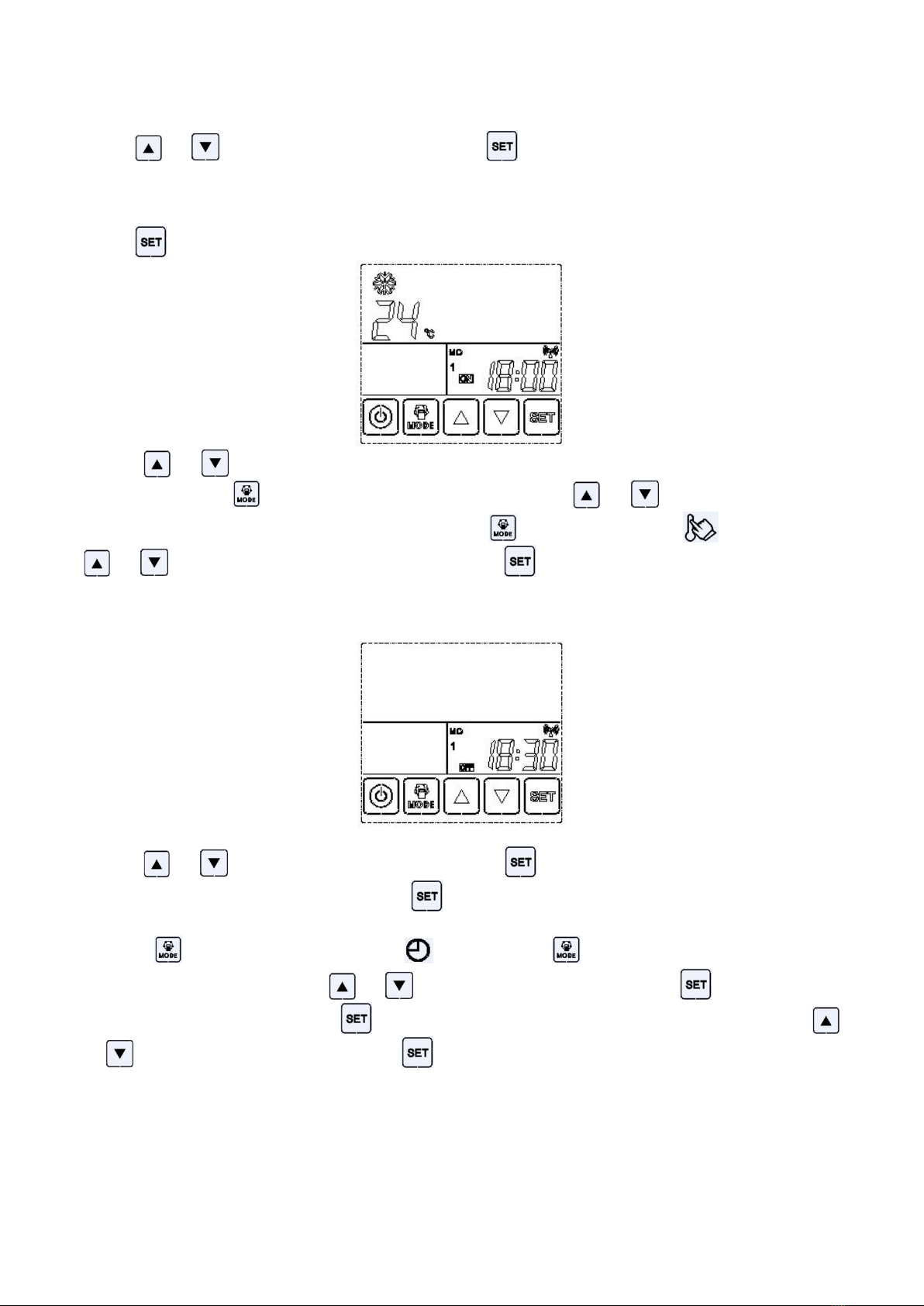

B, Set the target temperature

(1) Touch or key, the target temp setting appears.

(2) Touch key, choose the mode that you need to modify the target temperature.

Cooling mode Heating mode DHW mode

(3) Touch or key to adjust the target temperature.

C, The detailed settings in the table below

Item

Meaning

Setting range

Default

Change setting date

1

AC cooling

10°C~25°C

12°C

2

AC heating

10°C~55°C

45°C

3

Hot water

10°C~60°C

50°C

4

Antibacterial

60°C~70°C

65°C

4.4.5 Clock setting

Press key for 6 seconds, clock icon flashes :

Touch or key to adjust the time.

4.4.6 Timer setting

Press key for 6 seconds, clock icon flashes,

Press key for 6 seconds again, then ‘S’ or ‘C’appears

on the screen.

- 17-

S: once validity C:cyclic validity

Touch or key to choose ‘S’ or ‘C’, then touch to confirm, and enter to adjust time window.

A) One day can set 3 points for on.

Touch key to the day of week, then the timer No and the time data flash,

Touch or key to adjust the time of timer. Then choose the working mode and adjust the target

temperature. Touch key, ON and mode icon will flash, touch or key to choose the mode

you need. Then change the target temperature, touch key again , ON and will flash, touch

or key to change the target temperature. Touch key to confirm.

B) One day can set 3 points for on, 3 points for off .

When timer point 1 ON is finished, point 1 OFF flash.

Touch or key to adjust the time of timer, touch key to confirm.

C) If some points don’t need to be set, touch key to jump.

D) Press key for 6 seconds, clock icon flashes,Press key for 6 seconds again, then ‘S’ or

‘C’ appears on the screen. Touch or key to choose ‘S’ or ‘C’, then touch to confirm, and

enter to adjust time window. Touch key to choose the timer point that need to be cancel. Touch

or key to adjust the time to --:--, touch key, this timer point will be cancel.

- 18-

4.4.7 Night mode

(1) Night mode valid or not is up to parameter F21. If the data is set 0, means off, 1 means on. The

night mode starting time is decided by data F22. Ending time is decided by data F23.

(2) With night mode, hot water mode will run with the current setting temp +3° C, room heating run

with current setting -2°C. Room cooling run with current setting +2°C. Outdoor fan run at low

speed.

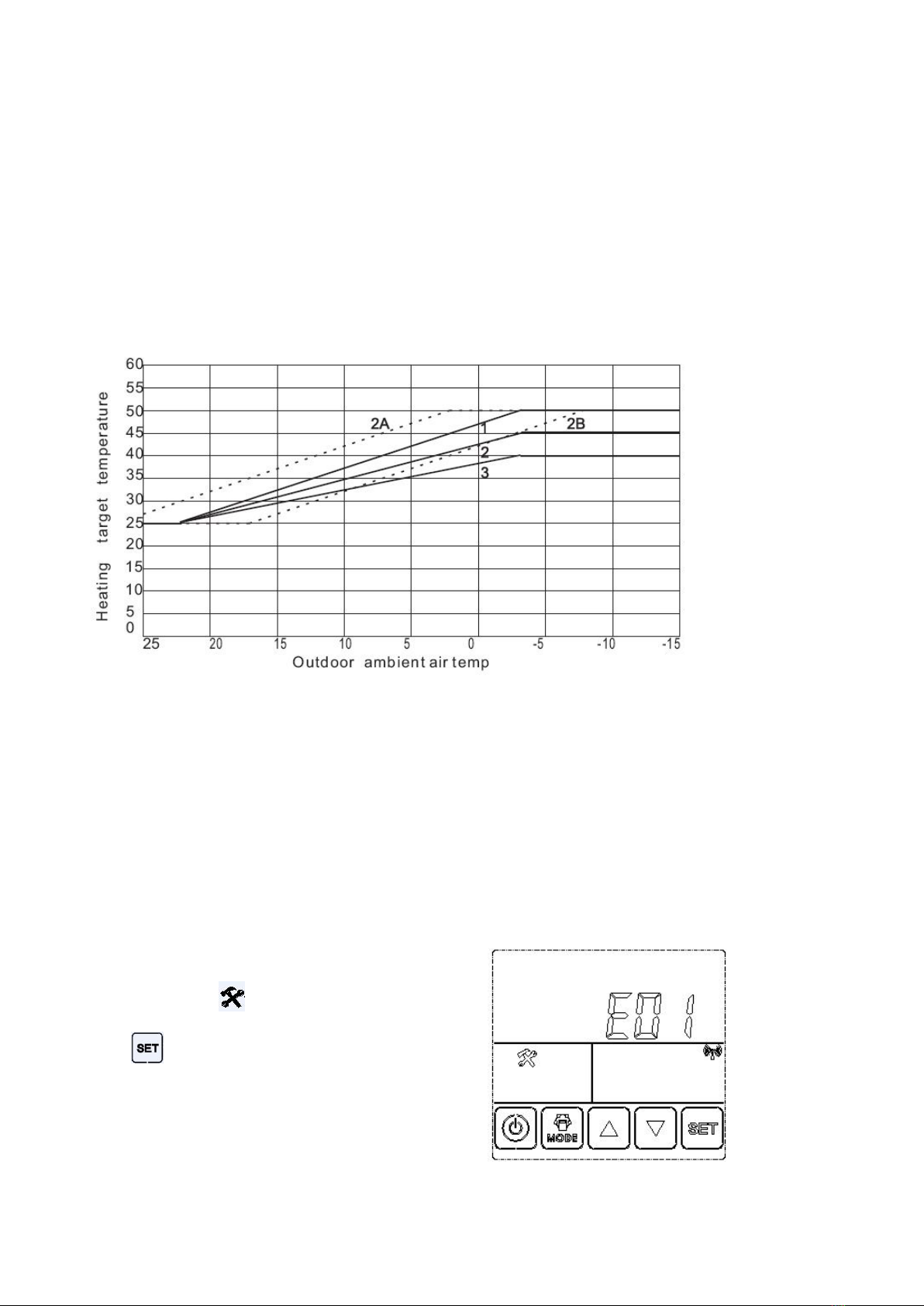

4.4.8 Auto heat curve

A. AU curve translate is decided by parameter(F14) , positive value means move up, negative value

means move down. (-15~15)

B. AC AU heat curve highest temp is decided by parameter (F13), from 30~50, default 45. When the

parameter is 45, the AU highest target temp is 45°C.

4.4.9 Communication with LCD controller

LCD controlled is connected with heat pump CN27 by 4 wires,(must in order) max 100m.

4.5 System Protection and Error Codes

If error,The Icon displays on the screen ,

touch key, the error code displays。

For example:E01

- 19-

Code

Meaning

Remark

E01/HP

High pressure switch off

1.Refrigerant volume too much 2.throtting part error

3. pressure switch fault.

E02

High pressure protection

1.Refrigerant volume too much 2.throtting part error

3. High pressure switch fault.

E03/LP

Low pressure switch off

1.Refrigerant volume too little 2.throtting part error

3. pressure switch fault.

E04

Low pressure protection

1.Refrigerant volume too little 2.throtting part error

3. Low pressure switch fault.

E06

Over current protection

Compressor current is too high

E08

High discharge temperature

protection

1.Refrigerant volume too little 2.throtting part error

3.discharge temperature sensor fault.

E09

Discharge sensor error

Temp sensor open circuit or short circuit

E10

Suction temperature sensor error

Temp sensor open circuit or short circuit

E11

Coil temperature sensor error

Temp sensor open circuit or short circuit

E12

Outdoor air temp sensor error

Outdoor air temp sensor open circuit or short circuit

E14

Inlet water temp sensor error

Temp sensor open circuit or short circuit

E15

DHW temp sensor error

Temp sensor open circuit or short circuit

E16

Outlet water temp sensor error

Temp sensor open circuit or short circuit

E17/FLO

Water flow error

1.Water flow volume too small 2. Water flow switch error

E18

Ambient temp too low

1.Outdoor air temp too low 2.temp sensor error

En

Communication error

Communication wire open or PCB error

E20

Miss/Wrong phase

Power supply error

E22

Password valid

E23

Memorizer error

PCB fault

E38

Temperature difference too high

Temperature difference between inlet and outlet water is

too high

E84

voltage protection

Voltage is too high or too low, heat pump will recover when

voltage be normal (165~265VAC)

E85

Voltage too high

Voltage≥265VAC

E86

Voltage too low

Voltage≤165 VAC

E97

DC Voltage too high

DC Voltage ≥ VDC

E98

DC Voltage too low

Voltage ≤ VDC

E99

Phase current too high

Phase current ≥ A

E100

DC motor out of step

DC motor out of step

E101/E102

Compressor Miss phase

Compressor connection line fault

E103/E103

IPM Error

IPM fault

E108

IPM temperature abnormity

IPM temperature sensor fault

E111

IPM doesn’t match compressor

IPM fault

E113/E114

PFC error

IPM fault

E116

PFC over current

IPM fault

E117

DC voltage abnormity

DC Voltage

E118

AC voltage too low

Voltage≤165 VAC

- 20-

4.6 System Adjustable Parameter Table

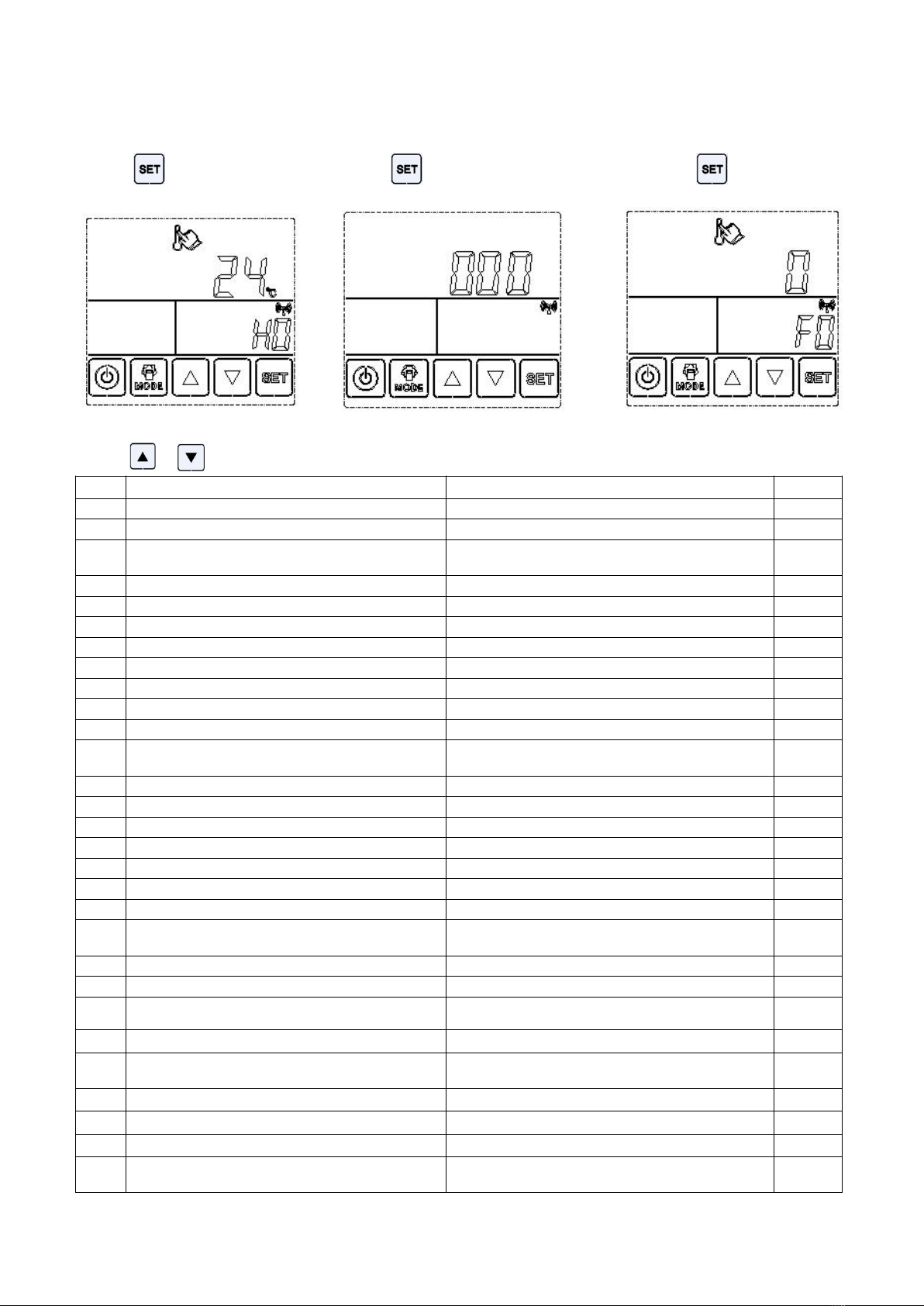

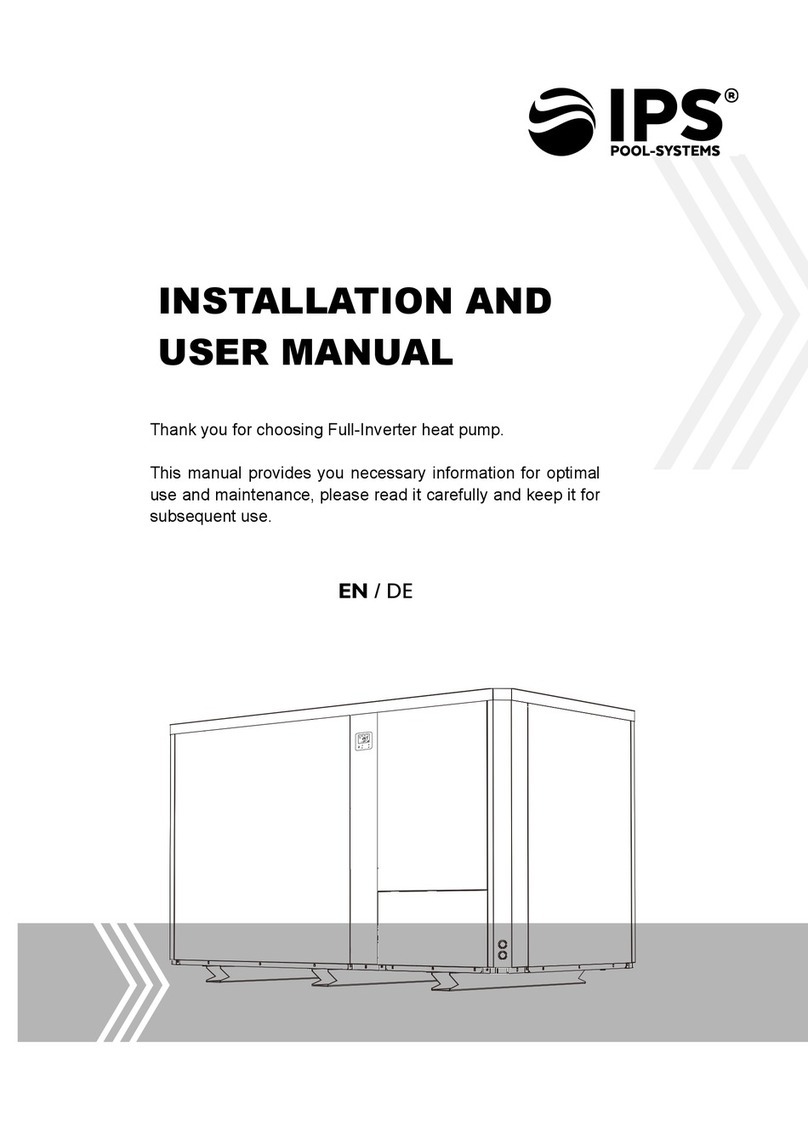

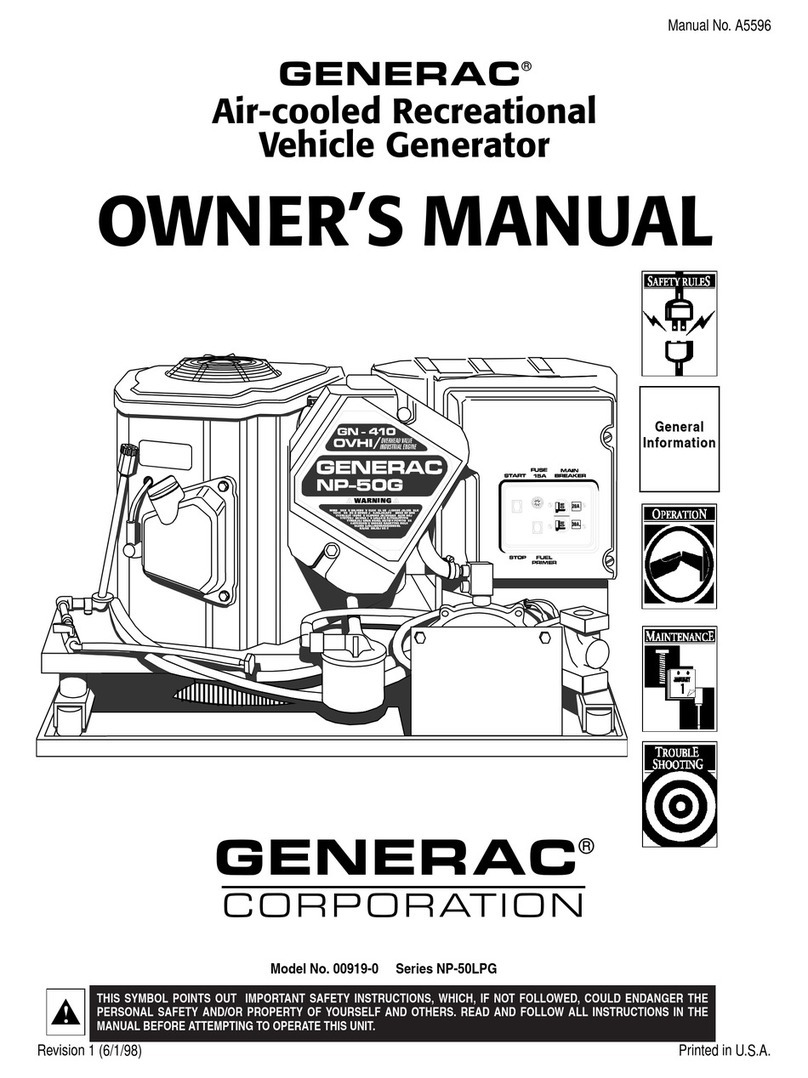

Press key for 6 seconds,Press key for 6 seconds again, Press key, enter the

the screen will show Hxx. then enter the password window. parameter check window.

Press or key to check different parameter.

Code

Name

Range

Default

F00

Parameter’s value return to default

0~255 : 10(return)

0

F01

Auto restart

0:off, 1:on

1

F02

Functional parameter

0: only heating 1:Cooling+heating

2: only cooling 3: DHW+(C+H)

3

F03

AC temp difference

1~30°C,minus difference

2°C

F04

DHW temp difference

1~30°C,minus difference

3°C

F05

AC auxiliary electric heater E2 validation

0: Invalid; 1:valid

0

F06

Ambient temperature to activate E2

-20~30°C

7°C

F07

The time of delayed to active E2

1~99 minutes

20

F08

DHW auxiliary electric heater E1 validation

0: Invalid; 1:valid

0

F09

Ambient temperature to activate E1

-20~30°C

7°C

F10

The time of delayed to active E1

1~99 minutes

20

F11

Water pump working mode

0(no stop),1(stop when reach temp)

2(running 1 minute every (15=F12)minutes)

F12

Water pump mode 2 interval time(F11=2)

1~99 minutes

15

F13

AC AU curve max temp value

30~50°C

45°C

F14

AC AU curve offset value

-10~10°C

0°C

F15

Auto remove error

0: no remove; 1~255minutes

30

F16

Sterilization temperature

40~80°C

65°C

F17

Sterilization interval time

0:sterilization invalid; 1~99 days

7

F18

Sterilization duration

1~99minutes

10

F21

Night mode validation (night mode: DHW

increase 3C, AC temp reduce 2C)

0:invalid; 1:valid

0

F22

Night mode starting point

0-23(time)

21

F23

Night mode ending point

0-23(time)

6

F24

Compressor and Motor speed’s output

ratio for night mode

0-100

80

F30

Defrost interval time

10~200 minutes

50

F31

Defrost time(defrost action lasting max time,will

stop defrost if longer than this value)

5~20 minutes

8

F32

Coil temp to active defrost

-30~15°C

-5°C

F33

Coil copper pipe temp to stop defrost

10~35°C

25°C

F34

Ambient temperature to active defrost

0~55°C

15°C

F35

Difference between ambient and coil temperature

to active defrost(Ambient temp lower than -7°C)

0~25°C

8°C

This manual suits for next models

2

Table of contents

Popular Inverter manuals by other brands

IPS

IPS IPS-600 Installation and user manual

IVT

IVT SW-100 user manual

GW Instek

GW Instek AFG-3021 quick start guide

Generac Power Systems

Generac Power Systems 00919-0 owner's manual

Tigo

Tigo ENERGY MODULE MAXIMIZER ES Series Installation and safety manual

Mitsubishi Electric

Mitsubishi Electric 800 Series INSTALLATION GUIDELINE