3

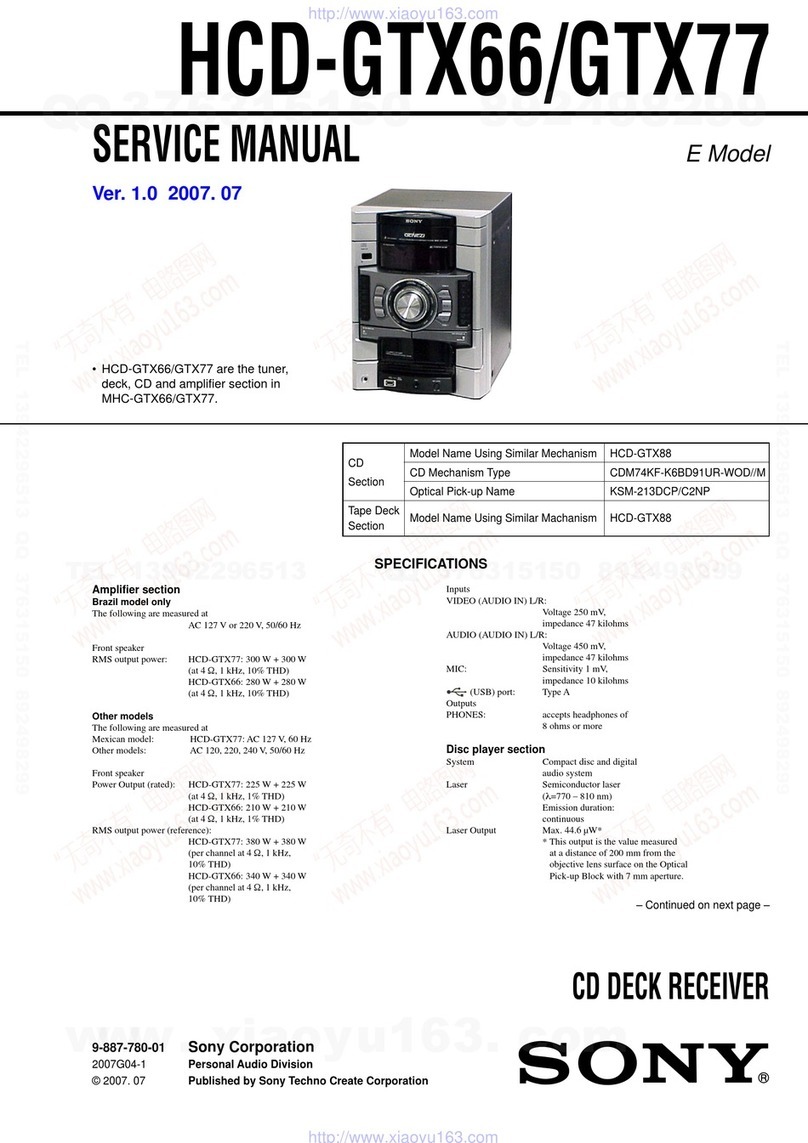

HCD-HP8V

1. SERVICING NOTES ······················································· 4

2. GENERAL ·········································································· 6

3. DISASSEMBLY

3-1. Case (Side-L)(Side-R),

Tape Mechanism Deck (CMAL1Z234A) ······················ 9

3-2. Front Panel Section ······················································· 9

3-3. Panel Board ································································· 10

3-4. Back Panel Section ······················································ 10

3-5. MAIN Board ······························································· 11

3-6. PWR AMP Board, Power Transformer ······················· 11

3-7. CD Mechanism Deck (CDM69BH-30BD62) ············· 12

3-8. JACK Board, VMP Board ··········································· 12

3-9. Base Unit Section ························································ 13

3-10.Base Unit (BU-30BD62) ············································· 13

3-11. BD Board ····································································· 14

3-12.SW Board, Bracket (Top) Assy ··································· 15

3-13.CONNECTOR Board ·················································· 15

3-14.Motor (Stocker) Assy (Stocker)(M761) ······················ 16

3-15.Motor (Roller) Assy (Roller)(M781) ··························· 16

3-16.Motor (Mode) Assy (Mode)(M771) ···························· 17

3-17.Rubber Roller (Slider) Assy ········································ 17

3-18.Timing Belt (Front/Rear)············································· 18

3-19.Cam (Gear) ·································································· 18

3-20.SENSOR Board ··························································· 19

4. ASSEMBLY

4-1. How to Install the Cam (Eject Lock) ···························· 20

4-2. How to Install the Cam (GEAR)··································· 20

4-3. How to Install the Gear (MODE C) ······························ 21

4-4. How to Install the Gear (MODE CAM) ······················· 21

4-5. How to Install the Rotary Encoder (S702),

Gear (STOCKER COMMUNICATION) ····················· 22

4-6. How to Install the Stocker Assy ···································· 22

5. TEST MODE ···································································· 23

6. MECHANICAL ADJUSTMENTS ····························· 24

7. ELECTRICAL ADJUSTMENTS ······························· 25

8. DIAGRAMS ······································································ 28

8-1. Block Diagram — CD SERVO Section — ················· 30

— AUDIO/VIDEO Section — ···································· 31

— MAIN Section — ··················································· 32

8-2. Printed Wiring Boards — BD Section — ··················· 33

8-3. Schematic Diagram — BD Section — ························ 34

8-4. Printed Wiring Boards — VMP Section (1/2) — ········ 35

8-5. Printed Wiring Boards — VMP Section (2/2) — ········ 36

8-6. Schematic Diagram — VMP Section (1/2) — ············ 37

8-7. Schematic Diagram — VMP Section (2/2) — ············ 38

8-8. Printed Wiring Boards — Changer Section — ··········· 39

8-9. Schematic Diagram — Changer Section — ················ 40

8-10.Printed Wiring Boards — Main Section —················· 41

8-11.Schematic Diagram — Main Section — ····················· 42

8-12.Printed Wiring Boards — Front Section — ················ 43

8-13.Schematic Diagram — Front Section —····················· 44

8-14.Printed Wiring Boards

— PWR AMP/Power Section —································· 45

8-15.Schematic Diagram

— PWR AMP/Power Section —································· 46

8-16.IC Block Diagrams ······················································ 47

8-17.IC Pin Function Description ········································ 50

9. EXPLODED VIEWS

9-1. Case, Top Panel Section ·············································· 57

9-2. Front Panel Section ····················································· 58

9-3. Chassis Section-1 ························································ 59

9-4. Chassis Section-2 ························································ 60

9-5. CD Mechanism Section-1 (CDM69BH-30BD62) ······ 61

9-6. CD Mechanism Section-2 (CDM69BH-30BD62) ······ 62

9-7. CD Mechanism Section-3 (CDM69BH-30BD62) ······ 63

9-8. CD Mechanism Section-4 (CDM69BH-30BD62) ······ 64

9-9. CD Mechanism Section-5 (CDM69BH-30BD62) ······ 65

9-10.CD Mechanism Section-6 (CDM69BH-30BD62) ······ 66

9-11.Base Unit Section (BU-30BD62) ································ 67

10.ELECTRICAL PARTS LIST ······································· 68

TABLE OF CONTENTS