5

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0OR DOTTED LINE WITH

MARK 0ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

ÀLA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉDE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

TABLE OF CONTENTS

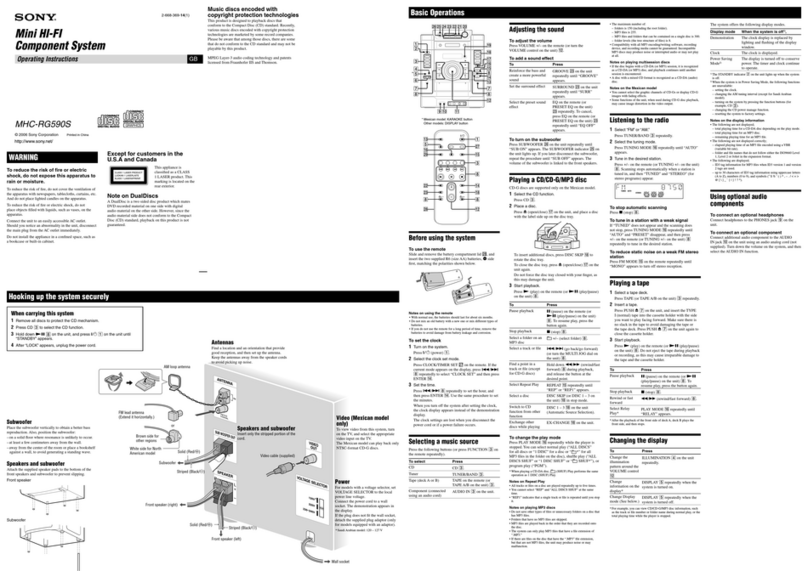

1. SERVICING NOTE ·························································· 6

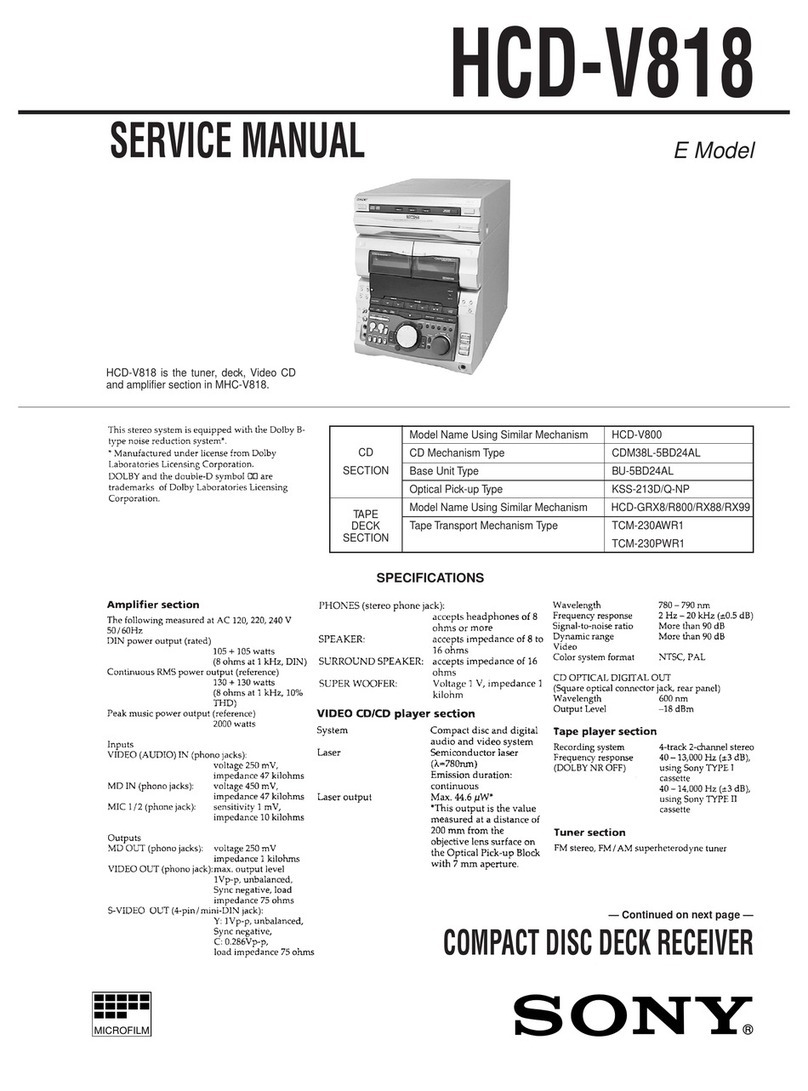

2. GENERAL ........................................................................ 18

3. DISASSEMBLY

3-1. Upper Cover ······························································· 21

3-2. Front Panel Section ····················································· 21

3-3. Panel Board ································································· 22

3-4. Main Board·································································· 22

3-5. Cassette Machanism ···················································· 23

3-6. Power Transformer/AMP Board ································· 23

3-7. CD Mechanism Deck ·················································· 24

3-8. Tray, Gear and Cam····················································· 24

3-11.BD (CD) Board, Spindle Motor (M101) and

Sled Motor (M102)······················································ 25

3-9. CD Base Unit ······························································ 25

3-10.Optical Pick-Up Section Of CD

(KSS-213BA/F-NP) ···················································· 25

3-12.MD Mechanism Deck ················································· 26

3-13.Slider (Cam) ································································ 26

3-14.Base Unit (MBU-5A) and BD (MD) Board ················ 27

3-15.Over Write Head·························································· 27

3-16.Optical Pick-Up Of MD (KMS-260B/J1N) ················ 27

3-17.Spindle Motor (M901) and

Sled Motor (M902) (MD)············································ 28

4. TEST MODE .................................................................... 29

5. ELECTRICAL ADJUSTMENTS34

6. DIAGRAMS

6-1. Block Diagrams

–BD (CD) Section – ··················································· 45

–BD (MD) Section (1/2) –·········································· 46

–BD (MD) Section (2/2) –·········································· 47

–Main Section – ························································· 48

6-2. Circuit Boards Location ·············································· 49

6-3. Printed Wiring Board –BD (CD) Section – ················ 50

6-4. Schematic Diagram –BD (CD) Section –··················· 51

6-5. Printed Wiring Board –BD (MD) Section – ··············· 52

6-6. Schematic Diagram –BD (MD) Section (1/2) – ········· 53

6-7. Schematic Diagram –BD (MD) Section (2/2) – ········· 54

6-8. Schematic Diagram –MAIN Section (1/2) – ·············· 55

6-9. Schematic Diagram –MAIN Section (2/2) – ·············· 56

6-10.Printed Wiring Board –MAIN Section – ···················· 57

6-11.Printed Wiring Board –MD DIGITAL Section – ······· 58

6-12.Printed Wiring Board –MD DIGITAL Section – ······· 59

6-13.Printed Wiring Board –AMP Section – ······················ 60

6-14.Schematic Diagram –AMP Section – ························· 61

6-15.Printed Wiring Board

–CASSETTE DECK Section – ·································· 62

6-16.Printed Wiring Board

–CASSETTE DECK Section – ·································· 63

6-17.Printed Wiring Board –PANEL Section – ·················· 64

6-18.Schematic Diagram –PANEL Section – ···················· 65

6-19.Printed Wiring Board –POWER Section –················· 66

6-20.Schematic Diagram –POWER Section – ·················· 67

6-21.Schematic Diagram –BD SWITCH Section – ·········· 68

6-22.Printed Wiring Board –BD SWITCH Section –········· 68

6-23.Schematic Diagram –LOADING Section – ·············· 68

6-24.Printed Wiring Board –LOADING Section – ············ 68

6-25.IC Block Diagrams ······················································ 69

6-26 IC Pin Fuction Description·········································· 74

7. EXPLODED VIEWS

7-1. Case and Casette Mechanism Deck

Section (CMAL1Z027A) ············································ 79

7-2. Front Panel Section ····················································· 80

7-3. Chassis Section ···························································· 81

7-4. Md Mechanism Deck Section-1 (MDM-5H) ·············· 82

7-5. Md Mechanism Deck Section-2 (MBU-5A) ··············· 83

7-6. CD Mechanism Deck Section-1

(CDM55A-5SBD32) ··················································· 84

7-7. CD Mechanism Deck Section-2 (BU-5SBD32)·········· 85

8. ELECTRICAL PARTS LIST ······································· 86