4

7. EXPLODEDVIEWS

7-1. Case and Back Panel Section .............................................. 53

7-2. Front Panel Section 1 .......................................................... 54

7-3. Front Panel Section 2 .......................................................... 55

7-4. Chassis Section ................................................................... 56

7-5. TC Mechanism Section 1 (TCM230PWR1)....................... 57

7-6. TC Mechanism Section 2 (TCM230PWR1)....................... 58

7-7. CD Mechanism Section (CDM37M-5BD32L)................... 59

7-8. Base Unit Section (BU-5BD32L) ....................................... 60

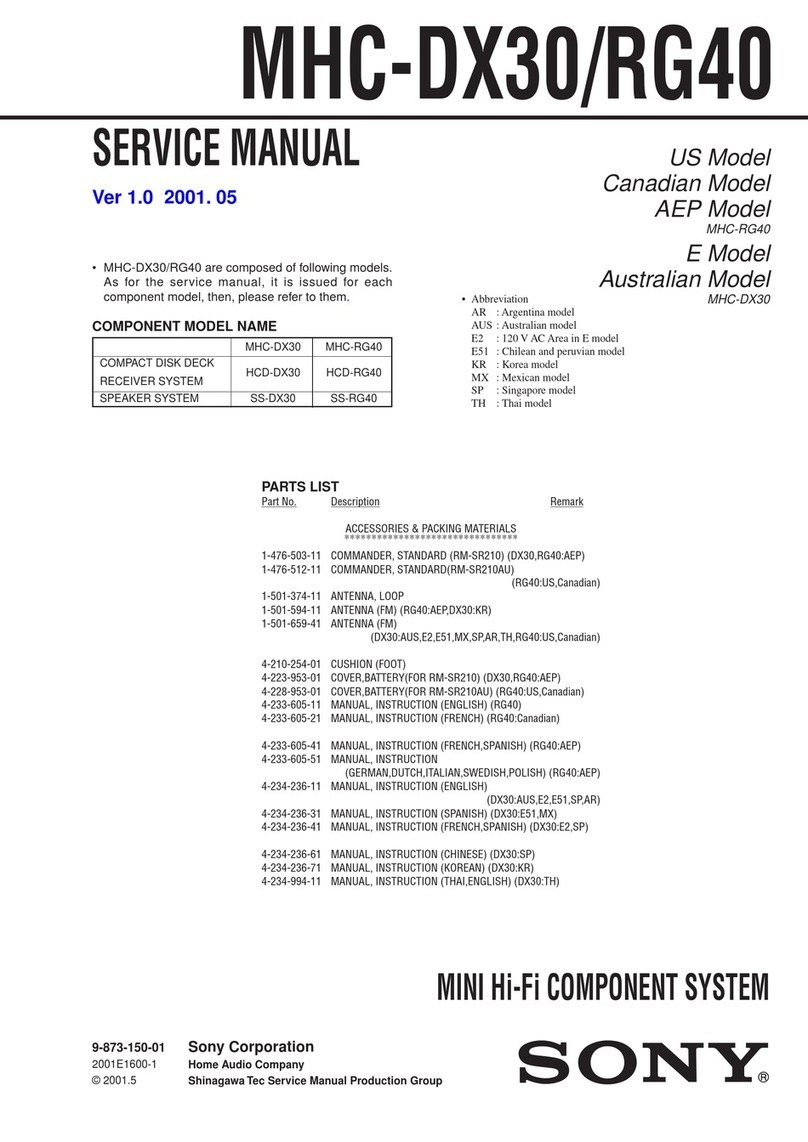

8. ELECTRICAL PARTS LIST ........................................ 61

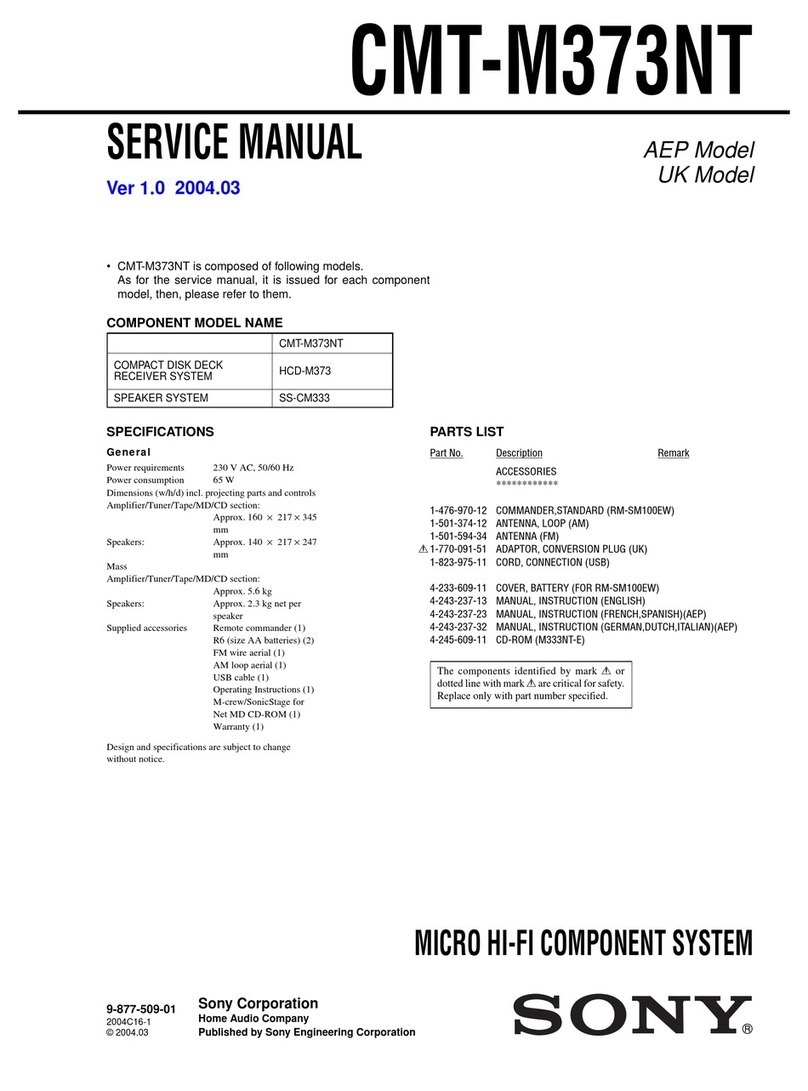

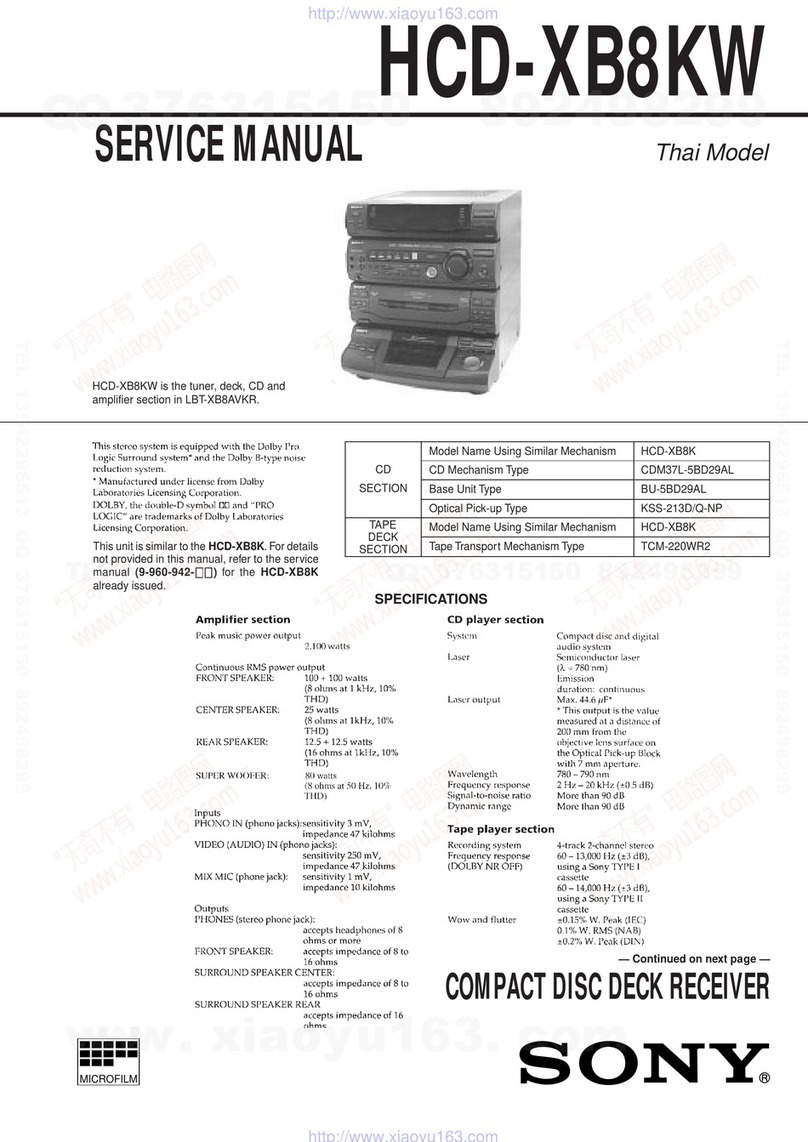

1. SERVICING NOTE .......................................................... 5

2. GENERAL ....................................................................9

3. DISASSEMBLY

3-1. Front Panel .......................................................................... 11

3-2. Main Board ......................................................................... 11

3-3. Sub Panel ............................................................................ 12

3-4. CD LID Assembly .............................................................. 12

3-5. Tape Mechanism Deck and Cassette LID ........................... 12

3-6. CD Mechanism Deck .......................................................... 13

3-7. Base Unit............................................................................. 13

3-8. Disc Table ........................................................................... 13

4. MECHANICAL ADJUSTMENTS ..........................14

5. ELECTRICAL ADJUSTMENTS ............................... 14

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 17

6-2. Block Diagrams

• BD (CD) Section.............................................................. 18

• Deck Section .................................................................... 19

• Main (1/2) Section ........................................................... 20

• Main (2/2) Section ........................................................... 21

• Power Section (LX8 model) ............................................ 22

• Power Section (LX7 model) ............................................ 23

• Display Section ................................................................ 24

6-3. Printed Wiring Board – BD (CD) Section – ....................... 26

6-4. Schematic Diagram – BD (CD) Section – .......................... 27

6-5. Printed Wiring Board – Main Section – .............................. 28

6-6. Schematic Diagram – Main (1/3) Section – ........................ 29

6-7. Schematic Diagram – Main (2/3) Section – ........................ 30

6-8. Schematic Diagram – Main (3/3) Section – ........................ 31

6-9. Schematic Diagram – Deck Section –................................. 32

6-10. Printed Wiring Board – Deck Section – ........................... 33

6-11. Schematic Diagram – Power Section – ............................ 34

6-12. Printed Wiring Board – Power Section – ......................... 35

6-13. Schematic Diagram – Panel FL Section – ........................ 36

6-14. Printed Wiring Board – Panel FL Section – ..................... 37

6-15. Schematic Diagram – Panel VR Section – ....................... 38

6-16. Printed Wiring Board – Panel VR Section – .................... 39

6-17. Schematic Diagram – TC Panel Section – ....................... 40

6-18. Printed Wiring Board – TC Panel Section –..................... 41

6-19. Schematic Diagram – CD Panel Section – .......................42

6-20. Printed Wiring Board – CD Panel Section – .................... 43

6-21. Schematic Diagram – CD Motor Section – ...................... 44

6-22. Printed Wiring Board – CD Motor Section – ................... 45

6-23. Schematic Diagram – Trans Section – (LX7 model) ....... 46

6-24. Printed Wiring Board – Trans Section – (LX7 model)..... 47

6-25. Schematic Diagram – Trans Section – (LX8 model) ....... 48

6-26. Printed Wiring Board – Trans Section – (LX8 model)..... 49

6-27. Schematic Diagram – Leaf SW Section – ........................ 49

6-28. Printed Wiring Board – Leaf SW Section – ..................... 49

6-29. IC Block Diagrams ........................................................... 50

6-30. IC Pin Functions ............................................................... 50

TABLE OF CONTENTS