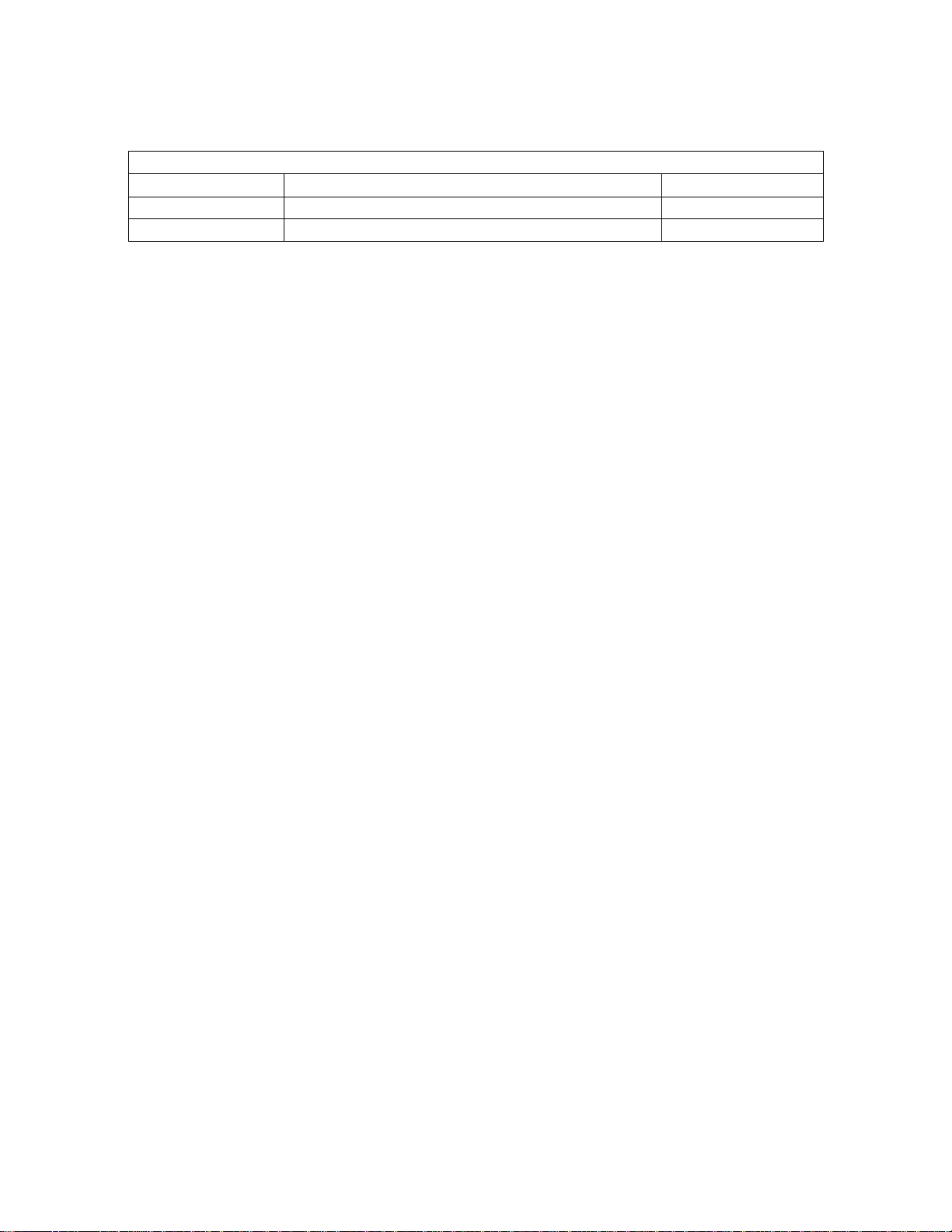

CAUTION: (Refer to accompanying documents)

READ BEFORE USING THE EQUIPMENT

WARNING

FAILURE TO RESPECT THESE WARNINGS CAN LEAD TO SEVERE OR

FATAL ELECTRICAL SHOCK.

DO NOT operate the unit without proper electrical grounding.

DO NOT use adapter plug or cut off ground terminal of plug.

DO NOT perform maintenance on the equipment without unplugging power

cord and disconnecting transducers.

IGNORING THESE WARNINGS CAN RESULT IN PERSONAL INJURY &

PROPERTY DAMAGE.

ALWAYS consult published safety regulations and manufacturer's data

sheet. Inform operating personnel as to the toxicity.

DO NOT use flammable solvents in the equipment.

DO NOT operate the equipment with solvent in a water based cleaning

solution. A solvent layer underneath the water layer can super heat

and expel the cleaning solution from the tank when the ultrasonics

are first applied.

DO NOT allow cleaning solution to come in contact with the human body.

Use a rack, basket, or tongs to insert or remove parts from the

solution. Remove harmful vapor/fumes from work area.

DO NOT place tank on a flammable or combustible surface.

ALWAYS us proper eye protection, gloves, and protective clothing when

working with the equipment.

DO NOT allow ultrasonically excited solutions to come in contact with the

human body.

CAUTION

IGNORING THESE CAUTIONS CAN RESULT IN EQUIPMENT AND PARTS

DAMAGE.

DO NOT use strong corrosive liquids such as strong acids or powerful

caustics directly in the cleaning tank. Even stainless steel is