3

7. EXPLODEDVIEWS

7-1. Case Section........................................................................ 63

7-2. Chassis Section ................................................................... 64

7-3. Front Panel Section ............................................................. 65

7-4. CD Mechanism Deck Section-1 (CDM38LH-26BD36L) .. 66

7-5. CD Mechanism Deck Section-2 (CDM38LH-26BD36L) .. 67

7-6. Base Unit Section (BU-26BD36L) ..................................... 68

7-7. TC Mechanism Section-1 (TCM230AWR2) ...................... 69

7-8. TC Mechanism Section-2 (TCM230AWR2) ...................... 70

8. ELECTRICAL PARTS LIST ....................................71

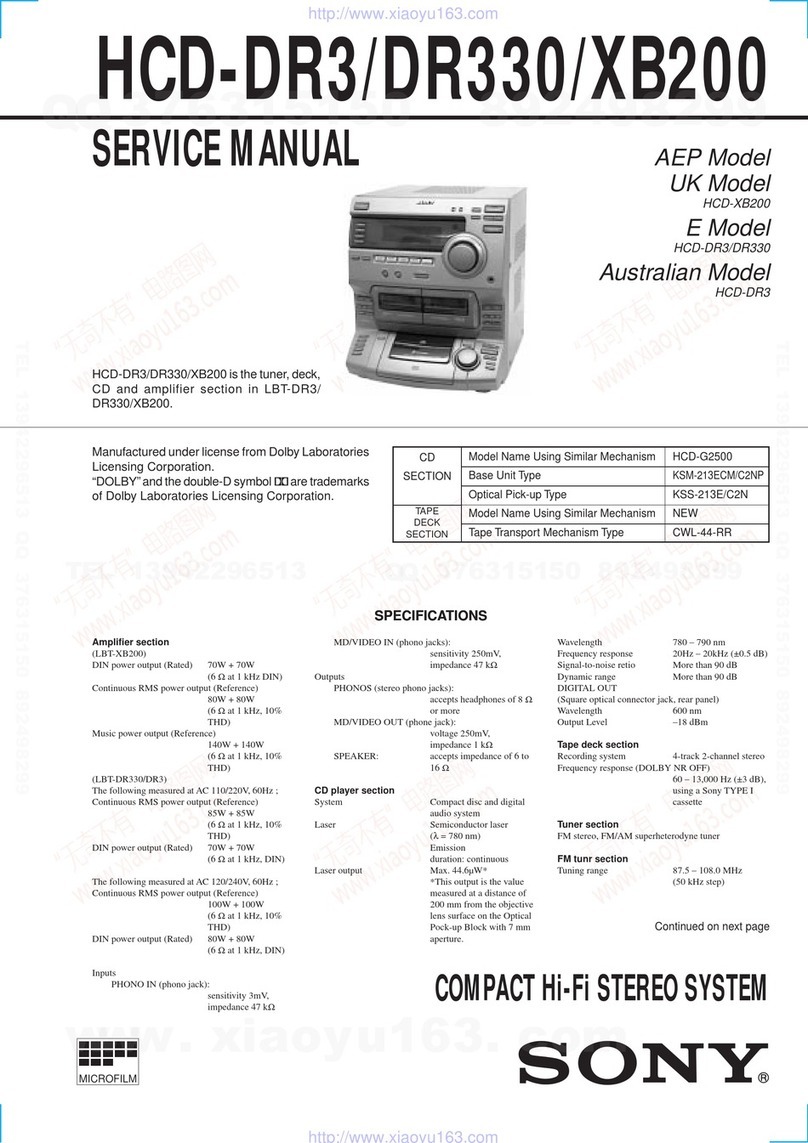

TABLE OF CONTENTS

1. SERVICING NOTES ...................................................4

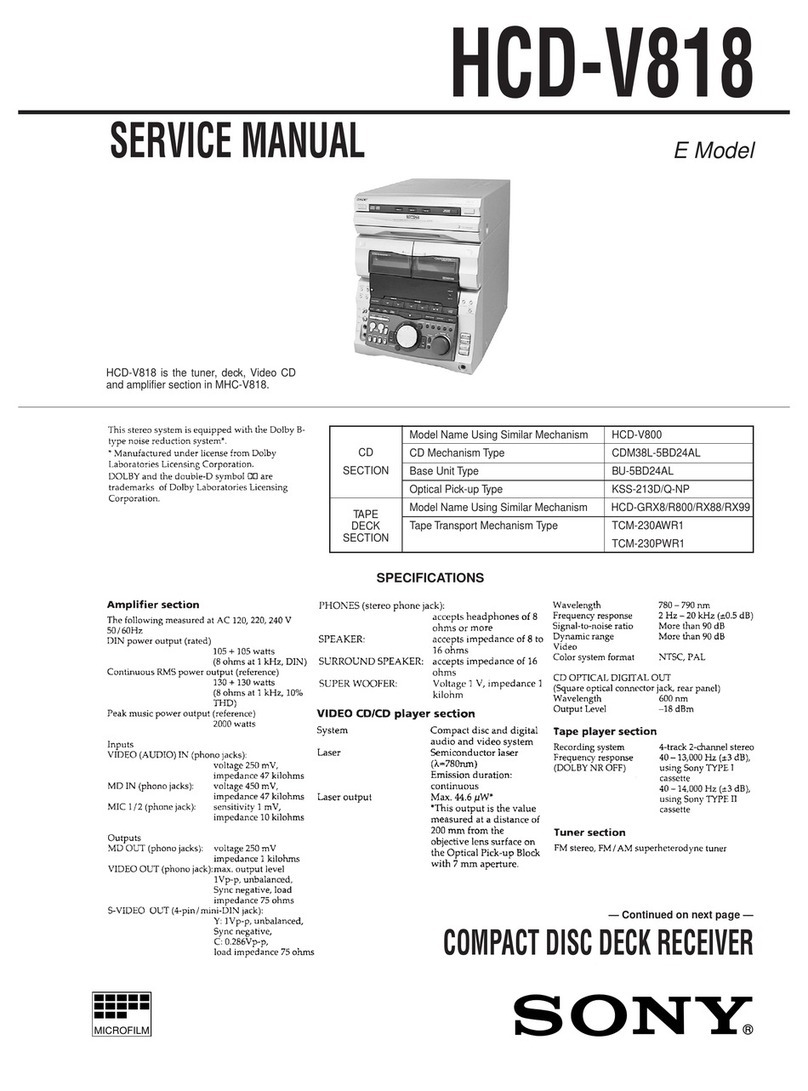

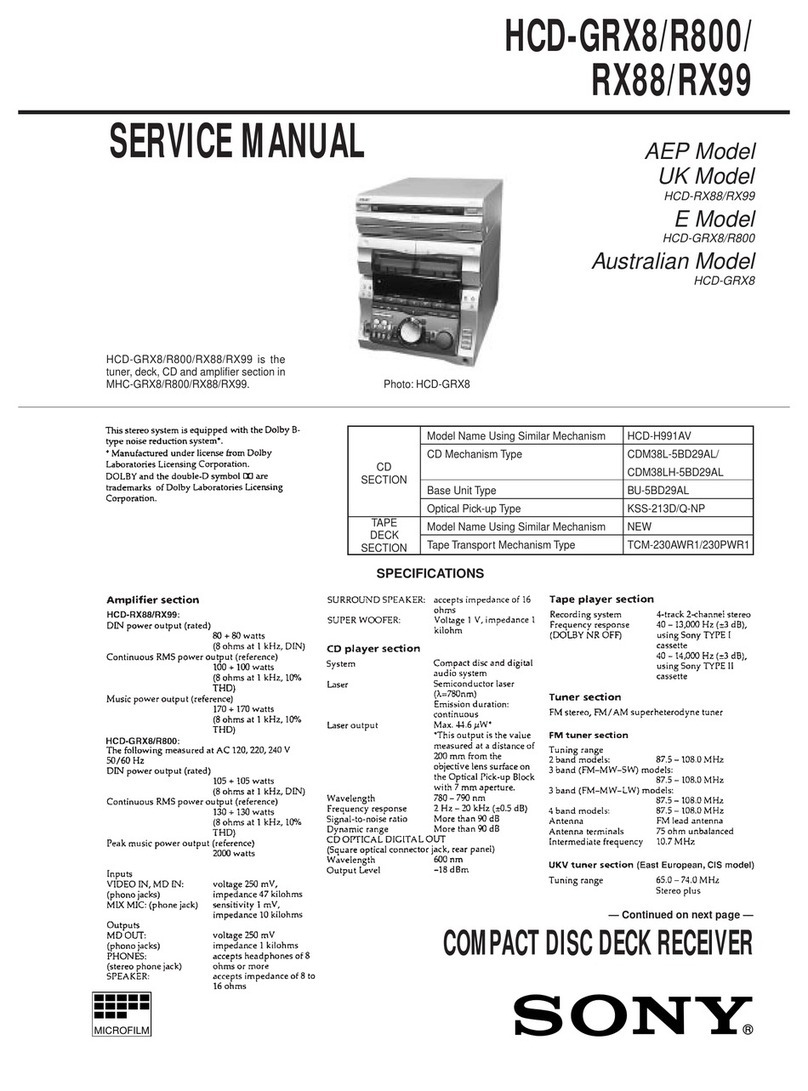

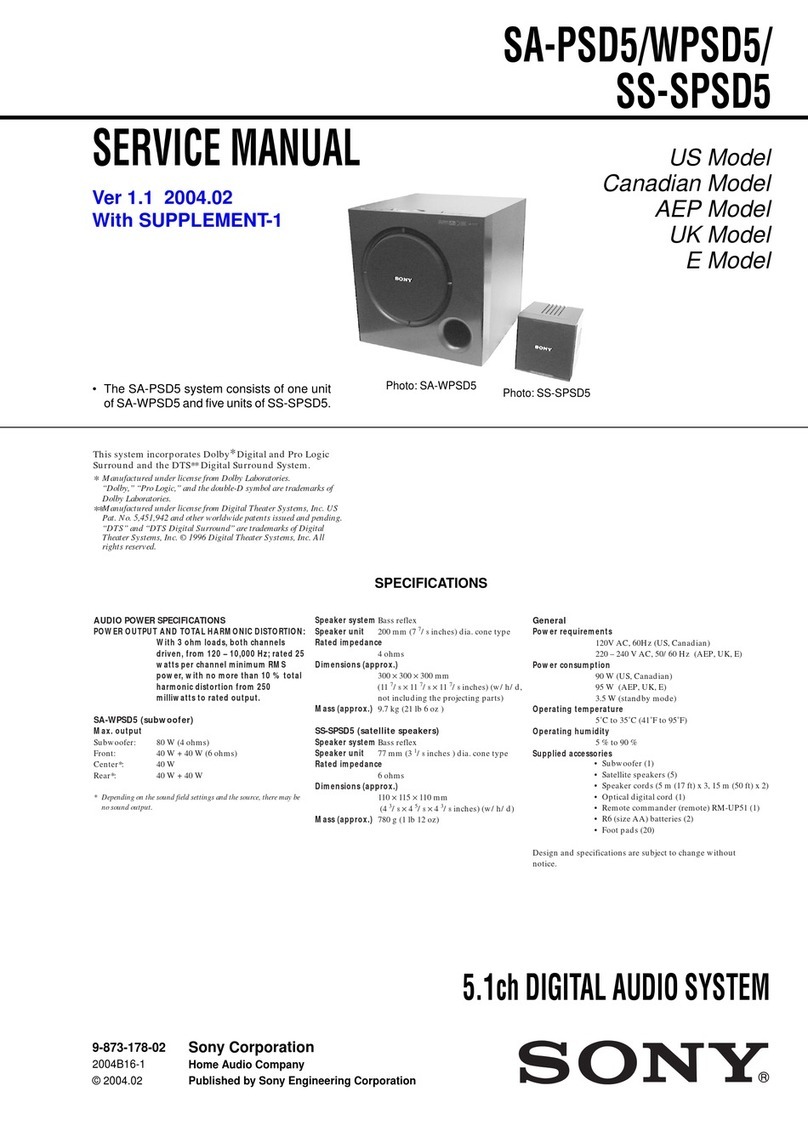

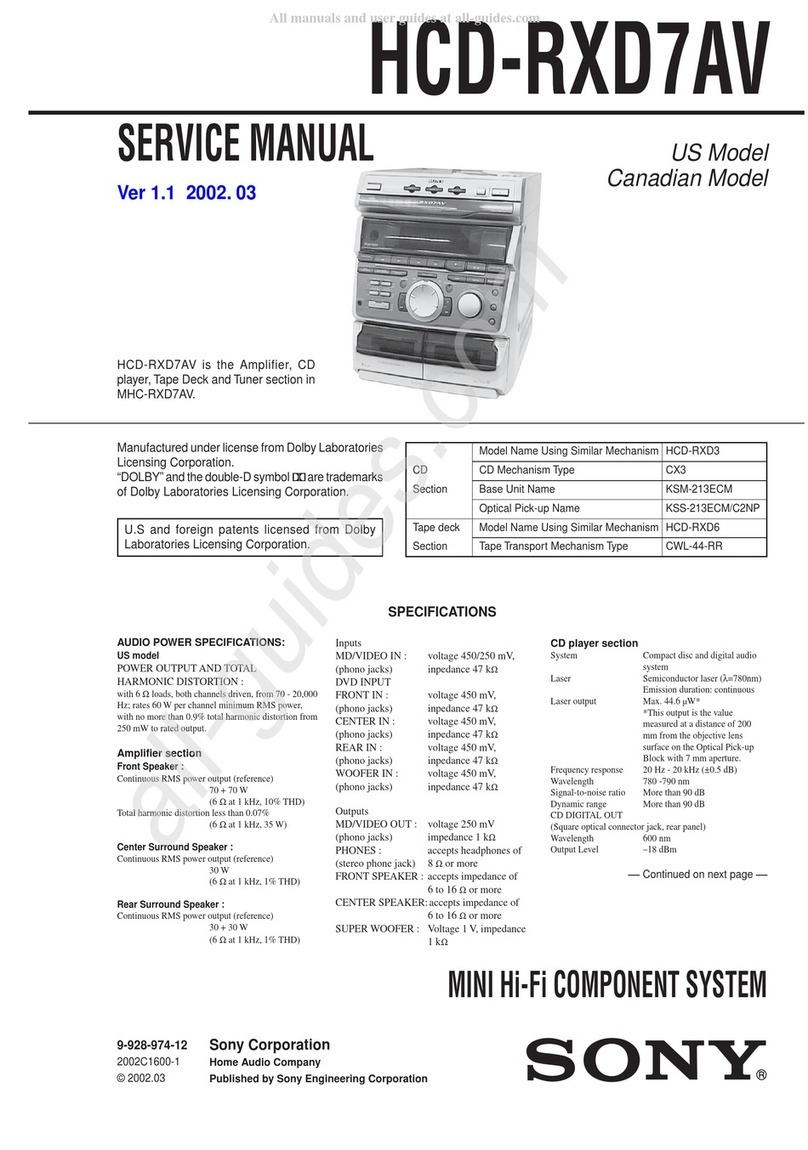

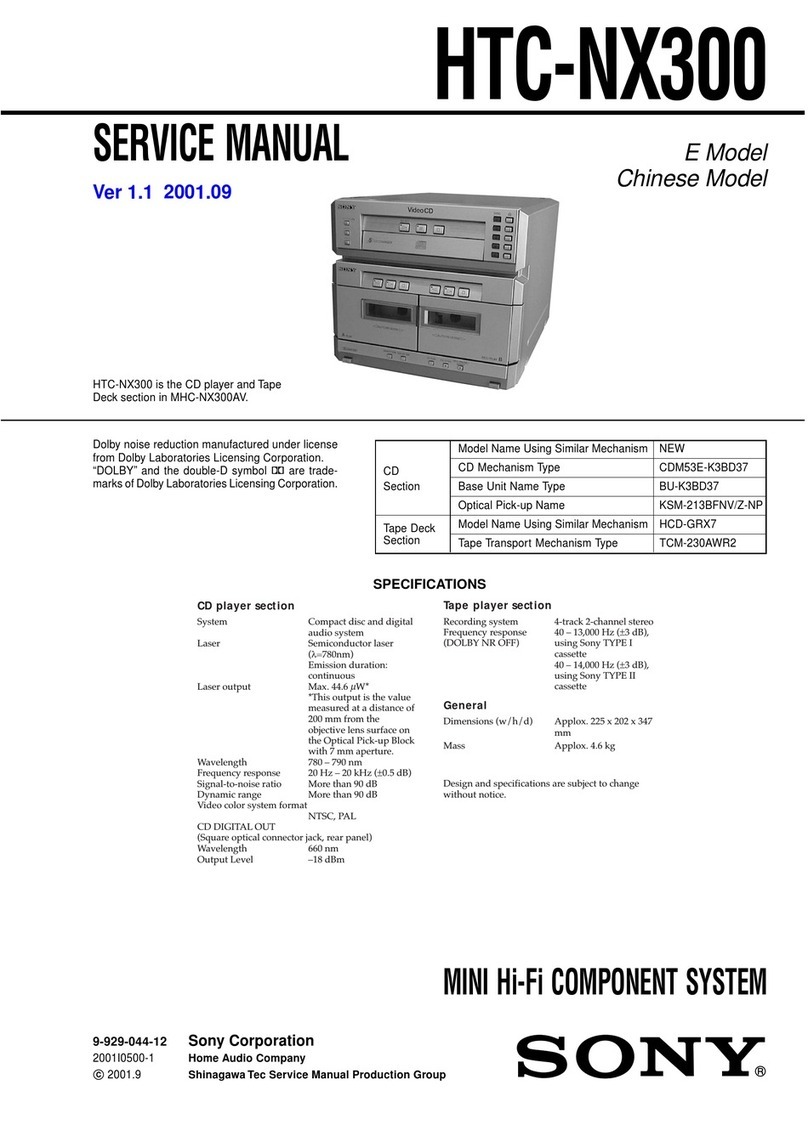

2. GENERAL ..................................................................10

3. DISASSEMBLY

3-1. Loading Panel ..................................................................... 12

3-2. Front Panel .......................................................................... 12

3-3. Cassette Lid and Tape Mechanism...................................... 13

3-4. CD SW Board and Panel Board .......................................... 13

3-5. Disc Tray ............................................................................. 14

4. MECHANICAL ADJUSTMENTS............................15

5. ELECTRICAL ADJUSTMENTS .............................15

6. DIAGRAMS

6-1. Circuit Boards Location...................................................... 20

6-2. Block Diagrams

• CD Section ....................................................................... 21

• Video Section ................................................................... 22

• Deck Section .................................................................... 23

• Main Section .................................................................... 24

• Power Section .................................................................. 25

• Display Section ................................................................ 26

6-3. Printed Wiring Board – BD Section –................................. 28

6-4. Schematic Diagram – BD Section – ................................... 29

6-5. Schematic Diagram – Deck Section – ................................ 30

6-6. Printed Wiring Board – Deck Section –.............................. 31

6-7. Printed Wiring Board – Video Section – ............................. 32

6-8. Schematic Diagram – Video (1/2) Section – ....................... 33

6-9. Schematic Diagram – Video (2/2) Section – ....................... 34

6-10. Schematic Diagram – Main (1/4) Section – ....................35

6-11. Schematic Diagram – Main (2/4) Section – ....................36

6-12. Schematic Diagram – Main (3/4) Section – ....................37

6-13. Schematic Diagram – Main (4/4) Section – ....................38

6-14. Printed Wiring Board – Main Section –........................... 39

6-15. Printed Wiring Board – Panel Section – .......................... 40

6-16. Schematic Diagram – Panel (1/2) Section – .................... 41

6-17. Schematic Diagram – Panel (2/2) Section – .................... 42

6-18. Printed Wiring Board – Leaf SW Section –..................... 43

6-19. Schematic Diagram – Leaf SW Section – ....................... 43

6-20. Schematic Diagram – Surround Section – ....................... 44

6-21. Printed Wiring Board – Surround Section – .................... 44

6-22. Schematic Diagram – Power Section –............................ 44

6-23. Printed Wiring Board – Power Section – ......................... 44

6-24. Schematic Diagram – Trans Section – ............................. 45

6-25. Printed Wiring Board – Trans Section – .......................... 45

6-26. Schematic Diagram – Front Amp Section – .................... 46

6-27. Printed Wiring Board – Front Amp Section –.................. 47

6-28. Schematic Diagram – CD Motor Section – ..................... 48

6-29. Printed Wiring Board – CD Motor Section – .................. 49

6-30. IC Block Diagrams .......................................................... 50

6-31. IC Pin Functions .............................................................. 52