Somerset CDR-700 User manual

CDR-700

Side Operated Dough Sheeter

OPERATIONS MANUAL

SOMERSET INDUSTRIES

137 PHOENIX AVE • LOWELL,MA01852 •USA • +1-978-667-3355

Email: somerset@smrset.com

Web: www.smrset.com

NOTICE: !! READ CAREFULLY ALL INSTRUCTIONS BEFORE YOU START.!!

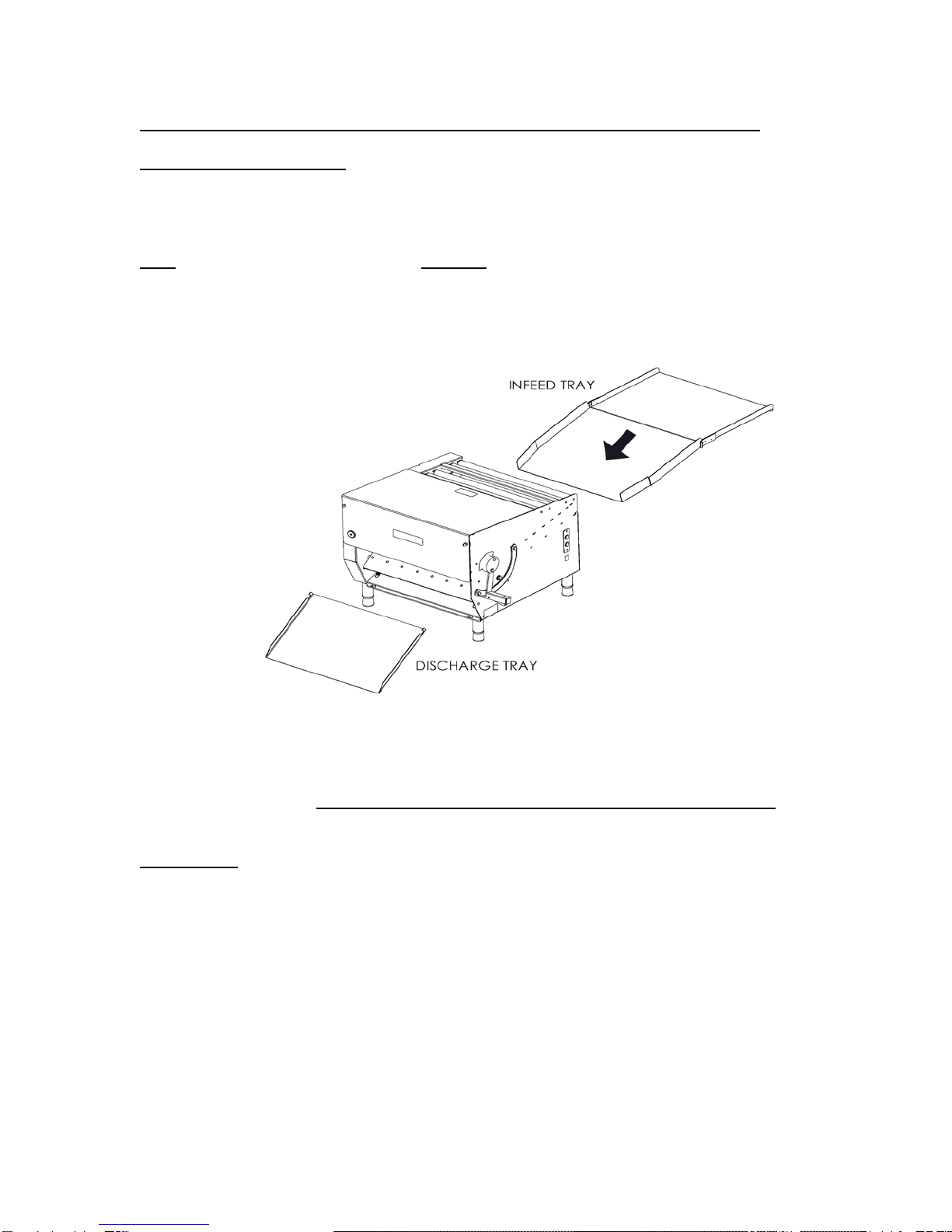

UNCRATING AND SETUP

Cut off the fastener wrapped around the machine and the base.

Lift the machine straight up out of the wooden base.

Install the machine in its final position or temporarily secure it to a solid surface.

Slide the infeed tray into the machine, as shown on Fig. 1.

Remove scraper #1 ( unhook the springs and lift the scraper up).

Mount discharge tray as shown in Fig. 1.

Reinstall scraper #1.

Fig.1

Wipe off any dirt that may accumulate during shipping. Use a soft cloth.

Check the nameplate for correct voltage and frequency.

Plug the machine to the proper power source that matches the nameplate requirements.

Turn the power switch “ON”(green button) and check for proper operation of the machine.

WARNING!!

* NEVER OPERATE THE MACHINE WITHOUT GUARDS IN PLACE

* KEEP YOUR HANDS FROM IN FEED AREAS

* DO NOT INSERT FOREIGN OBJECTS INTO THE IN FEED TRAY

* DO NOT CLEAN MACHINE WHILE CONNECTED TO ELECTRICAL SUPPLY

* WATCH YOUR HANDS AND FINGERS

NOTE: The machine will not operate when safety cover is removed.

OPERATING PROCEDURES

The rollers are easily adjustable to any thickness of crust you may need.

Release the adjusting handle, by squeezing the handle.

Move the handle to the left, to decrease the dough thickness.

Move the handle to the right, increase the dough thickness.

OPERATION

Dust the infeed tray with flour before using the machine.

For best results the dough to be rolled should be at room temperature.

Dust the dough with flour when putting it on the in feed tray.

If the dough tears or the machine makes a thumping sound, this indicates that the

dough is too thick to go through that particular setting of the rollers or the dough is too

cold and stiff and requires longer rest period before use.

* IF THE DOUGH GETS STUCK, TURN THE POWER OFF, REMOVE SAFETY

COVER THEN REMOVE THE DOUGH.

* NEVER ATTEMPT TO MOVE THE DOUGH BY HAND WHILE THE

MACHINE IS RUNNING.

CLEANING

BEFORE CLEANING: TURN POWER OFF AND DISCONNECT POWER CORD.

Remove the safety cover by removing the two thumbscrews.

All scrapers are readily removable.

Remove top scraper (#3) from its mounting pins by pushing scraper downward.

Unhook both springs by lifting scraper up and remove it.

Unhook both springs attached on bottom scraper (#2) and remove it by lifting up.

By removing both scrapers, the whole machine is exposed and ready to be cleaned.

Clean the rolls with dry cloth (never use water).

Wipe rollers with lightly oiled cloth (use vegetable oil).

Wash, dry and apply a thin film of vegetable oil on the edge of each scraper that touches the

roller.

Install the scrapers in the opposite order of their removal.

Close the safety cover and secure it with the 2 thumbscrews.

Reconnect the power cord to the same power outlet that was disconnected from.

The machine is ready for use.

!! CAUTION !!

!! THIS MACHINE IS MAINTENANCE FREE. !!

!! NEVER USE OIL OR GREASE ON ANY OF THE PARTS

OF THE MACHINE. !!

!! ALL PARTS ARE PERMANENT SELF-LUBRICATED. !!

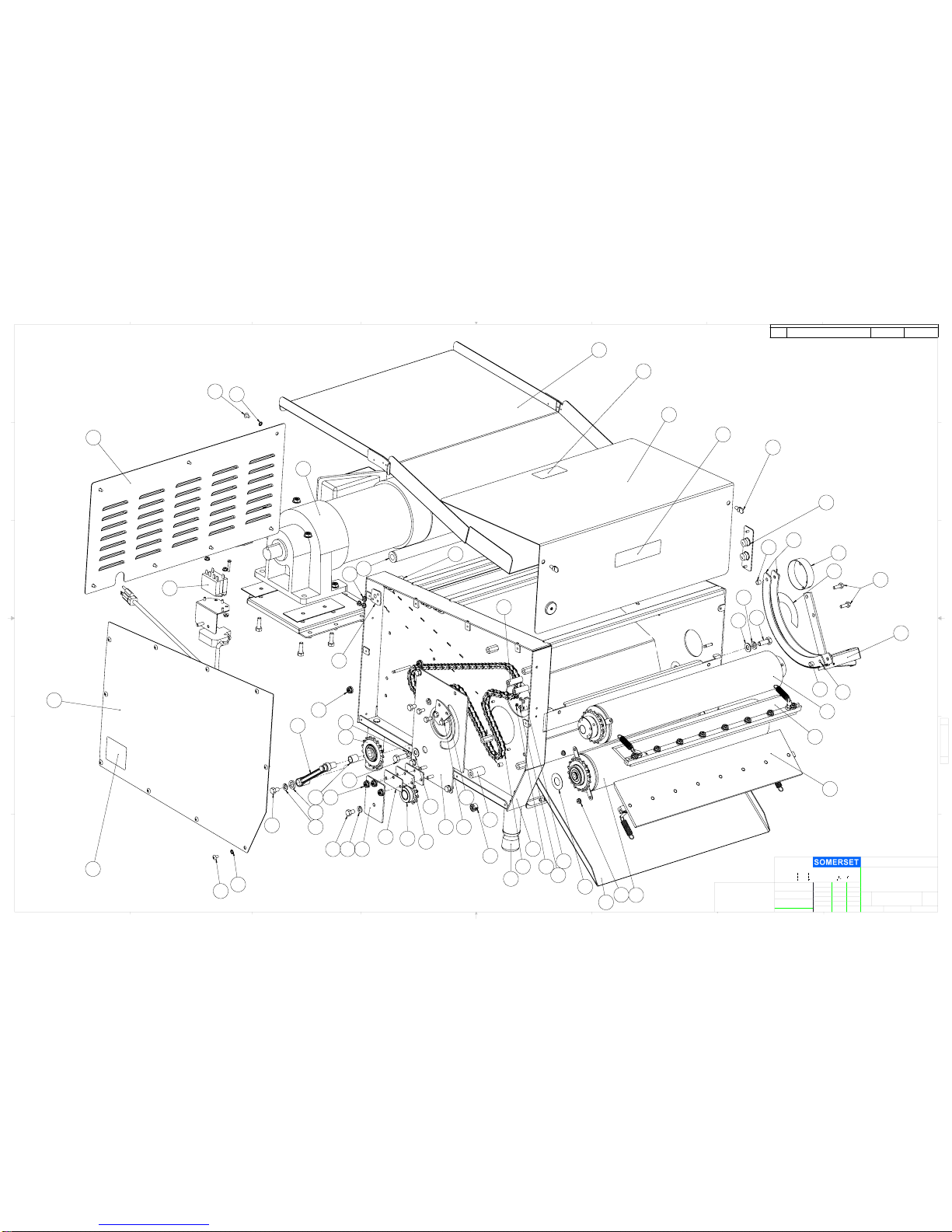

50

23

64

33

8

48

24

32

21

22

36

52

45

44

21

6

20

5

4

7

3

2

39

19

54

55

25

29

56

27

31

1

14

479

26 10

43

11

12

58

59

60

46

57

13

34

16

18

15

42 41

40

49

50

46

4142

45

44

61

49

20

43

40

17

REVISIONS

REV.

DESCRIPTION

DATE

APPROVED

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

REV

0700-PART NEW --

D

SHEET 1 OF 2

G. HURLEY

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:2.5

REV

DWG. NO.

D

SIZE

TITLE:

NAME

DATE

Q.A.

MFG APPR.

ENG APPR.

CHECKED

FINISH

MATERIAL

INTERPRET DRAWING PER:

ANSI Y14.5M - 1982

PROPRIETARY AND CONFIDENTIAL

C

C

SOMERSET INDUSTRIES, INC.

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

REV

0700-PART NEW --

D

0700-PART

SHEET 1 OF 2

12/14/2012

SCALE: 1:2.5

REV

DWG. NO.

D

SIZE

TITLE:

NAME

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET DRAWING PER:

ANSI Y14.5M - 1982

DIMENSIONS ARE IN INCHES [MILLIMETER]

.XX

.015 [

.4]

.XXX

.005 [

.13] FRACTIONAL

1/32 [

.8]

.XXXX

.0005 [

.013] ANGULAR:

1

C

C

SOMERSET INDUSTRIES, INC.

DATABASE:SOLIDWORKS

SEE NOTES

N/A

0700 EXPLODED

THE INFORMATION CONTAINED IN THIS

DRAWING AND ASSOCIATED CAD DATA

FILES IS THE SOLE PROPERTY OF

SOMERSET INDUSTRIES. IT MAY NOT

BE REPRODUCED IN PART, OR AS A

WHOLE, OR SENT TO ANY OTHER VENDOR,

WITHOUT THE EXPRESS WRITTEN

CONSENT OF SOMERSET INDUSTRIES.

N/A

WEIGHT

LOWELL, MA. 01852

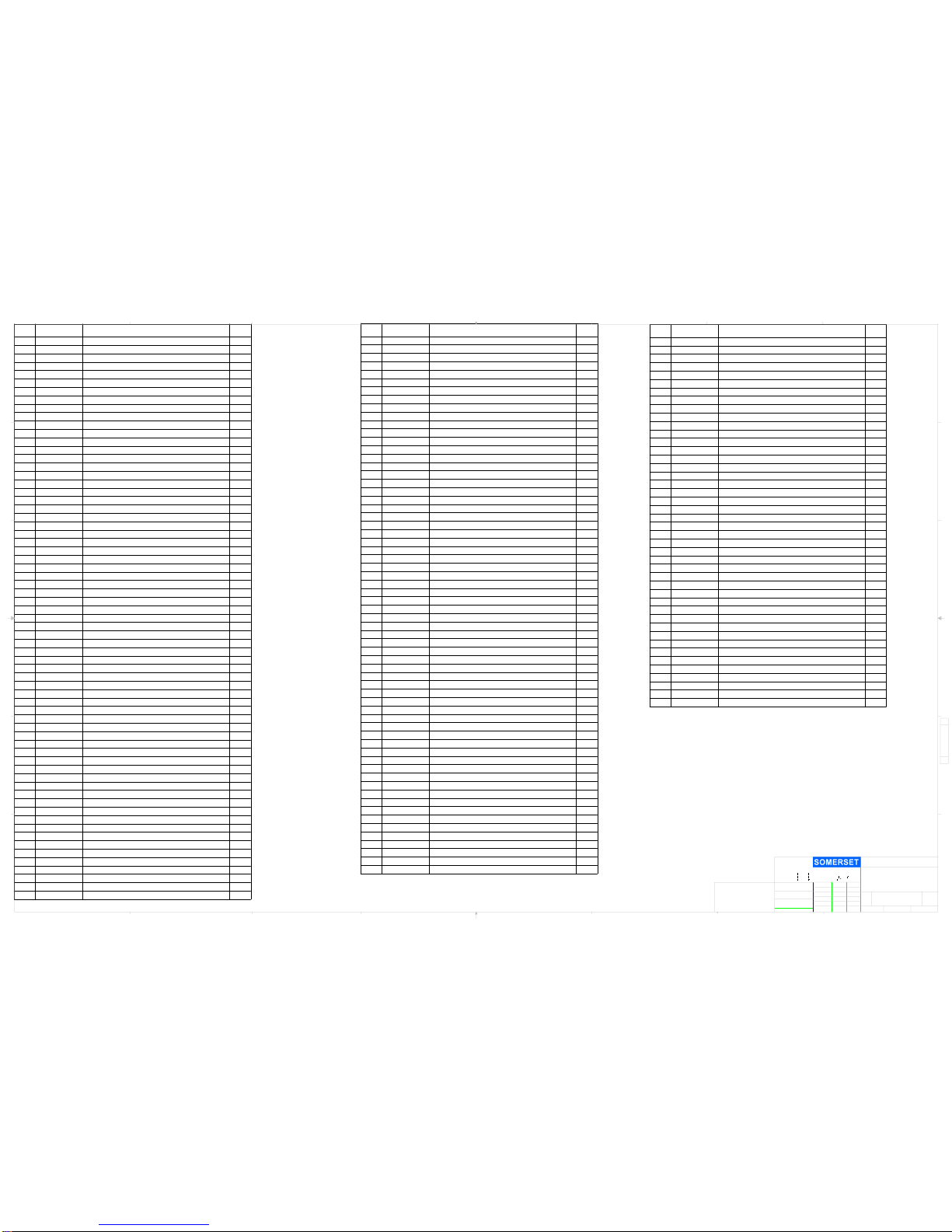

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

1

0700-010

FRAME CDR-700 MAIN

1

0700-011

BASE, RIGHT SIDE

1

0700-015

RAIL,SLIDE

1

0700-130

STUD,TRAY SUPPORT

1

2000-015

LOCATOR PLATE

1

3010-219

PEM, HFH-0616-16ZI

4

3010-206

PEM, FHS 420-12

2

3010-203

PEM, FHS-207-8

2

3010-201

PEM, YC3-16144

1

3010-204

PEM, FHS-0518-8

4

0700-011

BASE,RIGHT SIDE

1

0700-012

SIDE LEFT

1

0700-015

RAIL,SLIDE

1

0700-130

STUD,TRAY SUPPORT

1

0500-015

LOCATOR HSG #10

6

3010-201

PEM, YC3-16144

1

3010-203

PEM, FHS-207-8

2

3010-204

PEM, FHS-0518-8

5

3010-205

PEM, FHS-832-6

14

3010-212

PEM, FHS-440-6

2

0700-012

SIDE, LEFT

1

0700-013

PARTITION

1

3010-201

PEM, YC3-16144

2

2000-017

CHANNEL, TOP

4

0500-017

CHANNEL,TOP

1

0300-017

CHANNEL,TOP

1

3010-207

PEM, YC3-16271

2

2000-415

LEG, ASM COMPLETE

4

4000-200

INSERT, LEG ADJ

1

2000-413

LEG, WELDMENT TUBE&PLUG

1

4000-233

SPACER, HEX 0.5 X 1.0

4

3010-153

STUD, SCRAPER 2"

1

3000-303

NUT, FLANGE 1/4-20

2

3000-406

SCREW, 5/16-18 X 3/4 HEXHD GR8

1

3000-102

WASHER, LOCK SPLIT 5/16

1

2000-431

SHAFT,ALIGNMENT, IDLER SUPPORT

1

2

0700-402

ROLL ASM MIDDLE UHMW 700

1

2000-408

SHAFT, MIDDLE 20

1

2000-457

ROLL SYNTHETIC/PIPE 20"

1

2000-403

PIPE ROLL 21.110

1

2000-451

ROLL ETF 00039TIVAR 20.125

1

4000-100

BEARING, R12RS ROLL

2

4000-508

SPROCKET, 40B18H ROLL

1

3010-302

PIN, 21S 187-125

1

2000-316

DISC MIDDLE COMPLETE

1

2000-319

DISC, MIDDLE

1

2000-023

BRACKET, DISK

2

3

2000-400

ROLL ASM UPPER

1

2000-407

SHAFT, UPPER AND LOWER

1

2000-457

ROLL SYNTHETIC/PIPE 20"

1

2000-403

PIPE ROLL 21.110

1

2000-451

ROLL ETF 00039TIVAR 20.125

1

4000-100

BEARING, R12RS ROLL

2

2000-412

SPROCKET 41B18H ROLL

1

2000-318

DISC, TOP COMPLETE

1

2000-320

DISC, TOP

1

2000-023

BRACKET, DISC

2

3000-225

WASHER, NYLATRON 1.50

2

3010-302

PIN, 21S 187-125

3

2000-411

ECCENTRIC, UNIVERSAL

2

4

0700-501

SCRAPER #2 COMPLETE

1

2000-523

SHAFT SCRAPER #4 2000

1

0700-511

SCRAPER #2

1

3010-202

PEM, FHS-0420-16

8

3000-303

NUT, FLANGE 1/4-20

8

3010-152

STUD, SCRAPER 2 1/2"

2

3000-306

NUT, HEX 1/4-20

2

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

4000-251

SPRING, SCRAPER

2

5

0700-502

SCRAPER #3 COMPLETE 700

1

2100-520

SHAFT, SCRAPER #1 2100

1

0700-512

SCRAPER #3 700

1

3010-202

PEM, FHS-0420-16

8

3000-303

NUT, FLANGE 1/4-20

8

3010-100

STUD,SCRAPER 21/32 BENT

2

3000-306

NUT, HEX 1/4-20

2

4000-251

SPRING, SCRAPER

2

6

0700-424

HANDLE, ADJUST COMPLETE

1

0700-420

HANDLE, ADJUST COMPLETE

1

3010-303

PIN, 21S 187-100

1

4000-256

SPRING, HANDLE COMPRESSION

1

0700-423

TRIGGER, HANDLE

1

3010-216

PEM, FHS-032-6

1

7

0700-120

COVER,SAFETY

1

0700-121

COVER, SAFETY

1

4000-150

MAGNET,SAFETY COVER

1

3010-500

RIVET, 1/8 X .375

1

8

0700-300

TRAY,INTAKE

1

0700-299

BRACKET, WEDGE FILLER

2

0700-298

BRACKET,TRAY STOP

1

0700-297

BRACKET,TRAY STOP

1

9

0700-236

PLATE, ECCENTRIC COMPLETE

1

0700-231

PLATE,ECCENTRIC

1

3010-206 PEM, FHS 420-12

3

0700-235

PLATE, RING REINFORCE

1

10

0700-233

PLATE,ECCENTRIC

2

11

0700-234

PLATE,ECCENTRIC

1

12

0700-232

PLATE,ECCENTRIC

1

13

0700-018

BRACKET,SAFETY ROLLER

4

3010-204

PEM, FHS-0518-8

1

14

0700-118

BRACKET, ECCENTRIC

1

15

0700-301

PANEL,LOUVERED

1

16

0700-302

COVER,HOUSING

1

17

5000-133

MOTOR/BASE ASSY SUMITOMO 1HP

1

5000-110

MOTOR, 1HP SUMITOMO

1

0700-024

BASE, MOTOR SUMITOMO 1HP

1

3010-215

PEM, FH 518-8 ZI

9

5000-234

HARNESS, CORD POWER 19" MALE

1

2000-534

PAD, RUBBER MOTOR

2

5000-269

CONNECTOR, ROMEX

1

3000-414

SCREW, 5/16-18 X 1 HEXHD

4

3000-305

NUT, FLANGE 5/16-18

4

18

2000-632

RELAY 110 VAC

1

2000-328

BRACKET, RELAY

1

3010-205

PEM, FHS-832-6

3

3010-206

PEM, FHS 420-12

1

2000-328

BRACKET, RELAY

1

5000-230

HARNESS, POWER MOLDED

1

5000-150

RELAY, 120 VAC

1

3000-416

SCREW, 8-32 X 1 PAN HD PH

1

3000-300

NUT, FLANGE 8-32

3

19

0700-304

TRAY, DISCHARGE 700

1

20

0700-328

SPACER,TUBE ADJ PLATE

2

21

0700-417

PLATE,ADJUST

2

22

0700-623

COVER, ECCENTRIC COMPLETE

1

23

0700-624

ROLLER, ASSY COMPLETE 0700

4

0700-100

BAR,SAFETY

1

4000-315

BUSHING, NYLON

2

24

2000-629

SWITCH PLATE ASSY

1

2000-330

PLATE, P.B. SWITCH

1

3010-205

PEM, FHS-832-6

2

2000-330

PLATE, P.B. SWITCH

1

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

5000-202

SWITCH POWER RED

1

5000-203

SWITCH POWER GREEN

1

25

4000-010

SPACER,TUBE ADJ PLATE

2

26

4000-523

SPROCKET,40B11 W/ BUSHING

1

4000-512

SPROCKET,40B11H IDLER

1

4000-556

BUSHING, 12DU14 GARLOCK

1

27

4000-432

SHAFT TAKE UP SPROCKET

1

28

4000-510

SPROCKET, 40B16H

1

29

4000-358

CHAIN,40 RIV 91 (700)

1

30

5000-276

BUSHING, 90 STR REL HEYCO1320

1

31

5000-278

BUSHING, FINGER .625 HOLE

1

32

5000-312

LABEL, "SOMERSET" 3"

1

33

5000-313

LABEL, "KEEP FINGERS..."

1

34

5000-311

LABEL, ETL

1

35

5000-314

LABEL, "DO NOT OPERATE..."

1

36

5000-316

LABEL, CCW INDICATOR GRADUATED

1

37

5000-317

LABEL, NSF

1

38

5000-321

LABEL, "ARROW" RED

1

39

3000-225

WASHER, NYLATRON 1.50

3

40

3000-300

NUT, FLANGE 8-32

16

41

3000-102

WASHER, LOCK SPLIT 5/16

6

42

3000-405

SCREW, 5/16-18 X 1/2 HEXHD

6

43

3000-201

WASHER, FLAT 3/8

2

44

3000-103

WASHER, LOCK SPLIT 3/8

2

45

3000-409

SCREW, 3/8-16X1 HEXHD SS

2

46

3000-303

NUT, FLANGE 1/4-20

4

47

3000-410

SCREW, 1/4-20 X 1/2 HEXHD

4

48

3000-403

SCREW, 1/4-20 X 1/2 THUMB W/SHOULDER

2

49

3000-101

WASHER LOCK #10 INT TOOTH

17

50

3000-402

SCREW, 10-32 X 3/8 TRUSS PH SS

17

51

3000-302

NUT, ACORN 1/4-20

2

52

3000-404

SCREW, 1/4-20 X 3/4 HEXHD

2

53

3000-305

NUT, FLANGE 5/16-18

9

54

3000-204

WASHER, FLAT #4

2

55

3000-309

NUT, HEX 4-40

2

56

4000-300

LEG TIP RUBBER

4

57

4000-011

SPACER .50ID X .78OD X .123 PL

1

58

4000-506

SPROCKET ASSY, TENSION W/ BRG

1

59

4000-652

BUSHING,OILLITE (FROM 400-552)

1

60

2000-428

ARM, IDLER

1

61

5000-225

SWITCH, ELECTRONIC

1

62

5000-261

ORANGE WIRE NUT

5

63

5000-272

CABLE TIE, 3M

5

64

2000-431

SHAFT,ALIGNMENT, IDLER SUPPORT

8

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

REV

0700-PART NEW --

D

SHEET 2 OF 2

G. HURLEY

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:2.5

REV

DWG. NO.

D

SIZE

TITLE:

NAME

DATE

Q.A.

MFG APPR.

ENG APPR.

CHECKED

FINISH

MATERIAL

INTERPRET DRAWING PER:

ANSI Y14.5M - 1982

PROPRIETARY AND CONFIDENTIAL

C

C

SOMERSET INDUSTRIES, INC.

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

REV

0700-PART NEW --

D

0700-PART

SHEET 2 OF 2

12/14/2012

SCALE: 1:2.5

REV

DWG. NO.

D

SIZE

TITLE:

NAME

MFG APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET DRAWING PER:

ANSI Y14.5M - 1982

DIMENSIONS ARE IN INCHES [MILLIMETER]

.XX

.015 [

.4]

.XXX

.005 [

.13] FRACTIONAL

1/32 [

.8]

.XXXX

.0005 [

.013] ANGULAR:

1

C

C

SOMERSET INDUSTRIES, INC.

DATABASE:SOLIDWORKS

SEE NOTES

N/A

0700 EXPLODED

THE INFORMATION CONTAINED IN THIS

DRAWING AND ASSOCIATED CAD DATA

FILES IS THE SOLE PROPERTY OF

SOMERSET INDUSTRIES. IT MAY NOT

BE REPRODUCED IN PART, OR AS A

WHOLE, OR SENT TO ANY OTHER VENDOR,

WITHOUT THE EXPRESS WRITTEN

CONSENT OF SOMERSET INDUSTRIES.

N/A

WEIGHT

Table of contents

Other Somerset Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use