PAT-80 ●PAT-85 ●PAT-86 –USER MANUAL

CONTENTS

1Safety ................................................................................................................5

2General description and features of the instrument ....................................6

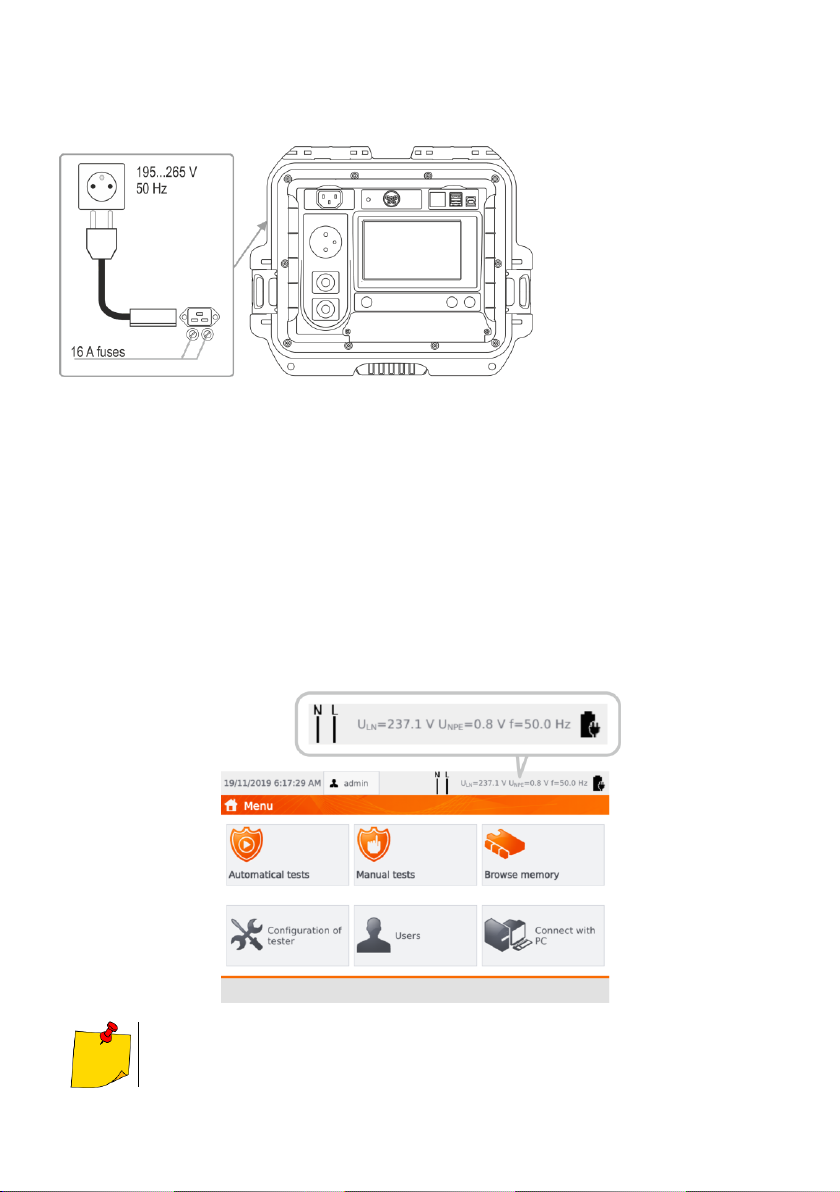

3Switching on and main menu.........................................................................8

3.1 Power supply ...........................................................................................................8

3.2 Start test after switching the tester on......................................................................8

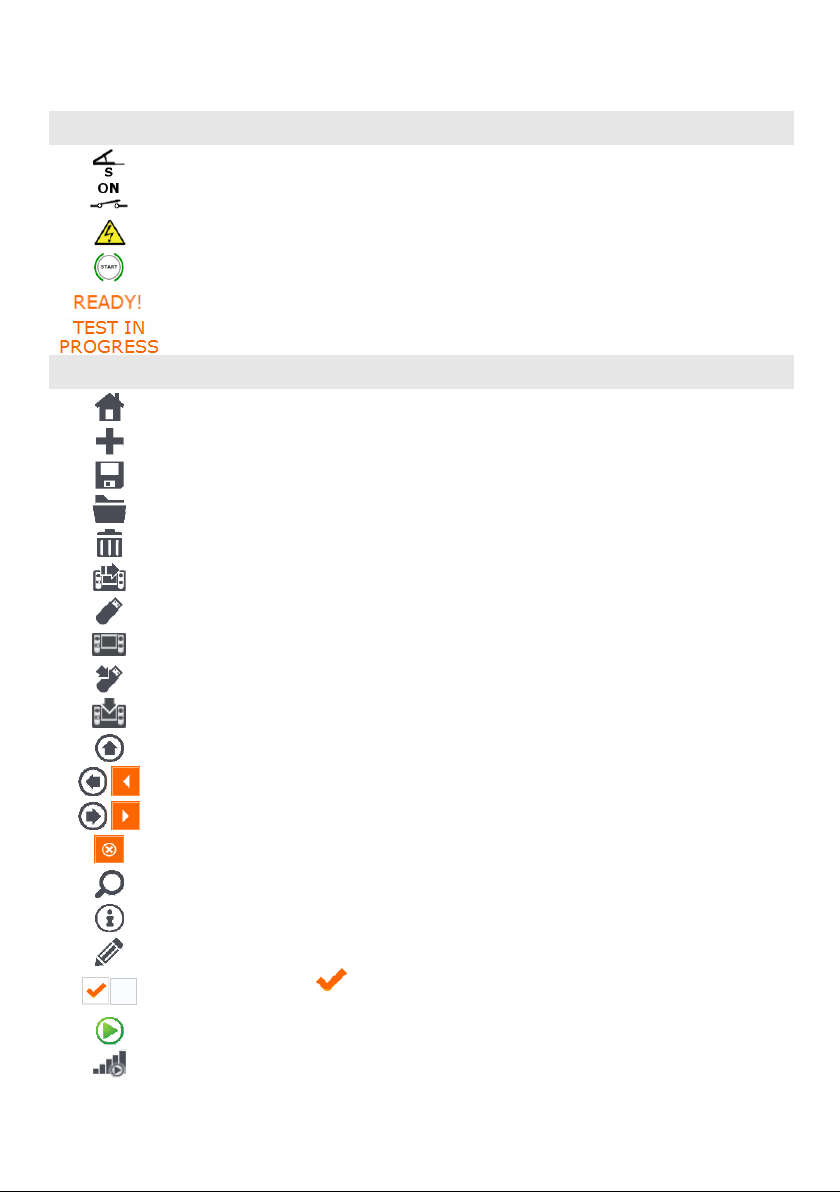

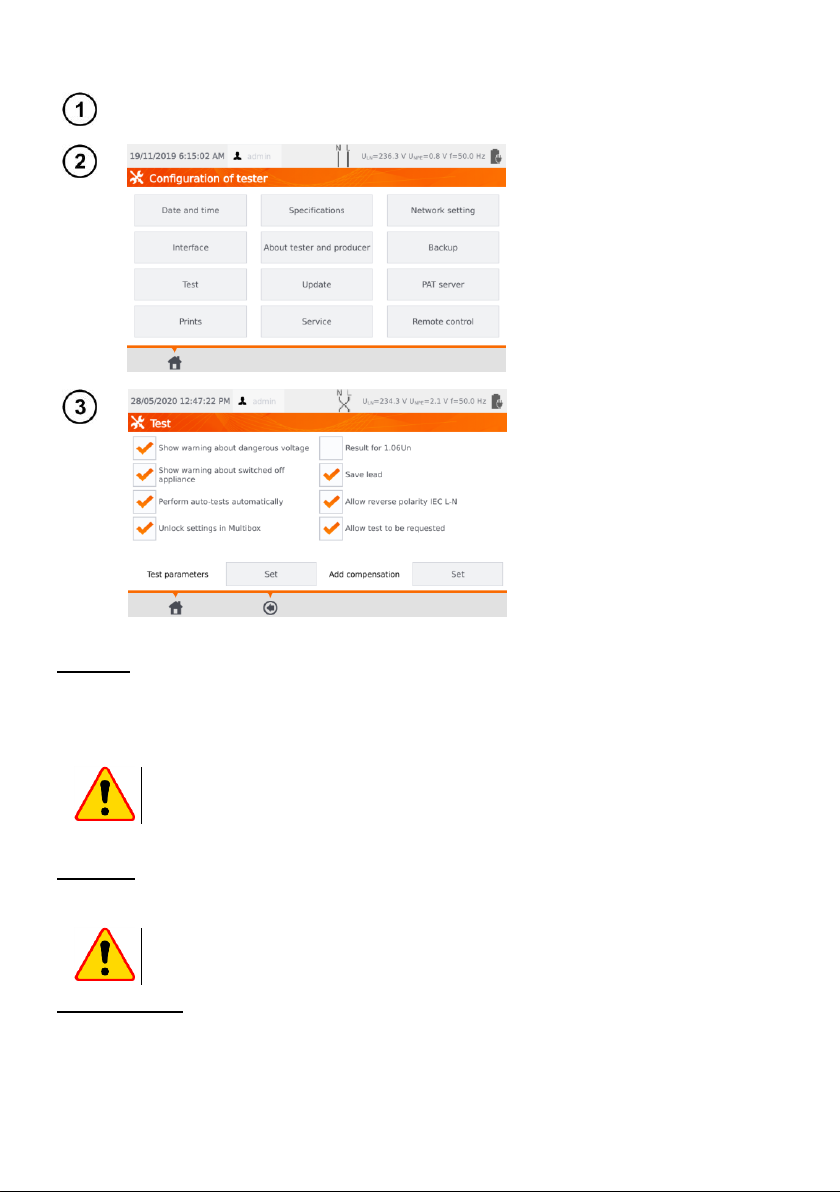

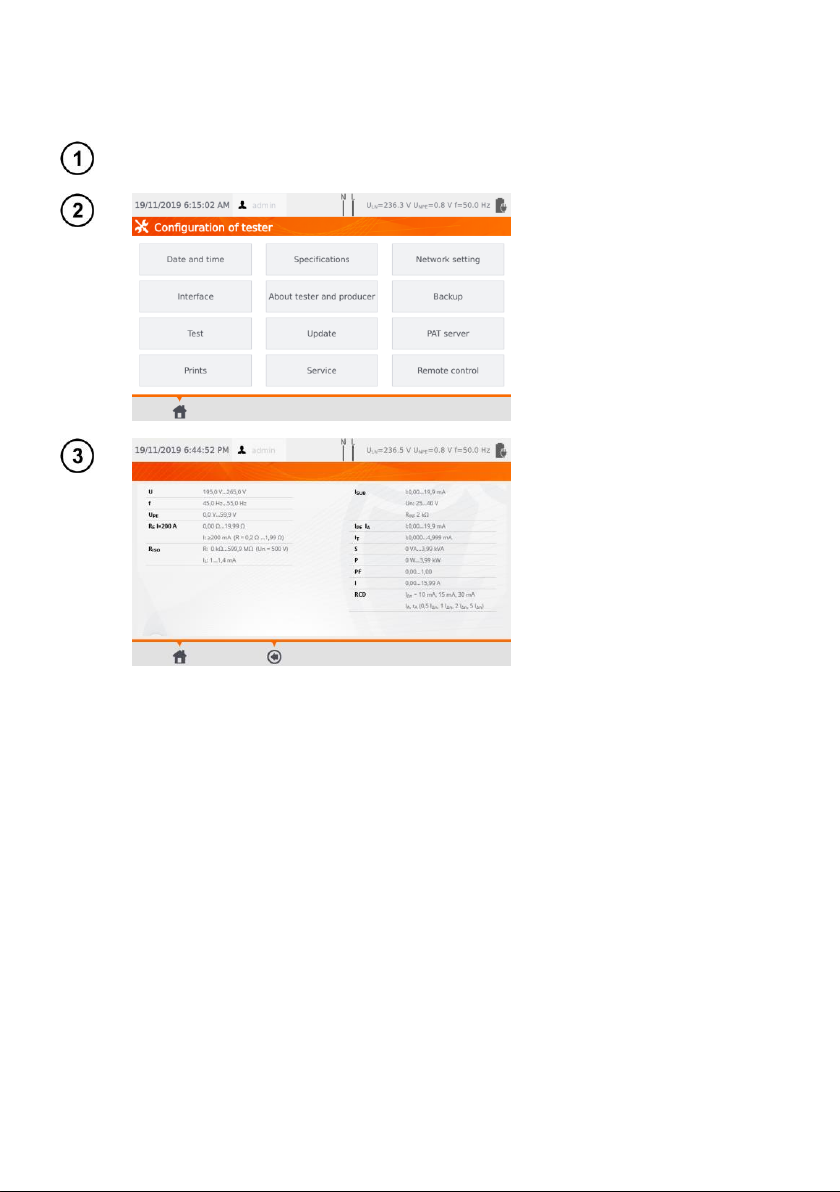

3.3 General settings –menu..........................................................................................9

3.3.1 Symbols on screen .........................................................................................................10

3.3.2 Setting date and time......................................................................................................11

3.3.3 Interface settings. QR-code scanner initialization............................................................12

3.3.4 Measurement settings.....................................................................................................13

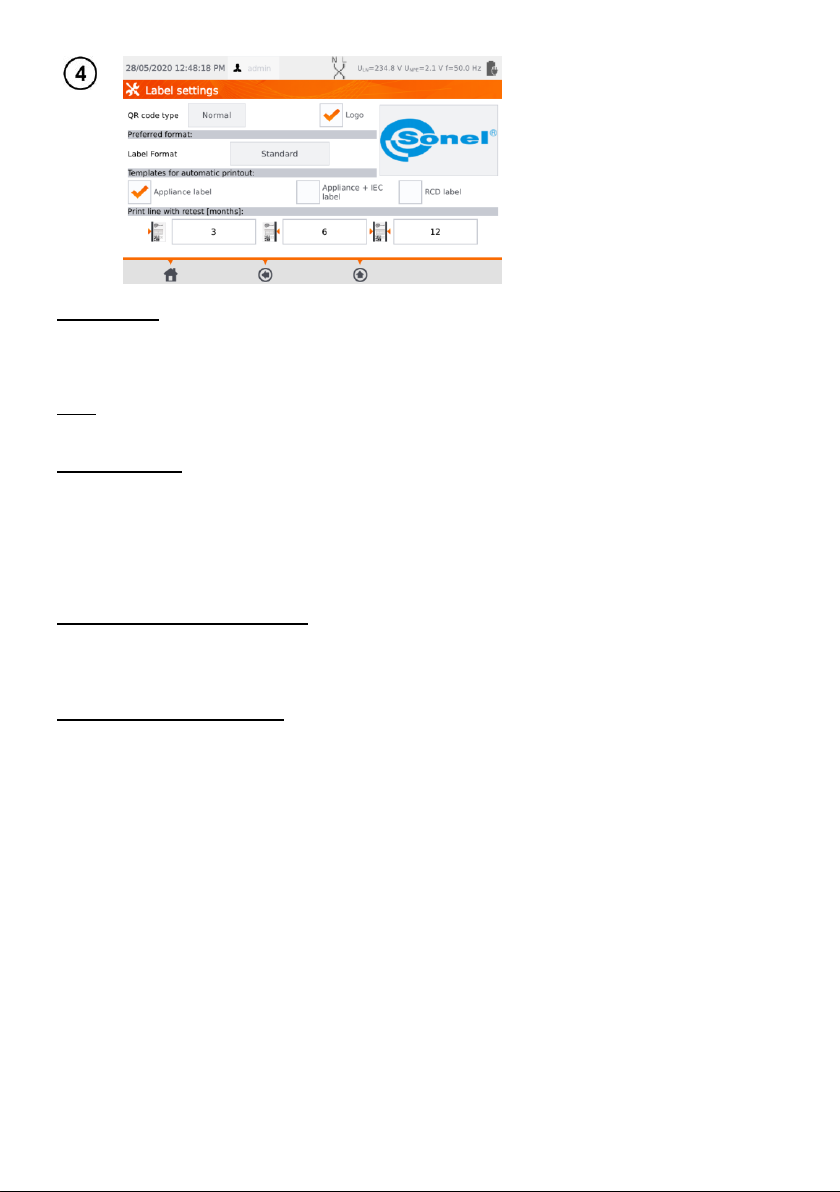

3.3.5 Printing ...........................................................................................................................14

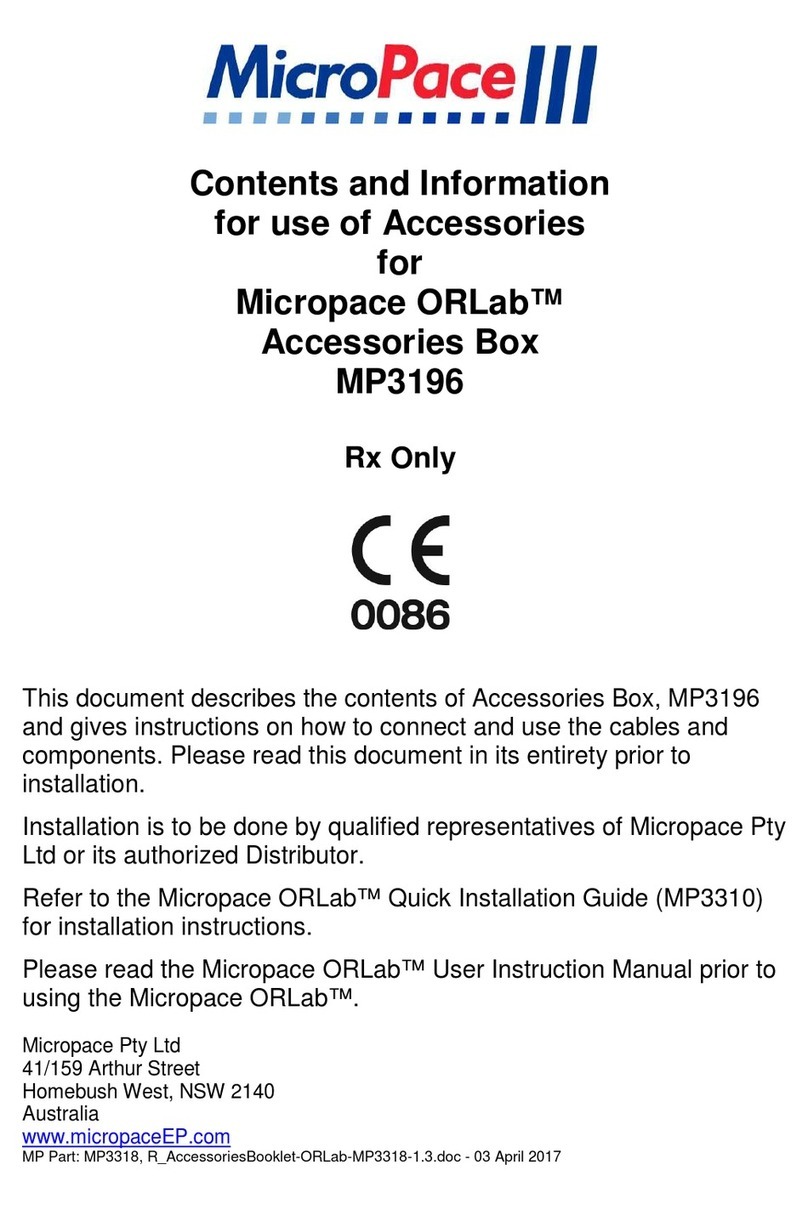

3.3.6 Specifications..................................................................................................................16

3.3.7 Information about tester and producer.............................................................................17

3.3.8 Firmware update.............................................................................................................17

3.3.9 Service............................................................................................................................18

3.3.10 WiFi settings...................................................................................................................19

3.3.11 Bluetooth settings ...........................................................................................................21

3.3.12 Backup............................................................................................................................21

3.3.13 PAT Server (optional function)........................................................................................22

3.3.14 Remote control (optional function)...................................................................................23

3.3.15 List of Users....................................................................................................................24

a.Managing Users................................................................................................................... 24

b.Switching Users ................................................................................................................... 25

3.3.16 Memory structure (clients, objects, subobjects and appliances)......................................26

a.Adding clients....................................................................................................................... 26

b.Adding objects...................................................................................................................... 28

c.Adding appliances................................................................................................................ 30

d.Deleting clients, objects and appliances............................................................................... 31

3.3.17 Communication with PC..................................................................................................32

4Measurements................................................................................................33

4.1 Visual check (preliminary test)............................................................................... 33

4.2 Measurement of protective conductor resistance RPE............................................ 34

4.3 Measurement of insulation resistance RISO............................................................ 38

4.4 Measurement od substitute leakage current ISUB ................................................... 41

4.5 Measurement of leakage current IPE ...................................................................... 43

4.6 Measurement of differential leakage current IΔ...................................................... 46

4.7 Measurement of touch leakage current IT..............................................................49

4.8 Measurement of current with clamp....................................................................... 51

4.9 IEC cord test ..........................................................................................................52

4.10 Testing PRCD devices (with built-in RCD).............................................................53

4.11 Measurement of fixed RCD parameters.................................................................54

4.12 SELV/PELV appliances test................................................................................... 56

4.13 Power test.............................................................................................................. 57

5Measurement of welding machines..................................................59

5.1 Measurement of RISO (LN-S, PE-S) in welding machines ...................................... 59

5.2 Measurement of leakage current IPin welding machines ...................................... 61