Solmetric PVA-600 User manual

Solmetric PVA-600

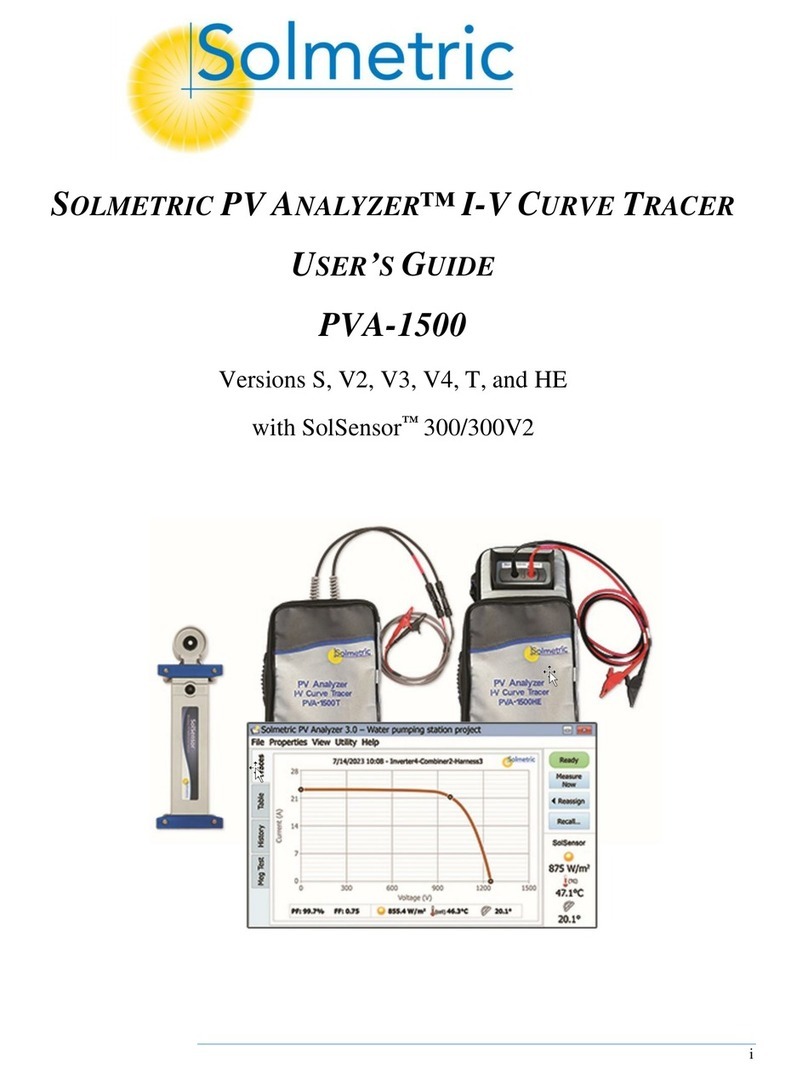

PV Analyzer

User‘s Guide

ii

© Copyright Solmetric Corporation, 2010

All Rights Reserved. Reproduction, adaptation, or

translation without prior written permission is prohibited,

except as allowed under copyright laws.

Part No. 600-90001

Version 1.0.2985.0

December 2010

Printed in USA

Solmetric Corporation

www.solmetric.com

Tel: (877) 263-5026

Fax: (707) 823-4620

End User Software License and Hardware

Agreement

CAREFULLY READ THE FOLLOWING AGREEMENT.

BY OPENING THE PACKAGE OR CLICKING ON "I

AGREE", YOU ARE CONSENTING TO BE BOUND BY

AND ARE BECOMING A PARTY TO THIS

AGREEMENT. IF YOU DO NOT AGREE TO ALL OF

THE TERMS OF THIS AGREEMENT, CLICK "I DO

NOT AGREE", DELETE ANY DOWNLOADED

INSTALLATION FILES, AND, IF APPLICABLE,

RETURN THIS PRODUCT TO THE PLACE OF

PURCHASE FOR A FULL REFUND.

Software License Grant

The package or downloaded installation file contains:

1. PV AnalyzerTM PC software (―PC Software‖),

2. PV Analyzer I-V Unit software ("Embedded

Software"), and

3. Related explanatory written materials

("Documentation").

"PC Software" and ―Embedded Software‖ includes any

upgrades, modified versions, updates, additions and copies

of the software. "You" means the person or company who

is being licensed to use the Software or Documentation.

"We", "us", and ―Solmetric‖ means Solmetric®

Corporation.

We hereby grant you a nonexclusive license to use one

copy of the PC Software on any single computer, provided

the PC Software is in use on only one computer at any

time. The PC Software is "in use" on a computer when it is

loaded into temporary memory (RAM) or installed into the

permanent memory of a computer—for example, a hard

disk, CD-ROM or other storage device. If the PC Software

is permanently installed on the hard disk or other storage

device of a computer (other than a network server) and one

person uses that computer more than 80% of the time, then

that person may also use the PC Software on a portable or

home computer.

We hereby grant you a nonexclusive license to use one

copy of the Embedded Software when it is running within

the relevant Solmetric hardware.

Software Title

Solmetric remains the owner of all right, title and interest in

the PC Software, Embedded Software, and Documentation.

Archival or Backup Copies of PC Software

You may either:

make one copy of the PC Software solely for

backup or archival purposes, or

transfer the PC Software to a single hard disk,

provided you keep the original solely for backup

or archival purposes.

Things You May Not Do With The Software Or

Documentation

The PC Software, Embedded Software, and Documentation

are protected by United States copyright laws and

international treaties. You must treat the PC Software,

Embedded Software, and Documentation like any other

copyrighted material--for example a book. You may not:

copy the Documentation,

copy the Embedded Software

copy the PC Software except to make archival or

backup copies as provided above,

modify or adapt the PC Software or Embedded

Software or merge it into another program,

reverse engineer, disassemble, decompile or

make any attempt to discover the source code of

the PC Software or Embedded Software,

place the PC Software or Embedded Software

onto a server so that it is accessible via a public

network such as the Internet, or

sublicense, rent, lease or lend any portion of the

PC Software, Embedded Software, or

Documentation.

iii

Transfers of PC Software or Embedded Software

You may transfer all your rights to use the PC Software and

Documentation to another person or legal entity provided

you transfer this Agreement, the PC Software and

Documentation, including all copies, updates and prior

versions to such person or entity and that you retain no

copies, including copies stored on computer.

You may transfer all your rights to use the Embedded

Software and Documentation to another person or legal

entity provided you transfer this Agreement, the hardware

associated with the Embedded Software, and the Embedded

Software and Documentation, including all copies, updates

and prior versions to such person or entity and that you

retain no copies, including copies stored on computer.

Limited Hardware and Software Warranty

This Solmetric PC Software and Embedded Software and

the Solmetric PV Analyzer hardware (―Hardware‖) are

warranted against defects in materials and workmanship for

a period of one year. During the warranty period,

Solmetric will, at its option, either repair or replace

products which prove to be defective. The warranty period

begins on the date of shipment.

For warranty service or repair, this product must be

returned to Solmetric. For products returned to Solmetric

for warranty service, the Buyer shall pay for shipping

charges to send the product to Solmetric, and Solmetric

shall pay for shipping charges to return the product to the

Buyer. However, the Buyer shall pay all shipping charges,

duties, and taxes for products returned to Solmetric from

another country.

The foregoing warranty shall not apply to defects resulting

from improper or inadequate maintenance by the Buyer,

unauthorized modification or misuse, or operation outside

of the environmental specifications for the product.

Unauthorized modification includes disassembly of the

Hardware or removal of any part of the Hardware

(including opening the PV Analyzer I-V unit). The design,

construction, and measurement of any system or building

by the Buyer is the sole responsibility of the Buyer.

Solmetric does not warrant the Buyer‘s system, products, or

malfunction of the Buyer‘s system or products. In addition

Solmetric does not warrant any damage that occurs as a

result of the Buyer‘s system, product, or the Buyer‘s use of

Solmetric products.

To the extent permitted by applicable law, THE

FOREGOING LIMITED WARRANTY IS IN LIEU OF

ALL OTHER WARRANTIES OR CONDITIONS,

EXPRESS OR IMPLIED, AND WE DISCLAIM ANY

AND ALL IMPLIED WARRANTIES OR CONDITIONS,

INCLUDING ANY IMPLIED WARRANTY OF TITLE,

NONINFRINGEMENT, MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, regardless of

whether we know or had reason to know of your particular

needs. No employee, agent, dealer or distributor of ours is

authorized to modify this limited warranty, nor to make any

additional warranties.

SOME STATES DO NOT ALLOW THE EXCLUSION

OF IMPLIED WARRANTIES, SO THE ABOVE

EXCLUSION MAY NOT APPLY TO YOU. THIS

WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

Limited Remedy

Our entire liability and your exclusive remedy shall be the

replacement or repair of any Solmetric Hardware or

Solmetric PC Software or Embedded Software not meeting

our Limited Hardware And Software Warranty which is

returned to us or to an authorized Dealer or Distributor with

a copy of your receipt.

IN NO EVENT WILL WE BE LIABLE TO YOU FOR

ANY DAMAGES, INCLUDING ANY LOST PROFITS,

LOST SAVINGS, INJURY, DEATH, OR OTHER

INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING FROM THE USE OF OR THE INABILITY TO

USE THE PC SOFTWARE, EMBEDDED SOFTWARE,

HARDWARE, OR DOCUMENTATION (EVEN IF

SOLMETRIC OR AN AUTHORIZED DEALER OR

DISTRIBUTOR HAS BEEN ADVISED OF THE

POSSIBILITY OF THESE DAMAGES), OR FOR ANY

CLAIM BY ANY OTHER PARTY.

SOME STATES DO NOT ALLOW THE LIMITATION

OR EXCLUSION OF LIABILITY FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

Term and Termination

This agreement takes effect upon your use of the PC

Software, Embedded Software, or Hardware and remains

effective until terminated. You may terminate it at any time

by destroying all copies of the PC Software, Embedded

Software, and Documentation in your possession and

returning the Hardware to Solmetric or to an authorized

distributor. It will also automatically terminate if you fail to

comply with any term or condition of this license

agreement. You agree on termination of this license to

either return to us or destroy all copies of the PC Software,

Embedded Software, and Documentation in your

possession and to return the Hardware to us or to an

authorized distributor.

iv

Confidentiality

The PC Software and Embedded Software contains trade

secrets and proprietary know-how that belong to us and it is

being made available to you in strict confidence. ANY USE

OR DISCLOSURE OF THE PC SOFTWARE,

EMBEDDED SOFTWARE, OR OF THEIR

ALGORITHMS, PROTOCOLS OR INTERFACES,

OTHER THAN IN STRICT ACCORDANCE WITH THIS

LICENSE AGREEMENT, MAY BE ACTIONABLE AS

A VIOLATION OF OUR TRADE SECRET RIGHTS.

Trademarks

SOLMETRIC, PV ANALYZER, PV DESIGER,

SOLMERIC IPV and SOLMETRIC ISV are trademarks

owned by Solmetric Corporation. SOLMETRIC and

SUNEYE are registered trademarks in the U.S. Patent and

Trademark Office.

General Provisions

1. This written agreement is the exclusive agreement

between you and us concerning the PC Software,

Embedded Software, Hardware, and Documentation

and supersedes any and all prior oral or written

agreements, negotiations or other dealings between us

concerning the PC Software, Embedded Software,

Hardware or Documentation.

2. This license agreement may be modified only in

writing and written documentation must be signed by

Buyer and Solmetric.

3. In the event of litigation between Buyer and Solmetric

concerning the PC Software, Embedded Software,

Hardware, or Documentation, the prevailing party in

the litigation will be entitled to recover attorney fees

and expenses from the other party.

4. This license agreement is governed by the laws of the

State of California.

5. Buyer agrees that the PC Software, Embedded

Software, or Hardware will not be shipped, transferred

or exported into any country or used in any manner

prohibited by the United States Export Administration

Act or any other export laws, restrictions or

regulations.

v

Contents

1INTRODUCTION .......................................................................................................................................... 1-1

OVERVIEW............................................................................................................................................................. 1-1

COMPUTER MINIMUM SYSTEM REQUIREMENTS .................................................................................................... 1-2

PVA-600 EQUIPMENT............................................................................................................................................ 1-2

PVA-600 SPECIFICATIONS..................................................................................................................................... 1-3

Electrical Specifications ................................................................................................................................... 1-3

Mechanical Specifications ................................................................................................................................ 1-4

PVA SENSOR KIT EQUIPMENT (OPTIONAL)........................................................................................................... 1-4

PVA SENSOR KIT SPECIFICATIONS (OPTIONAL) .................................................................................................... 1-5

SAFETY AND REGULATORY.................................................................................................................................... 1-6

Warnings, Cautions, and Notes......................................................................................................................... 1-6

Declaration of Conformity................................................................................................................................ 1-6

Cleaning............................................................................................................................................................ 1-6

Instrument Markings......................................................................................................................................... 1-7

2GETTING STARTED.................................................................................................................................... 2-1

PRECAUTIONS ........................................................................................................................................................ 2-1

PV Connectors.................................................................................................................................................. 2-1

PV/Electrical Safety Precautions...................................................................................................................... 2-1

Battery Precautions .......................................................................................................................................... 2-3

Measuring High-Efficiency PV Modules

........................................................................................................ 2-3

UNDERSTANDING THE PVA-600............................................................................................................................ 2-3

Application Overview........................................................................................................................................ 2-3

I-V Measurements............................................................................................................................................. 2-4

Logging Mode................................................................................................................................................... 2-4

PV Models......................................................................................................................................................... 2-4

INSTALLATION PROCEDURE................................................................................................................................... 2-5

Hardware Installation....................................................................................................................................... 2-5

Software Installation......................................................................................................................................... 2-5

SPECIAL XP OPERATING SYSTEM INSTRUCTIONS .................................................................................................. 2-6

INSTALLING DRIVERS FOR THE OPTIONAL PVA SENSOR KIT................................................................................. 2-7

CHARGING THE BATTERY ...................................................................................................................................... 2-7

3USING THE PVA-600.................................................................................................................................... 3-1

SYSTEM CONTROLS AND SETTINGS........................................................................................................................ 3-1

PVA-600 States ................................................................................................................................................. 3-1

SETTING UP THE PVA-600..................................................................................................................................... 3-3

SETTING UP THE OPTIONAL PVA SENSOR KIT ...................................................................................................... 3-4

CONNECTING TO THE SOLAR PV EQUIPMENT ........................................................................................................ 3-5

POWERING-UP THE I-V MEASUREMENT UNIT........................................................................................................ 3-7

I-V MEASUREMENTS.............................................................................................................................................. 3-7

SWEEP DISABLED................................................................................................................................................... 3-8

vi

OVER-TEMPERATURE PROTECTION ....................................................................................................................... 3-8

Thermal Shutdown............................................................................................................................................ 3-8

Operating Under High-Temperature Conditions.............................................................................................. 3-9

OVER-VOLTAGE PROTECTION ............................................................................................................................... 3-9

OVER-CURRENT PROTECTION................................................................................................................................ 3-9

REVERSE POLARITY PROTECTION........................................................................................................................ 3-10

4USING THE PVA-600 SOFTWARE............................................................................................................ 4-1

MAIN SCREEN OVERVIEW...................................................................................................................................... 4-1

TITLE BAR ............................................................................................................................................................. 4-2

MENU BAR............................................................................................................................................................. 4-2

File Menu.......................................................................................................................................................... 4-2

Model Menu...................................................................................................................................................... 4-2

Utility Menu...................................................................................................................................................... 4-6

Help Menu ........................................................................................................................................................ 4-7

TABS...................................................................................................................................................................... 4-7

Table Tab.......................................................................................................................................................... 4-7

Traces Tab ...................................................................................................................................................... 4-10

Verify Tab ....................................................................................................................................................... 4-11

Logging Tab.................................................................................................................................................... 4-13

Sensors Tab..................................................................................................................................................... 4-14

SETTING UP A NEW MODEL................................................................................................................................. 4-15

Start the PVA-600 Software............................................................................................................................ 4-15

Enter the Name and Notes .............................................................................................................................. 4-16

Enter Latitude, Longitude, and Time Zone ..................................................................................................... 4-16

Select the Modules and Enter String Information........................................................................................... 4-18

Select an Inverter............................................................................................................................................ 4-20

Select Wire Gauge and Enter Wire Length..................................................................................................... 4-21

Select the Sensor Methods .............................................................................................................................. 4-22

Enter Array Slope and Azimuth ...................................................................................................................... 4-23

COPYING AN EXISTING MODEL FILE.................................................................................................................... 4-24

MAKING MEASUREMENTS ................................................................................................................................... 4-25

SAVING DATA TO A DIRECTORY TREE................................................................................................................. 4-29

SAVING TRACE DATA .......................................................................................................................................... 4-30

USING SNAPSHOT................................................................................................................................................. 4-31

SAVING A SCREEN IMAGE .................................................................................................................................... 4-31

VIEWING AND ANALYZING YOUR DATA.............................................................................................................. 4-32

SETTING UP DATA LOGGING MODE..................................................................................................................... 4-34

VIEWING AND ANALYZING LOGGING DATA ........................................................................................................ 4-36

TROUBLESHOOTING PVA-600 OPERATION.......................................................................................................... 4-37

5INTERPRETING MEASURED I-V CURVES............................................................................................ 5-1

INTRODUCTION ...................................................................................................................................................... 5-1

INPUTS TO THE PV MODEL..................................................................................................................................... 5-1

I-V CURVE TERMINOLOGY .................................................................................................................................... 5-2

THE SHAPE OF A NORMAL I-V CURVE ................................................................................................................... 5-3

INTERPRETING I-V CURVES ................................................................................................................................... 5-4

1. THE MEASURED I-V CURVE SHOWS HIGHER OR LOWER CURRENT THAN PREDICTED........................................ 5-6

PV Array Is Soiled ............................................................................................................................................ 5-7

vii

PV Modules Are Degraded............................................................................................................................... 5-7

Incorrect PV Module Is Selected for the Model................................................................................................ 5-7

Number of PV Strings in Parallel Is Not Entered Correctly in the Model........................................................ 5-7

Irradiance Changed Between Irradiance and I-V Measurements .................................................................... 5-7

Irradiance Sensor Is Oriented Incorrectly........................................................................................................ 5-7

Irradiance Sensor Calibration Factor Is Entered Incorrectly.......................................................................... 5-8

Reflections Contribute Additional Irradiance................................................................................................... 5-8

Irradiance Is Too Low, or the Sun Is Too Close to the Horizon ....................................................................... 5-8

Manual Irradiance Sensor Is Not Well Calibrated ........................................................................................... 5-8

2. THE SLOPE OF THE CURVE NEAR ISC DOES NOT MATCH THE PREDICTION ........................................................ 5-9

Shunt Paths Exist In PV Cells or Modules...................................................................................................... 5-10

Module Isc Mismatch...................................................................................................................................... 5-10

3. THE SLOPE OF THE CURVE NEAR VOC DOES NOT MATCH THE PREDICTION .................................................... 5-11

PV Wiring Has Excess Resistance or Is Insufficiently Sized........................................................................... 5-12

Electrical Interconnections in the Array Are Resistive................................................................................... 5-12

Series Resistance of PV Modules Has Increased............................................................................................ 5-12

4. THE I-V CURVE HAS NOTCHES OR STEPS ........................................................................................................ 5-13

Array Is Partially Shaded ............................................................................................................................... 5-15

PV Cells Are Damaged................................................................................................................................... 5-15

Cell String Conductor Is Short Circuited........................................................................................................ 5-15

5. THE I-V CURVE HAS A HIGHER OR LOWER VOC VALUE THAN PREDICTED ..................................................... 5-16

PV Cell Temperature Is Different than the Modeled Temperature................................................................. 5-16

One or More Cells or Modules Are Completely Shaded................................................................................. 5-17

One or More Bypass Diodes Are Conducting or Shorted............................................................................... 5-17

Figures

FIGURE 1. WELCOME SCREEN..................................................................................................................................... 2-5

FIGURE 2. DIRECTORY STRUCTURE OF PVA-600 SOFTWARE...................................................................................... 2-5

FIGURE 3. LAUNCHING THE PVA-600 SOFTWARE ...................................................................................................... 2-6

FIGURE 4. PVA-600 SOFTWARE USER INTERFACE ...................................................................................................... 2-6

FIGURE 5. BATTERY CHARGER CONNECTOR ON THE PVA-600................................................................................... 2-7

FIGURE 6. LED-ILLUMINATED BUTTON SWITCH......................................................................................................... 3-1

FIGURE 7. PVA SENSOR KIT ...................................................................................................................................... 3-4

FIGURE 8. EXAMPLE OF PVA-600 TEST LEADS CLIPPED TO THE BUSS BARS OF A PV COMBINER BOX ........................ 3-6

FIGURE 9. POWERING-UP THE I-V MEASUREMENT UNIT............................................................................................ 3-7

FIGURE 10. PVA-600 MAIN SCREEN........................................................................................................................... 4-1

FIGURE 11. TABLE TAB............................................................................................................................................... 4-7

FIGURE 12. TRACES TAB........................................................................................................................................... 4-10

FIGURE 13. VERIFY TAB ........................................................................................................................................... 4-12

FIGURE 14. LOGGING TAB ........................................................................................................................................ 4-13

FIGURE 15. SENSORS TAB......................................................................................................................................... 4-14

FIGURE 16. TABLE SCREEN....................................................................................................................................... 4-15

FIGURE 17. MODEL SCREEN...................................................................................................................................... 4-16

FIGURE 18. LOCATION SCREEN................................................................................................................................. 4-16

FIGURE 19. MODULES/STRING SCREEN .................................................................................................................... 4-18

FIGURE 20. CHANGE…MODULE SCREEN ................................................................................................................. 4-18

FIGURE 21. MODULE PROPERTY AND VALUE COLUMNS........................................................................................... 4-19

viii

FIGURE 22. SIMPLE PERFORMANCE MODEL .............................................................................................................. 4-19

FIGURE 23. INVERTER SCREEN.................................................................................................................................. 4-20

FIGURE 24. CHANGE…INVERTER SCREEN ............................................................................................................... 4-20

FIGURE 25. INVERTER DESCRIPTION AND VALUE COLUMNS .................................................................................... 4-21

FIGURE 26. WIRING SCREEN..................................................................................................................................... 4-21

FIGURE 27. CONTROLS FOR DERIVING THE IRRADIANCE AND/OR TEMPERATURE FROM MEASURED I-V CURVE (ARRAY-

AS-SENSOR METHOD).............................................................................................................................. 4-22

FIGURE 28. CONTROLS FOR ENTERING IRRADIANCE AND/OR TEMPERATURE MANUALLY ......................................... 4-22

FIGURE 29. CONTROLS FOR MEASURING IRRADIANCE AND/OR TEMPERATURE AUTOMATICALLY USING WIRELESS

SENSORS ................................................................................................................................................. 4-23

FIGURE 30. ARRAY PLANE SCREEN .......................................................................................................................... 4-24

FIGURE 31. COPYING A MODEL FILE ......................................................................................................................... 4-24

FIGURE 32. OPEN A MODEL FILE .............................................................................................................................. 4-26

FIGURE 33. TURN ON THE I-V MEASUREMENT UNIT ................................................................................................ 4-26

FIGURE 34. IRRADIANCE AND TEMPERATURE COMMUNICATION STATUS.................................................................. 4-27

FIGURE 35. PREDICTED/MEASURED COLUMNS IN TABLE TAB .................................................................................. 4-28

FIGURE 36. I-V AND P-V GRAPHS............................................................................................................................. 4-28

FIGURE 37. PERFORMANCE FACTOR VALUE ............................................................................................................. 4-29

FIGURE 38. CREATING A DIRECTORY TREE ............................................................................................................... 4-30

FIGURE 39. SNAPSHOT TABLE................................................................................................................................... 4-31

FIGURE 40. TRACE DATA.......................................................................................................................................... 4-32

FIGURE 41. PREDICTED CURRENT,VOLTAGE,AND MAXIMUM POWER POINTS........................................................... 4-33

FIGURE 42. LOGGING SCREEN................................................................................................................................... 4-34

FIGURE 43. START LOGGING SCREEN ....................................................................................................................... 4-35

FIGURE 44. LOGGING DATA...................................................................................................................................... 4-36

FIGURE 45. THE FILL FACTOR IS DEFINED AS IMP X VMP (THE GRAY AREA)DIVIDED BY ISC X VOC (THE CROSS-

HATCHED AREA)....................................................................................................................................... 5-2

FIGURE 46. EFFECT OF SERIES AND SHUNT LOSSES ON THE SHAPE OF THE I-V CURVE ................................................ 5-3

FIGURE 47. ANORMAL I-V CURVE FOR THE PARALLEL COMBINATION OF TWO STRINGS OF EIGHT 175-WATT MODULES,

SHOWING CONFORMANCE WITH FIVE POINTS PREDICTED BY THE PV MODEL............................................ 5-3

FIGURE 48. EXAMPLE OF A MEASURED I-V CURVE THAT SHOWS HIGHER CURRENT THAN PREDICTED........................ 5-6

FIGURE 49. AN I-V CURVE SHOWING MORE SLOPE THAN EXPECTED IN THE REGION ABOVE ISC................................. 5-9

FIGURE 50. AN I-V CURVE IN WHICH THE SLOPE OF THE MEASURED I-V CURVE NEAR VOC DOES NOT MATCH THE

PREDICTED SLOPE ................................................................................................................................... 5-11

FIGURE 51. THE EFFECT OF PARTIAL SHADING ON TWO PARALLELED STRINGS OF EIGHT 175-WATT MODULES ........ 5-13

FIGURE 52. THE SHADING IMPACT OF PLACING A BUSINESS CARD ON A SINGLE CELL IN A STRING OF FIFTEEN 180-WATT

MODULES................................................................................................................................................ 5-13

FIGURE 53. THE EFFECT OF INTENTIONALLY SHADING ENTIRE MODULES IN DIFFERENT COMBINATIONS,IN TWO

PARALLEL-CONNECTED STRINGS ............................................................................................................ 5-14

FIGURE 54. EXAMPLE OF AN I-V CURVE WITH LOWER VOC VALUE THAN PREDICTED .............................................. 5-16

ix

Tables

TABLE 1. PVA-600 ELECTRICAL SPECIFICATIONS ...................................................................................................... 1-3

TABLE 2. PVA-600 MECHANICAL SPECIFICATIONS .................................................................................................... 1-4

TABLE 3. PVA SENSOR KIT TEMPERATURE SPECIFICATIONS...................................................................................... 1-5

TABLE 4. PVA SENSOR KIT IRRADIANCE SPECIFICATIONS ......................................................................................... 1-5

TABLE 5. PVA-600 STATES........................................................................................................................................ 3-2

TABLE 6. FILE MENU DESCRIPTION............................................................................................................................. 4-2

TABLE 7. MODEL MENU DESCRIPTION ........................................................................................................................ 4-2

TABLE 8. UTILITY MENU DESCRIPTION....................................................................................................................... 4-6

TABLE 9. HELP MENU DESCRIPTION............................................................................................................................ 4-7

TABLE 10. TABLE TAB DESCRIPTION .......................................................................................................................... 4-8

TABLE 11. TRACES TAB DESCRIPTION ...................................................................................................................... 4-11

TABLE 12. VERIFY TAB DESCRIPTION ....................................................................................................................... 4-12

TABLE 13. LOGGING TAB DESCRIPTION .................................................................................................................... 4-14

TABLE 14. SENSORS TAB DESCRIPTION..................................................................................................................... 4-15

TABLE 15. TIME ZONES ............................................................................................................................................ 4-17

x

The page left blank intentionally.

1 Introduction

1-1

1Introduction

Overview

The PVA-600 PV Analyzer is a portable test instrument designed to measure the current-

voltage (I-V) curves of PV modules and strings and immediately compare the results to

on-board PV model predictions. Measurement results are easily saved for future reference

and analysis.

The current-voltage (I-V) curve of a PV module, string, or array provides a detailed

description of its energy collecting ability. The curve ranges from the short circuit current

(Isc) at zero volts, to the open circuit voltage (Voc) at zero current. At the ‗knee‘ of a

normal I-V curve are the maximum power current and voltage (Imp, Vmp), the point at

which the array generates maximum electrical power. All of these important voltages and

currents are captured when the I-V curve is measured. The detailed shape of the curve

between these points gives additional information about the health of the PV module,

string, or array under test.

The value of a measured I-V curve is greatly increased when it can be compared with a

predicted I-V curve derived from an accurate PV model. Models take into account the

specifications of the PV modules, the number of modules in series and strings in parallel,

and the losses in system wiring. Other data used by the models include the irradiance in

the plane of the array, the module temperature, and array orientation.

1 Introduction

1-2

Computer Minimum System Requirements

Test and Supported Operating System: Windows 7® (32 and 64 bit versions),

Windows Vista® (32 bit versions only), Windows XP® SP3

Two USB Ports (or one USB port if wireless sensors will not be used)

Display Resolution: 1024 X 600 (minimum)

Processor Speed: >700 MHz

RAM: >500 Mbytes

Available Disc Space: 100 Mbytes or more

Systems that do not meet these requirements may not operate correctly.

PVA-600 Equipment

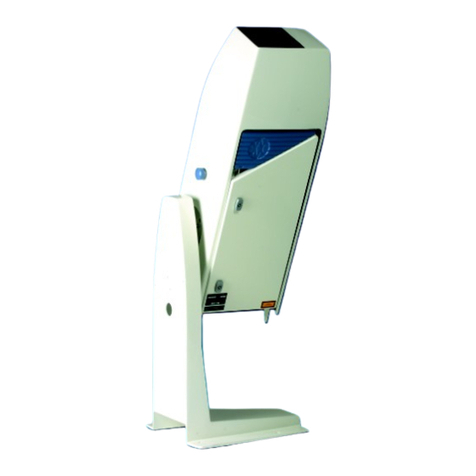

I-V Measurement Unit

Soft Case

Wireless USB Adapter and PVA-600 Software Application

Battery Charger

MC-4 to MC-4 Connector-Saver Cable (2)

MC-4 to MC-3 Adapter Cable (2)

User‘s Guide (on Installation DVD)

Quick Start Guide

1 Introduction

1-3

PVA-600 Specifications

Electrical Specifications

Safety Rating: Measuring Category CATIII 600V.

Table 1. PVA-600 electrical specifications

Parameter

Specification

Current Measurement Range1

0 to 20 A dc

Voltage Measurement Range

0 to 600 V dc

Minimum Voc

20 V dc

Minimum Isc

1 A dc

Wireless Communications Range

10 m (industrial building walls) to 75 m (open

range)

Measurement Sweep Time2

80 ms to 240 ms

Measurement Points per Trace (typical)

100

PV Models

Sandia (>420 modules)

5-Parameter (>1760 modules)

Simple Datasheet Model (user enters datasheet

values)

Battery Life

≈20 hours (normal use)

Charging Time

6 hours

Operating Temperature

+0º C to +50º C

Storage Temperature

-20º C to +60º C

Operating Humidity

The normal humidity range is 80% relative

humidity for temperatures up to 31ºC,

decreasing linearly to 50% at 40ºC. Higher

humidity levels should not affect the

performance or safety of the PVA-600.

1 Conventional PV modules and strings may be measured in parallel, up to the current

limit specified here. High-efficiency modules should NOT be measured in parallel.

2 Automatically selected. Measurement sweep time depends upon the characteristics of

the test device (PV module, string, or array).

1 Introduction

1-4

Mechanical Specifications

Table 2. PVA-600 mechanical specifications

Parameter

Specification

PV Connectors1

MC-4

Weight

9.2 lbs (not including weight of the soft case)

Height

15 in

Width

8 in

Depth

5 in

1 At ends of the primary test leads permanently attached to the I-V Measurement Unit.

PVA Sensor Kit Equipment (Optional)

Irradiance Sensor

Temperature Sensor

5-Pack of Replacement Temperature Sensors

Wireless USB Adapter

Transmitter (irradiance)

Transmitter (temperature)

Case

Rechargeable AAA batteries and battery charger

1 Introduction

1-5

PVA Sensor Kit Specifications (Optional)

Table 3. PVA Sensor Kit temperature specifications

Parameter

Specification

Thermocouple Type

K

Range

-100º C to 1260º C (-148º F to 2300º F)

Resolution

1º C

Accuracy (greater of)

±0.5% of rdg or ±1.0º C (1.8 º F)

Table 4. PVA Sensor Kit irradiance specifications

Parameter

Specification

Sensor Type

Silicon Solar Cell

Angle of Incidence Effect

Typically < 1% if AOI is less than 60 degrees from

normal

Temperature Effect

Typically < ±2.7% variation over -20º C to +70º C

Uncertainty Contributed by Wireless Link

±0.5% or reading

Uncertainty from Time Lead or Lag in

Reading Irradiance Sensor

0.5% to > 5% depending on atmospheric conditions

1 Introduction

1-6

Safety and Regulatory

Warnings, Cautions, and Notes

Before operating the PVA-600, familiarize yourself with the following notations.

WARNING A Warning calls attention to a procedure, which, if not performed correctly, could

result in personal injury or loss of life. Do not proceed beyond a warning note until

the indicated conditions are fully understood and met.

CAUTION A Caution calls attention to a procedure that, if not performed correctly, could result in

damage to, or destruction of, the instrument. Do not proceed beyond a caution note until

the indicated conditions are fully understood and met.

NOTE A Note provides important or special information.

Declaration of Conformity

A declaration of conformity is available upon request.

Cleaning

To remove dirt or dust from the external case and/or hard enclosure of the PVA-600, use

a dry or slightly dampened cloth only.

WARNING To prevent electrical shock, disconnect the PVA-600 from the PV system and/or

battery charger before cleaning. Use only a dry cloth or cloth slightly dampened

with water to clean the external case and hard enclosure parts. Do not attempt to

clean internally.

1 Introduction

1-7

Instrument Markings

The PVA-600 has the following markings on the front and/or rear panel. Familiarize

yourself with these markings before operating the PVA-600.

The instruction manual symbol. The product is marked with this

symbol when it is necessary for you to refer to instructions in the

manual.

Compliance pending. The TUV mark indicates compliance with

USA/EU safety regulations.

Compliance pending. This symbol indicates compliance with the

requirements of CAN/CSA-C22.2 No. 61010-1, 2nd edition, including

Amendment 1. This product has been tested to the requirements of

CAN/CSA-C22.2 No. 61010-1, second edition, including Amendment

1, or a later version of the same standard incorporating the same level

of testing requirements

This symbol indicates separate collection for electrical and electronic

equipment, mandated under EU law as of August 13, 2005. All

electrical and electronic equipment are required to be separated from

normal waste for disposal. (Reference WEEE Directive, 2002/96/EC.)

The IEC HV symbol indicates the presence of hazardous voltages.

Danger exists of electrical shock that can cause severe injury or death.

This symbol marks the position of the power switch.

1 Introduction

1-8

The page left blank intentionally.

2 Getting Started

2-1

2Getting Started

Precautions

PV Connectors

PV connectors, regardless of manufacturer, are not designed for large numbers of

connections/disconnections. For this reason, the PVA-600 is shipped with connector-

saver jumpers attached to its primary test leads. These short jumpers are sacrificial. PV

devices under test (modules, strings, or arrays), extension cables, and clip leads are

always connected to the connector-saver jumpers, extending the life of the primary PV

connectors. When the lifetime of the connector-saver jumper has been reached, it should

be replaced, cut in half to prevent re-use, and recycled. With the use of connector-saver

jumpers, the life of the primary test leads of the PVA-600 should be extended to 5,000 to

10,000 connections.

PV/Electrical Safety Precautions

Installed PV systems are not consistent in design or construction. Therefore the guidance

provided in this section is general in nature, and it is critical that the user apply

techniques and precautions appropriate to the circumstances, following best PV/electrical

safety precautions.

WARNING The information below is important but not necessarily complete; the operator must

assess the potential dangers of each PV system, and take appropriate precautions.

FAILURE TO TAKE APPROPRIATE SAFETY PRECAUTIONS COULD LEAD

TO PERSONAL INJURY OR LOSS OF LIFE.

Avoid working alone.

Do not use the PVA-600 in wet environments.

Do not operate or subject the PVA-600 to temperatures beyond the published

operating and storage temperature specifications.

Wear electrical safety gloves.

Wear eye protection.

Wear fall protection where required.

2 Getting Started

2-2

Assume that metal surfaces are energized unless proven otherwise.

Isolate the PV source circuit under test from the inverter, and from other PV source

circuits, before making any connections to the test device (PV module, string, or

array).

Always pause the measurement sequence using the LED-illuminated pushbutton

switch on the I-V unit before connecting or disconnecting the test leads of the PVA-

600.

Do not use the PVA-600 to test devices that produce more than the instrument‘s

specified maximum current and voltage.

Connect the test leads to the test device (PV module, string, or array) with the correct

polarity.

Protect the primary test lead connectors of the PVA-600 by installing connector-

saver jumpers. Replace the connector-saver jumpers when they have reached 100

connections.

Make sure that user-provided cables or clip leads used to extend the test leads of the

PVA-600 are rated to safely handle the PVA-600‘s specified maximum current and

voltage.

When using probes or clip leads, they should be of the insulated type with minimal

exposed metal. Keep your fingers behind the insulating finger guards.

WARNING Do not remove instrument covers. There are no user serviceable parts within.

Operation of the instrument in a manner not specified by Solmetric may result in

personal injury or loss of life.

Do not use the I-V Measurement Unit if it is damaged. Always inspect for damage

before using.

Inspect primary test leads and connectors for damage before using. Do not use if

damaged.

Do not use the I-V Measurement Unit if it is performing abnormally. Contact

Solmetric for guidance or return the I-V Measurement Unit to the factory for service.

Other manuals for PVA-600

1

Table of contents

Other Solmetric Measuring Instrument manuals

Solmetric

Solmetric PVA-1500T User manual

Solmetric

Solmetric PV ANALYZER PVA-1500 Series User manual

Solmetric

Solmetric PVA-1500V2 User manual

Solmetric

Solmetric SunEye 210 User manual

Solmetric

Solmetric PVA-1500V2 Reference guide

Solmetric

Solmetric PVA-1500S User manual

Solmetric

Solmetric PVA-600 User manual

Solmetric

Solmetric PVA-1000S User manual