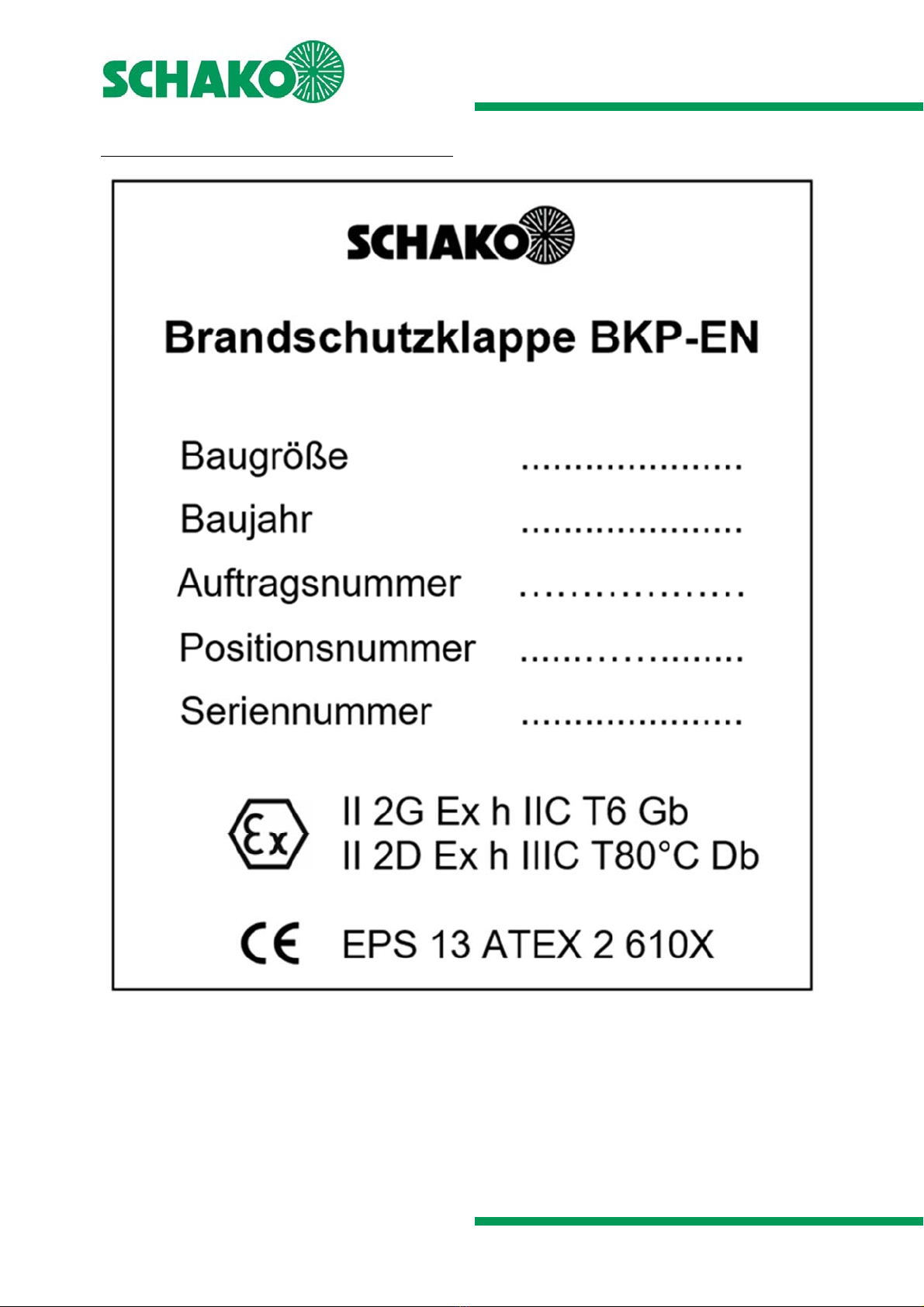

Fire damper BKP-EN

Additional operating instructions according to ATEX 2014/34/EU

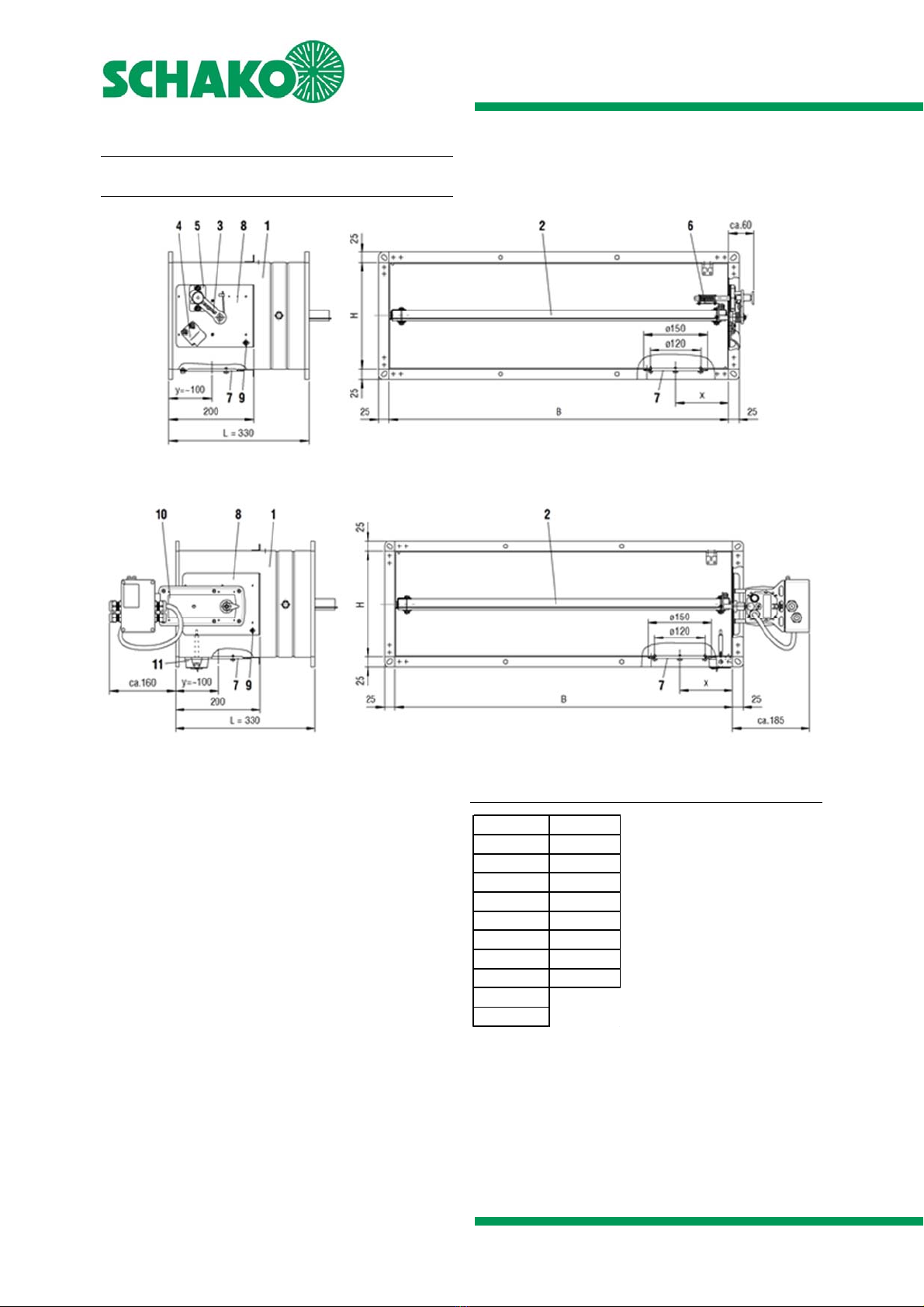

Models and dimensions

Construction subject to change

No return possible Version: 2020-09-01 | Page 8

Improper transport/handling may result in damage/func-

tional impairment. In addition to that, the film of the

transport packaging must be removed and the delivery in-

spected for completeness.

In storage, fire dampers must be protected from dust,

dirt, moisture and the effects of temperature (e.g. direct

sunlight, heat-emitting light source, etc.). They must not

be exposed to direct effects of the weather and must not

be stored below -20 °C or above 50 °C.

The fire damper must be protected from dirt and damage.

After installation is complete, any dirt must be removed

immediately.

Enough space must be provided for installation, mortar

lining, etc.

Carry out a functional check of the fire damper before and

after mounting and ensure ready access.

Electrical installations or work on electrical components

may only be carried out by skilled electricians. The supply

voltage must be switched off when performing this work

and secured against being switched on again.

We would like to point out that only suitable cleaning ma-

terials may be used for cleaning fire dampers in stainless

steel design!

Information regarding assembly and commissioning

Prior to being installed in the ventilation system, the fire

damper must be checked for damage. Damaged fire dampers

must not be installed.

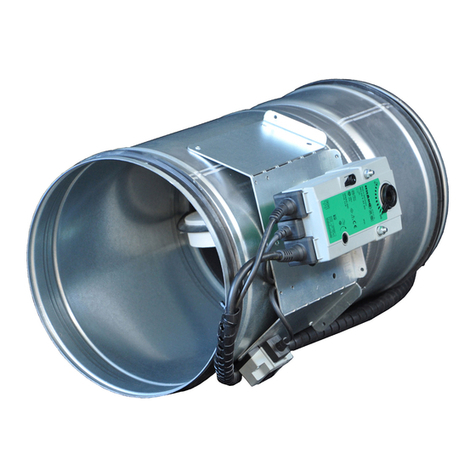

The device may only be used in accordance with its desig-

nated use in air ventilation systems for supply air and return

air.

Use only approved fastening material for mounting.

No additional parts may be

fastened to the fire damper.

The fire damper must be connected to the ventilation duct

network on both sides in electrically conducting fashion.

In order to avoid the risk of static charges, the fire damper

must be connected to the on-site equipotential bonding on

the grounding connection provided for this purpose.

Make sure that the ventilation systems are not subjected to

any anomalous operating conditions, such as vibrations, pres-

sure surges or high proportions of solids in the medium.

Information regarding functional check and inspec-

tion

Proper functional check increases operational safety and the

service life of the device. This is why the devices should be

subjected to regular inspection.

If inspection dates are prescribed by law, they must be com-

plied with.

The operating personnel must be informed, prior to starting

functional check and inspection work.

The personal safety measures must be looked up in the safety

data sheet. Hazard caused by contact or inhaling hazardous

substances must be excluded by taking appropriate safety

measures.

Prior to functional check or inspection, all system components

up- and downstream of the device must be switched off and

secured against being switched on again.

The following inspection criteria must be observed:

Visual inspection of the device

Check the fastening of the device

Check the electrical connections

Check the grounding connection for tight fit and good

contact

Functional control

For additional inspections, please refer to the technical

documentation or additional instructions for functional

check

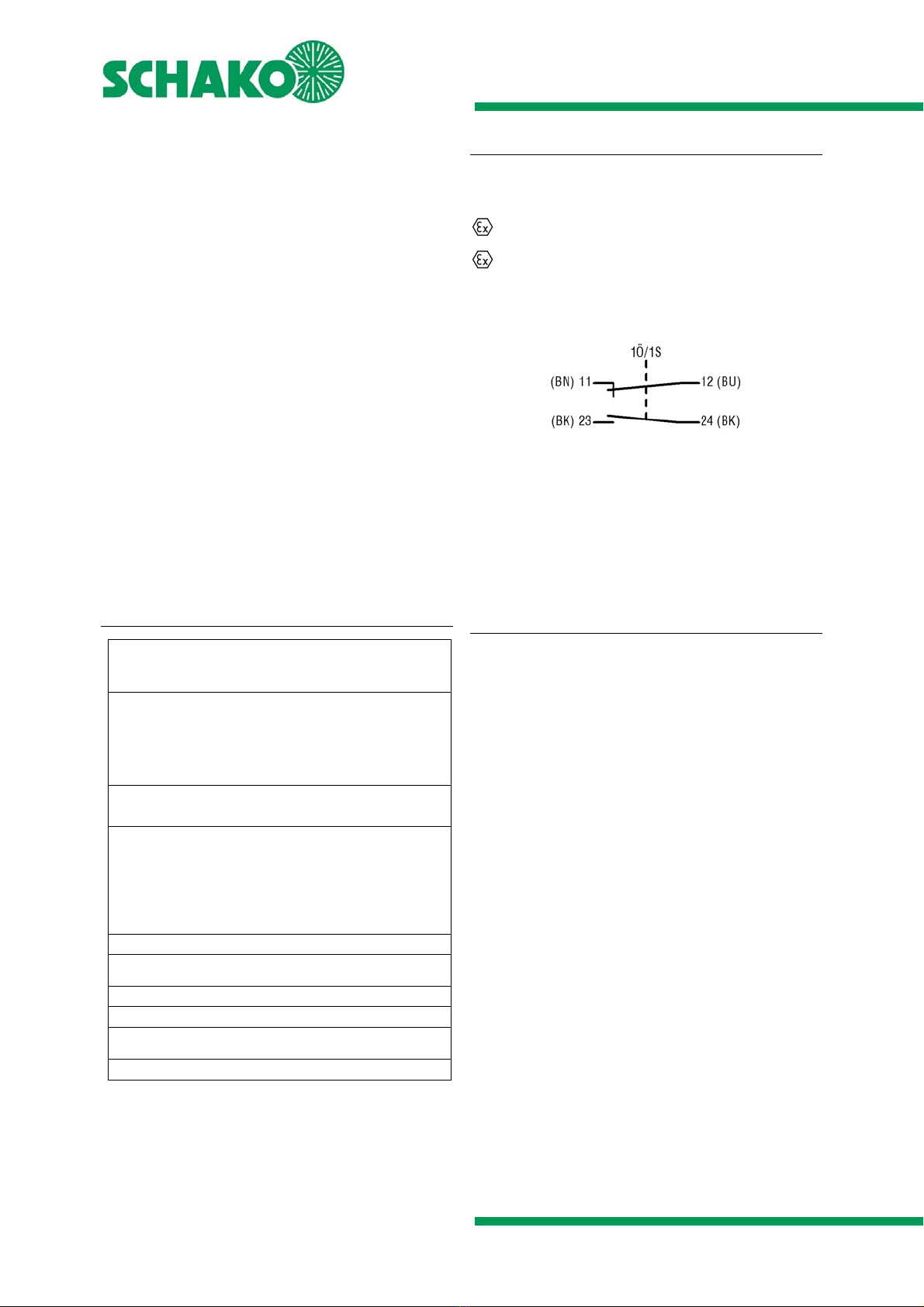

Use and electrical connection of actuators in areas

subject to explosion hazards

Only ATEX-approved electrical equipment according to ATEX

Directive 2014/34/EU for the zones 1, 2, 21, 22, such as actu-

ators, terminal boxes and thermocouples according to our

specifications may be used for SCHAKO KG devices.

The connection lines must be installed for permanent use and

in such a way that they are sufficiently protected from me-

chanical and thermal damage.

Devices with explosion-protected actuators and terminal

boxes have to be attached over the external potential con-

necting terminal to the potential equalisation provided by the

customer with at least 4 mm² cooper solid-core.

The electrical connection lines of the actuators

must be connected in a terminal box according to ATEX Di-

rective 2014/34/EU for the zones 1, 2, 21, 22, if the electrical

connection is made in an explosive area.

The dimensioning of the conductor cross-sections must be ob-

served.

The actuators are maintenance-free with respect to their

function, but the test specifications according to ATEX direc-

tives

or factory regulations must be observed.