Sorel HCC 4 User manual

Read carefully before installation, commissioning and operation

Heating-Controller HCC 4

Installation and operating instructions

Weathercontrolled heat circuit regulator

pagepage

Content

A.1 EC declaration of conformity 3

A.2 General instructions 3

A.3 Explanation of symbols 3

A.4 Changes to the unit 4

A.5 Warranty and liability 4

B.1 Specications 5

B.2 Temperature resistance table

for Pt1000 sensors 5

B.3 About the controller 6

B.4 Scope of supply 6

B.5 Disposal and pollutants 6

B.6 Hydraulic variants 7

C.1 Wall installation 8

C.2 Electrical connection 9

C.3 Installing the temperature sensors 10

C.4 Installation of additional functions 10

D Electrical terminals 11

E.1 Display and input 12

E.2 Commissioning help 13

E.3 Free commissioning 13

E.4 Menu sequence and menu structure 14

1. Measurement values 15

2. Statistics 16

2.1 Today 16

2.2 28-days 16

2.3 Operating hours Heat Circuit 16

2.4 Operating hours Heat Circuit 2 16

2.5 Operating hours heating 16

2.6 Error messages 16

2.7 Reset / clear 16

3. Times 17

3.1 Time & Date 17

3.2 Heating circuit day 17

3.3 Heating comfort 17

4. Operating modes 18

4.1 Heat circuit 18

4.2 Heat circuit 2 18

4.3 Manual 19

4.4 Heat circuit reference 19

4.5 14 day reference 19

4.6 Heat circuit2 reference 19

4.7 Heat ciruit2 14 day reference 19

5. Settings Heating circuit 20

5.1 Su/Wi Day 20

5.2 Su/Wi Night 20

5.3 Curve 21

5.4 Day correction 22

5.5 Night correction 22

5.6 Comfort temperature boost 22

5.7 Reference/actual - 23

5.8 Reference/actual + 23

6. Settings Heating circuit 2 24

6.1 Curve 24

6.2 Day correction 25

6.3 Night correction 25

6.4 Comfort temperature boost 25

7. Protective functions 26

7.1 Anti-seizing protection 26

7.2 Frost protection 26

7.3 min.owtemperature 26

7.4 max.ow 27

7.5 max.ow2 27

7.6 Discharge protection 27

8. Special functions 28

8.1 Sensor calibration 28

8.2 Commissioning 28

8.3 Factory settings 28

8.4 Expansions 29

8.5 Mixer 29

8.6 Room controller 30

9. Menu lock 31

11. Language 31

10. Service values 32

Z.1. Malfunctions with error messages 33

Z.2 Replacing the fuse 34

Z.3 Maintenance 34

3

Safety instructions

Danger

Caution

A.1 EC declaration of conformity

ByaxingtheCEmarktotheunitthemanufacturerdeclaresthattheHCC4conforms

tothefollowingrelevantsafetyregulations:

- EClowvoltagedirective

73/23/EEC, as amended by 93/68/EEC

- EC electromagnetic compatibility directive

89/336/EEC version 92/31/EEC version 93/68/EEC

Conformityhasbeenveriedandthecorrespondingdocumentationand

theECdeclarationofconformityarekeptonlebythemanufacturer.

A.2 General instructions It is essential that you read this!

These installation and operating instructions contain basic instructions and important

information regarding safety, installation, commissioning, maintenance and the optimal

use of the unit. Therefore these instructions must be read completely and understood

by the installation technician / specialist and by the system user before installation, com-

missioning and operation of the unit.

The valid accident prevention regulations, VDE regulations, the regulations of the lo-

cal power utility, the applicable DIN-EN standards and the installation and operating

instruction of the additional system components must also be observed. The controller

does not under any circumstances replace any safety devices to be provided by the

customer!

Installation, electrical connection, commissioning and maintenance of the unit may only

becarriedoutbyspecialistswhopossesstheappropriatetraining.

Fortheuser:Makesurethatthespecialistgivesyoudetailedinformationonthefunc-

tionandoperationofthecontroller.Alwayskeeptheseinstructionsinthevicinityofthe

controller.

A.3 Explanation of symbols

Failure to observe these instructions can result in danger to life from elec-

tric voltage.

Danger

Failure to observe these instructions can result in serious damage to

health such as scalding, or even life-threatening injuries.

Caution

Failure to observe these instructions can result in destruction of the unit

or the system, or damage to the environment.

Informationwhichisespeciallyimportationforthefunctionandoptimal

use of the unit and the system.

4

A.4 Changes to the unit

A.5 Warranty and liability

Thecontrollerhasbeenmanufacturedandtestedwithregardtohighquality

andsafetyrequirements.Theunitissubjecttothestatutoryguarantee

periodoftwoyearsfromthedateofsale.

Thewarrantyandliabilityshallnotinclude,however,anyinjurytopersonsormaterial

damagethatisattributabletooneormoreofthefollowingcauses:

- Failure to observe these installation and operating instructions

- Improper installation, commissioning, maintenance and operation

- Improperly executed repairs

- Unauthorised structural changes to the unit

- Installation of additional components that have not been tested together

withtheunit

- Any damage resulting from continued use of the unit despite an obvious defect

- Failure to use original spare parts and accessories

- Use of the device for other than its intended purpose

- Operationaboveorbelowthelimitvalueslistedinthespecications

- Force majeure

- Changes,additionstoorconversionoftheunitarenotpermittedwithout

writtenpermissionfromthemanufacturer

- Itislikewiseforbiddentoinstalladditionalcomponentsthathavenot

beentestedtogetherwiththeunit

- If it becomes clear that safe operation of the unit is no longer possible,

for example because of damage to the housing, then turn the controller

oimmediately

- Any parts of the unit or accessories that are not in perfect condition must

be exchanged immediately

- Use only original spare parts and accessories from the manufacturer.

- Markingsmadeontheunitatthefactorymustnotbealtered,removed

or made illegible

- Only the settings actually described in these instructions may be made

on the controller

Changes to the unit can compromise the safety and function of theunit or

the entire system.

Safety instructions

Danger

5

B.2 Temperature resistance table for Pt1000 sensors

B.1 Specications

Electrical specications:

Mains Voltage 230VAC +/- 10%

Mainsfrequency 50...60Hz

Powerconsumption 2VA

Totalswitchedpower 460VA(Relayoutputs1-5)

Switchedpowerperrelay 460VAforAC1/185WforAC3

Internalfuse 2Aslowblow250V

Protection category IP40

Protection class II

Sensor inputs 5x Pt1000 temperature sensor

1x Room

Measuring range -40 to110°C

Permissible ambient conditions:

Ambient temperature

for controller operation 0°C...40°C

for transport/storage 0°C...60°C

Air humidity

for controller operation max. 85% humidity at 25°C

for transport/storage no moisture condensation permitted

Other specications and dimensions

Housing design 2-part, ABS plastic

Installation methods Wall installation, optionally panel installation

Overall dimensions 163mm x 110mm x 52mm

Aperture installation dimensions157mm x 106mm x 31mm

Display Fully graphical display 128 x 64 dots

Light diode Multicolour

Operation 4entrykeys

Temperature sensors: (maynotbeincludedinthescopeofsupply)

Immersion sensor Pt1000, e.g. immersion sensor TT/P4

Pipe-mounted sensor Pt1000, e.g. pipe-mounted sensor TR/P4

Outdoor sensor Pt1000, e.g. outdoor sensor TA52

Remote adjuster Pt1000, Typ RC21

Sensor leads 2x0.75mm² extendable up to 30m

°C 0 10 20 30 40 50 60 70 80 90 100

Ω1000 1039 1077 1116 1155 1194 1232 1270 1308 1347 1385

Description of controller

6

B.4 Scope of supply

• Heating controller HCC4

• 3screws3,5x35mmand3plugs6mmforwallinstallation

• 6strainreliefswith12screws,replacementfuse2AT

• installation and operating instructions HCC4

Optionallycontaineddependingondesign/order:

• 1xoutdoorsensore.g.TA52(Pt1000)

• 1-2xpipe-mountedsensore.g.TR/P4(Pt1000)

• 1xbuersensore.g.TT/P4(Pt1000)

• 1xIndoorsensor/remoteadjusterwithmodeswitchRC21

• 1x Immersion sleeve e.g. TH150

• various additional functions expansion boards

B.5 Disposal and pollutants

The unit conforms to the European RoHS directive 2002/95/EC for the restriction of the

useofcertainhazardoussubstancesinelectricalandelectronicequipment.

Caution

Theunitmustnotunderanycircumstancesbedisposedofwithordinary

household refuse. Dispose of the unit only at appropriate collection points

orshipitbacktothesellerormanufacturer.

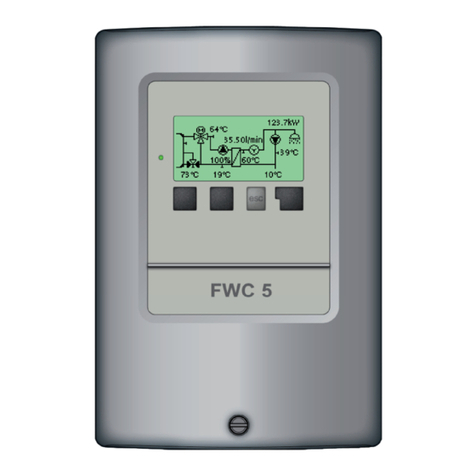

B.3 About the controller

TheweathercontrolledHeatCircuitControllerHCC4facilitatesecientuseandfunc-

tion control of your heating system. The device is impressive

most of all for its functionality and simple, almost self-explanatory operation.

Foreachstepintheinputprocesstheindividualentrykeysareassigned

to appropriate functions and explained. The controller menu contains

headwordsforthemeasuredvaluesandsettings,aswellashelptextsor

clearly-structured graphics.

ImportantcharacteristicsoftheHCC4:

• Depiction of graphics and texts in a lighted display

• Simpleviewingofthecurrentmeasurementvalues

• Statistics and monitoring of the system by means of statistical graphics, etc.

• Extensivesettingmenuswithexplanations

• Menublockcanbeactivatedtopreventunintentionalsettingchanges

• Resetting to previously selected values or factory settings

• various additional functions are available e.g. 0...10V connection for boiler control

Description of controller

7

Regulated heating circuit

withoutadd.heating

withoutbuer

Regulated heating circuit

withadd.heating

withoutbuer

Regulated heating circuit

withadd.heating

withbuer

2heat.circuits(reg./notreg.)

withadd.heating

withoutbuer

2heat.circuits(reg./notreg.)

withadd.heating

withoutbuer

2heat.circuits(reg./notreg.)

withadd.heating

withbuer

M

M

M

M

M

HCC

3

4

M

B.6 Hydraulic variants

Description of controller

Caution

Thefollowingillustrationsshouldbeviewedonlyasschematicdiagrams

showingtherespectivehydraulicsystems,anddonotclaimtobecomple-

te. The controller does not replace safety devices under any circumstan-

ces. Depending on the specic application, additional system compo-

nentsandsafetycomponentsmaybemandatory,suchascheckvalves,

non-return valves, safety temperature limiters, scalding protectors, etc.,

and must therefore be provided.

1

3

5

2

4

6

8

C.1.1

C.1.2

Caution

C.1 Wall installation

Install the controller only in dry areas and under the ambient conditions described

underB.1„Specications“.Carryoutthefollowingsteps1-8.

1.Unscrewcoverscrewcompletely

2. Carefully pull upper part of housing from

lowerpart.

3. Set upper part of housing aside, being

sure not to touch the electronics when

doing so.

4. Hold the lower part of the housing up

totheselectedpositionandmarkthe3

mountingholes.Makesurethatthewall

surface is as even as possible so that

the housing does not become distorted

whenitisscrewedon.

5. Using a drill and size 6 bit, drill 3 holes at

thepointsmarkedonthewallandpush

in the plugs.

6. Insert the upper screw and screw it in

slightly.

7. Fit the upper part of the housing and in-

serttheothertwoscrews.

8. Align the housing and tighten the three

screws.

Installation

9

C.2 Electrical connection

Installation

Danger

Before working on the unit, switch o the power supply and secure it

againstbeingswitchedonagain!

Checkfortheabsenceofpower!

Electrical connections may only be made by a specialist and in comp-

liancewiththeapplicableregulations.Thecontrollermaynotbeputinto

operationifthereisvisibledamagetothehousing,e.g.cracks.

Caution

Low-voltagecablessuchastemperaturesensorcablesmustberouted

separately from mains voltage cables. Feed temperature sensor cables

only into the left-hand side of the unit, and mains voltage cables only into

the right-hand side.

Caution

The customer must provide an all-pole disconnecting device, e.g. a hea-

tingemergencyswitch.

Caution

The cables being connected to the unit must not be stripped by more than

55mm,andthecablejacketmustreachintothehousingjusttotheother

side of the strain relief.

1. Opencontrollerhousing(seeC.1.1)

2. Stripcablesmax.55mm,insert,tthe

strain relief devices, strip the last 8-9

mmofthewires.(Fig.C.2.1)

3. Open the terminals using a suitable

screwdriver(Fig.C.2.1)andmakeelec-

tricalconnectionsonthecontroller(see

sectionD)

4. Retupperpartofhousingandfasten

withscrew.

6. Switch on mains voltage and place

controller in operation

8...9

~30°

max. 55

C.2.1

10

Installation

C.3 Installing the temperature sensors

C.4 Installation of the additional functions via clamps Z1/Z2

Der Regler arbeitet mit Pt1000-Temperaturfühlern, die für eine gradgenaue Tempera-

turerfassungsorgen,umdieAnlagenfunktionregeltechnischoptimalsicherzustellen.

Caution

If desired the sensor cables can be extended to a maximum of 30m using a

cablewithacross-sectionofatleast0.75mm².

Makesurethatthereisnocontactresistance!

Position the sensor precisely in the area to be measured!

Onlyuseimmersion,pipe-mountedorat-mountedsensorsuitableforthespe-

cicareaofapplicationwiththeappropriatepermissibletemperaturerange.

Caution

S6isbydefaultconnectedbyjumperwiththeterminalblockS-toenablethe

heatingcircuitfunctions.Ifthejumperisremoved,theheatingcircuitisswitched

o.WhenconnectingtheremoteadjusterRC21thejumperhastoberemoved.

If a third party external thermostat is connected, it’s electrical contacts has to be

oatingandoflowresistance=0Ohm.

Caution

Connect sensor S3 in an optional 2nd heat circuit.

Theoptionalsensor4isusedtoswitchotheadditionalheatingatthebuer

storage.

The temperature sensor cables must be routed separately from mains voltage

cables, and must not, for example, be routed in the same cable duct!

Caution

Theinstructionsaresuppliedwiththeexpansionboard.Theinstallationhasto

becommencedaccordinglyandallwarningshavetobeobserved.

Caution

11

Caution

Left-hand terminal

compartment only for

lowvoltageif

max. 12VAC/DC

Danger

Right-hand terminal

compartment only for mains

voltages of

230VAC 50-60Hz

Low voltage max. 12VAC/DC

connection in the left-hand terminal com-

partment!

Terminal: Connectionfor:

- JumperterminalblockS-

S1 outdoor

S2 heating circuit

S3 heating circuit 2

S4 buer

S5 indoor sensor

S6 remote adjuster*

+ not used

Z1 Option / add. function

Z2 Option / add. function

Use terminal block S- for connecting the

sensor earths of S1-S6. The polarity of the

sensors is freely selectable.

The sensors S3-S6 are optional, depen-

ding on the hydraulic variant chosen.

Mains Voltage 230VAC 50-60Hz con-

nection in the right-hand terminal com-

partment.

Terminal: Connectionfor:

N JumperterminalblockN

L Mains phase conductor L

R1 Heat circuit pump

R2 Mixer open

R3 Mixer close

R4 Heatcircuitpump(HC2)

R5 add. heating

R5I add. heating

The PE protective conductor must be con-

nectedtothePEmetalterminalblock!

*Note:IftheremoteadjusterRC21oradierentexternaloatingthermostatis

connected, the bridge at S6 has to be removed.

ConnectionsMainsVoltage:

- Protective conductor PE metal terminal

block

-NeutralconductorterminalblockN

- Mains phase conductor L

-SwitchoutputR1-R4

- Floating contact at R5/R5I

Caution:Onlysuitablefor230V!

Connectionslowvoltage:

- Temperature sensors S1 - S6

(polarityfreelyselectable)

- Optional additional functions Z1/Z2

D Electrical terminals

Installation

12

Examplesofdisplaysymbols:

Heating circuit pump

(rotateswhenactive)

Heating circuit mixer

(blackwhenactive)

HC-Daymode(Timeprogr.)

HC-Nightmode(Timeprogr.)

HC-Comfortmode(Timeprogr.)

Day mode

Night mode

Day mode due to RC21

Night mode due to RC21

Additional heating

Reference value mode

Reference value 14 day

externalthermostato

Warning / Error message

Newinformationavailable

(1)

(2)

(3)

(4)

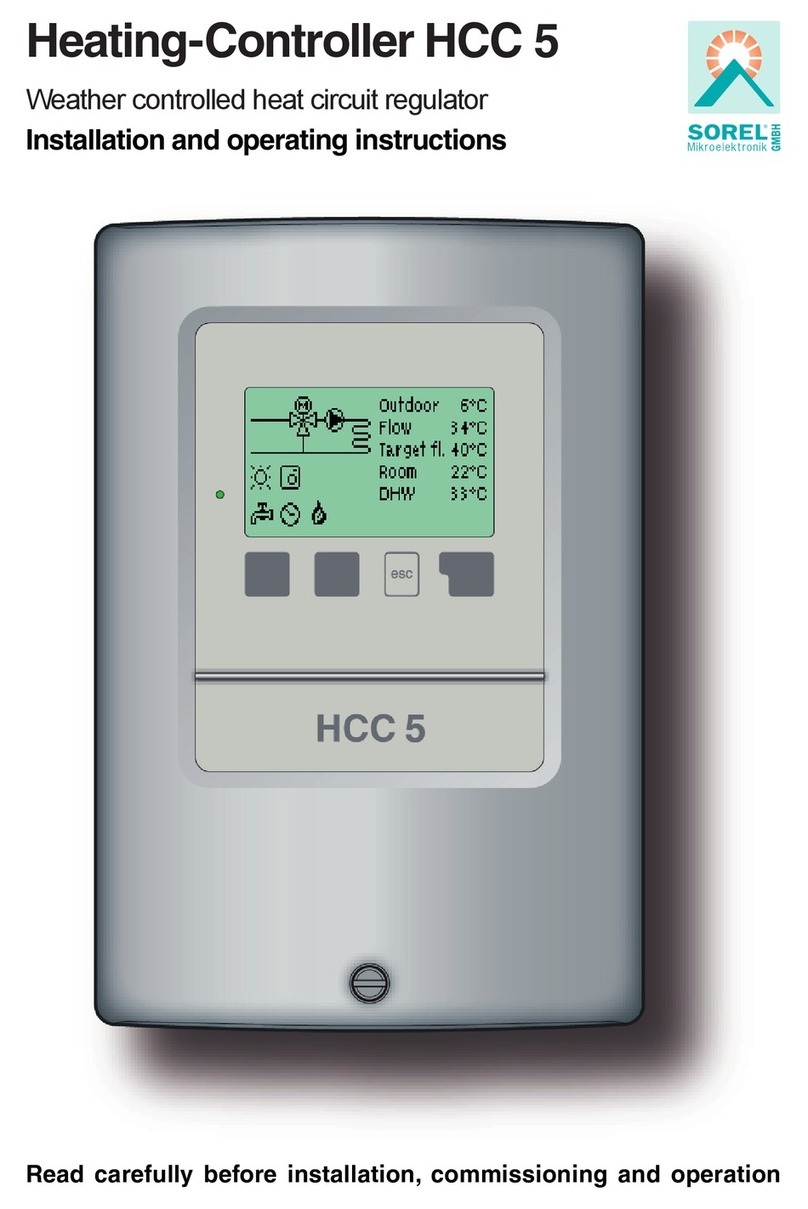

Thedisplay(1),withitsextensivetextand

graphics mode, is almost self-explanatory,

allowingeasyoperationofthecontroller.

TheLED(2)lightsupgreenwhenarelay

isswitchedon.

TheLED(2)lightsupredwhenoperating

mode„O“isset.

TheLED(2)ashesslowlyredintheope-

ratingmode„Manual“.

The LED (2) ashes quickly red when an

error is present.

Entries are made using four keys (3+4), to

which dierent functions are assigned de-

pending on the situation. The „esc“ key (3)

is used to cancel an entry or to exit a menu.

Ifapplicabletherewillbearequestforcon-

firmationastowhetherthechangeswhich

have been made should be saved.

The function of each of the other three

keys(4)isshowninthedisplaylinedirectly

above the keys; the right-hand key is ge-

nerally has a con rmation and selection

function.

Examplesofkeyfunctions:

+/- =enlarge/shrinkvalues

▼/▲ =scrollmenudown/up

yes/no =approve/reject

Info =additionalinformation

Back =topreviousscreen

ok =conrmselection

Conrm =conrmsetting

Operation

E.1 Display and input

Examplesofdisplaysymbols:

13

Operation

E.2 Commissioning help

E.3 Free commissioning

Ifyoudecidenottousethecommissioninghelp,youshouldmakethenecessaryset-

tingsinthefollowingsequence:

- Menu 10. Language

- Menu 3. Time, date and operating times

- Menu 5 Settings for heat circuit, all settings

- Menü 6. Protective functions if necessary

- Menü 7. Special functionsif necessary

Finally,menu4.2underoperatingmode„Manual“shouldbeusedtotesttheswitchout-

putswiththeconsumersconnected,andtocheckthesensorvaluesforplausibility.Then

switchonautomaticmode.

tions ofeachparameterin the display.Pressing the„esc“ keytakesyoubackto the

previousvaluesoyoucanlookattheselectedsettingagainoradjustitifdesired.Pres-

singthe„esc“morethanoncetakesyoubackstepbysteptotheselectionmode,thus

cancellingthecommissioninghelp.Finally,menu4.3underoperatingmode„Manual“

shouldbeusedtotesttheswitchoutputswiththeconsumersconnected,andtocheck

thesensorvaluesforplausibility.Thenswitchonautomaticmode.

The rst time the controller is turned on

and after the language and time are set, a

query appears as towhetheryouwantto

parametrise the controller using the com-

missioning help or not. The commissioning

help can also be terminated or called up

again at any time in the special functions

menu. The commissioning help guides you

through the necessary basic settings in the

correct order, and provides brief descrip-

Caution

Observe the explanations for the the individual parameters on the follo-

wingpages,andcheckwhetherfurthersettingsarenecessaryforyour

application.

Caution

Observe the explanations for the the individual parameters on the follo-

wingpages,andcheckwhetherfurthersettingsarenecessaryforyour

application.

14

1. Measurements

4. Operating

7. Protections

2. Statistics

5. HC settings

8. Special functions

3. Times

6. HC2 settings

9. Menu lock

10. Service Data

11. Language

E.4 Menu sequence and menu structure

Operation

Currenttemperaturevalueswith

explanations

Functioncontrolofthesystemwith

operating hours, etc.

Operating times for heating circuit and hot

water,settingtheclock

Operating times for heating circuit and hot

water,manualmode

Set parameters for the heating circuit

Anti-seizing protection, Frost prot.,

Anti-Legionella activation

Sensor calibration, Remote adjuster, Mi-

xer, etc.

Against unintentional setting changes at

critical points

For diagnosis in the event of an

error

Selection of the menu language

Set parameters for the 2nd heating circuit

The graphics or overview mode appears

when no key has been pressed for 2 mi-

nutes,orwhenthemainmenuisexitedby

pressing„esc“.

Pressing a key in graphics or overview

modetakesyoudirectlytothemainmenu.

Thefollowingmenuitemsarethenavailab-

leforselectionthere:

15

Menu “1. Measurement values” serves to

display the currently measured tempera-

tures.

The menu is closed by pressing “esc” or

selecting“Exitmeasurementvalues”.

Selecting “Info” leads to a brief help text

explaining the measurement values.

Selecting“Overview”or“esc”exitstheInfo

mode.

Caution

If“Error”appearsonthedisplayinsteadofthemeasurementvalue,then

there may be a defective or incorrect temperature sensor.

If the cables are too long or the sensors are not placed optimally, the

result may be small deviations in the measurement values. In this case

thedisplayvaluescanbecompensatedforbymakingentriesonthecon-

troller.

Followtheinstructionsunder8.3.

What measurement values are displayed depends on the selected pro-

gram,theconnectedsensorsandthespecicdevicedesign.

Measurement values

1. Measurement values

16

2. Statistics

Menu “2. Statistics” is used for function

control and long-term monitoring of the

system.

The menu is closed by pressing “esc” or

selecting“Exitstatistics”.

2.1 Today

Flow temperature for the present day

Inthegraphicaloverviewthecharacteristicsofoutdoor-andowtemperatureforthe

presentdayisshownfrom0-24h.Therightbuttonchangestheunitoftimeandthetwo

left buttons scroll through the diagram.

2.2 28-days

Flow temperature during the last 28 days

Inthegraphicaloverviewthecharacteristicsoftheoutdoorandowtemperatureduring

thelast28daysisshown.Therightbuttonchangestheunitoftime(Days)andthetwo

left buttons scroll through the diagram.

2.3 Operating hours Heat Circuit

Display of operating hours of the heat pump connected to the controller, and the date

the measurement started.

2.4 Operating hours Heat Circuit 2

Display of operating hours of the 2nd heat pump connected to the controller, and the

date the measurement started.

2.5 Operating hours heating

Display of operating hours of additional heating, and the date the measurement star-

ted.

2.6 Error messages

Displayofthelastthreeerrorsinthesystemwithindicationofdateandtime.

2.7 Reset / clear

Resettingandclearingtheindividualstatistics.Selecting“Allstatistics”clearseverything

except for the error log.

Statistics

Caution

For system data statistics it is essential for the time to be set accurately

onthecontroller.Pleasenotethattheclockcontinuestorunforabout24

hours if the mains voltage is interrupted, and after that has to be reset.

Improper operation or an incorrect time may result in data being cleared,

recordedincorrectlyoroverwritten.

The manufacturer accepts no liability for the recorded data!

17

3. Times

Caution

Menu “3. Times” is used to set the time,

date, operating times for the heating circuit

andhotwater.

The menu is closed by pressing “esc” or

selecting“Exitdisplaymode”.

The associated temperature re-

ference values are specied in

menu5“Settings”!

3.1 Time & Date

This menu is used to set the current time and date.

3.2 Heating circuit day

Thismenuisusedtoselectthedaytimemodetimesfortheheatingcircuit;threetime

periodscanbespeciedforeachweekdayandcopiedovertothefollowingdays.

Setting range: Three time ranges for each day of the week

Default: Mo-Su 6:00-22:00

Note: See 5. for the associated temperature settings

3.3 Heating comfort

Thismenucanbeusedtoselectatimerangeforeachdayoftheweekinwhichthe

heatingcircuitissuppliedwithanincreasedcomforttemperature,e.g.forquickheating

in the morning.

Setting range: One time range for each day of the week

Default: Mo-Su o

Note: See 5. for the associated temperature settings.

Times

Caution

For proper functioning of the controller and statistics for the system data it

is essential for the time to be set accurately on the controller. Please note

thattheclockcontinuestorunforabout24hoursifthemainsvoltageis

interrupted, and after that has to be reset.

Caution

Timesthatarenotspeciedareautomaticallyconsideredtobenighttime

mode. The set times are only taken into account in the heating circuit

operatingmode“Automatic”

18

4. Operating modes

Menu“4.Operatingmodes”isusedtospe-

cify the operating modes for the heating

circuit.

After an interruption of the mains voltage

the controller automatically returns to the

last operating mode selected!

The menu is closed by pressing “esc” or

selecting“Exitoperatingmodes”.

Auto=Automatic/Normalmodeusingthesettimes.

Continous Day =Thesetvaluesfordaymodeareused.

Continous Night =Thesetvaluesfornightmodeareused.

Reference Value =Fixedowtemperatureregardlessoftheoutdoortemperature.The

desiredowtemperaturehastobesetinmenu4.3.

14 day reference value =Specicxedowtemperaturescanbesetforthenext14

days in menu 4.4. After 14 days, the reference temperature of the 14th day is used until

the operating mode is changed.

O=Heatingcircuitisswitchedo(exceptFrostprotection)

Settings range: Auto, Continous day, Continous night, Reference value, 14 day refer-

ence, O

Default: Automatic

Auto=Automatic/Normalmodeusingthesettimes.

Continous Day =Thesetvaluesfordaymodeareused.

Continous Night =Thesetvaluesfornightmodeareused.

Reference Value =Fixedowtemperatureregardlessoftheoutdoortemperature.The

desiredowtemperaturehastobesetinmenu4.6.

14 day reference value =Specicxedowtemperaturescanbesetforthenext14

days in menu 4.7. After 14 days, the reference temperature of the 14th day is used until

the operating mode is changed.

O=Heatingcircuitisswitchedo(exceptFrostprotection)

Settings range: Auto, Continous day, Continous night, Reference value, 14 day refer-

ence, O

Default: Automatic

4.1 Heat circuit

4.2 Heat circuit 2

Operating modes

Thecontrollerworkswiththesetoperatingtimesandthecorresponding

dierentreferenceowtemperaturevaluesonlyintheautomaticmode.

Caution

19

In Manual mode the individual relay outputs and the connected consumers can be che-

ckedforproperfunctioningandcorrectassignment.

Functioninmanualmode:

Therelaysandthustheconnectedconsumerareswitchedonandobypressingakey,

withnoregardtothecurrenttemperaturesandtheparameterswhichhavebeenset.At

thesametime,thecurrentmeasurementvaluesoftemperaturesensorsarealsoshown

in the display for the purposes of function control.

Ifoperatingmode“Referencevalue”isselected,(Menu4.1),thereferenceowtempe-

rature has to be set here, regardless of the curve/outdoor temperature.

Settingsrange:10°Cto75°C

Default: 30 °C

Ifoperatingmode“Referencevalue”isselected,(Menu4.2),thereferenceowtempe-

rature has to be set here, regardless of the curve/outdoor temperature.

Settingsrange:10°Cto75°C

Default: 30 °C

Ifoperatingmode“14dayreferencevalue”isselected(Menu4.1),thereferenceow

temperature for each of the 14 days can be set here.

Intherstmenu4.4.1thestartingtimeoftheprogramisshown.Tostarttheprogram,

hit restart.

Hitting“restart”againwillresetthe14dayreferenceprogramandstartitatday1.

Ifoperatingmode“14dayreferencevalue”isselected(Menu4.2),thereferenceow

temperature for each of the 14 days can be set here.

Intherstmenu4.7.1thestartingtimeoftheprogramisshown.Tostarttheprogram,

hit restart.

Hitting“restart”againwillresetthe14dayreferenceprogramandstartitatday1.

4.3 Manual

4.4 Heat circuit reference

4.6 Heat circuit2 reference

4.5 14 day reference

4.7 Heat ciruit2 14 day reference

Operating modes

Danger

Theoperatingmode“Manual”mayonlybeused byspecialistsforbrief

function tests, e.g. during commissioning!

20

The menu is closed by pressing “esc” or

selecting“Exitsettings”.

Settings Heating circuit

5. Settings Heating circuit

Thenecessarybasicsettingsrequiredfor

the control function of the heating circuit

aremadeinmenu“5.SettingsHC”.

This does not under any circum-

stances replace the safety facilities

to be provided by the customer!

Caution

Summer/Winter changeover in daytime mode

If this value is exceeded at outdoor sensor S1 during the daytime mode times, the con-

trollerautomaticallyswitchestheheatingcircuito=Summermode.

If the outdoor temperature drops below this value, the heating circuit is switched on

again=Wintermode.

Setting range: from 0°C to 30°C / default setting: 18°C

Summer/Winterchangeover in nighttime mode

If this value is exceeded at outdoor sensor S1 during the nighttime mode times, the con-

trollerautomaticallyswitchestheheatingcircuito=Summermode.

If the outdoor temperature drops below this value, the heating circuit is switched on

again=Wintermode.

Settings range: 0°C to 30°C / Default: 12°C

5.1 Su/Wi Day

5.2 Su/Wi Night

Caution

In addition to the operating times in normal daytime operation, this setting is

alsovalidfortimeswithactivatedcomforttemperatureboostandactivated

low-rateperiodboost.

Table of contents

Other Sorel Controllers manuals

Popular Controllers manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1400 user manual

ComAp

ComAp IM-NT-BB reference guide

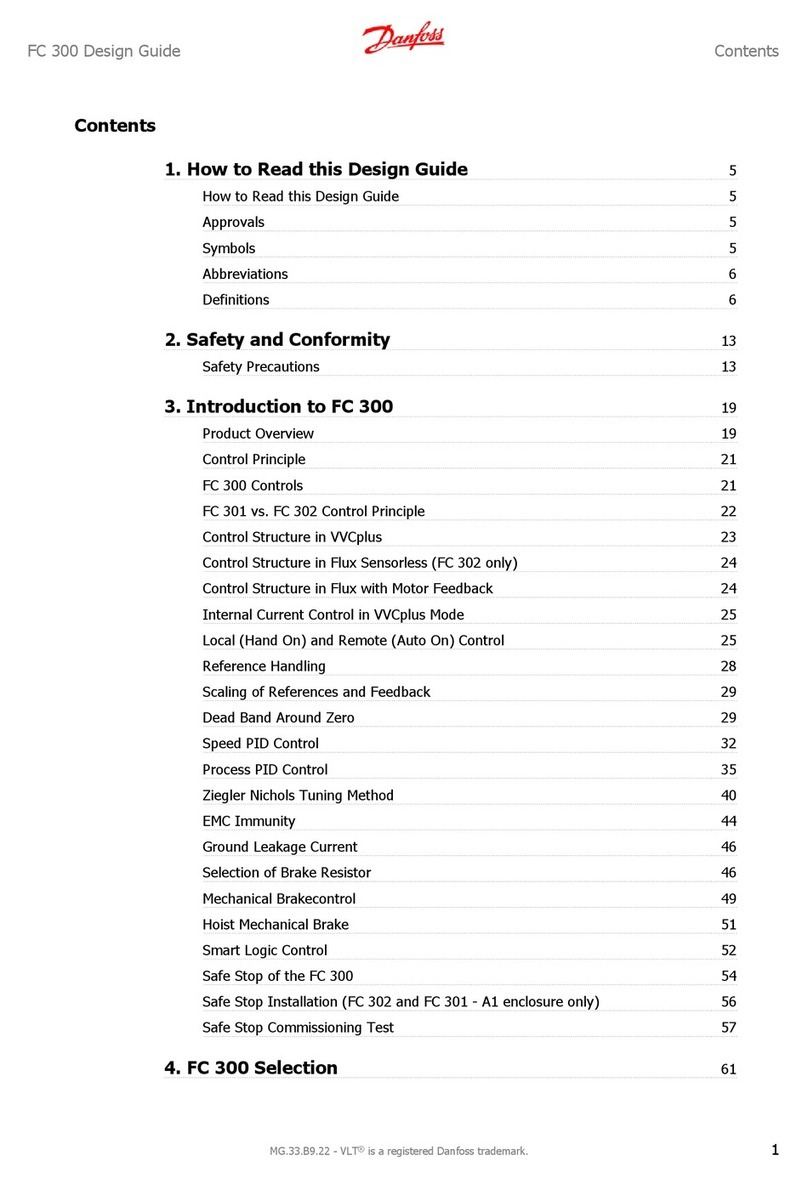

Danfoss

Danfoss FC 300 Design guide

Danfoss

Danfoss VLT AutomationDrive FC 300 Design guide

RBH Access Technologies

RBH Access Technologies UNC100 manual

TWR Lighting

TWR Lighting E-2/3DB manual

CAL Controls

CAL Controls CAL 9500P Abridged user manual

Marathon Electric

Marathon Electric DVR 2000E Installation, operation and maintenance manual

Camus Hydronics

Camus Hydronics ProtoNode FPC-N34 Startup guide

Gavita

Gavita ECM1 AU manual

GFB

GFB Sig-naTrak ACE User's manual supplement

Aurora

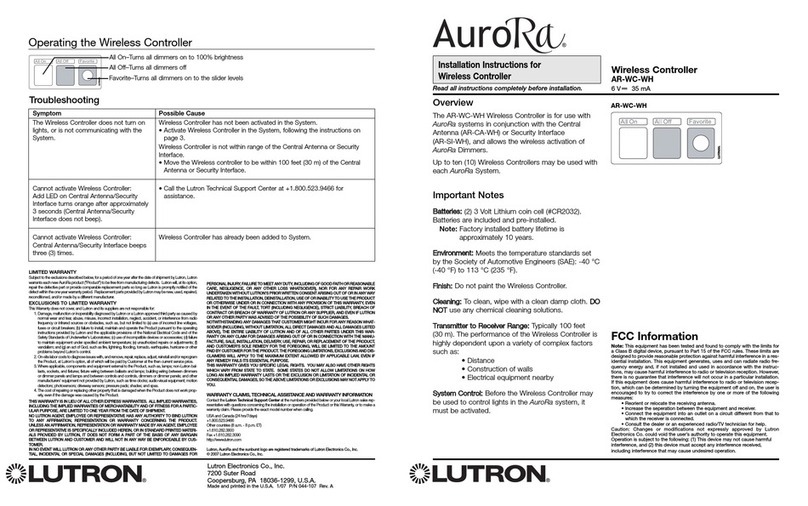

Aurora AR-WC-WH installation instructions