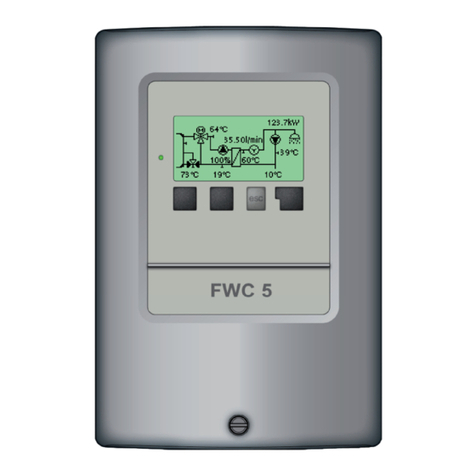

Sorel LHCC User manual

Heating Controller LHCC

Weather-compensated heating circuit controller

Installation and operating instructions

Read carefully before installation, commissioning and operation

CONTENT

Safety Instructions 5

EU-Conformity 5

General instructions 5

Explanation of Symbols 5

Changes to the Unit 6

Warranty and Liability 6

Disposal and Pollutants 6

Description LHCC 7

Specifications 7

About the Controller 8

Scope of Supply 8

Hydraulic Variants 9

Wall Installation 11

Installation 12

Electrical Terminals 12

Additional Information 13

External relay at signal output V(X) (0-10V / PWM) 13

Electrical Terminals 13

Electrical Connection 21

Installing the Temperature Sensors 21

Temperature Resistance Table for Pt1000 Sensors 21

Combining multiple SOREL products 22

CAN bus 22

°CALEON Room Controller 23

RC21 Room thermostat with remote control 26

Operation 27

Display and Input 27

Commissioning help 28

1. Measurement values 28

2. Statistics 29

Today 29

28 days 29

Operating hours 29

Heat quantity 29

Graphic overview 29

Notifications 29

Reset / Clear 29

3. Periods 30

Time & Date 30

Daylight saving time 30

Heating Circuit (Day) 30

Heating Circuit Comfort 30

DHW enable 30

DHW comfort 30

4. Operating mode 31

Manual 31

Mode Circuit (X) 31

5. Settings 32

Heating Circuit (X) 32

Operating mode 32

Season switch 33

S/W Day 33

S/W Night 33

Curve 33

Day Correction 33

Night Correction 33

Comfort Temperature Boost 33

Min. Flow 34

Max. Flow 34

Reference/Actual - 34

Reference/Actual + 34

Variant 34

Heating circuit off 34

Room hysteresis 34

Buffer sensor 34

Insulation factor 35

Overload protection 35

Min. Flow cooling 35

Max. flow cooling 35

Dew Point protection 35

Dew point correction 35

Room Controller Heating Circuit (X) 35

Smart grid 1/ PV contact 37

Smart grid 2 37

Settings Domestic Hot Water (DHW) 37

Operating mode 37

Hot water minimum 37

DHW reference 37

DHW comfort 37

DHW hysteresis 37

Buffer DHW load 37

DHW priority 37

DHW sensor 37

Smart grid 1/ PV contact 38

6. Protective Functions 38

Seizing Protection 38

Frost Protection 38

Discharge Protection 38

Dew point correction 38

Pressure Monitoring 38

RPS1 / RPS2 38

RPS Min 38

RPS Max 38

Protective functions for Solar 39

System protection 39

Collector protection 39

Recooling 39

Frost Protection 39

Collector alarm 39

7. Special Functions 40

Program selection 40

Pump settings V(X) 40

Signal type 40

Pump 40

Output Signal 40

PWM / 0-10V off 40

PWM / 0-10V on 40

PWM / 0-10V max. 40

Show signal 40

Speed control 40

Variant 40

Purging time 41

Sweep time 41

Max. Speed 41

Min. Speed 41

Setpoint 41

Sensor Calibration 41

Relay functions 41

Heat quantity 42

Flow temperature sensor (X) 42

Return flow sensor 42

Glycol type 42

Glycol percentage 42

Flow rate supply flow (X) 42

Offset ∆T 42

VFS (X) 42

VFS - Position 42

Reference sensor 42

Commissioning 42

Factory Settings 43

Eco Display Mode 43

Network 43

Access Control 43

Ethernet 43

Datalogger Version 44

CAN bus ID 44

Sensor send interval 44

8. Menu Lock 44

9. Service Values 44

10. Language 44

Function overview 45

Mixer 45

Direction 45

Mixer turn time 45

Mixer off factor 45

Mixer increase 45

Mixer run time 45

Signal type 45

Cooling valve Heating circuit 1/ Heating circuit 2 45

Heating Circuit 2 45

Free Cooling 45

RFI mixer 45

Operating mode 46

Reference flow sensor 46

Tref: 46

Return flow sensor: 46

Storage sensor: 46

Direction: 46

Min off time: 46

On-time: 46

Off factor: 46

Increase: 46

Max one direction: 46

Signal type 46

Difference 47

Δ T Difference 47

DF-Source 47

Tmin Source 47

DF-Drain 47

Tmax Drain 47

Heat transfer 47

Δ T Heat transfer 47

HT Tmax 47

HT Tmin 47

Source 47

Drain 47

Thermostat 47

DHW request 48

Heating Circuit request 48

Tset 48

Hysteresis 48

Energy Saving Mode 48

Delay 48

Thermostat sensor 1 48

Thermostat sensor 2 48

Thermostat enable 48

Electric heating rod (auxiliary heating) 48

DHW request 48

HC request 48

TH Set 48

Delay 48

Hysteresis 49

Eco mode 49

Sensor 1 49

Sensor 2 49

Electric heating rod approval times 49

Anti-legionella heating rot 49

Dissipation (Cooling) 49

Tset 49

Cooling sensor 49

Delay 49

Season switch 49

Off hysteresis 49

On hysteresis 50

Cool storage 50

Buffer sensor 50

Solid fuel boiler 50

Solid fuel boiler Tmax 50

Solid fuel boiler Tmin 50

ΔT Solid fuel boiler 50

Boiler sensor of this function 50

Storage sensor 50

Solar 50

Tmin Collector 50

ΔT Solar 50

Tmax Storage 51

Starting aid 51

Purging time 51

Increase 51

Protective Functions 51

Collector 51

Solar storage 51

Solar bypass 51

Variant 51

Bypass sensor 51

Booster 51

Charge time 51

Zone valve 52

Tmax storage 2 52

Solar storage 2 52

Heat exchanger 52

Heat exchanger sensor 52

Burner 52

DHW request 52

Heating Circuit request 52

Burner sensor 52

Delay 52

Burner offset 52

Eco mode (during solar charge) 52

Tmax 52

Enable 52

Anti Legionella 53

Boiler pump 53

Boiler pump Tmin 53

Compressor 53

DHW request 53

HC request 53

Cooling request 53

Eco mode (during solar charge) 53

Heating circuit offset 53

Min heat pump runtime 53

Heat pump idle time 53

Heat pump delay 53

Storage charge pump (SLP) overshoot 53

Bivalent temperature 53

Min. outdoor temperature 53

Periods 54

Anti Legionella 54

Loading pump 54

Storage charge pump (SLP) overshoot 54

Glycol pump 54

Gylcol pump lag 54

Return flow increase 55

Return flow increase Tmin 55

Return flow increase Tmax 55

ΔT return flow 55

Return flow sensor 55

Storage sensor 55

Domestic hot water valve 55

Circulation 55

Tmin 55

Hysteresis 55

Circulation sensor 55

Circulation pause time 55

Purging time 55

Circulations periods 55

Anti Legionella 56

Error Messages 56

Error message 56

Pressure monitor 56

Pressure monitor 56

RPS-Type 56

RPS Max 56

RPS Min 56

Dehumidifier 56

Operating mode 56

Reference humidity 56

Hysteresis 56

Dehumidifier periods 57

Parallel operation 57

Parallel operation 57

Parallel to 57

Delay 57

Follow-up time 57

Remote 57

Relay status 57

Title 57

Always on 57

Anti Legionella 58

Malfunctions/Maintenance 59

Tips 60

Support Guideline 60

Appendix 60

Pump 60

Output Signal 60

PWM / 0-10V off 60

PWM / 0-10V on 60

PWM / 0-10V max. 61

Speed when „On“ 61

Example for pump settings 61

Technical data PWM and 0-10V 61

Show signal 61

Final Declaration 62

Safety Instructions

EU-Conformity

By affixing the CE mark to the unit the manufacturer declares that theLHCC conforms to the following relevant safety regulations:

lEU low voltage directive 2014/35/EU

lEU electromagnetic compatibility directive 2014/30/EU

conforms. Conformity has been verified and the corresponding documentation and the EU declaration of conformity are kept on file by

the manufacturer.

General instructions

Please read carefully!

These installation and operating instructions contain basic instructions and important information regarding safety, installation, com-

missioning, maintenance and the optimal use of the unit. Therefore these instructions must be read and understood completely by the

installation technician/specialist and by the system user before installation, commissioning and operation of the unit.

This unit is an automatic, electrical Weather-controlled heating circuit controller for heating and cooling systems for/inHeating system

and similar applications. Install the device only in dry rooms and under environmental conditions as described under "Technical

Data".

The valid accident prevention regulations, VDE regulations, the regulations of the local power utility, the applicable DIN-EN standards

and the installation and operating instruction of the additional system components must also be observed.

Under no circumstances does the unit replace any safety devices to be provided by the customer!

Installation, electrical connection, commissioning and maintenance of the device may only be carried out by an appropriately trained

specialist. Users: Make sure that the specialist gives you detailed information on the function and operation of the unit. Always keep

these instructions in the vicinity of the unit.

The manufacturer does not take over any liability for damage caused through improper usage or non-compliance of this manual!

Explanation of Symbols

Danger

Failure to observe these instructions can result in electrocution.

Danger

Failure to observe these instructions can result in serious damage to health such as scalding or life-threatening

injuries.

Caution

Failure to observe these instructions can result in destruction of the unit or the system, or environmental damage.

Caution

Information which is especially importation for the function and optimal use of the unit and the system.

5

Changes to the Unit

lChanges, additions to or conversion of the unit are not permitted without written permission from the manufacturer.

lIt is likewise forbidden to install additional components that have not been tested together with the unit.

lIf it becomes clear that safe operation of the unit is no longer possible, for example because of damage to the housing, turn the Unit

off immediately.

lAny parts of the unit or accessories that are not in perfect condition must be exchanged immediately.

lUse only original spare parts and accessories from the manufacturer.

lMarkings made on the unit at the factory must not be altered, removed or made illegible.

lOnly the settings described in these instructions may be set using the Unit.

Changes to the unit can compromise the safety and function of the unit or the entire system.

Warranty and Liability

The unit has been manufactured and tested with regard to high quality and safety requirements. The unit is subject to the statutory guar-

antee period of two years from the date of sale. The warranty and liability shall not include, however, any injury to persons or material

damage that is attributable to one or more of the following causes:

lFailure to observe these installation and operating instructions.

lImproper installation, commissioning, maintenance and operation.

lImproperly executed repairs.

lUnauthorised structural changes to the unit.

lUse of the device for other than its intended purpose.

lOperation above or below the limit values listed in the ‚Specifi cations‘ section.

lForce majeure.

Disposal and Pollutants

The unit conforms to the European RoHS 2011/65/EU for 2011/65/EUthe restriction of the use of certain hazardous substances in elec-

trical and electronic equipment.

Under no circumstances may the device be disposed of with the normal household waste. Dispose of the unit only at appro-

priate collection points or ship it back to the seller or manufacturer.

6

Description LHCC

Specifications

Model LHCC Weather-controlled heating circuit controller for heating and cooling

systems

Temperature controller class VI

Energy efficiency 4%; When operating at min. 3 ° CALEONs or RC20

a energy efficiency of 5% is achieved

Standby loss 0.5 W

Request type heater On / off operation or modulating

Electrical specifications:

Power supply 100 - 240VAC, 50 - 60 Hz

Power consumption / standby 0.5 - 2.5 W/ 0.5 W

Total switched power 2 A

Switched power per relay 460VA

Internal fuse 1 2 A slow 250V

Protection Class IP40

Protection class / overvoltage category II / II

Inputs/Outputs Measuring range

Sensor inputs 6 Pt1000 -40 °C ... 300 °C

Sensor inputs VFS / RPS 2 Grundfos Direct Sensor 0°C-100°C (-25°C /120°C short term)

Outputs mechanical relay 4

of relay potential free 1 R4

mechanical relay R1 - R4 460VA for AC1 / 460VA for AC3

0-10V/PWM output V1 - V2 for 10 k Ω working resistance 1 kHz, level 10 V

+ Terminal/

Voltage output

+ Max. load by external devices 24V/6W (e.g. power supply of 3

°CALEON room controllers)

Max. cable length

VFS/RPS sensors <3m

CAN <3m; at >=3m, a shielded twisted-pair cable is to be

used and connected to the protective conductor on one side.

0-10V/PWM <3m

24 VDC <30 m

mechanical relay <10m

Interface

Fieldbus CAN

Permissible Ambient Conditions

for controller operation 0 °C - 40 °C, max. 85 % rel. humidity at 25 °C

for transport/storage 0 °C - 60 °C, no moisture condensation permitted

Other Specifications and Dimensions

Housing Design 2-part, ABS plastic

Installation Methods Wall installation, optionally panel installation

Overall dimensions 163 mm x 110 mm x 52 mm

Aperture installation dimensions 157 mm x 106 mm x 31 mm

Display Fully graphical display, 128 x 64 dots

Light diode multicolour

Real Time Clock RTC with 24 hour power reserve

Operation 4 entry keys

7

About the Controller

The Weather-controlled heating circuit controller for heating and cooling systems LHCC facilitates efficient use and function control of

your Heating system possible while its handling is intuitive. After every input step the suitable functions are matched to the keys and

explained in a text above. In the menu 'measurement values and settings' are help text and graphics in addition to key words.

The LHCC can be used for the various system variants.

Important characteristics of the LHCC are:

lDepiction of graphics and texts using a lit display.

lSimple viewing of the current measurement values.

lStatistics and system monitoring by means of statistical graphics

lExtensive setting menus with explanations.

lMenu block can be activated to prevent unintentional setting changes.

lResetting to previously selected values or factory settings.

Scope of Supply

lWeather-controlled heating circuit controller for heating and cooling systemsLHCC

l3 screws 3,5 x 35 mm and 3 plugs 6 mm for wall installation.

lLHCC Installation and operating instructions

Optionally contained depending on design/order:

lOutdoor sensor: TA55 (87005)

lEthernet connection: optionally possible via datalogger (77701)

lTemperature sensor Pt1000: e.g. TR / S2 (81220)

lRoom Controller: °CALEON (70001) / °CALEON Clima (70002)

lCAN Bus Accessories: e.g. CAN Connection kit 1.00m (89211)

l0-10V relay 1W / 6A (77502)

8

Hydraulic Variants

The following illustrations should be regarded only as schematic representations of the respective hydraulic systems and do not claim to be complete. Under no cir-

cumstances should the controller replace any safety devices. Depending on the specific application, additional system and safety components such as check

valves, non-return valves, safety temperature limiters, scalding protectors, etc., may be required.

Heating circuit and burner Mixed heating circuit Mixed PWM heating circuit

Mixed heating circuit and burner Mixed heating circuit, burner

and solar

Mixed heating circuit and heat pump

Mixed heating circuit, heat pump

and solar

Mixed heating circuit and solid fuel

solid fuel boiler

Mixed heating circuit, heat pump

and cooling function

2 heating circuits, combined water

tank, DHW-valve and burner

Mixed heating circuit, unmixed heat-

ing circuit and burner

Mixed heating circuit, DHW-valve

and burner.

2 mixed PWM heating circuit Mixed PWM-Hc, DHW, solar, burner

and zone valve

Mixed heating circuit and

combination storage

9

Mixed PWM heating circuit and

solid fuel boiler

Mixed heating circuit, solid fuel

boiler and burner

Unmixed heating circuit, DHW and

heat transfer

Mixed heating circuit, DHW, and

heat transfer

Mixed PWM heating circuit, DHW,

and heat transfer

Mixed heating circuit, DHW, heat

transfer and burner

Mixed heating circuit, DHW, heat

transfer and heat pump

Mixed heating circuit with unmixed

heating circuit and solid fuel boiler

10

Wall Installation

1. Unscrew cover screw completely.

2. Carefully pull upper part of housing from lower part.

During the removal, the brackets are released as

well.

3. Set upper part of housing aside. Do not touch the

electronics.

4. Hold the lower part of the housing in the selected

position and mark the 3 mounting holes. Make sure

that the wall surface is as even as possible so that

the housing does not become distorted when

screwed on.

5. Using a drill and size 6 bit, drill three holes at the

points marked on the wall and push in the plugs.

6. Insert the upper screw and screw it in lightly.

7. Fit the upper part of the housing and insert the

other two screws.

8. Align the housing and tighten the three screws.

1. Open the terminal cover.

2. Strip lines a max. of 55 mm, assemble the strain

reliefs, strip wire ends 8-9 mm (Figure 1)

3. Open the terminals with a fitting screwdriver (figure

2) and connect the electrical system to the con-

troller.

4. Clip on the terminal cover again and close it with

the screw.

5. Turn on mains supply and put the controller into

operation.

If problems occur with the operation of the terminals, our video on our YouTube page can help you:

http://www.sorel.de/youtube

11

Installation

Electrical Terminals

Low voltages

max. 24 VAC / DC

Mains voltages

230 VAC 50 - 60 Hz

Terminal: Connection for:

- GND bridge on the lower ground terminal block

S1 Temperature Sensor 1

S2 Temperature Sensor 2

S3 Temperature Sensor 3

S4 Temperature Sensor 4

S5 Temperature Sensor 5

V1 0-10V / PWM signal output e.g. for controlling high-effi-

ciency pumps

V2 0-10V / PWM signal output e.g. for controlling high-effi-

ciency pumps

S6 Temperature Sensor 6 (outdoor)

+ Terminal/

Voltage out-

put

24V voltage output

Max. load by external devices 24V / 6W

The connection of the ground wire is made at the lower gray terminal

block.

Terminal: Connection for:

N Neutral conductor N

L Network outer conductor L

R1 Relays 1

R2 Relays 2

R3 Relays 3

R4| Relay 4 | (potential-free contact)

R4 Relay 4 (potential-free contact)

The neutral conductor N must be connected to the N ter-

minal block.

The PE protective conductor must be con-

nected to the PE metal terminal block!

For high-efficiency pumps with 0-10V / PWM

signal input, the power can be provided (V1

/ V2 parallel operation) over a free relay.

On the control board

VFS1 Grundfos Direct Sensor "Connection of PWM pumps"

PWM pumps are connected to the controller with 2 wires 1)

PWM Input (default: brown) 2) GND (default: blue). Some

pumps have a third wire (PWM Output Signal (default: black)).

This is not used for the connection!

VFS2 Grundfos Direct Sensor

CAN CAN bus connection (1=high,2=low)

CAN CAN bus connection (1=high,2=low)

12

Additional Information

External relay at signal output V(X) (0-10V / PWM)

Using an external relay (art. no. 77502), a 0-10V/PWM output V(X)

(V1, V2) can be used to get a switching power of 230 VAC (I) or a

potential-free changeover contact (II). The external relay is activated

via the signal output (0V = "off" (0 VAC or opened or closed), 10V =

"on" (230 VAC or closed or opened).

1. Connect external 0-10V relay to signal output, e.g. V1.

2. Assign additional function to signal V1. See " Relay functions " on

page 41

3. Disable the speed control for the corresponding 0-10V / PWM out-

put (Off). See " Variant " on page 40

Electrical Terminals

For high-efficiency pumps with 0-10V / PWM signal input, the power can be provided (V1 / V2 parallel operation) over a

free relay.

The connection of the ground wire is made at the lower gray terminal block. The neutral conductor N is connected to ter-

minal block N. The PE protective conductor must be connected to the PE metal terminal block!

Program 1 heating circuit and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S5 Flow sensor R1 Heating circ.pump/ Cir-

culation pump

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external

devices 24V/6W

R4 Burner

13

Program 2 mixed heating circuit

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S5 Flow sensor R1 Heating circ.pump/ Cir-

culation pump

S6 Outdoor sensor R2 Mixer open

+24V 24V voltage output

Max. external devices

24V/6W

R3 Mixer close

Program 3 mixed PWM heating circuit

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S5 Flow sensor R1 Heating circ.pump/ Cir-

culation pump

V1 PWM Mixer (external

power supply)

S6 Outdoor sensor

+24V 24V voltage output

Max. external devices

24V/6W

Program 4 mixed heating circuit and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S5 Flow sensor R1 Heating circ.pump/ Cir-

culation pump

S6 Outdoor sensor R2 Mixer open

+24V 24V voltage output

Max. external devices

24V/6W

R3 Mixer close

R4| Burner

R4 Burner

14

Program 5 mixed heating circuit, burner and solar

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S1 Solar storage sensor L Network outer conductor

L

S2 Buffer sensor R1 Heating circ.pump/ Cir-

culation pump

S4 Collector sensor R2 Mixer open

S5 Flow sensor R3 Mixer close

V1 Solar pump (external

power supply)

R4| Burner

S6 Outdoor sensor R4 Burner

+24V 24V voltage output

Max. external devices

24V/6W

Program 6 mixed heating circuit and heat pump

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S5 Flow sensor R1 Heating circ.pump/ Cir-

culation pump

S6 Outdoor sensor R2 Mixer open

+24V 24V voltage output

Max. external devices

24V/6W

R3 Mixer close

R4| Compressor

R4 Compressor

Program 7 mixed heating circuit, heat pump and solar

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S1 Solar storage sensor L Network outer conductor

L

S2 Buffer sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

V1 Solar pump (external

power supply)

R3 Mixer close

S6 Outdoor sensor R4| Compressor

+24V 24V voltage output

Max. external devices

24V/6W

R4 Compressor

15

Program 8 mixed heating circuit and solid fuel boiler

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S5 Flow sensor R1 Pump

S6 Outdoor sensor R2 Mixer open

+24V 24V voltage output

Max. external

devices 24V/6W

R3 Mixer close

R4| Solid fuel boiler

R4 Solid fuel boiler

Program 9 mixed heating circuit, heat pump and cooling function

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S5 Flow sensor R1 Heating circ.pump/ Circulation

pump

V1 Season switch R2 Mixer open

S6 Outdoor sensor R3 Mixer close

+24V 24V voltage output

Max. external

devices 24V/6W

R4| Compressor

R4 Compressor

Program 10 2 heating circuits, combined storage, DHW valve and

burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Circulation

pump heating circuit 2

S4 Flow sensor heating

circuit 2

R2 Heating circ.pump/ Circulation

pump heating circuit 1

S5 Flow sensor heating

circuit 1

R3 valve

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external

devices 24V/6W

R4 Burner

16

Program 11 mixed heating circuit, unmixed heating circuit and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S4 Flow sensor heating

circuit 2

R1 Heating circ.pump/ Circulation

pump heating circuit 1

S5 Flow sensor heating

circuit 1

R2 Mixer open

V1 Heating circ.pump/

Circulation pump

heating circuit 2

R3 Mixer close

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external

devices 24V/6W

R4 Burner

Program 12 mixed heating circuits, DHW valve and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

V1 DHW valve (via

external relay)

R3 Mixer close

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external devices

24V/6W

R4 Burner

Program 13 2 mixed PWM heating circuits

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S4 Flow sensor heating cir-

cuit 2

R1 Heating circ.pump/ Cir-

culation pump heating cir-

cuit 2

S5 Flow sensor heating cir-

cuit 1

R2 Heating circ.pump/ Cir-

culation pump heating cir-

cuit 1

V1 PWM mixer heating cir-

cuit 1 (external power

supply)

V2 PWM mixer heating cir-

cuit 2 (external power

supply)

S6 Outdoor sensor

+24V 24V voltage output

Max. external devices

24V/6W

17

Program 14 mixed PWM heating circuit, DHW, solar, burner and

zone valve

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S4 Collector sensor R2 Solar pump

S5 Flow sensor R3 DHW valve

V1 PWM Mixer (external

power supply)

R4| Burner

S6 Outdoor sensor R4 Burner

+24V 24V voltage output

Max. external devices

24V/6W

Program 15 mixed heating circuit, and combination storage

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

S6 Outdoor sensor R3 Mixer close

+24V 24V voltage output

Max. external devices

24V/6W

R4| DHW-pump

R4 DHW-pump

Program 16 mixed PWM heating circuit and storage

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor

L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 DHW-pump

V1 PWM mixer

S6 Outdoor sensor

+24V 24V voltage output

Max. external devices

24V/6W

18

Program 17 mixed heating circuit, storage and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

V1 Heat transfer pump R3 Mixer close

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external

devices 24V/6W

R4 Burner

Program 18 unmixed heating circuit, DHW and storage transfer

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 DHW-pump

S6 Outdoor sensor

+24V 24V voltage output

Max. external

devices 24V/6W

Program 19 mixed heating circuit, DHW and storage transfer

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

S6 Outdoor sensor R3 Mixer close

+24V 24V voltage output

Max. external

devices 24V/6W

R4| DHW-pump

R4 DHW-pump

19

Program 20 mixed PWM heating circuit, DHW and storage transfer

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 DHW-pump

V1 PWM mixer

S6 Outdoor sensor

+24V 24V voltage output

Max. external

devices 24V/6W

Program 21 mixed heating circuit, DHW, storage transfer and burner

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

V1 Heat transfer pump R3 Mixer close

S6 Outdoor sensor R4| Burner

+24V 24V voltage output

Max. external devices

24V/6W

R4 Burner

Program 22 mixed heating circuit. DHW, storage transfer and heat

pump

Terminal: Connection: Terminal: Connection:

- GND N Neutral conductor N

S2 Buffer sensor L Network outer conductor L

S3 DHW sensor R1 Heating circ.pump/ Cir-

culation pump

S5 Flow sensor R2 Mixer open

V1 Heat transfer pump R3 Mixer close

S6 Outdoor sensor R4| Compressor

+24V 24V voltage output

Max. external

devices 24V/6W

R4 Compressor

20

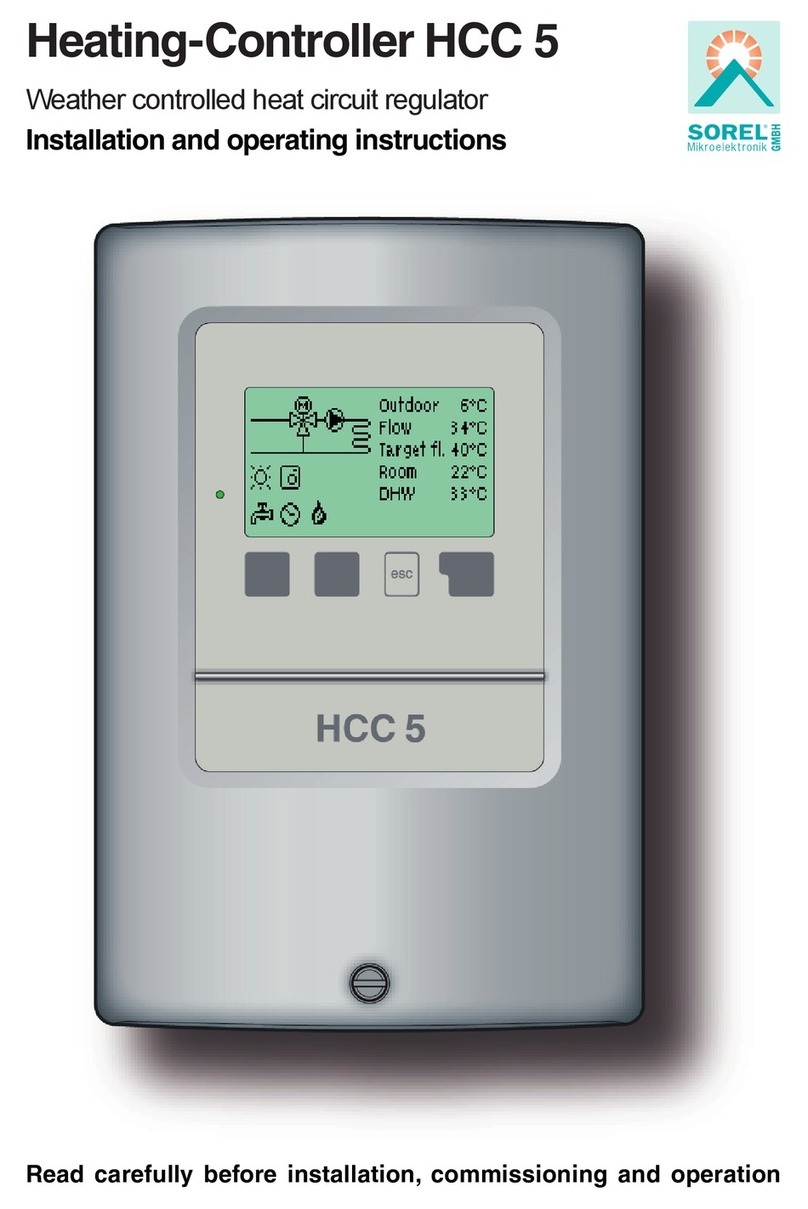

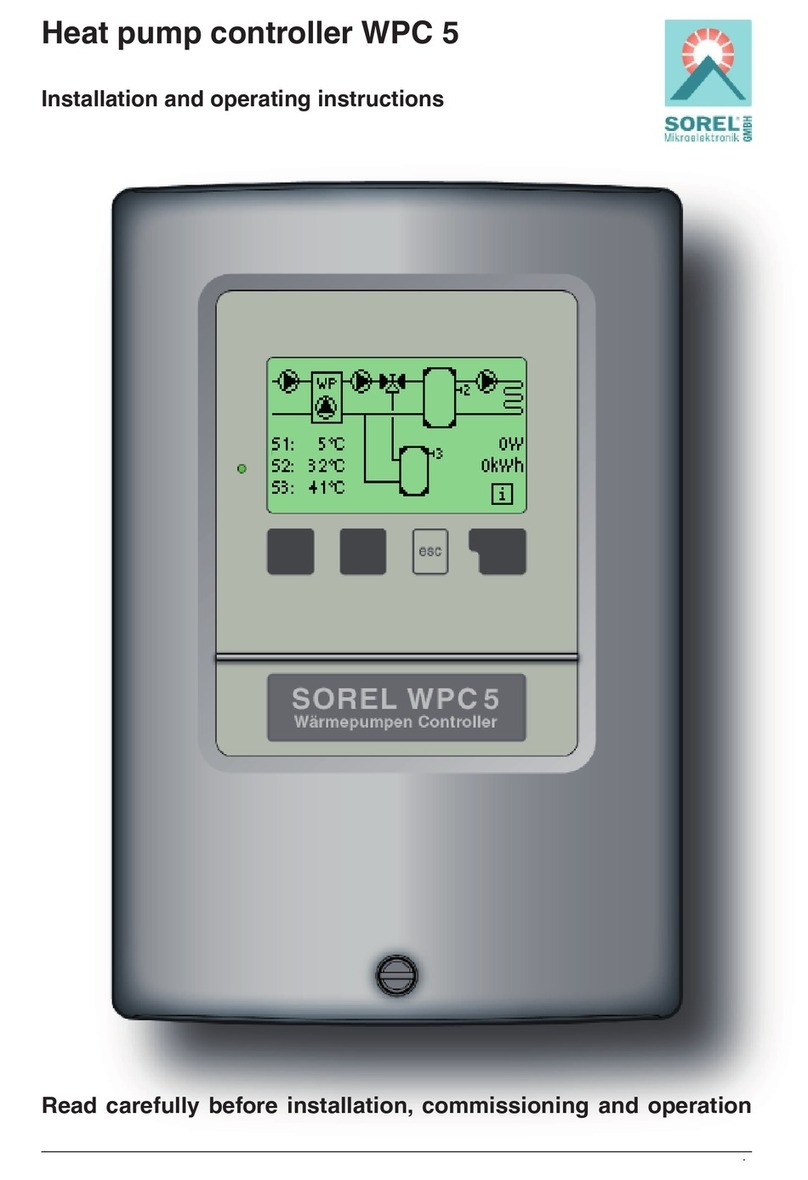

This manual suits for next models

2

Table of contents

Other Sorel Controllers manuals