Sorel CALEONbox User guide

°CALEONbox

Heating circuit controller for surface heating systems

Installation and operating instruction

Read carefully before installation, commissioning and operation

CONTENT

Safety Instructions 3

EU-Conformity 3

General instructions 3

Explanation of Symbols 3

Changes to the Unit 4

Warranty and Liability 4

Disposal and Pollutants 4

Description °CALEONbox 4

Description 4

Specifications 5

Scope of Supply 6

Installation 6

Wall Installation 6

Electrical Connection 7

Electrical Terminals 8

LED status 9

Connection Examples Room Controller 10

Connection example apartment building 11

Connection Examples 1-Wire Sensors 12

1-Wire ID overview 13

Setup Wizard 14

Operation 14

Room Overview 14

Operating Mode 15

Menu 15

Set Operation Hours 16

Set Operation Hours 16

Expert Menu 17

Settings 18

Devices 19

Rooms 20

Temperature/Humidity 21

Functions °Cbox 22

Zones 27

Example zone setting 28

WiFi 29

Service Values 30

°CALEON WiFi and App Configuration 31

Tips 31

2

Safety Instructions

EU-Conformity

By affixing the CE mark to the unit the manufacturer declares that the°CALEONbox conforms to the following relevant safety reg-

ulations:

lEU low voltage directive 2014/35/EU

lEU electromagnetic compatibility directive 2014/30/EU

lEU RoHS Directive 2011/65/EU

lEU WEEE Directive 2012/19/EU (Reg.nr. DE 23479719)

conforms. Conformity has been verified and the corresponding documentation and the EU declaration of conformity are kept on

file by the manufacturer.

General instructions

Please read carefully!

These installation and operating instructions contain basic instructions and important information regarding safety, installation,

commissioning, maintenance and the optimal use of the unit. Therefore these instructions must be read and understood com-

pletely by the installation technician/specialist and by the system user before installation, commissioning and operation of the

unit.

This unit is an automatic, electrical Heating circuit controller for surface heating systems for and similar applications. Install the

device only in dry rooms and under environmental conditions as described under "Technical Data".

The valid accident prevention regulations, VDE regulations, the regulations of the local power utility, the applicable DIN-EN stand-

ards and the installation and operating instruction of the additional system components must also be observed.

Under no circumstances does the unit replace any safety devices to be provided by the customer!

Installation, electrical connection, commissioning and maintenance of the device may only be carried out by an appropriately

trained specialist. Users: Make sure that the specialist gives you detailed information on the function and operation of the unit.

Always keep these instructions in the vicinity of the unit.

The manufacturer does not take over any liability for damage caused through improper usage or non-compliance of this manual!

Explanation of Symbols

Danger

Failure to observe these instructions can result in electrocution.

Danger

Failure to observe these instructions can result in serious damage to health such as scalding or life-threatening

injuries.

Caution

Failure to observe these instructions can result in destruction of the unit or the system, or environmental dam-

age.

Caution

Information which is especially importation for the function and optimal use of the unit and the system.

3

Changes to the Unit

lChanges, additions to or conversion of the unit are not permitted without written permission from the manufacturer.

lIt is likewise forbidden to install additional components that have not been tested together with the unit.

lIf it becomes clear that safe operation of the unit is no longer possible, for example because of damage to the hous-

ing, turn the Unit off immediately.

lAny parts of the unit or accessories that are not in perfect condition must be exchanged immediately.

lUse only original spare parts and accessories from the manufacturer.

lMarkings made on the unit at the factory must not be altered, removed or made illegible.

lOnly the settings described in these instructions may be set using the Unit.

Changes to the unit can compromise the safety and function of the unit or the entire system.

Warranty and Liability

The unit has been manufactured and tested with regard to high quality and safety requirements. The unit is subject to the statutory

guarantee period of two years from the date of sale. The warranty and liability shall not include, however, any injury to persons or

material damage that is attributable to one or more of the following causes:

lFailure to observe these installation and operating instructions.

lImproper installation, commissioning, maintenance and operation.

lImproperly executed repairs.

lUnauthorised structural changes to the unit.

lUse of the device for other than its intended purpose.

lOperation above or below the limit values listed in the ‚Specifi cations‘ section.

lForce majeure.

Disposal and Pollutants

The unit conforms to the European RoHS 2011/65/EU for 2011/65/EUthe restriction of the use of certain hazardous substances in

electrical and electronic equipment.

Under no circumstances may the device be disposed of with the normal household waste. Dispose of the unit only at appro-

priate collection points or ship it back to the seller or manufacturer.

Description °CALEONbox

Description

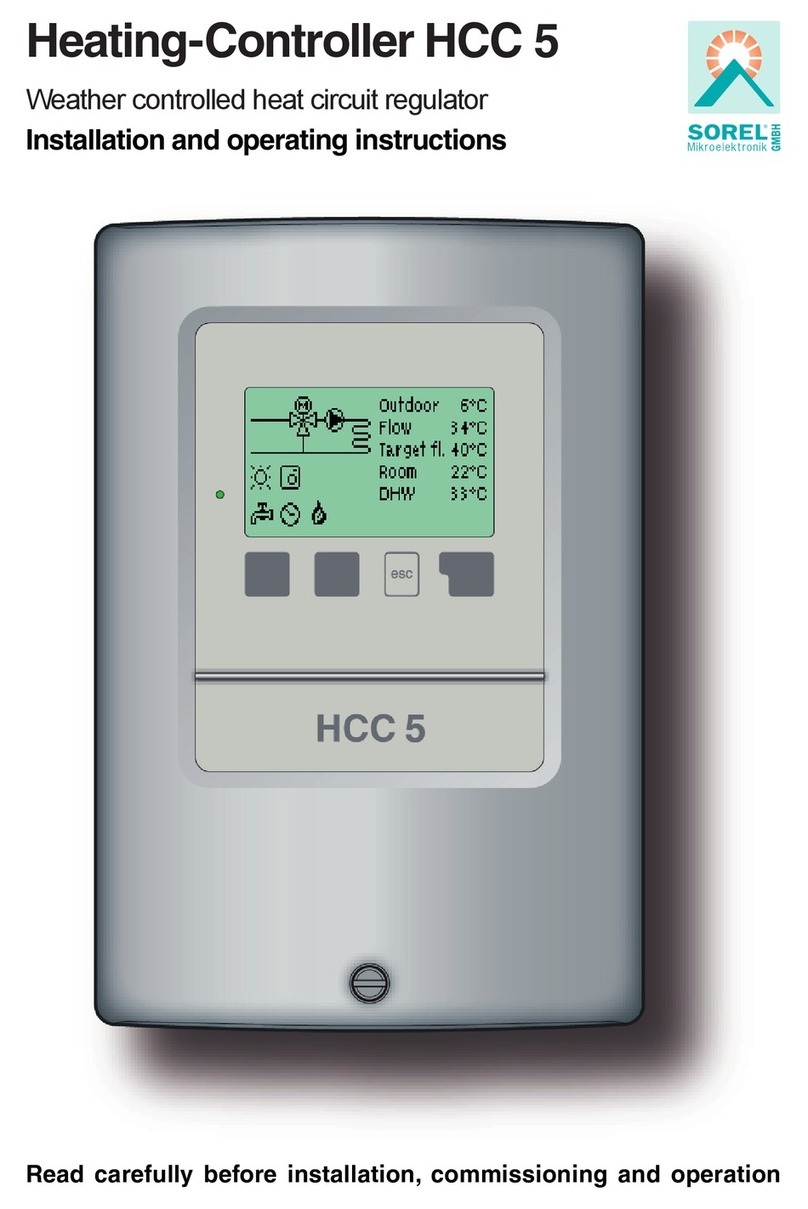

The °CALEONbox is a universal heating and individual room controller for surface heating systems. In combination with up to 8

°CALEON Room Controllers, this enables efficient use and function control of your surface heating with intuitive operation. The inputs

and outputs can be freely assigned via °CALEON, so that different heating systems can be implemented.

Important characteristics of the °CALEONbox:

lControl of 8 heating zones with 1 - 4 thermostatic radiator valves each

lMeasurement of room temperature and humidity in combination with °CALEON room controllers

or 1-Wire sensors

loptionally weather compensated via an external temperature sensor

loptional control of heating circuit pump and mixer (PWM oder 0-10V) possible

l2 separate CAN bus interfaces for building network and private floor or apartment network

lconnectable with other SOREL products via CAN bus

lControl of mixers, valves and energy generators via 0-10V / PWM

l2 additional floating changeover contacts (terminals J and K) for flexible assignment

loptionally usable with standard room thermostats

leasy to install due to innovative strain relief and coloured terminal strip

loptional up to 20 1-Wire temperature sensors connectable

4

Specifications

Model °CALEONbox Heating circuit controller for surface heating systems

Temperature controller class

(ErP)

8

Energy efficiency (ErP) 5%

Standby loss 0,5 W

Request type invertible heat

pump

"On /off" and/or "modulating"

Electrical specifications:

Power supply 230 VAC (+/- 5%), 50 - 60 Hz

Power consumption / standby 0,5 - 2,5W/ 0,5 W

Internal fuse 1 1 (Pos A, left) 4A slow blow 250V

Fuse protection for terminal area A and electronics

Internal fuse 2 1 (Pos B, right) 4A slow blow 250V

Fuse protection for terminal area B - I

Protection Class IP30

Protection class / overvoltage category II / II

Inputs Quantity Measuring range / design

1-Wire temperature sensor

parasitic

≤ 20 pices -55 °C ... 125 °C (2 pole version)

1-Wire temperature sensor

powered

> 20 pices -55 °C ... 125 °C (3 pole version)

Outputs

Switching relay outputs 11

Relay heat pump 1 230 VAC, 4A, (AC1 920 VA, AC3 185W)

Relay actuator 8 230 VAC, 4A, (AC1 920 VA, AC3 185W)

Relay additional function 2 Potential-free max. 4A

PWM output 1 for 10 k Ω working resistance 1 kHz, level 10 V

0-10V output 1

0-10V/PWM 1 (switchable)

+ Voltage outputs 24VDC 3 Total max. 12 W for external devices e.g. °CALEON Room Controller

Interface

Fieldbus 2 x CAN bus, isolated building bus and multi-storey bus

Max. cable length

1-Wire Sensors up to 50 m parasitic, up to 100 m powered, use twisted pair cable

CAN <3m; at> = 3m, a shielded twisted pair cable must be used. Isolate shield-

ing and connect it to the protective conductor of only one of the devices.

Max. cable length of the complete system 200 m.

0-10V/PWM <3m

24 VDC <30m

mechanical relay <30m

Permissible Ambient Conditions

during operation 0 °C - 40 °C, max. 85 % rel. humidity at 25 °C

for transport/storage 0 °C - 60 °C, no moisture condensation permitted

Other Specifications and Dimensions

Housing Design multi-part ABS

Installation Methods DIN rail mounting or wall mounting on DIN rail

Overall dimensions 95 mm x 303 mm x 57 mm

Light diode 14 x LED green

Real Time Clock RTC with 24 hour power reserve

Operation about °CALEON Room Controller

5

Scope of Supply

lHeating circuit controller for surface heating systems°CALEONbox

lReplacement fuse

ladditional separation wall for use of non-230V AC actuators

lDIN rail H=35mm L=280mm 2 screws 3,5 x 35 mm and 2 dowels S6

l°CALEONbox Installation and operating instructions

Installation

Wall Installation

Fix the DIN rail horizontally to the wall using screws.

Installation

1. Place the °CALEONbox on the upper edge of the DIN

rail with the locking catch on top.

2 Engage the device by pressing it down. Ensure that

the locking catches engage completely and that the

device is firmly seated on the rail.

Disassembly

Remove the °CALEONbox from the DIN rail by inserting

two screwdrivers into the eyelets and pulling them down-

wards.

Separation walls and cover

The separation walls and the cover can be removed for

easier connection of the cables. They must then be rein-

stalled in order to safely separate areas carrying mains

voltage from areas carrying low voltages.

Open the cover (90° degree) and then pull it out of the attach-

ment laterally.

If the terminal blocks (B-I) are to be supplied with a voltage other than the mains voltage, proceed as follows:

1. Remove existing bridges A1 - B1 and A2 - B2

2. It is absolutely necessary to insert a separating wall between A - B.

3. Connect the power supply to B1 (L) and B2 (N).

4. Observe max. switching power of relay and fuse (4AT)

Heating zones with 230 VAC actuators (bridge) Heating zones with e.g. 24 VAC actuators (separation wall)

6

Electrical Connection

Low-voltage cables such as temperature sensor cables must be routed separately from mains voltage cables.

Before working on the unit, switch off the power supply and secure it against being switched on again! Check that there

is no power flowing! Electrical connections may only be made by a specialist and in compliance with the applicable

regulations. The unit may not be put into operation if there is visible damage to the housing, e.g. cracks.

The customer must provide an all-pole disconnecting device, e.g. an emergency heating switch.

The strain reliefs are suitable for flexible

cables with a cable sheath diameter of 5 mm

to 8 mm, primarily using the lower strain relief

(as shown). The cables must be checked for

firm placement. Solid, thicker and thinner

cables must always be laid firmly and must

be fixed on the installation side.

Solid cables or wires with special wire end

ferrules can simply be pushed into the ter-

minals. For other wires, the push button must

first be completely pressed on with a screw-

driver as shown.

Wire ferrules made of brass can be

difficult to clamp due to their asym-

metric crimping shape. In this case,

remove the wire ferrule. The plug-in

terminals are also suitable for flex-

ible cables.

7

Electrical Terminals

1 L' ----- L' L' L' L' L' L' L' L' NC NC 24 VDC CAN high

2 N' ----- N' N' N' N' N' N' N' N' C C GND CAN low

3 L L' L' L' L' L' L' L' L' NO NO CAN high CAN high GND

4 N N' N' N' N' N' N' N' N' CAN low CAN low

5L L' L' L' L' L' L' L' L' 24 VDC VDD

6 N N' N' N' N' N' N' N' N' GND DQ GND

7 --- L' L' L' L' L' L' L' L' CAN high GND 24

VDC

8 PE N' N' N' N' N' N' N' N' CAN low

9 PE L' L' L' L' L' L' L' L' GND

Example Wiring of Terminal Blocks

Mains connection heating circuit pump Actuators for the heating zones

Potential-free switching contacts for additional functions °CALEON Room Controller in private CAN bus

8

Building CAN bus and 1-Wire sensors 0-10V/PWM outputs for additional functions

LED status

LED A Flashes, if mains voltage is present and relay A is not switched

Lights up, if mains voltage is present and relay A is switched.

LED B - K Lights up, if relay B - K is switched.

LED L Flashes, if the private CAN bus is active.

LED M Flashes, if the building CAN bus is active.

LED N Lights up, if outputs V1, V2 or V3 are active.

9

Connection Examples Room Controller

Example 1: Tree Structure

A 120 Ohm terminating resistor must be set on the first and last device in the CAN network.

Example 2: Line

A 120 Ohm terminating resistor must be set on the first and last device in the CAN network.

10

Connection example apartment building

Example: °CALEONboxes connected with LHCC controller

A 120 Ohm terminating resistor must be set on the first and last device in the CAN network.

11

Connection Examples 1-Wire Sensors

When connecting the 1-Wire sensors, please record the 16-digit 1-Wire ID and the location of the sensor for

later commissioning of the system! The 1-Wire ID can be found in the device housing and in the device menu

under: Devices -> °CALEONbox -> Resources -> 1-Wire sensor.

Example 1: Line. The installation leads from one sensor to the next. A twisted pair cable must be used for the connecting cable.

Example 2: Tree Structure. A twisted pair cable must be used for the connecting cable.

Only the GND and 1-wire data terminals are used in parasitic operation (two conductors) - the jumper in the 1-wire room

sensor must be plugged into the position described inside the device.

12

1-Wire ID overview

For systems with 1-Wire sensors, you must assign the respective 1-Wire

ID to a room on the °CALEON Room Controller. Writing down the IDs in

combination with the room in which the sensor hangs in the following

list simplifies the later assignment.

The 1-Wire ID can be found inside the sensor on the type plate (1) and

on the supplied sticker (2). We recommend to insert the sticker into the

following table.

(1)

(2)

1-Wire Room Sensor

1-Wire Room Sensor flush-mounted

1-Wire Pipe Sensor

1-Wire Floor Sensor

1-Wire Outdoor Sensor

Location 1-Wire ID Location 1-Wire ID

Example Bathroom 1053f67c0308009e 11

1 12

2 13

3 14

4 15

5 16

6 17

7 18

8 19

9 20

10 21

13

Setup Wizard

The setup wizard in the °CALEON Room Controller starts automatically when the device is commissioned for the first time and guides

you through the necessary basic settings in the correct sequence. Press the arrow keys in the upper right/left corner to return to the

next or previous setting.

Commissioning must also be completed on all other °CALEON Room Controllers in the network.

The °CALEONbox is configured exclusively on a °CALEON Room Controller.

The setup wizard is restarted via the "Factory settings" menu item.

Operation

To configure the °CALEONbox, you need at least one °CALEON Room Controller. This is connected to the °CALEONbox through the

private CAN bus as described before (See " Electrical Connection " on page 7).

Room Overview

Displays the room temperature, humidity and external temperature once the start screen was activated.

14

Operating Mode

Overview > Operating Mode

Menu

Overview > Operating Mode > Menu

15

Set Operation Hours

Overview > Operating Mode > Menu > Timer

Setting of individual heating times for the selected room.

Set Operation Hours

In the interests of efficient and energy-saving single room

control, the operating times should be set specifically for

each room.

When setting the operating times, please consider that sur-

face heating systems are inherently inert.

16

Expert Menu

Overview > Operating Mode > Menu > Expert

17

The menu structure described here is based on the status at the time of production and may vary due to subsequent soft-

ware changes.

Settings

Overview > Operating Mode > Menu > Expert > Settings

18

Devices

Overview > Operating mode > Menu > Expert > Settings > Devices

Overview > Operating mode > Menu > Expert > Settings > Devices > °CALEONbox

19

Rooms

Overview > Operating mode > Menu > Expert > Settings > Rooms

Overview > Operating mode > Menu > Expert > Settings > Room 2

20

Other manuals for CALEONbox

1

This manual suits for next models

1

Table of contents

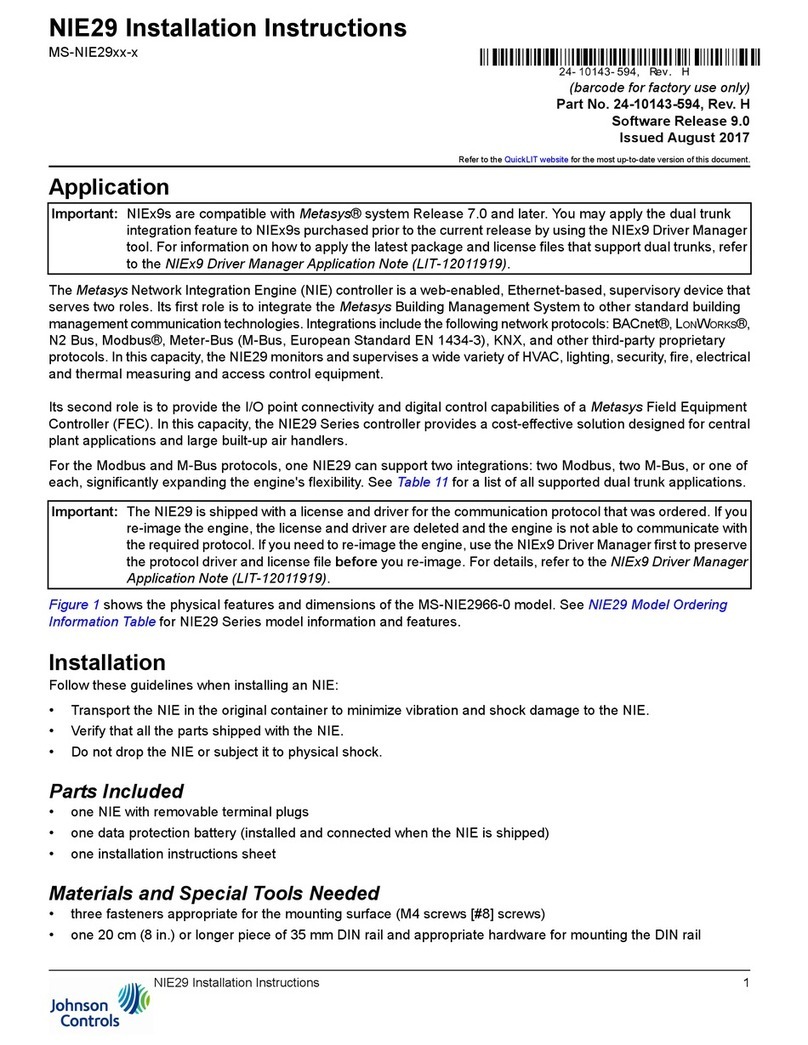

Other Sorel Controllers manuals

Popular Controllers manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1400 user manual

ComAp

ComAp IM-NT-BB reference guide

Danfoss

Danfoss FC 300 Design guide

Danfoss

Danfoss VLT AutomationDrive FC 300 Design guide

RBH Access Technologies

RBH Access Technologies UNC100 manual

TWR Lighting

TWR Lighting E-2/3DB manual

CAL Controls

CAL Controls CAL 9500P Abridged user manual

Marathon Electric

Marathon Electric DVR 2000E Installation, operation and maintenance manual

Camus Hydronics

Camus Hydronics ProtoNode FPC-N34 Startup guide

Gavita

Gavita ECM1 AU manual

GFB

GFB Sig-naTrak ACE User's manual supplement

Aurora

Aurora AR-WC-WH installation instructions