3

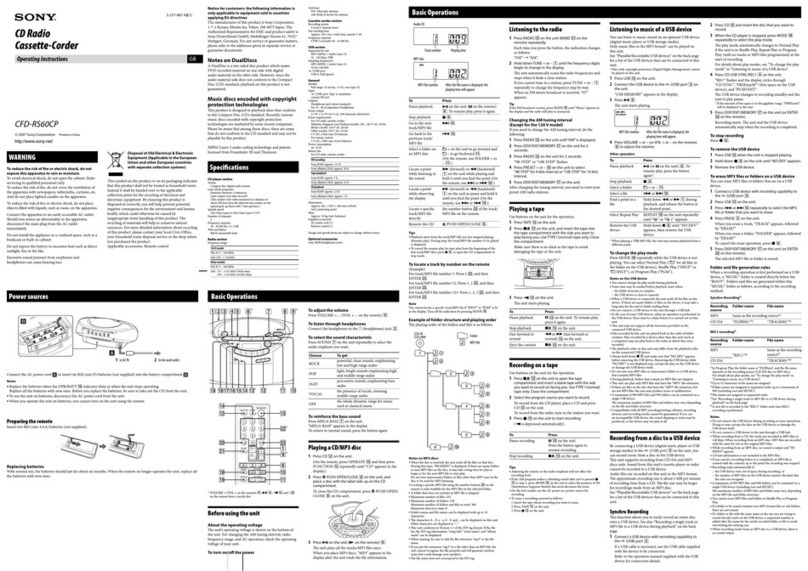

TABLE OF CONTENTS

1. GENERAL

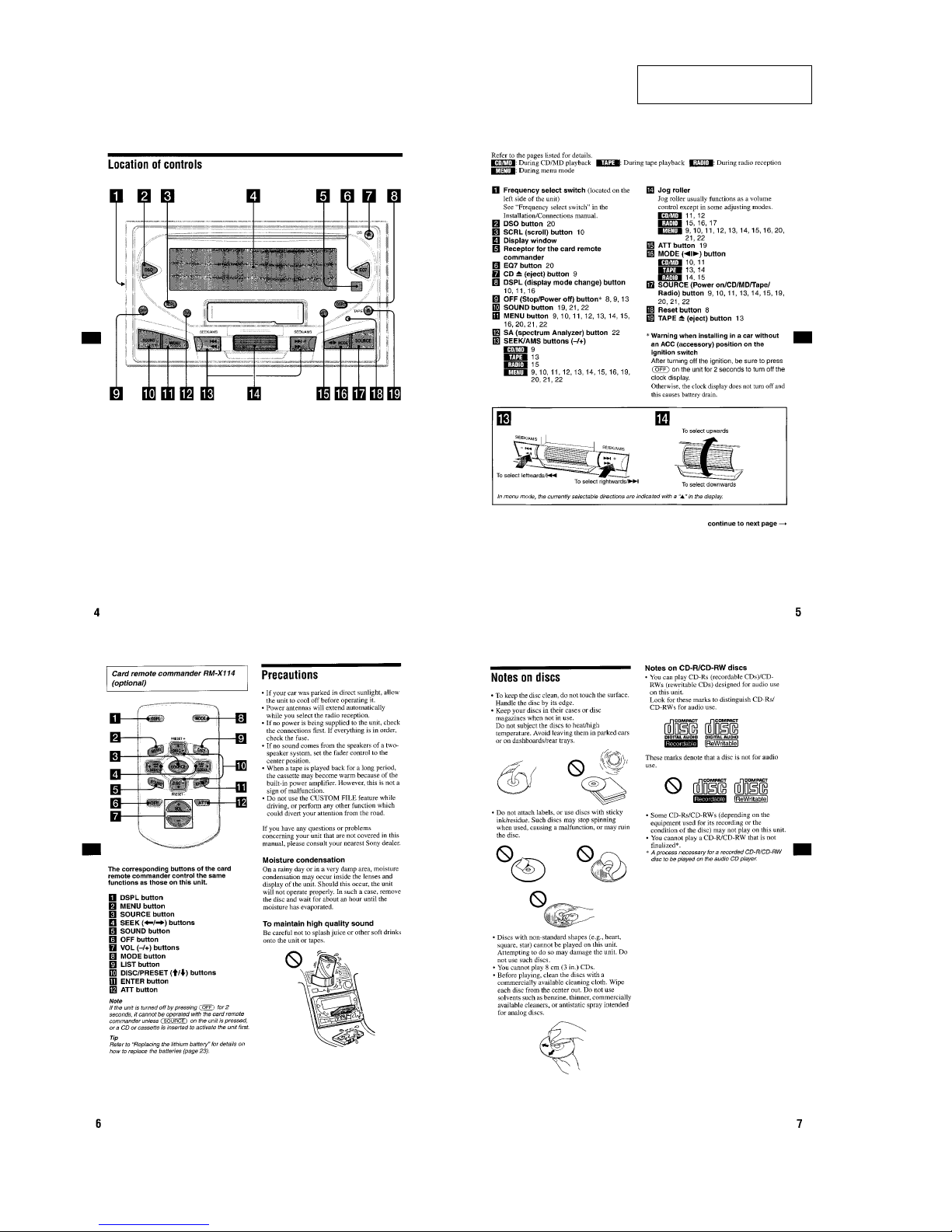

Location of Controls............................................................... 4

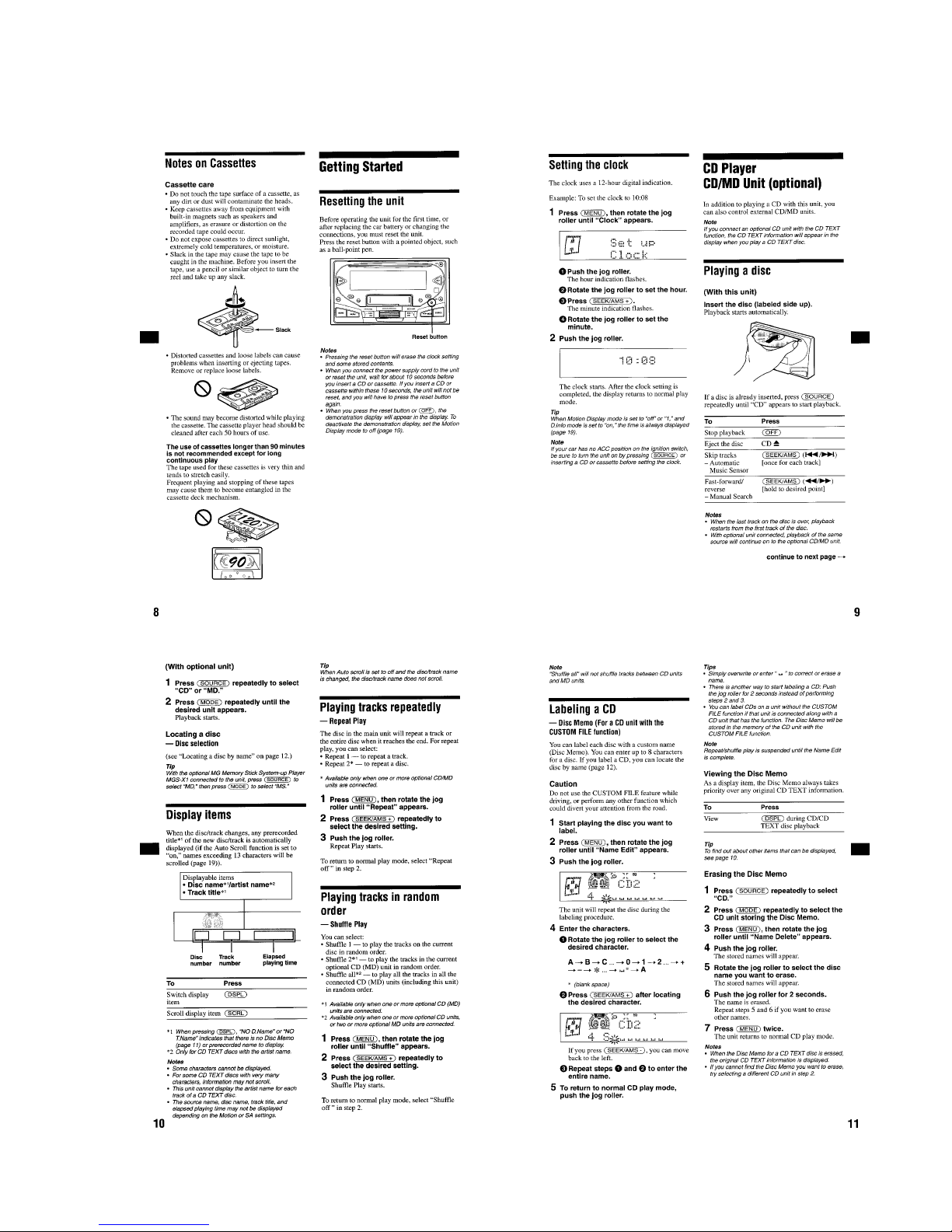

Getting Started........................................................................ 5

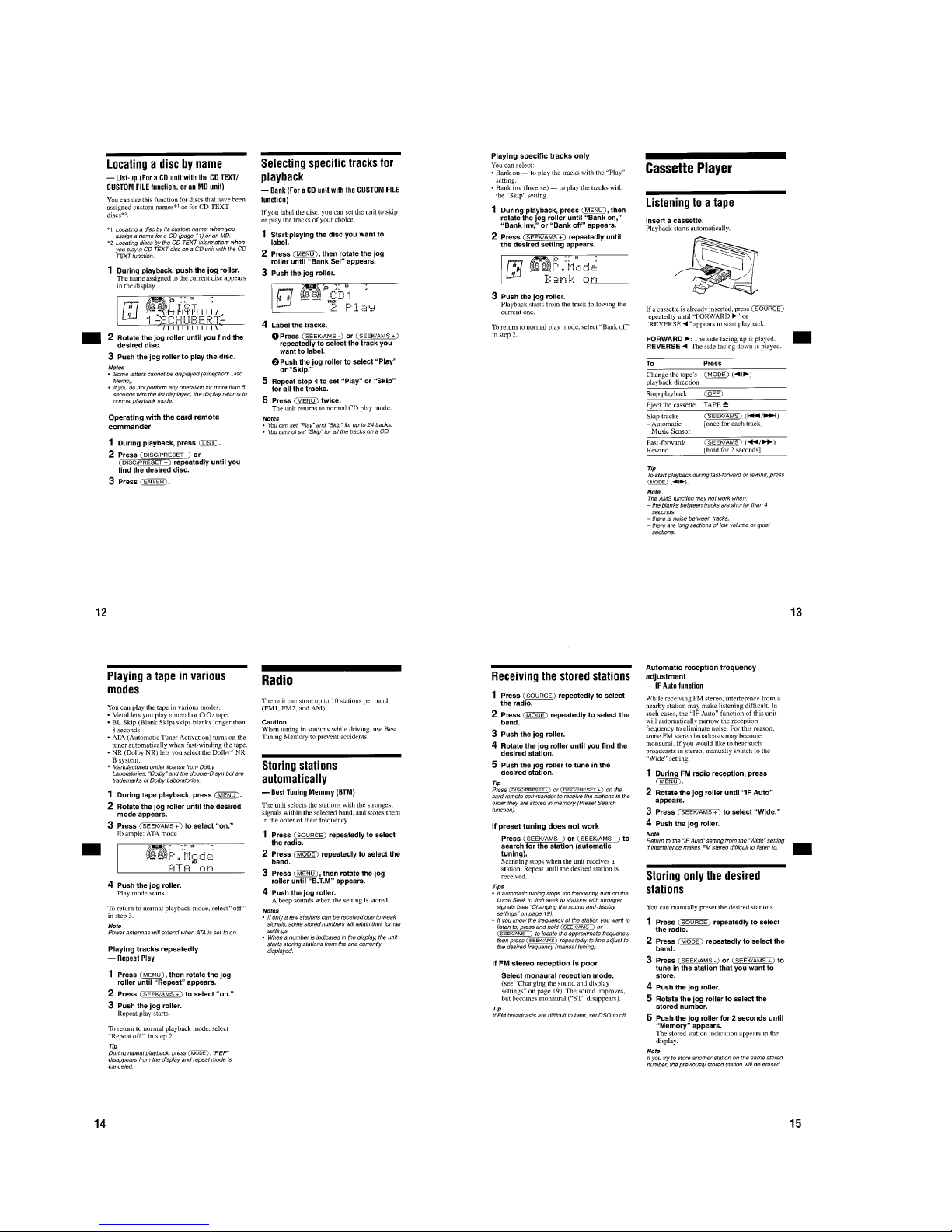

CD Player ............................................................................... 5

Cassette Player ....................................................................... 6

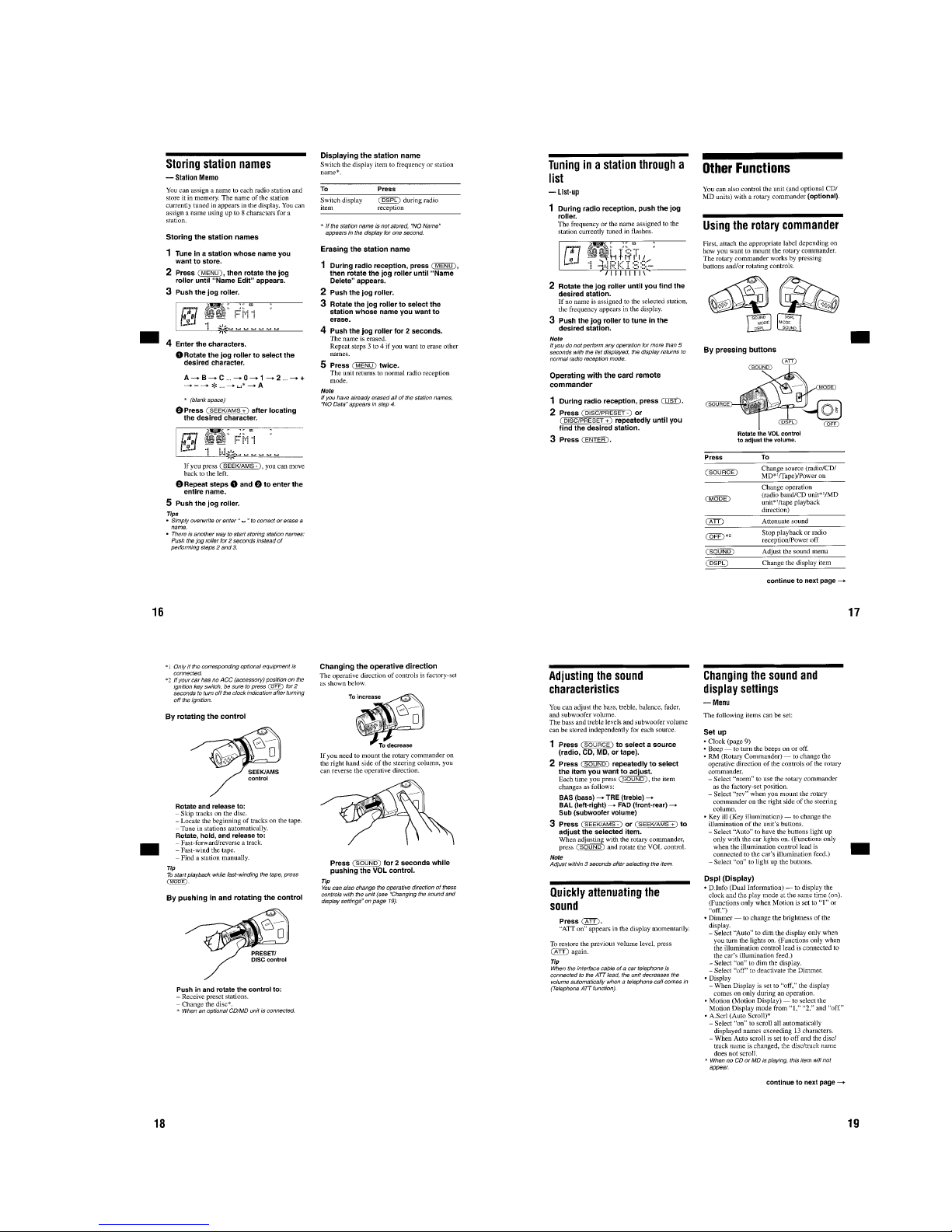

Radio ...................................................................................... 6

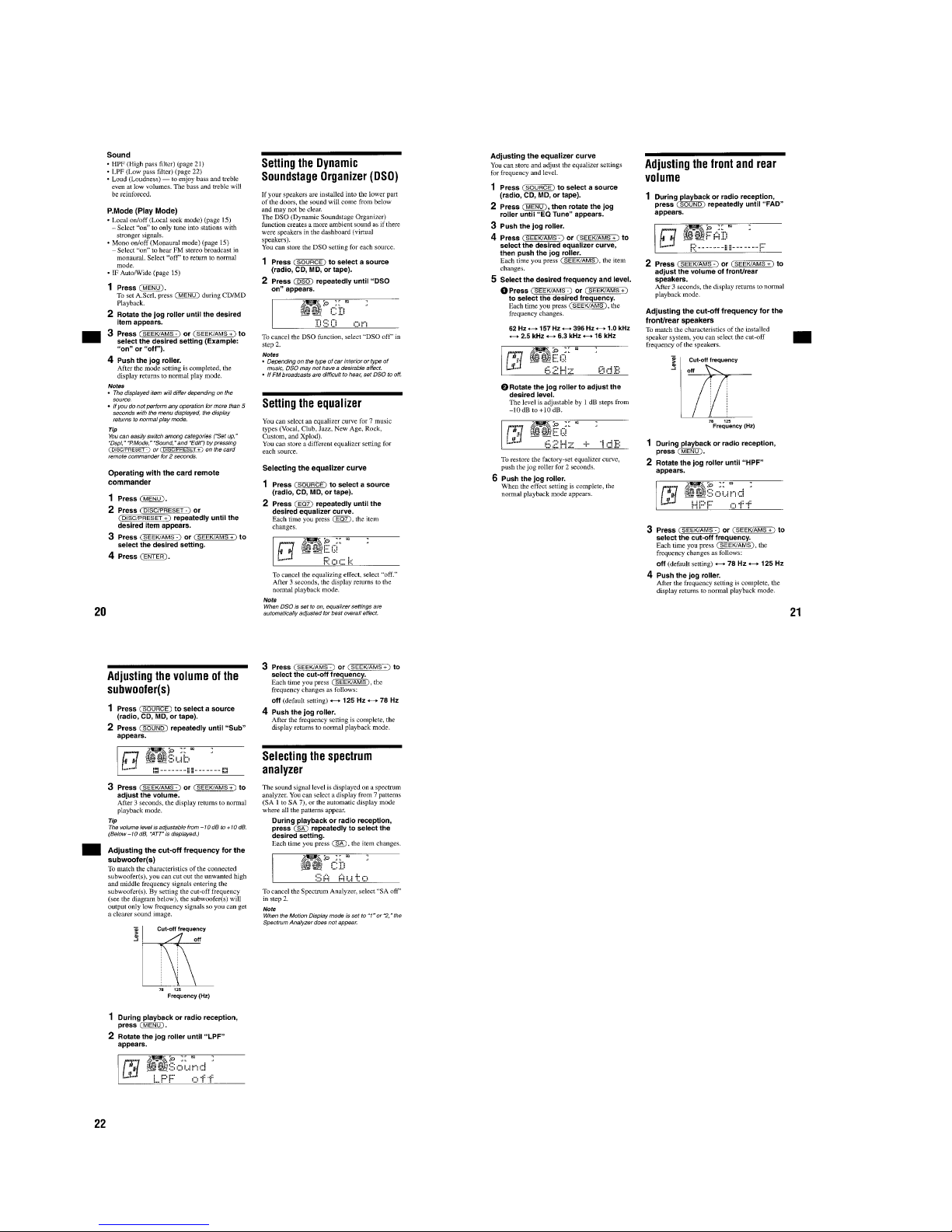

Other Functions ...................................................................... 7

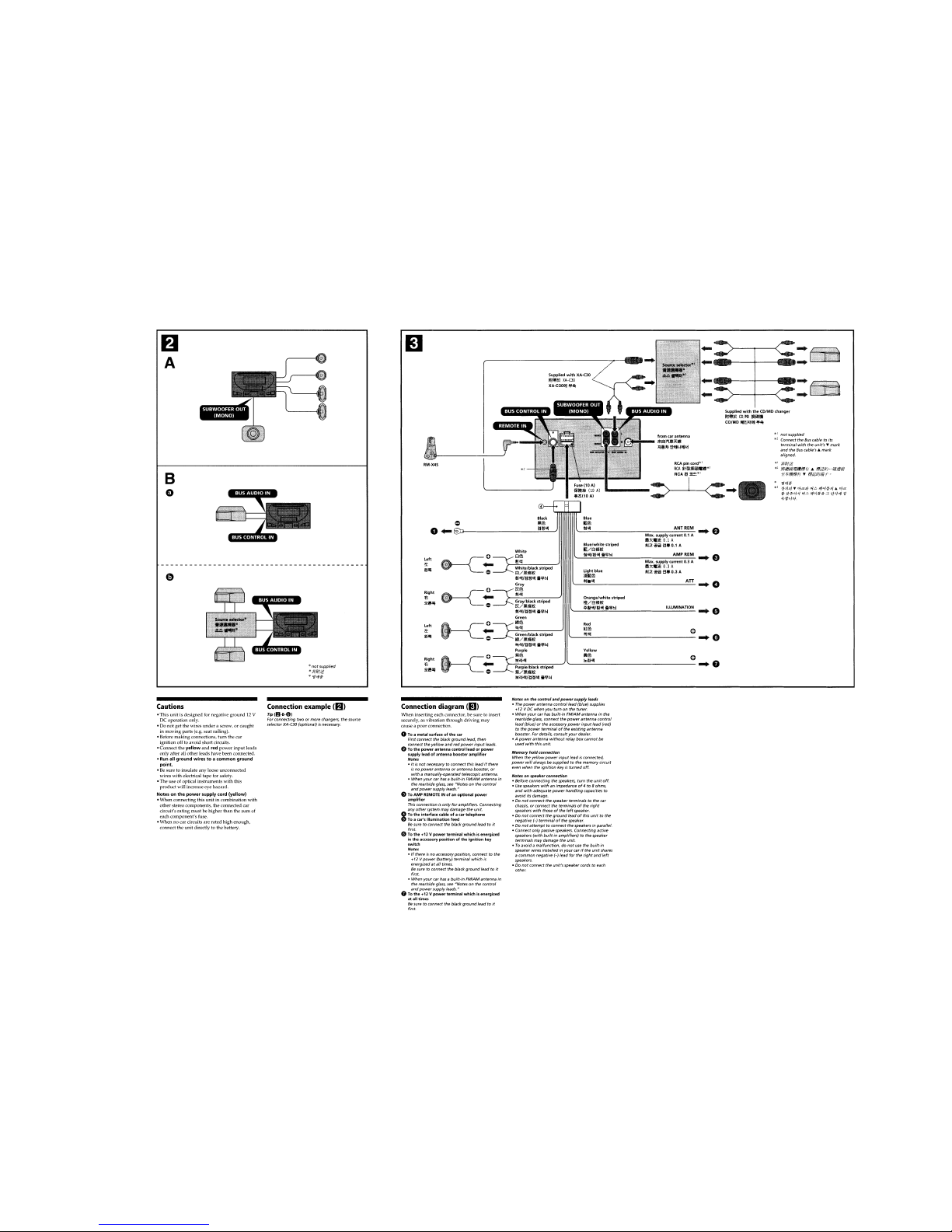

Connections ............................................................................ 9

2. DISASSEMBLY

2-1. Front Panel Assy .............................................................. 11

2-2. CD Mechanism Block ...................................................... 12

2-3. CD Main Board ................................................................ 12

2-4. Tension Spring (FL) ......................................................... 13

2-5. Floating Block Assy ......................................................... 13

2-6. Roller Arm Assy ............................................................... 14

2-7. Optical Pick-up Assy........................................................ 14

2-8. Chassis (Top) Assy ........................................................... 15

2-9. Main Board ...................................................................... 15

2-10. Heat Sink .......................................................................... 16

2-11. Tape Mechanism Block .................................................... 16

3. ASSEMBLY OF MECHANISM DECK

3-1. Housing ............................................................................ 17

3-2. Arm (Suction)................................................................... 17

3-3. Lever (LDG-A)/(LDG-B) ................................................ 18

3-4. Gear (Loading FT) ........................................................... 18

3-5. Guide (U) ......................................................................... 19

3-6. Main Motor Assy ............................................................. 19

4. MECHANICAL ADJUSTMENTS .............................. 20

5. ELECTRICAL ADJUSTMENTS

Tape Section ......................................................................... 20

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 22

6-2. Block Diagram –CD Section–.......................................... 26

6-3. Block Diagram –Tuner Section– ...................................... 27

6-4. Block Diagram –Tape Section– ....................................... 28

6-5. Circuit Boards Location ................................................... 29

6-6. Printed Wiring Boards –CD Mechanism Section–........... 30

6-7. Schematic Diagram –CD Mechanism Section – .............. 31

6-8. Printed Wiring Board –Main Section– ............................. 32

6-9. Schematic Diagram –Main Section (1/3)– ....................... 34

6-10. Schematic Diagram –Main Section (2/3)– ....................... 35

6-11. Schematic Diagram –Main Section (3/3)– ....................... 36

6-12. Printed Wiring Board –Jog Section–................................ 37

6-13. Printed Wiring Board –Display Section– ......................... 38

6-14. Schematic Diagram –Display, Jog Section– .................... 40

7. EXPLODED VIEWS

7-1. Cover Section ................................................................... 46

7-2. Front Panel Section .......................................................... 47

7-3. Main Board Section ......................................................... 48

7-4. CD Mechanism Section (1) .............................................. 49

7-5. CD Mechanism Section (2) .............................................. 50

7-6. Tape Mechanism Section ................................................. 51

8. ELECTRICAL PARTS LIST ................................... 52

WX-4500X