SOLUXTEC Das modul Mono XSC User manual

USER GUIDE

SOLUXTEC SOLAR

PRODUCTS

2

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

1. INTRODUCTION 3

2. BASIC SAFETY INSTRUCTIONS 3

3. REGULATION 4

4. TRANSPORT AND HANDLING 4

5. PRODUCT DETAILS 5

6. INSTALLATION 6

Modules Design 6

Precaution 13

Installation Option 15

7. ELECTRICAL INSTALLATION 13

Precaution 18

Wiring 18

8. MAINTENANCE AND CLEANING 21

3

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

1 INTRODUCTION

Thank you for electing SOLUXTEC GmbH PV modules. The following user guide is covering

important points to be read and understood before installation of SOLUXTEC products. This

document is not having any aims in relation to quality warranties but only for safety, electrical,

mechanical and general handling of SOLUXTEC products.

In case a pv installation is not respecting above mentioned points, the quality warranty of

SOLXTEC product will become invalid.

This document belongs to SOLUXTEC, all contents are SOLUXTEC intellectual properties.

SOLUXTEC reserves the right to modify this document without prior notice.

- Please read this document carefully before installation

- Please make sure that this document is always available for installers and operators to

handle SOLUXTEC’s products.

- Please give a copy of this document to the installation owner.

- If any questions are not well answered in this document, please contact SOLUXTEC

support prior installation.

2 SAFETY

The installation of photovoltaic modules must respect the current standards from the

place of installation. It is imperative to refer to the standards of each local authority

in case specifics rules are imposed.

Installation of photovoltaic modules must be operated by qualified peoples, knowing

and respecting all regulation and requirements for compliance with country of

installation.

Solar modules create DC electricity and are even energized under a slight

illumination level. Several modules connected together may occur an accumulation

of voltage and intensity. Please respect all personal security to avoid a risk of

electrocution.

Please respect the data given from the elected module’s data sheet to respect all

module’s limits and comply with other materials that will be need to operate the

photovoltaic generator.

- Never open the junction box on the back of the photovoltaic module

- Make sure that connectors are clean and not dirty or wet before connection.

- Never disconnect the photovoltaic connector under load. Always turn off the DC breaker

prior any photovoltaics connector disconnection.

- Tools must be dedicated for solar installation and supporting DC current.

- The final photovoltaic generator must follow all needed standard and requirement in

compliance with the installation country (PV, inverter, cable, grounding and other

accessories from the pv generator).

- Never disassembled any part of the module.

4

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

3 REGULATION

All modules presented in this document are covered from the following standards:

IEC 61215

IEC 61730

IEC 62804 (PID)

IEC 61701 (SALT MIST)

IEC 62716 (AMMONIA)

EMC and Low Voltage regulation

NOTE: As SOLUXTEC is always improving his products. Please contact your customer service

if a standard is missing for your project from above list.

4 TRANSPORT AND HANDLING

During transportation and Interim storage, following point have to be respected:

Transportation of the modules need to be done only with SOLUXTEC original

packaging.

Never exceed the maximum number of pallets to be stacked. Only original SOLUXTEC

packaging may allow pallet stacking.

When unpacking modules from the packaging, please wear soft and clean gloves. It is

forbidden to use suction cup to carry the module as it will damage the anti-reflective

coating for the solar glass.

It is forbidden to carry/lift the modules from the solar cables or from the junction box or

any conductive elements.

Do not drop module directly on module.

By handling modules be cautious especially on the corners to not shock them.

By handling the modules, never scratch the anodised coating of the frame.

Corrosion may occur and brings to a mechanical resistance diminution.

It is forbidden to drill holes in the aluminium frames.

It is forbidden to paint the modules or to apply any adhesive on the module’s surface.

Never walk on the module.

5

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

5 PRODUCTS DETAILS

This document is valid for all products above:

cell type availability reference Type Variante colours

Das modul Mono XSC Perc M10 until 2023 DMMXSC glass foil framed Anti Glare

/ AC black, white

Das modul Mono XSC Pure

Glass Perc M10 until 2023 DMMXSC_PG glass glass Bifacial framed AC black,

transparent

PowerSlate Mono XSC Perc M10 until 2023 PSMXSC glass foil frameless na black

Das Modul Mono XSC Ninside Ntype M10 from 2023 DMMXSCNi glass foil framed Anti Glare

/ AC black, white

Das Modul Mono XSC Ninside

Pure Glass Ntype M10 from 2023 DMMXSCNi_PG glass glass Bifacial framed AC black,

transparent

PowerSlate Mono XSC

Ninside Ntype M10 from 2023 PSMXSCNi glass foil frameless na black

Das Modul Mono Alpine XSC

Ninside Ntype M10 from 2023 DMMAXSCNi glass foil framed AC black, white

Das Modul Mono Alpine XSC

Ninside Pure Glass Ntype M10 from 2023 DMMAXSCNi_PG glass glass Bifacial framed AC black,

transparent

PowerSlate Mono Alpine XSC

Ninside Pure Glass Ntype M10 from 2023 PSMAXSCNi_PG glass glass Bifacial frameless na transparent

Label explanation:

All Module Type from SOLUXTEC is having his own label

on back.

This label is summarizing the module data sheet as follow:

- Place of production

- Commercial name

- STC (standard test condition) data:

- Pmpp : Power in watt at maximum power point

- Isc : Short circuit Intensity in ampere

- Impp : Intensity in ampere at power point

- Voc : Voltage in volt in open circuit

- Vmpp : Voltage in volt at power point

- EAN 13 code

For more details about mechanical or electrical module behaviour, please refer to dedicated

data sheet.

Serial number codification:

S T U V WW XX YYY ZZZZ, where:

- S = D for DAS MODUL

P for POWERSLATE

- T = F for foil module 108 cells

G for glass glass module 108 cells

H for foil Module 90 cells

I for glass glass module 90 cells

J for foil module Anti-glare 108 cells

- U = I Perc Half cut mono M10

N Half cut mono Topcon M10

- V = 1 for production in FAB 1 Bitburg

2 for production in FAB 2 Trier

- W = month of production

- X = year of production

- Y = Production order number

- Z = Module number from above Production

Order number.

6

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

6 INSTALLATIONS ON SITE

SOLUXTEC pv modules installation need to respect the following guidelines on site.

MODULE DESIGN PRESENTATION

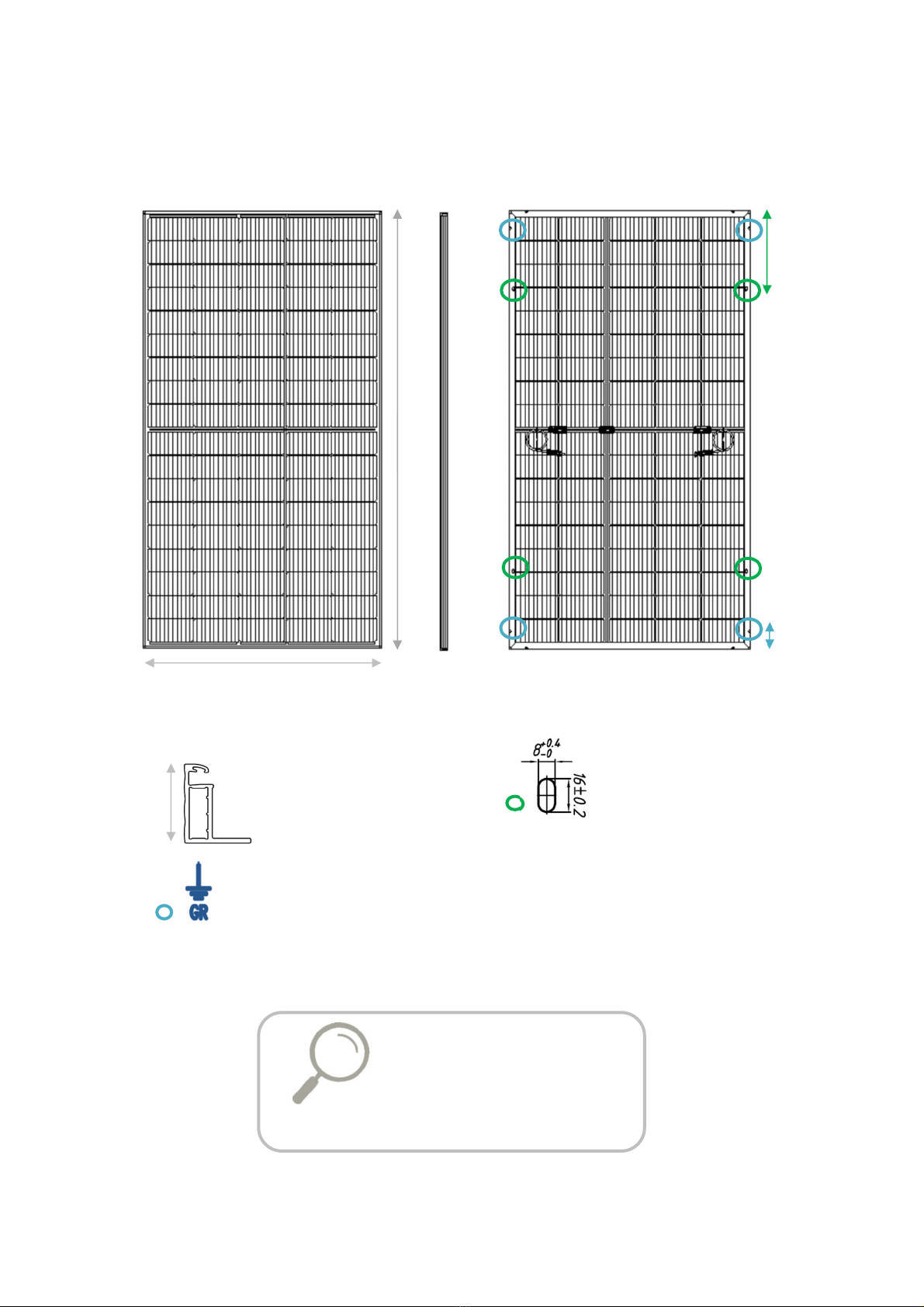

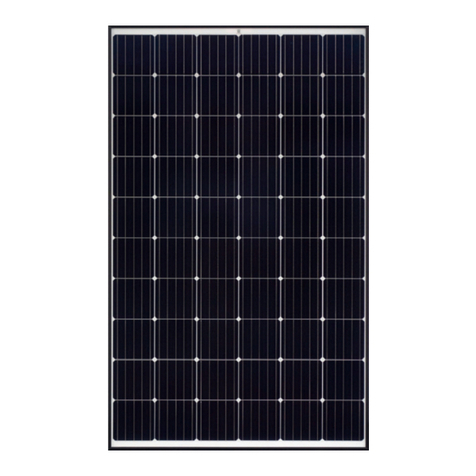

a) DAS MODUL MONO XSC (DMMXSC)

Mono perc M10 half cut

(all values are given in mm)

Frame section (double section):

: 4 grounding holes

Maximum load test: + 5400 Pa // - 2400 Pa

1133

1722

35

: 4 mounting holes

306 78

7

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

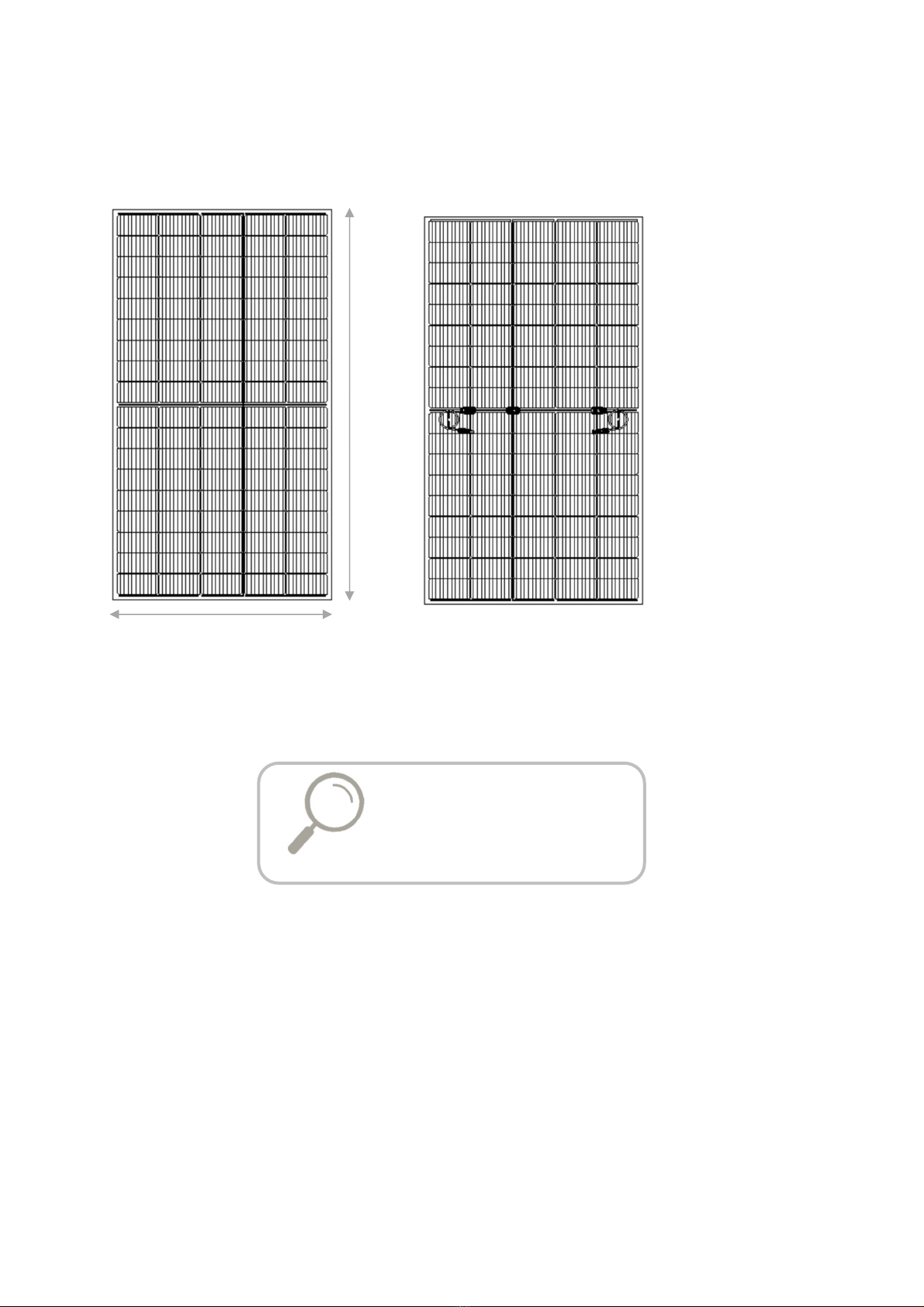

b) DAS MODUL MONO XSC Ni (DMMXSCNi)

Mono ntype M10 half cut TOPCON

(all values are given in mm)

Frame section:

: 4 grounding holes

Maximum load test: + 5400 Pa // - 2400 Pa

1133

1722

: 4 mounting holes

306 78

30

New cells Ntype Topcon

New Frame with stronger alloy

New plastic corner unbreakable

8

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

c) DAS MODUL MONO XSC Ni Pure Glass (DMMXSCNi_PG)

Mono ntype M10 half cut TOPCON GLASS GLASS

(all values are given in mm)

Frame section:

: 4 grounding holes

Maximum load test: + 8100 Pa // - 2400 Pa

1133

1722

: 4 mounting holes

306 78

30

New cells Ntype Topcon

New Frame with stronger alloy

New plastic corner unbreakable

Bifaciality 0,8

9

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

d) DAS MODUL MONO Alpine XSC Ni (DMMAXSCNi)

Mono ntype M10 half cut TOPCON 90 cells

(all values are given in mm)

Frame section:

: 4 grounding holes

Maximum load test: + 5400 Pa // - 2400 Pa

967

1722

: 4 mounting holes

306 78

30

New cells Ntype Topcon

New Frame with stronger alloy

New plastic corner unbreakable

Easy to carry

10

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

e) DAS MODUL MONO Alpine XSC Ni Pure Glass (DMMAXSCNi_PG)

Mono ntype M10 half cut TOPCON 90 cells GLASS GLASS

(all values are given in mm)

Frame section:

: 4 grounding holes

Maximum load test: + 8100 Pa // - 2400 Pa

967

1722

: 4 mounting holes

306 78

30

New cells Ntype Topcon

New Frame with stronger alloy

New plastic corner unbreakable

Bifaciality 0,8

Easy to carry

11

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

f) PowerSlate MONO XSC Ni (PSMXSCNi)

Mono ntype M10 half cut TOPCON 108 cells frameless

(all values are given in mm)

Maximum load test: + 2400 Pa // - 2400 Pa

1128

1717

New cells Ntype Topcon

Frameless

Total thickness 5,5 mm

12

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

g) PowerSlate MONO Alpine XSC Ni PG (PSMAXSCNi_PG)

Mono ntype M10 half cut TOPCON 90 cells frameless Glass/Glass

(all values are given in mm)

Maximum load test: + 3600 Pa // - 2400 Pa

962

1717

New cells Ntype Topcon

Frameless 3,2 / 2

Total thickness 6,5 mm

Bifaciality 0,8

13

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

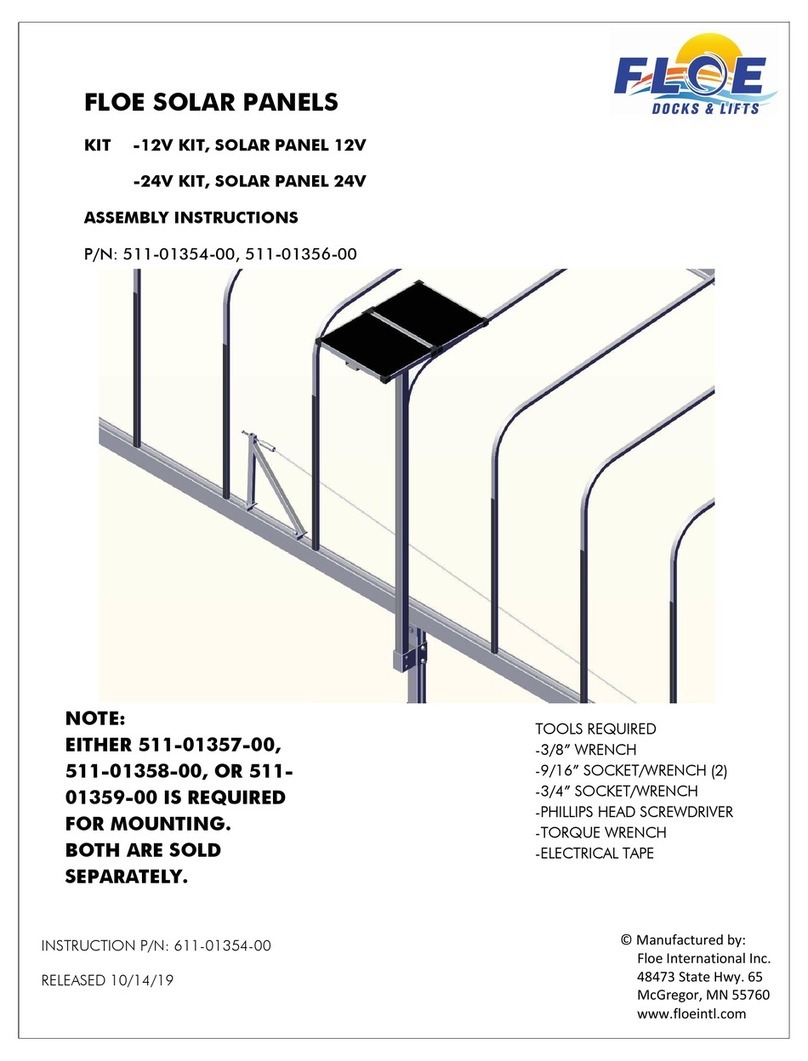

PRECAUTION:

Operate Solar Pv modules in a safe environment. Suitable and exempt of any risks.

Maximum height to operate the modules is 4000 m above the sea level

Please do not use any abrasive or chemical solution on the modules. Neither on

glass nor on aluminium frames.

Avoid to bring module in direct contact with salt water.

Solar pv modules are not to be considered as a roofing substitute. Solar Pv modules

alone can’t grant any roof waterproofing.

Roof waterproofing can be obtain considering the addition of a PV module and a

BIPV* solution.

*building integrated photovoltaic.

Operating Temperature from -40°C to 85°C.

The best efficiency will be obtained by optimising the angle of inclination and facing

the Sun.

When electing final position of the pv modules it is recommended to avoid any

potential shadowing that could result from building, chimney, trees and so on…

Shadowing could result in to a significant energy loss.

SOLUXTEC’s pv modules can be installed only with mounting structures.

Mounting structures need to comply with any applicable law requested from the

country of installation.

Modules need to be installed on mounting structure following producer user guide.

Respect a sufficient ventilation of the pv modules.

Respect mounting structure dilatation to avoid any extra mechanical stress on pv

modules

Make sure to use a mounting structure material that won’t present any chemical

reaction on pv module frame material (corrosion phenomena)

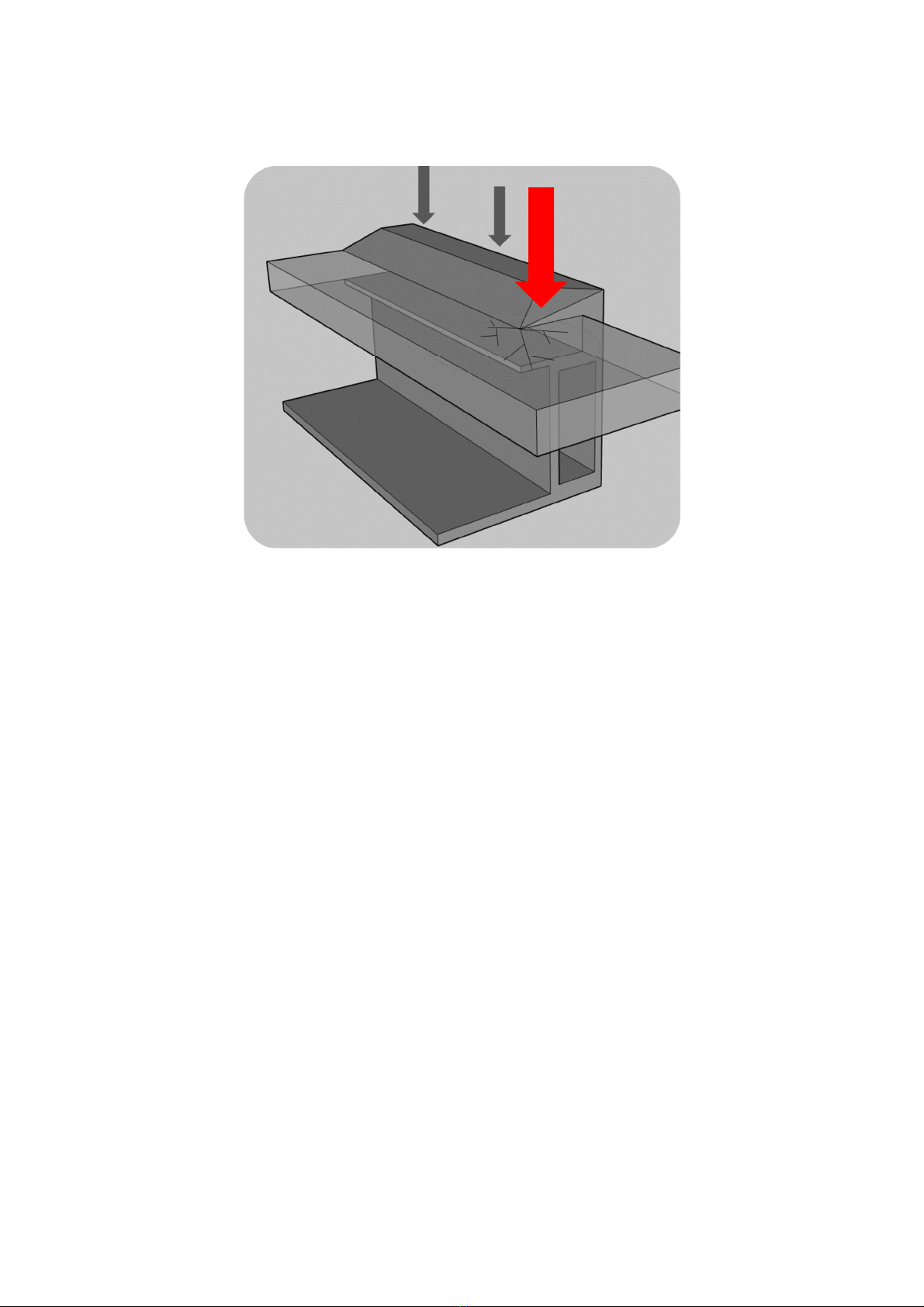

Clamp’s election is important and need to full fill those minimum standards:

Frameless module clamps need an EPDM protection to tight on glass.

For each type of Frameless modules, a minimal length of 120 mm is mandatory.

For each type of framed modules, a minimal length of 80 mm clamps is

mandatory.

Clamps are not in contact with front glass, or clamps for frameless modules

are not shadowing solar cells.

A minimum of 4 clamps/module is mandatory.

Tightening force in Newton must follow recommendation of the clamp’s

producer.

14

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

When tightened, it is forbidden that clamps shown a module frame

deformation.

When clamping, please make sure that force is homogenous shared on aluminium

part. Forced cannot deform top frame flange. For modules series equipped with a

water drain corner, clamp must not be applied directly on.

Please refer to table on next page showing the different installation option from

SOLUXTEC’s modules range. Please note as well that the mechanical behaviour from

our product will vary depending on the option elected.

Any solutions not shown in this table need to get an official validation from the technical

department prior installation.

INSTALLATION OPTION

a) DMMXSC b) DMMXSCNi c) DMMXSCNi_PG d) DMMAXSCNi e) DMMAXSCNi_PG f) PSMXSCNi g) PSMAXSCNi_PG

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+8100 Pa / -2400 Pa

Design load:

+5400 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+8100 Pa / -2400 Pa

Design load:

+5400 Pa / -1600 Pa

X = 305 mm

+/- 20 mm

Clamp mini 120 mm

+ EPDM

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

X = 305 mm

+/- 20 mm

Clamp mini 120 mm

+ EPDM

Test load:

+3600 Pa / -2400 Pa

Design load:

+2400 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 195 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 195 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Clam

p

s lon

g

side

Clamps short side

X

X

16

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

a) DMMXSC b) DMMXSCNi c) DMMXSCNi_PG d) DMMAXSCNi e) DMMAXSCNi_PG f) PSMXSCNi g) PSMAXSCNi_PG

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+8100 Pa / -2400 Pa

Design load:

+5400 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+5400 Pa / -2400 Pa

Design load:

+3600 Pa / -1600 Pa

X = 305 mm

+/- 50 mm

Clamp mini 80 mm

Test load:

+8100 Pa / -2400 Pa

Design load:

+5400 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 225 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 195 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

0 mm <X< 195 mm

Clamp mini 80 mm

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

Test load:

+2400 Pa / -2400 Pa

Design load:

+1600 Pa / -1600 Pa

With mounting holes

Long side

With mounting holes

short side

X

X

With insertion profiles

All above data are given based on module resistance. It is on the installer to elect a mounting instruction

having at least same behaviour than the module.

The whole solution needs to be evaluated by the solution supplier for the set “PV module + mounting

system + clamp system”.

All accessories such as bolt, screws and other metal parts are corrosion-proof and exempt of any

chemical reaction with the frame of the solar module.

Make sure that the module’s junction boxes are not in contact with any metal part belonging to the

mounting structure.

Make sure that module’s cables are not damaged and not in mechanical stress.

Make sure that the mounting system or any sharp component are not in contact with the surface of

the modules nor the foil or glass backside.

18

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

7 ELECTRICAL INSTALLATIONS

PRECAUTION for individual protection

Please make sure to wear your individual protection equipment.

WIRING AND PLANNING

Before starting with modules wiring, a visual inspection is recommended to make sure that all

module’s components are in a good shape.

The final wiring conception is determinate in function to the final project on site. Modules deployed

for a given project should present the same technical characteristics to prevent any mismatching.

PV modules can be connected in serial or in parallel.

In serial:

total voltage is the sum of each module voltage

(in serial we add voltage, we do not add intensities)

helmet

Insulated gloves for

electrical work

Safety clothes

covering whole body

Security shoes

Fall protection for

height working.

Safety glasses

- - -

- + + +

+

19

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

In parallel:

total intensity is the sum of the serial lines in parallel (in

parallel we add the intensities)

total voltage is the sum of each module voltage in from 1 line

(in parallel we do not add the voltage)

Note: When a project is wired with modules in parallel, it is important to check at the fuse rating of the

module. This value is available on the module’s label as well as on the dedicated data sheet. Indeed, in

case of 1 line shadowing, the line that is still producing energy will “load” the other. This is why an appropriate

line fuse protection must be applied and following appropriate standards.

The maximal overall voltage of a pv generator need to take into consideration the worst-case

scenario. It means that we need to consider the Voltage open circuit and the minimal temperature

on site.

You can calculate it with the following formula:

𝑀𝑎𝑥 𝑠𝑦𝑠𝑡𝑒𝑚 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 𝑁 𝑥𝑈𝑜𝑐1𝑇𝑐𝑈𝑜𝑐𝑥𝑇𝑚𝑖𝑛 25°

Where:

N=number of modules in serial

Uoc = Open circuit voltage of a module

TcUoc = Temperature coefficient at open circuit voltage

Tmin = Minimal temperature on project site

The cables section from our products is always given at 4mm², cables are always UV resistants

and qualified for direct current (DC). This section is enough for a single component. However, and

depending on the configuration of the pv generator, it is recommended to check at the maximal

short circuit current from the whole project in order to elect the right cables cross section in respect

to the local standards.

The planning of the wiring of the PV system should consider a tight loop wiring of the plus and

minus line. The area enclosed by the conductors should be kept as small as possible (here in grey).

This reduces the risk of inductive coupling caused by lightning strokes.

-

- +

+

+

-

-

- +

+

20

SOLUXTEC USER GUIDE 2023_Version 2/a_ALL RIGHTS RESERVED

Connectors need to be kept dry and clean. When wiring connectors together, make sure that both

are from same manufacturer and same reference.

When well connected, you must listen a “click” confirming the right connection.

A bad connection may result into arcs and electrical shock. Arcs may also be the origin of a fire

departure. This point is extremely important.

All framed modules need to be connected together with a grounding solution to the main

equipotential bonding of the project location.

On each module, you can find 4 different locations allowing the grounding bonding and mark with

this logo:

It is recommended to use a 10 mm² bonding connector to realize the grounding between each

module. The recommended section to the main equipotential bonding is 16 mm².

The legal standard from the installation place might be different and need to be follow in priority.

click

Frame

This manual suits for next models

19

Table of contents

Other SOLUXTEC Solar Panel manuals

Popular Solar Panel manuals by other brands

REC

REC TwinPeak 2S Mono 72 Series installation instructions

Solarland

Solarland SLP010-12V Installation and instruction manual

Astronergy

Astronergy CHSM6610M manual

Silicon Solar

Silicon Solar PathLight-12W instruction manual

Solar Technology International

Solar Technology International PV Logic user manual

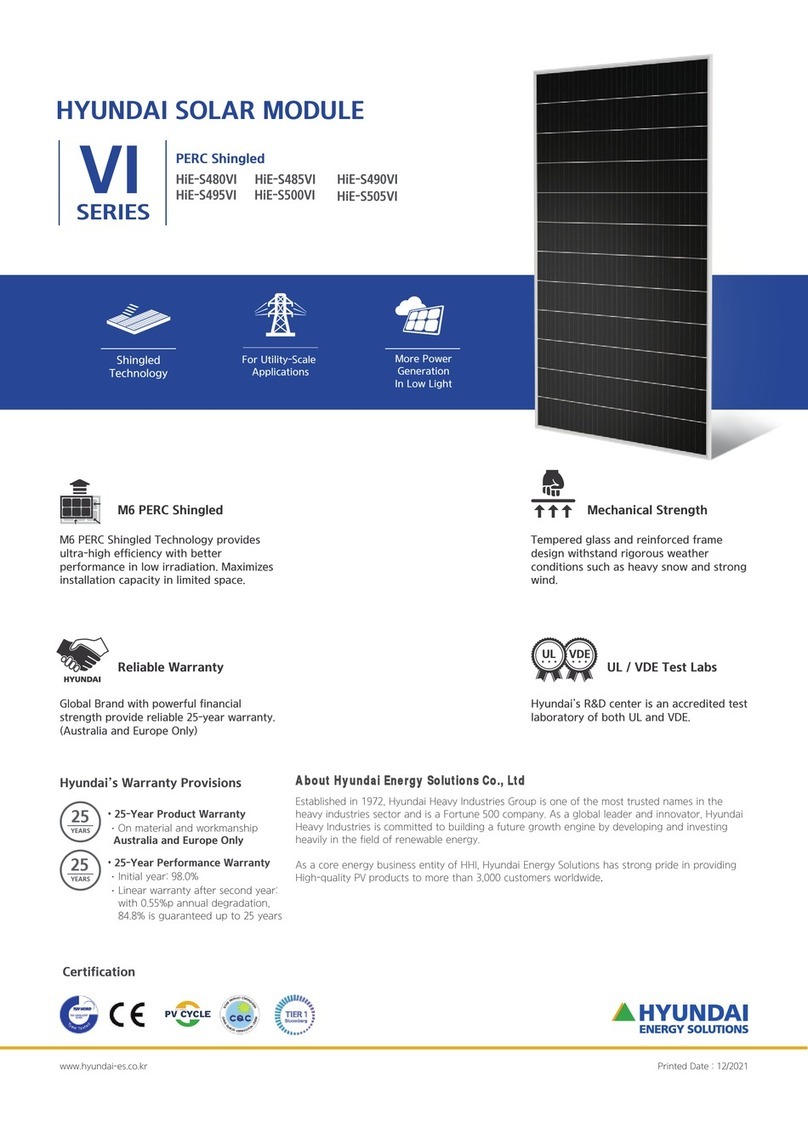

Hyundai

Hyundai VI Series manual