3

TIP Photograph roof

damage!

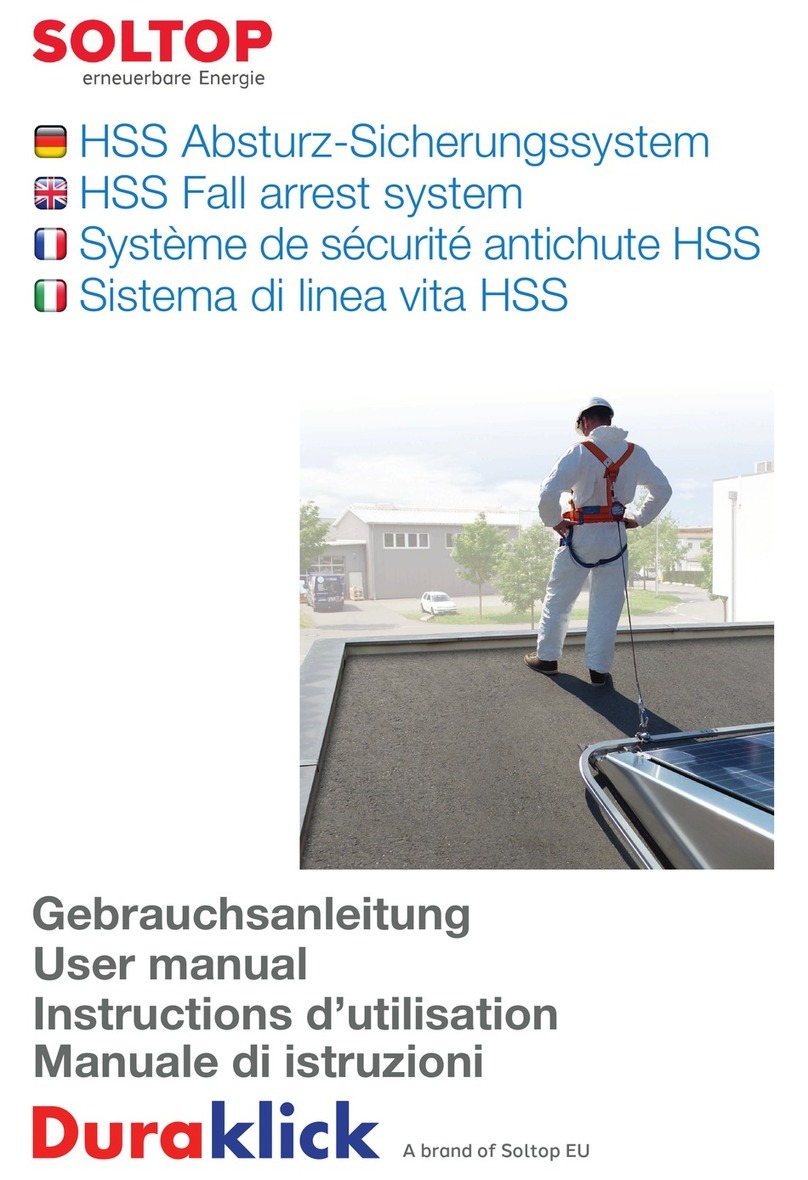

The Duraklick HSS is a personal safety device and was spe-

cially developed for the Duraklick PV mounting systems. It can

be installed on all systems (SR, EW, GR and ECO). The safety

system may only be installed by Duraklick certified fitters. It

must be installed according to the specifications in these in-

stallation instructions.

1. Anchor devices

Anchor devices Type D and E according to DIN EN 795,

CEN/TS 16415:2013 Type: Duraklick-HSS-Hight Safety Sys-

tem tested by DEKRA EXAM GmbH according to dynamic

and static load capacity according to item 4.4.4 und 4.4.5

DIN EN 795:2012 und CEN/TS 16415:2013 am 06.03.2013.

Approved for max. 4 persons at the same time.

2. Equipment sets (case/bag)

The cases/bags containing the equipment sets (safety

harness, fall protection runner, fall arrester/ AM4 fall arrester)

should be stored near the entrance or roof access.

3. Protection during assembly

Please ensure that you are properly secured against falling

during installation! For safety reasons, work in the fall area

must not be carried out alone

Photograph roof damages!

Before installation, it should be checked whether there is any

damage of any kind - especially water seepage or damage

to the roof cladding. These should be documented with the

digital camera to avoid later recourse claims.

Clean roof

Drilling and metal chips must be removed from the roof! Do

not place any screws or sharp tools on the roof foil!

The roof membrane could be damaged!

General instructions and preparations

Clean roof!

!

The installation of the HSS height safe-

ty system may only be carried out by a

certified fitter.

Attention!

!

Gloves!

Wear gloves during assembly!

Risk of injury from sharp edges!

!

Instruction manual