3

SECTION 1

SERVICING NOTES

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emis-

sion, observe from more than 30 cm away from the objective lens.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous ra-

diation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL : USYNLIG LASERSTRÅLING VED ÅBNING NÅR

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT : UNSICHTBARE LASERSTRAHLUNG, WENN

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO

!

:AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALT-

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING : OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

OCH SPÄRREN ÄR URKOPPLAD.BETRAKTA EJ STRÅLEN.

ADVERSEL : USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT

!

:A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

GÁRVESZÉLY

!

KERÜLJE A BESUGÁRZÁST

!

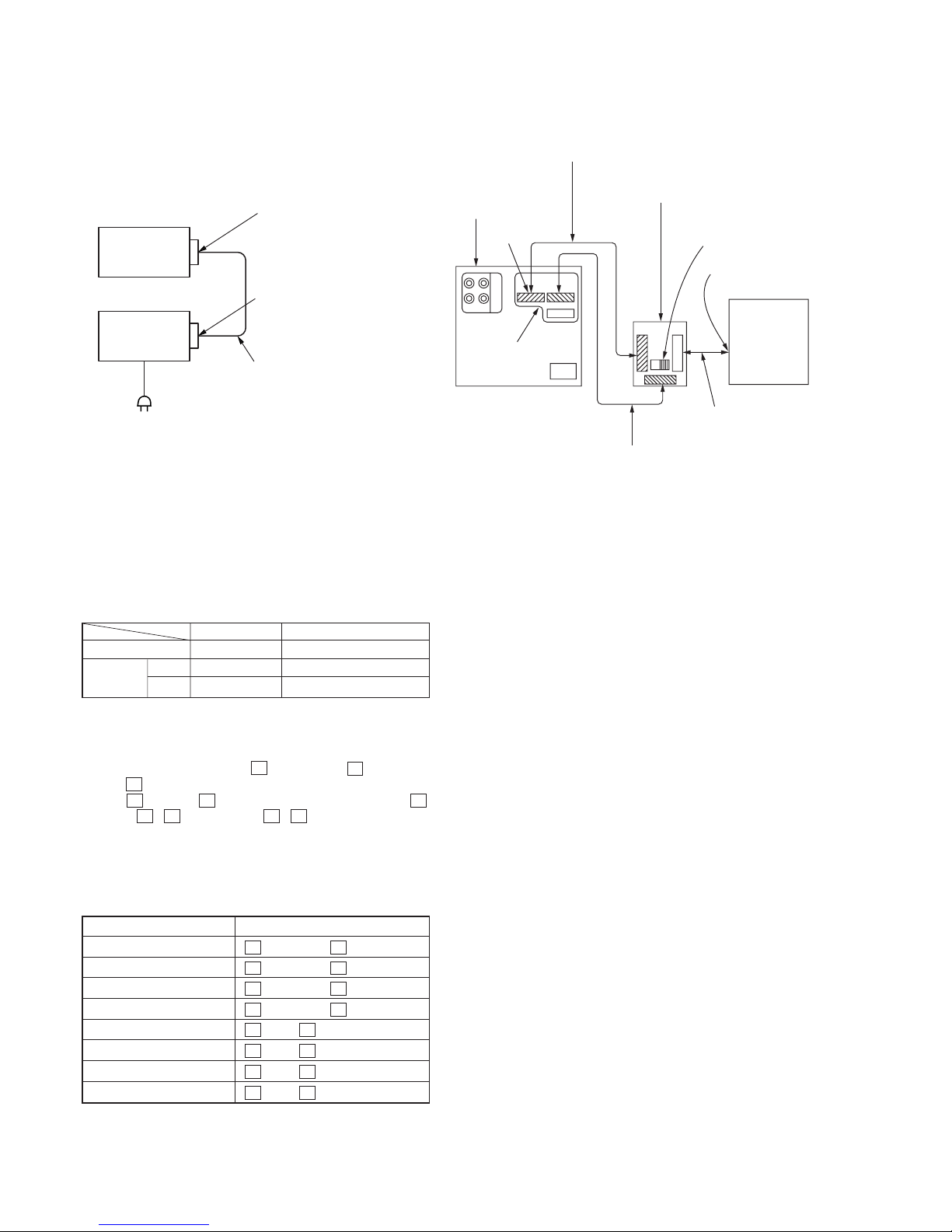

SELF-DIAGNOSIS

This unit is equipped with a self-diagnosis function.

The function is used for diagnosing the conditions of the circuits

of the VIDEO board.

The circuits can be determined if normal or abnormal by the light-

ing of D502 of the VIDEO board.

Lighting of D502

When lit : Operates normally

Blinks repeatedly: The circuit may be faulty.

[VIDEO Board] (Side B)

CN501

SL501

SL502

SL50