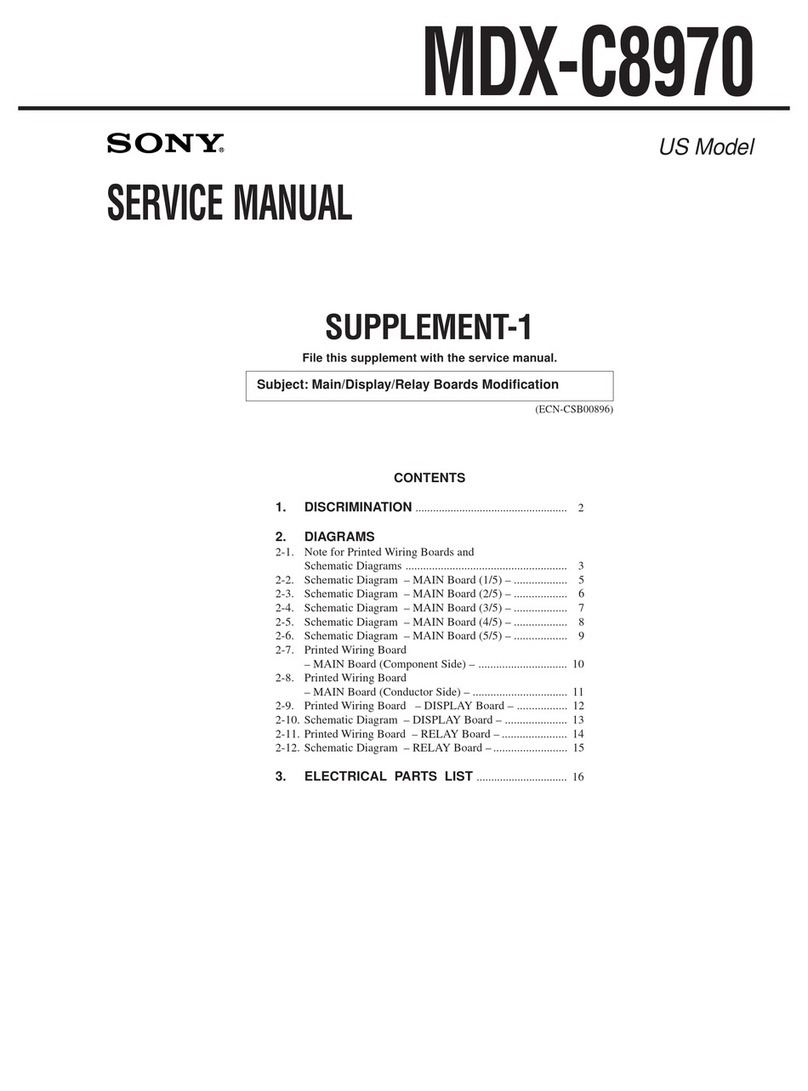

– 2 –

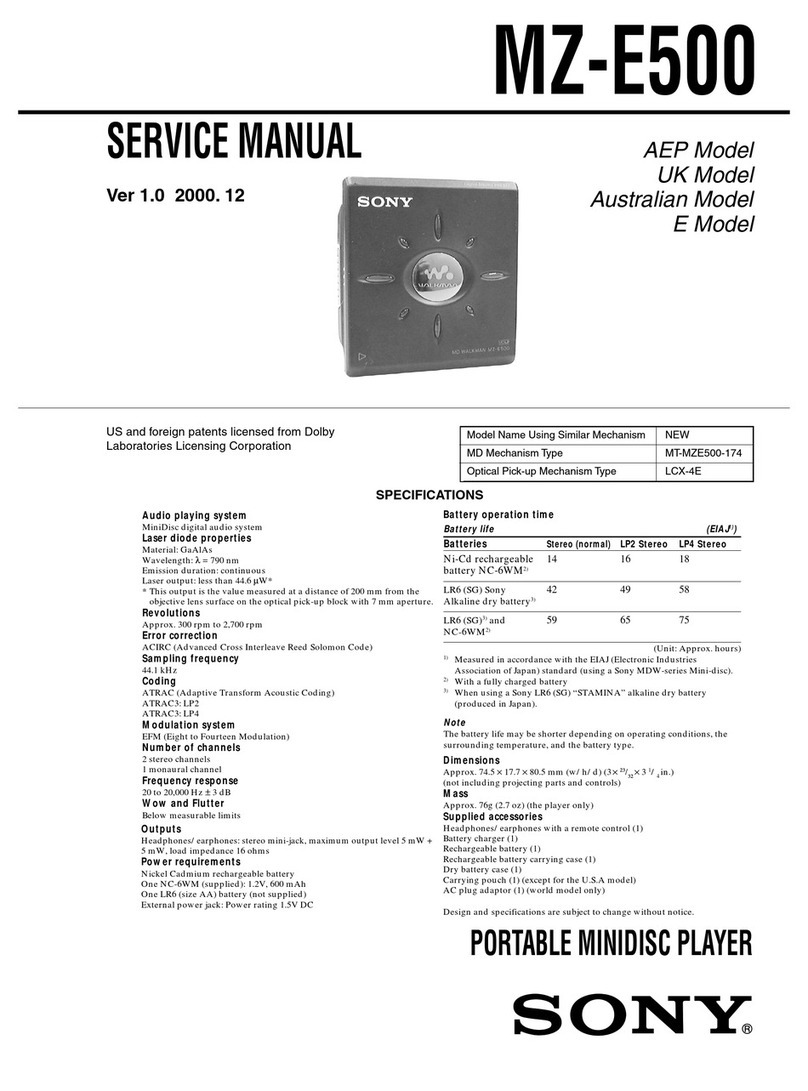

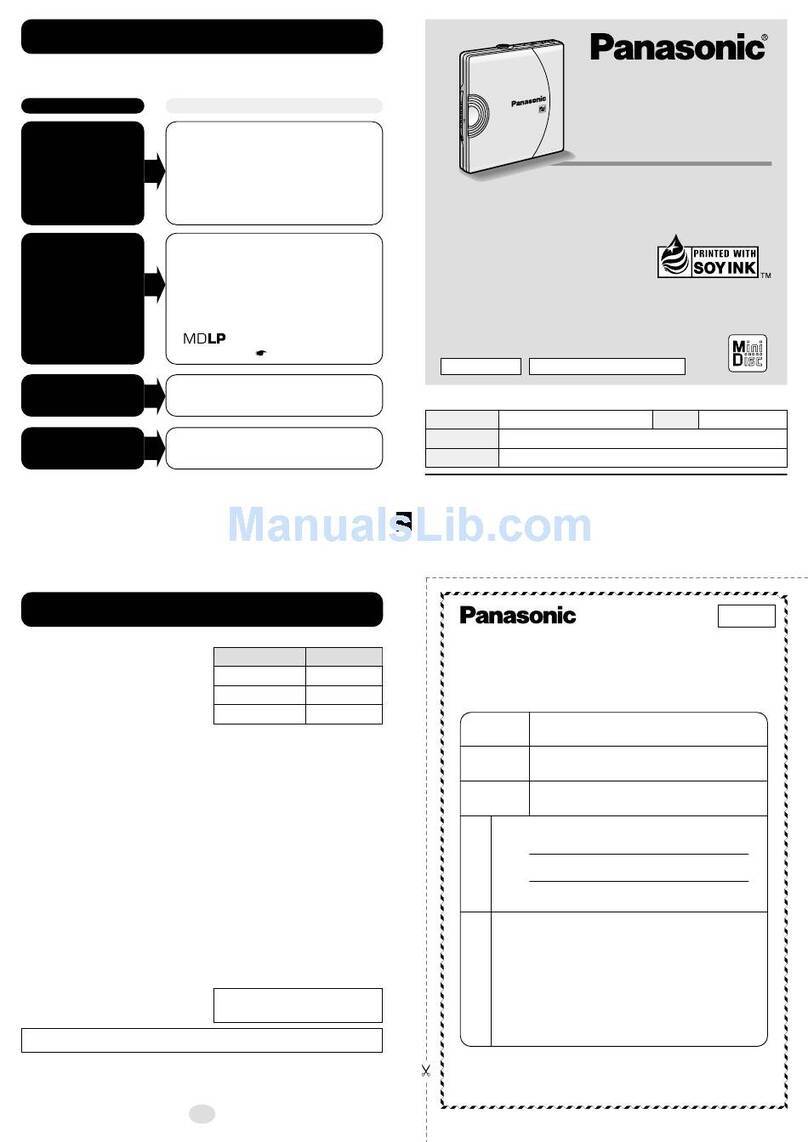

Specifications ........................................................................... 1

1. SERVICING NOTE....................................................... 2

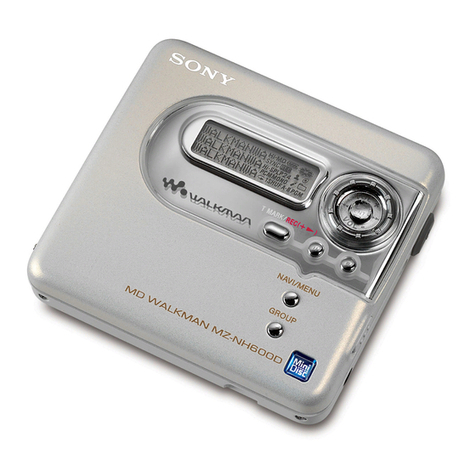

2. GENERAL

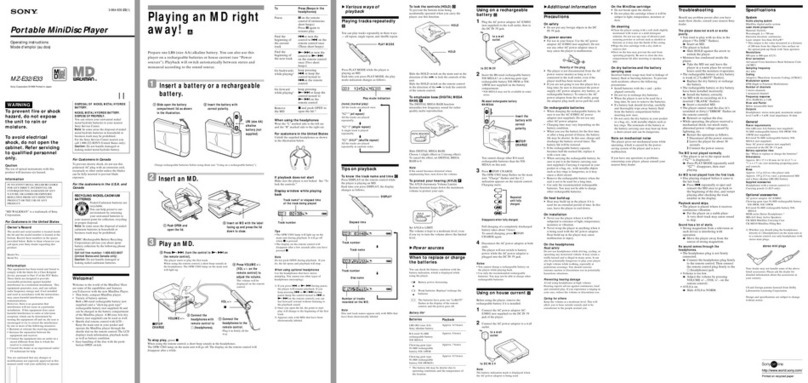

Location and Function of Controls .................................... 3

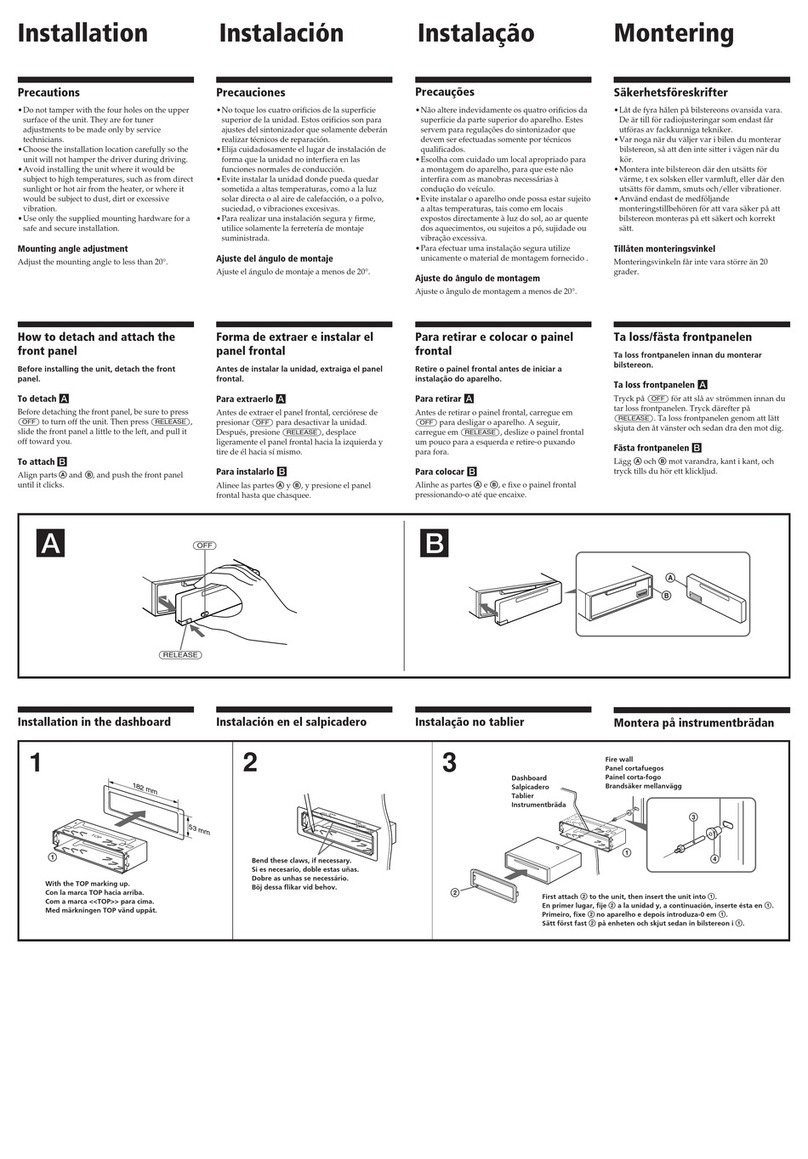

3. DISASSEMBLY

3-1. Upper Panel Assy ....................................................... 4

3-2. Bottom Panel Assy ..................................................... 4

3-3. Main board.................................................................. 4

3-4. Belt Assy, Front Panel Assy........................................ 5

3-5. Mechanism Deck Section ........................................... 5

3-6. Optial Pick-up Block Assy ......................................... 6

4. TEST MODE................................................................... 7

SAFETY-RELATED COMPONENTWARNING!!

COMPONENTS IDENTIFIED BY MARK !OR DOTTED LINEWITH

MARK !ON THE SCHEMATIC DIAGRAMS AND INTHE PARTS

LIST ARE CRITICALTO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

TABLE OF CONTENTS

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OFANY PRODUCT.

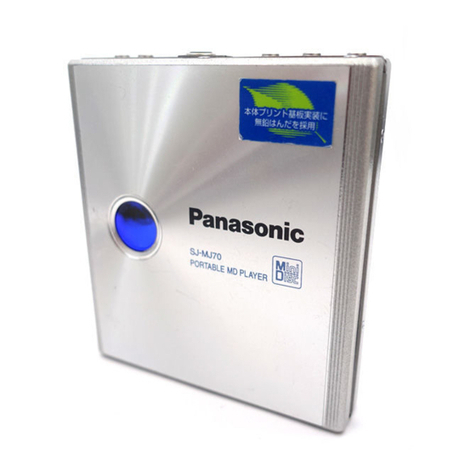

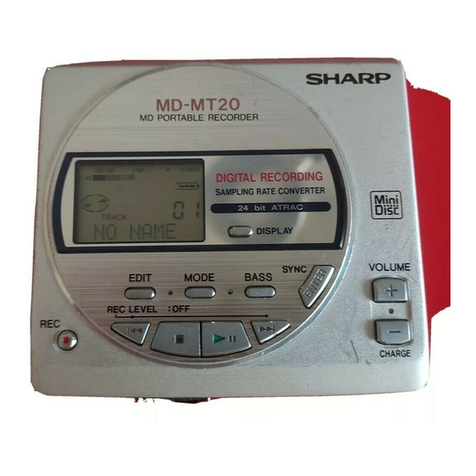

“MD WALKMAN” is a trademark of Sony

Corporation.

This Mini Disc player is classi-

fied as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on

the bottom exterior.

5. ELECTRICAL ADJUSTMENTS............................ 10

6. DIAGRAMS

6-1. Explanation of IC Terminals..................................... 13

6-2. Block Diagram.......................................................... 15

6-3. Printed Wiring Boards .............................................. 18

6-4. Schematic Diagram................................................... 21

7. EXPLODED VIEWS

7-1. Panel Section ............................................................ 28

7-2. Main Section............................................................. 29

7-3. Mechanism Deck Section ......................................... 30

8. ELECTRICAL PARTS LIST ................................31

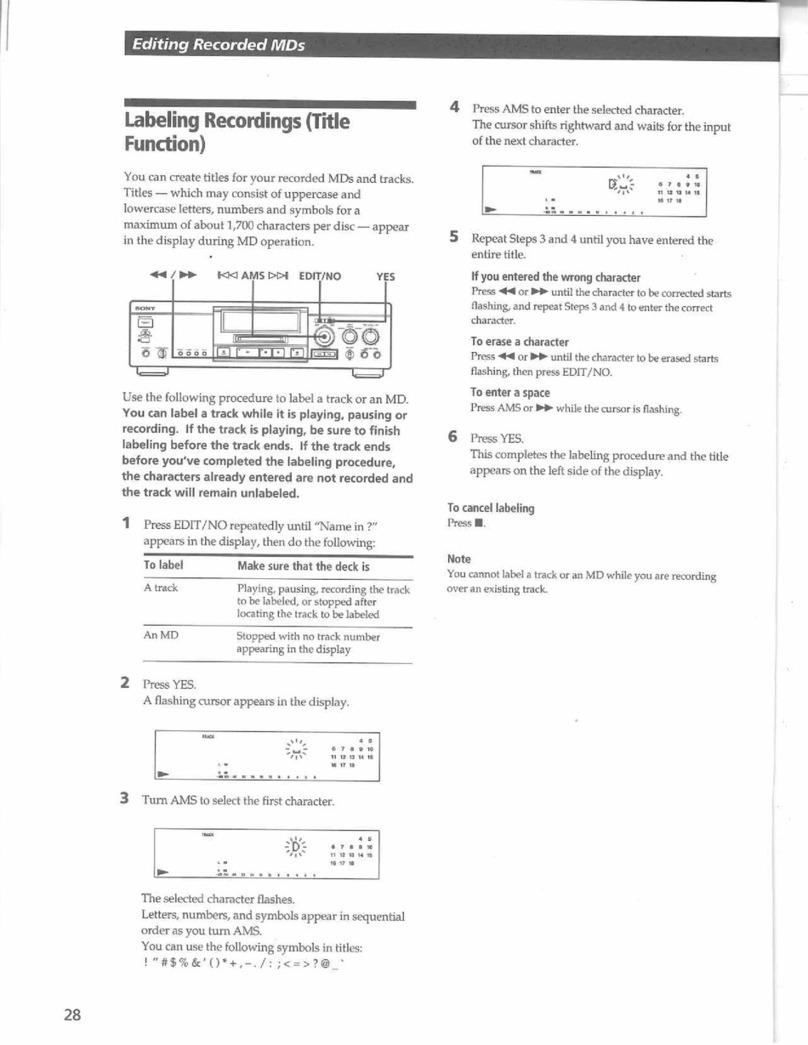

SECTION 1

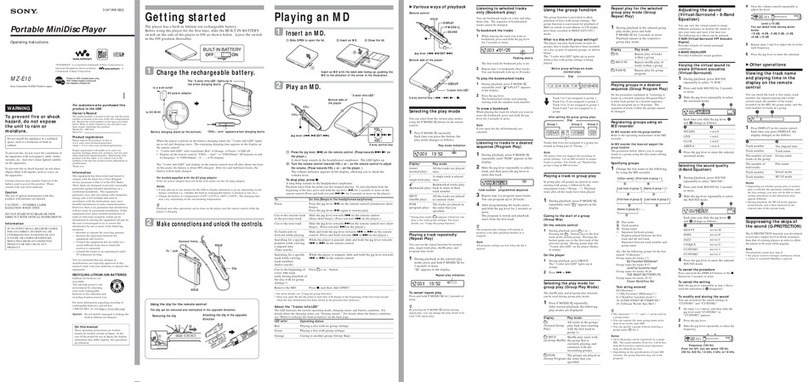

SERVICING NOTE

When repairing this device with the power on, if you remove the main board, this device stops working.

In this case, you work without the device stopping by fastening the hook of the Open/Close detection switch (S801) with tape.

Chassis ASSY

Main board

Tape

Open/Close switch (S801)