– 4 –

TABLE OF CONTENTS

7-11. Printed Wiring Board – Main Section – ........................... 51

7-12. Schematic Diagram – Main (1/4) Section – ..................... 53

7-13. Schematic Diagram – Main (2/4) Section – ..................... 55

7-14. Schematic Diagram – Main (3/4) Section – ..................... 57

7-15. Schematic Diagram – Main (4/4) Section – ..................... 59

7-16. Printed Wiring Board – Mic/HP Section – ....................... 61

7-17. Schematic Diagram – Mic/HP Section –.......................... 62

7-18. Printed Wiring Board – Power Section – ......................... 63

7-19. Schematic Diagram – Power Section – ............................ 65

7-20. Schematic Diagram – Transformer Section – ................... 67

7-21. Printed Wiring Board –Transformer Section –................ 69

7-22. Printed Wiring Board – Leaf SW Section – ..................... 70

7-23. Schematic Diagram – Leaf SW Section – ........................ 70

7-24. Printed Wiring Board – Display Section – ....................... 71

7-25. Schematic Diagram – Display Section – .......................... 73

7-26. Schematic Diagram – Panel Section – ............................. 75

7-27. Printed Wiring Board – Panel Section – ........................... 77

7-28. Schematic Diagram – CD Motor Section –...................... 79

7-29. Printed Wiring Board – CD Motor Section – ...................81

7-30. Schematic Diagram – Surround Section – ....................... 83

7-31. Printed Wiring Board – Surround Section –..................... 83

7-32. IC Block Diagrams ...........................................................84

7-33. IC Pin Functions ...............................................................90

8. EXPLODEDVIEWS

8-1. Case Section...................................................................... 100

8-2. Chassis Section ................................................................. 101

8-3. Front Panel Section ........................................................... 102

8-4. CD Mechanism Deck Section-1

(CDM38L-5BD29AL, CDM38LH-5BD29AL) ............... 103

8-5. CD Mechanism Deck Section-2

(CDM38L-5BD29AL, CDM38LH-5BD29AL) ............... 104

8-6. Base Unit Section (BU-5BD29AL) .................................. 105

8-7. TC Mechanism Section 1

(TCM230AWR1, TCM230PWR1) ................................... 106

8-8. TC Mechanism Section 2

(TCM230AWR1, TCM230PWR1) ................................... 107

9. ELECTRICAL PARTS LIST ...................................... 108

1. SERVICING NOTE ..........................................................5

2. GENERAL ..........................................................................6

3. DISASSEMBLY

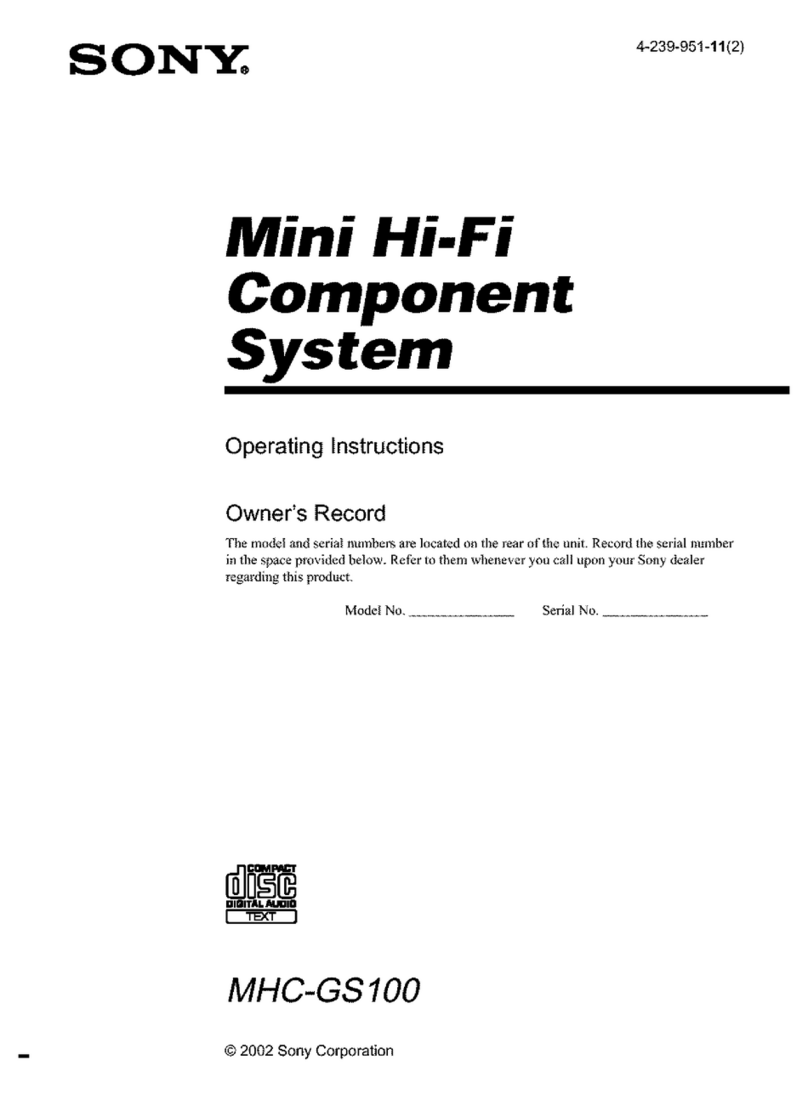

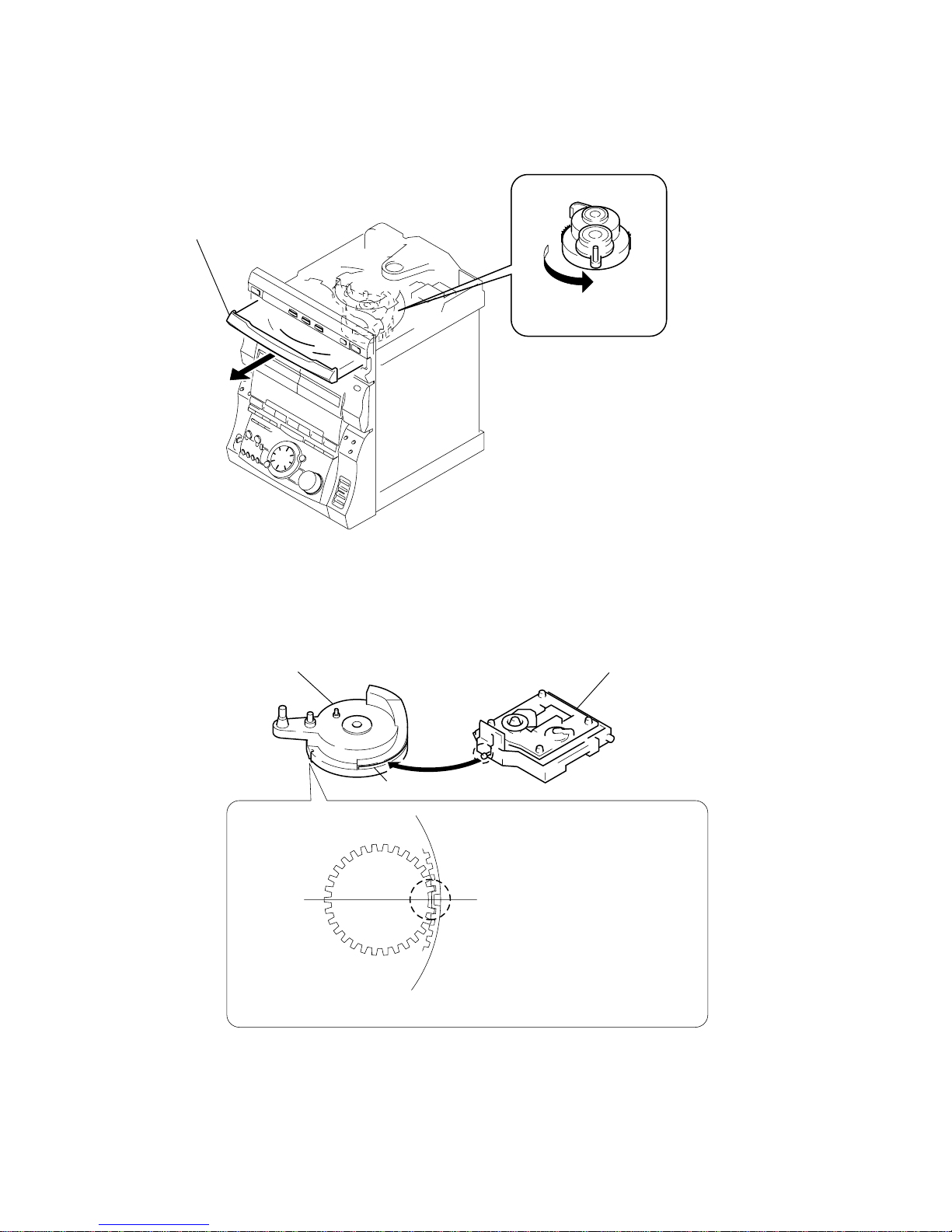

3-1. Loading Panel ....................................................................... 8

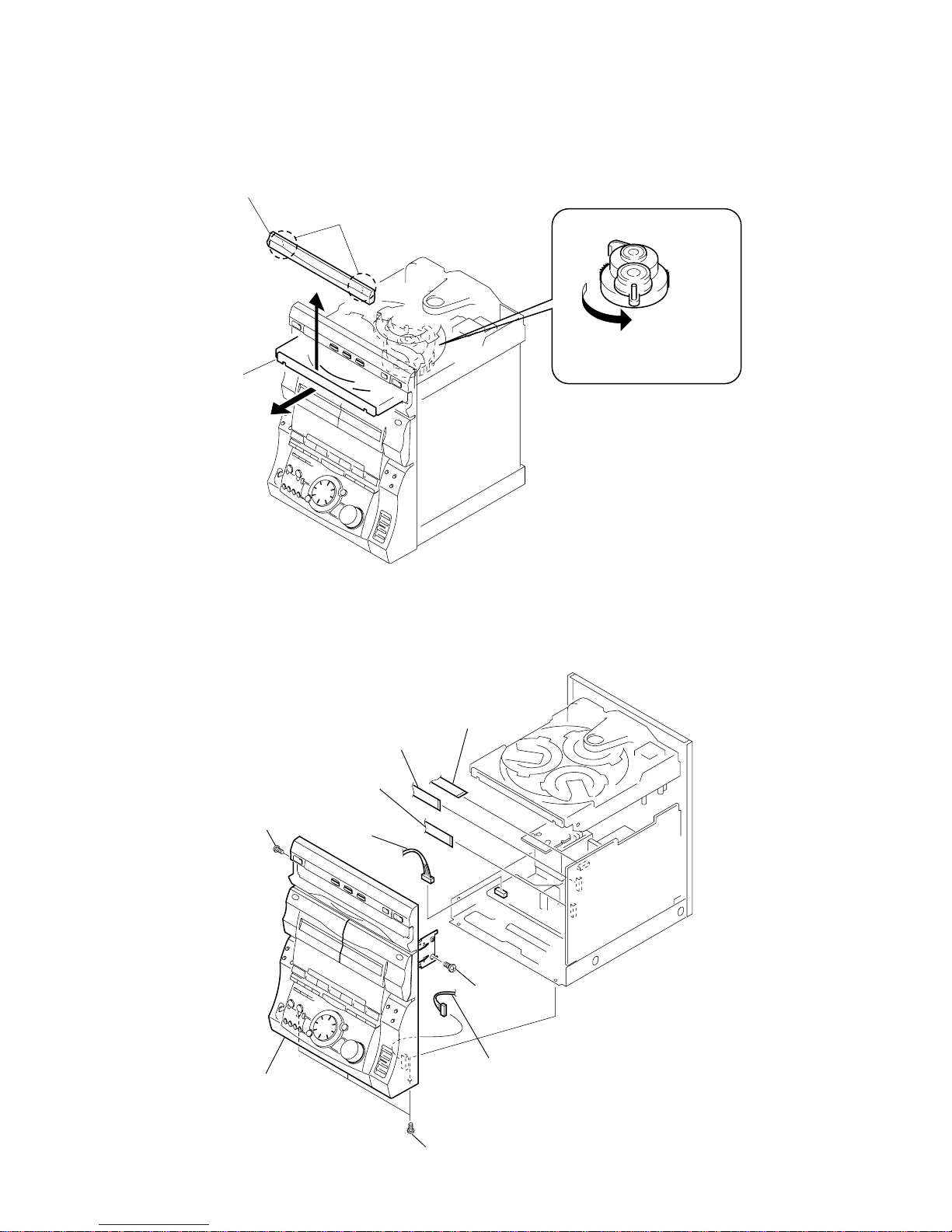

3-2. Front Panel ........................................................................... 8

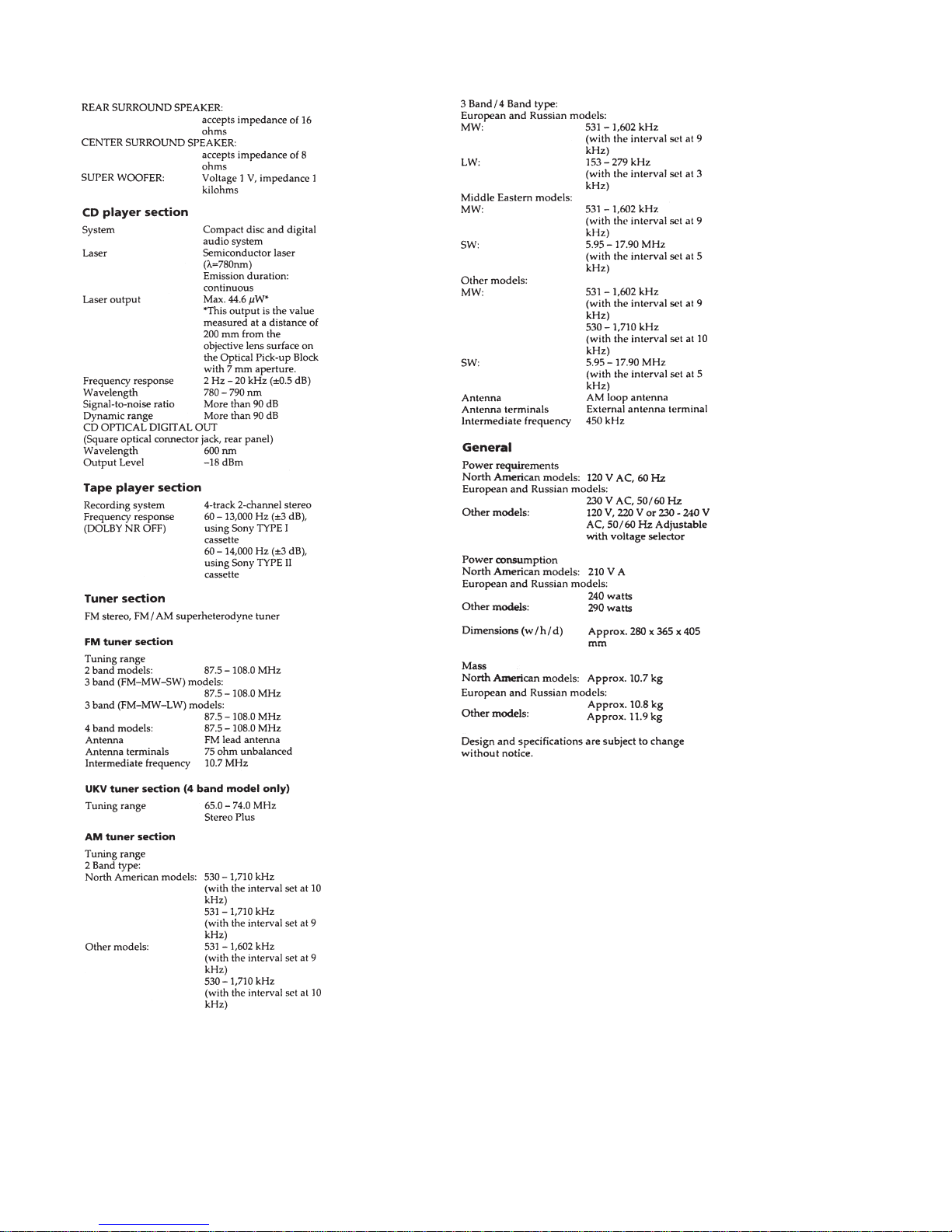

3-3. Cassette Mechanism Deck .................................................... 9

3-4. Panel Board and Cont Com Board ........................................9

3-5. Disc Tray ........................................................................... 10

4. SERVICE MODE ............................................................11

5. MECHANICAL ADJUSTMENTS ..........................14

6. ELECTRICAL ADJUSTMENTS ............................... 14

7. DIAGRAMS

7-1. Circuit Boards Location ......................................................20

7-2. Block Diagrams

• Tuner Section (AEP, UK, German model)....................... 21

• Tuner Section (East European, CIS model) .....................23

• CD Section ....................................................................... 25

• Deck Section .................................................................... 27

• Main Section .................................................................... 29

• Power Section ..................................................................31

• Display Section ................................................................ 33

7-3. Printed Wiring Board – CD Section –................................. 37

7-4. Schematic Diagram – CD Section – ................................... 39

7-5. Schematic Diagram

–Tuner (AEP, UK, German model) Section –..................... 41

7-6. Printed Wiring Board

–Tuner (AEP, UK, German model) Section –..................... 43

7-7. Printed Wiring Board

–Tuner (East European, CIS model) Section – ................... 44

7-8. Schematic Diagram

–Tuner (East European, CIS model) Section – ................... 45

7-9. Schematic Diagram – Deck Section –................................. 47

7-10. Printed Wiring Board – Deck Section – ........................... 49