—4 —

KV-21ME43KV-21ME43

KV-21ME43KV-21ME43

KV-21ME43

WW

WW

WARNINGS ARNINGS

ARNINGS ARNINGS

ARNINGS AND CAUTIONSAND CAUTIONS

AND CAUTIONSAND CAUTIONS

AND CAUTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD,

BECAUSE OF LIVE CHASSIS. THE CHASSIS OF THIS

RECEIVER IS DIRECTLY CONNECTED TO THE AC POWER

LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS, AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT

ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS ARE

REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURT-CIRCUITER L'ANODE

DU TUBE CATHODIQUE ET CELUI DE L'ANODE DU CAP AU CHASSIS

METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE PEINTE SUR LE

TUBE CATHODIQUE OU AU BLINDAGE DU TUBE CATHODIQUE.

ATTENTION!!!!

!!!!

!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT D'UN CHÁSSIS

SOUS TENSION, UN TRANSFORMATEUR D'ISOLEMENT DOIT ETRE UTILISÉ

LORS DE TOUT DÉPANNAGE. LE CHÁSSIS DE CE RÉCEPTEUR EST

DIRECTEMENT RACCORDÉ À L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE MARQUE SUR

LES SCHEMAS DE PRINCIPE, LES VUES EXPLOSEES ET LES LISTES DE

PIECES SONT D'UNEIMPORTANCE CRITIQUE POUR LA SECURITE DU

FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES COMPOSANTS SONY

DONT LE NUMERO DE PIECE EST INDIQUE DANS LE PRESENT MANUEL OU

DANS DES SUPPLEMENTS PUBLIES PAR SONY. LES REGLAGES DE

CIRCUIT DONT L'IMPORTANCE EST CRITIQUE POUR LA SECURITE DU

FONCTIONNEMENT SONT IDENTIFIES DANS LE PRESENT MANUEL. SUIVRE CES

PROCEDURES LORS DE CHAQUE REMPLACEMENT DE COMPOSANTS

CRITIQUES, OU LORSQU'UN MAUVAIS FONTIONNEMENT SUSPECTE.

SELF-DIAGNOSTIC FUNCTIONSELF-DIAGNOSTIC FUNCTION

SELF-DIAGNOSTIC FUNCTIONSELF-DIAGNOSTIC FUNCTION

SELF-DIAGNOSTIC FUNCTION

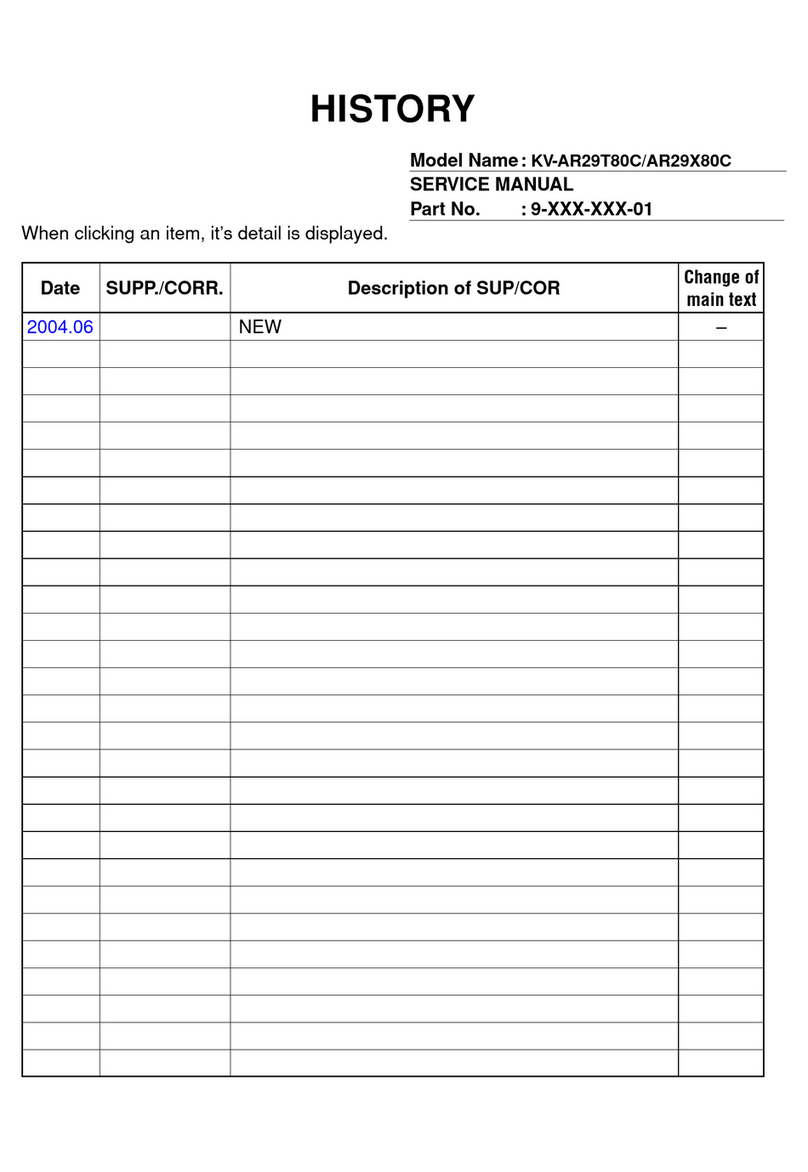

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIME LED will automatically begin to

flash. The number of times the LED flashes translates to a probable source of the problem. A definition of the STANDBY/TIME LED

flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the

emote Commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

Diagnostic TDiagnostic T

Diagnostic TDiagnostic T

Diagnostic Test Indicato sest Indicato s

est Indicato sest Indicato s

est Indicato s

When an error occurs, the STANDBY/TIME LED will flash a set number of times to indicate the possible cause of the problem. If

there is more than one error, the LED will identify the first of the problem areas.

esults for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

No. of Times

STANDBY/TIMER

LED Flashes

Self-diagnosticDisplay/

Diagnostic Result Probable Cause

Location Detected Symptoms

Power does not turn on Does not light • Power cord is not plugged in.

• Fuse is burned out (F601). • Power does not come on.

• No power is supplied to the TV.

• AC power supply is faulty.

+B overcurrent (OCP)* 2 times 2:0 or 2:1 • H.OUT (Q502) is shorted (A Board)

• IC701 and Q701 (C Board) are shorted. • Power does not come on.

• Load on power line is shorted.

Vertical deflection stopped* 4 times 4:0 or 4:1 • +13V is not supplied. (A Board)

• IC541 is faulty. (A Board) • Has entered standby state afterhorizontal raster.

• Vertical deflection pulse isstopped.

• Power line is shorted or power supply is stopped.

White balance failure

(not balanced) 5 times 5:0 or 5:1 • VideoOUT (Q394 to 392) is faulty. (A Board)

• IC301 is faulty. (A Board)

• Screen (G2) is improperly adjusted.**

• No raster isgenerated.

• CRT cathode current detection reference

pulse output is small.

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously.

The symptom that is diagnosed first by the microcontroller is displayed on the screen.

** Refer to Screen (G2) Adjustments in Sections 3 and 4 of this manual.