Sorel Pool TDCM+ User manual

Read carefully before installation, commissioning and operation

Pool Controller

Pool TDCM+

Installation and operating instructions

Table of Contents

Safety instructions

A.1. EC declaration of conformity 3

A.2. General instructions 3

A.3. Explanation of symbols 3

A.4. Changes to the unit 4

A.5. Warranty and liability 4

Description of controller

B.1. Specications 5

B.2. Temperature resistance table for PT1000

sensors 5

B.3. About the controller 6

B.4. Scope of supply 6

B.5. Disposal and pollutants 6

B.6. Hydraulic variants 7

Installation

C.1. Wall installation 8

C.2. Electrical connection 9

C.3. Installing the temperature sensors 10

D. Terminal connection diagram 11

Operation

E.1. Display and input 12

E.2. Commissioning help 13

E.3. Free commissioning 13

E.4. Menu sequence and menu structure 14

1. Measurement values 15

2. Statistics 16

2.1. Operating hours 16

2.2. Average pool temperature 16

2.3. Heat output 16

2.4. Graphic overview 16

2.5. Message log 16

2.6. Reset/clear 16

3. Display mode 17

3.1. Schematic 17

3.2. Overview 17

3.3. Alternating 17

3.4. Sleep mode 17

4. Operating mode 18

4.1. Automatic 18

4.2. Manual 18

4.3. O 18

5. Settings 19

5.1. Tmin S1 19

5.2. Tmax S2 19

5.3. ∆TR1 20

5.4. TsetS2 20

5.5.Hysteresis 20

5.6. Followup/Switch-odelay 20

pagepage

5.7. Delay/Switch-ondelay 20

Filterpumpruntime 20

5.8. Hourlylterpumpruntime 20

5.9. Eco mode 21

5.10. Runtimeoptimization 21

5.11. Dailylteringtime 21

5.12. Solar times 21

5.13. Heating times 21

6. Protective functions 21

6.1. Seizingprotection 21

6.2. Frost protection 21

6.3. System protection 22

7. Special functions 23

7.1. Program selection 23

7.2. Time and date 23

7.3. Sensor calibration 23

7.4. Commissioning 24

7.5. Factory settings 24

7.6. Heat quantity 24

7.7. Daylight saving time 25

8. Menu lock 26

9. Service values 27

10. Language 28

Malfunctions

Z.1. Malfunctions with error messages 29

Z.2. Replacing the fuse 30

Z.3. Maintenance 30

3

Safety instructions

ByaxingtheCEmarktotheunitthemanufacturerdeclaresthatthePool TDCM+ con-

formstothefollowingrelevantsafetyregulations:

- EClowvoltagedirective2006/95/EC

- ECelectromagneticcompatibilitydirective2004/108/EC

ConformityhasbeenveriedandthecorrespondingdocumentationandtheECdeclaration

ofconformityarekeptonlebythemanufacturer.

A.1. EC declaration of conformity

These installation and operating instructions contain basic instructions and important

informationregardingsafety,installation,commissioning,maintenanceandtheoptimal

useoftheunit.Thereforetheseinstructionsmustbereadcompletelyandunderstood

bytheinstallationtechnician/specialistandbythesystemuserbeforeinstallation,com-

missioningandoperationoftheunit.

Thevalidaccidentpreventionregulations,VDEregulations,theregulationsofthelo-

calpowerutility,theapplicableDIN-ENstandardsandtheinstallationandoperating

instructionsoftheadditionalsystemcomponentsmustalsobeobserved.Thecon-

trollerdoesnotunderanycircumstancesreplaceanysafetydeviceswhicharetobe

provided by the customer!

Installation,electricalconnection,commissioningandmaintenanceoftheunitmay

only be carried out by specialists who have the appropriate training.

Fortheuser:Makesurethatthespecialistgivesyoudetailedinformationonthefunc-

tionandoperationofthecontroller.Alwayskeeptheseinstructionsinthevicinityofthe

controller.

A.2. General instructions

Danger

Caution

A.3. Explanation of symbols

Failuretoobservetheseinstructionscanresultindangertolifefrom

electric voltage.

Danger

Failure to observe these instructions can result in serious damage to

healthsuchasscalding,orevenlife-threateninginjuries.

Caution

Failuretoobservetheseinstructionscanresultindestructionoftheunit

orthesystem,ordamagetotheenvironment.

Informationwhichisespeciallyimportantforthefunctionandoptimaluse

oftheunitandthesystem.

4

A.4. Changes to the unit

A.5. Warranty and liability

Safety instructions

• Changes,additionstoorconversionoftheunitarenotpermittedwithoutwritten

authorisationfromthemanufacturer

• Itislikewiseforbiddentoinstalladditionalcomponentsthathavenotbeentested

together with the unit

• Ifitbecomesclearthatsafeoperationoftheunitisnolongerpossible,forexample

becauseofdamagetothehousing,turnthecontrolleroimmediately

• Anypartsoftheunitoraccessoriesthatarenotinperfectconditionmustbere-

placed immediately

• Useonlyoriginalsparepartsandaccessoriesfromthemanufacturer

• Markingsmadeontheunitatthefactorymustnotbealtered,removedormade

illegible

• Only the settings described in these instructions may be used on the control-

ler

Changestotheunitcancompromisethesafetyandfunctionoftheunitor

the entire system.

Danger

Thecontrollerhasbeenmanufacturedandtestedwithregardtohighqualityandsafety

requirements.Theunitissubjecttothestatutoryguaranteeperiodoftwoyearsfrom

thedateofsale.

Thewarrantyandliabilityshallnotinclude,however,anyinjurytopersonsormaterial

damagethatisattributabletooneormoreofthefollowingcauses:

• Failure to observe these installation and operating instructions

• Improperinstallation,commissioning,maintenanceandoperation

• Improperrepairs

• Unauthorised structural changes to the unit

• Installationofadditionalcomponentsthathavenotbeentestedtogetherwith

the unit

• Anydamageresultingfromcontinueduseoftheunitdespiteanobviousfault

• Failure to use original spare parts and accessories

• Useofthedeviceforanythingotherthanitsintendedpurpose

• Operationaboveorbelowthelimitvalueslistedinthespecications

• Forcemajeure

5

B.2. Temperature resistance table for PT1000 sensors

B.1.

°C 0 10 20 30 40 50 60 70 80 90 100

Ω1000 1039 1077 1116 1155 1194 1232 1270 1308 1347 1385

Description of controller

Electrical

mechanical relay 4 A maximum AC3

920VA for AC1 (non-inductive loads) / 460 VA for AC3 (for inductive loads such as electric motors for

filter pumps)

PT1000 sensor input measuring range -40 °C to 300 °C

2 (R1-R2)

3

Permissible cable length of sensors and appliances:

Collector and outdoor sensor < 30 m

Other PT1000 sensors < 10 m

Electronic relay < 3 m

Mechanichal relay < 10 m

Real Time Clock RTC with 24 hour power reserve

Permissible ambient conditions:

Ambient temperature

for controller operation 0 °C ... 40 °C

for transport/storage 0 °C ... 60 °C

Air humidity

for controller operation max. 85 % rel. humidity at 25 °C

for transport/storage no moisture condensation permitted

Other and dimensions

Housing design 3-part, ABS plastic

Installation methods Wall installation, optional panel

Overall dimensions 163 mm x 110 mm x 52 mm

Cut out installation dimensions 157 mm x 106 mm x 31 mm

Display Fully graphical display, 128 x 128 dots

Light diode Multicolor red / green

Operation 4 entry keys

Mains voltage 230 VAC +/-10 %

Mains frequency 50 - 60 Hz

Power consumption 1.5 W - 2.3 W

Internal fuse 4 A slow blow 250 V

Protection category IP40 / IP 44 (only with the supplied

seal kit)Protection class II

Overvoltage Category II

Degree of Pollution Category II

6

The Pool Controller Pool TDCM+facilitatesecientuseandfunctioncontrolofyour

solarorheatingsystemwithyourswimmingpool.Thedeviceisimpressivemostof

allforitsfunctionalityandsimple,almostself-explanatoryoperation.Foreachstepin

theinputprocesstheindividualentrykeysareassignedtoappropriatefunctionsand

explained.Thecontrollermenucontainsheadwordsforthemeasuredvaluesandset-

tings,aswellashelptextsorclearly-structuredgraphics.

The BADU®Logic 1canbeusedasasolarcontrollerforthevarioussystemvariants

illustrated and explained under “B.6. Hydraulic variants” on page 7.

ImportantcharacteristicsofthePool TDCM+:

- Depictionofgraphicsandtextsinanilluminateddisplay

- Simpleviewingofthecurrentmeasurementvalues

- Analysisandmonitoringofthesystembymeansofstatisticalgraphics,etc.

- Individualcongurationofspecialfunctions

- Extensive menu settings with explanations

- Menublockactivationtopreventunintentionalsettingchanges

- Resettingtopreviouslyselectedvaluesorfactorysettings

- Awiderangeofadditionalfunctions

B.3. About the controller

Description of controller

- Pool Controller Pool TDCM+

- 3pcs.3.5x35mmscrewsand3pcs.6mmplugsforwallinstallation

- 6strainreliefclipswith12screws,replacementfuse1xT4A/250V

- InstallationandoperatinginstructionsPool TDCM+

Optionallycontaineddependingondesign/order:

- PT1000temperaturesensorsandimmersionsleeves

Additionallyavailable:

- PT1000temperaturesensor,immersionsleeves,overvoltageprotection

B.4. Scope of supply

B.5. Disposal and pollutants

TheunitconformstotheEuropeanRoHSdirective2011/65/EUfortherestrictionofthe

useofcertainhazardoussubstancesinelectronicequipment.

Caution

Theunitmustnotunderanycircumstancesbedisposedofwithordinary

householdrefuse.Disposeoftheunitonlyatappropriatecollectionpoints.

7

B.6. Hydraulic variants

Description of controller

Caution

Thefollowingillustrationsshouldbeviewedonlyasschematicdia-

grams showing the respective hydraulic systems and do not claim to

becomplete.Thecontrollerdoesnotreplacesafetydevicesunderany

circumstances.Dependingonthespecicapplication,additionalsystem

componentsandsafetycomponentsmayberequired,suchascheck

valves,non-returnvalves,safetytemperaturelimiters,scaldingprotec-

torsetc.andmustthereforebeprovided.

Poolwithsolar,ballvalveandlterpumpcontrol

Poolwithauxiliaryheater,ballvalveandlter

pump control

Poolwithheatpump,ballvalveandlterpump

control

Poolwithheatpump,heatexchangerandlter

pump control

Poolwithlterpumpcontrol

Poolwithsolar,ballvalve,auxiliarypumpand

lterpumpcontrol

8

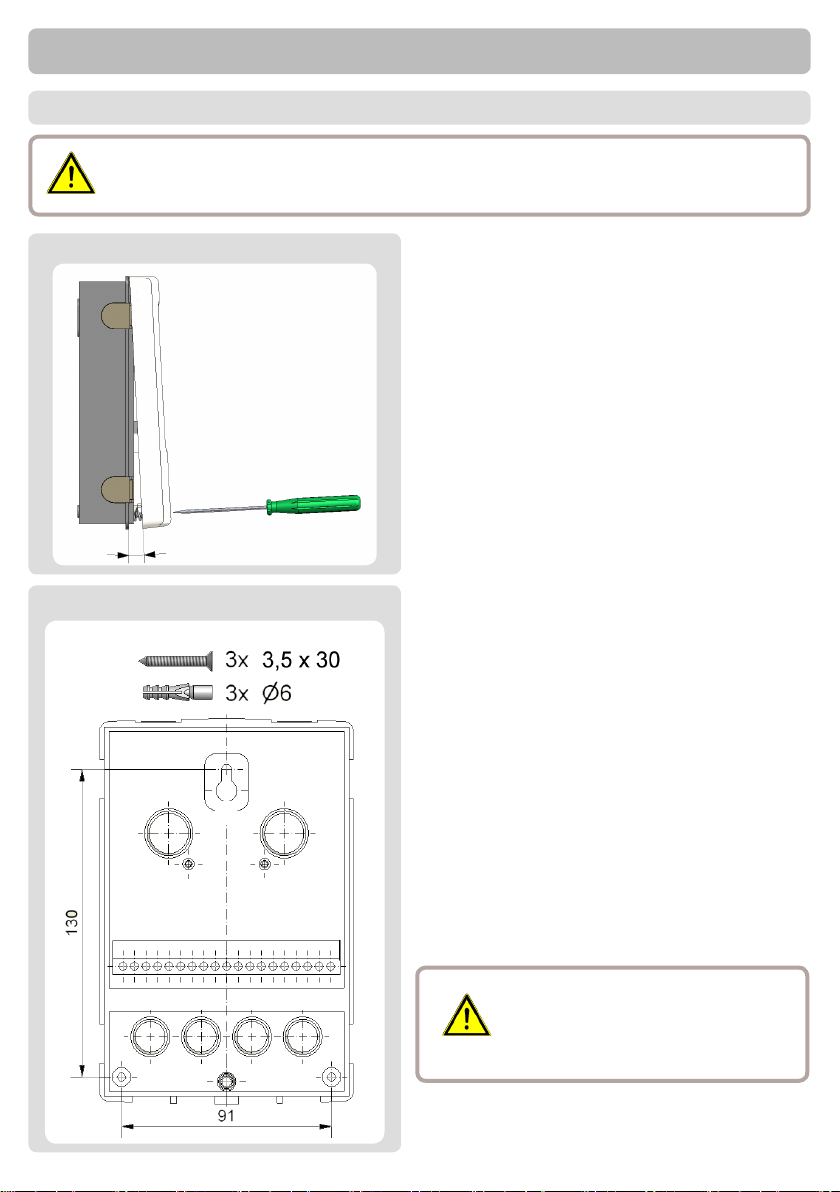

C.1.1 .

C.1.2.

Caution

C.1. Wall installation

Installthecontrollerindryareasonlyandundertheambientconditionsde-

scribedunder“B.1.Specications”.

1. Unscrew cover completely

2.Carefullypullupperpartofhousing

fromlowerpart.Terminalclampsare

released during this process.

3.Setupperpartofhousingaside,being

sure not to touch the electrics when doing

so.

4.Holdthelowerpartofthehousingup

totheselectedpositionandmarkthe3

mountingholes.Makesurethatthewall

surfaceisasevenaspossiblesothatthe

housing does not become distorted when

it is screwed on.

5.Usingadrillandsize6bit,drill3holes

atthepointsmarkedonthewallandpush

in the plugs.

6.Inserttheupperscrewandscrewitin

slightly.

7.Fittheupperpartofthehousingand

insert the other two screws.

8. Align the housing and tighten the three

screws.

Installation

Controller must be inaccessible

fromtherear.

Caution

9

Installation

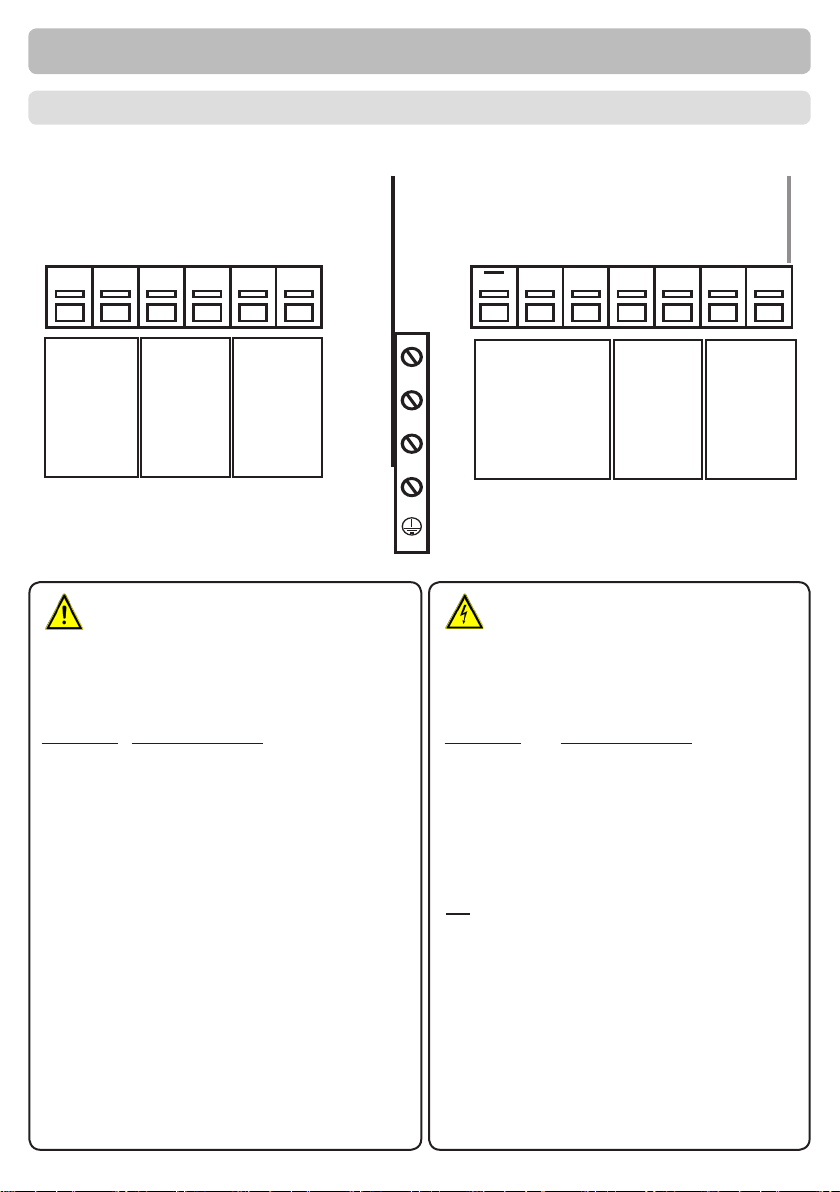

C.2. Electrical connection

Danger

Beforeworkingontheunit,switchothepowersupplyandsecureitfrom

beingswitchedonagain!Checkfortheabsenceofpower!

Electrical connections may only be made by a specialist and in compli-

ance with the applicable regulations.

Donotusethecontrollerifthehousingshowsvisibledamage.

Caution

Low-voltage cables such as temperature sensor cables must be routed

separatelyfromthemainsvoltagecables.Feedtemperaturesensorca-

blesonlyintotheleft-handsideoftheunit,andmainsvoltagecablesonly

into the right-hand side.

Caution

Thecustomermustprovideanall-poledisconnectingdevice,

e.g. a heating emergency switch.

Caution

The cables being connected to the unit must not be stripped by more than

55mm,andthecablejacketmustreachintothehousingjusttotheother

sideofthestrainrelief.

Achtung

FollowtheprotectiveareastoGermanInstituteforStandardizationVDE0100-702for

theinstallationofthecontrol(distancestoSchuztbereich0and1).

Achtung

Electricshockdangerbyimproperconnection!

• VDE-andEVUregulationsoftheenergysupplyenterprisefollow.

• Pumps and swimming pools and their protective area according to

GermanInstituteforStandardizationVDE0100-702instal.

• Dividingdevicefortheinterruptionofthetensioncarewithmin3

mmofcontactopeningperpoolinstal.

Electricshockdangerbytensioninthecase!

• A correctly opposed engine guard counter must be installed. Be-

sides,thevaluesonthetypesignfollow.

• Circuitwithamistakestreamprotectioncounter,nominalmistake

streamI∆N≤30mA.

• Onlysuitablemanagementtypesaccordinglyoftheregionalregula-

tions use.

• Leastcrosssectionofthelines,theenginepowerandtheachieve-

ment situation adapt.

• Ifdangeroussituationscanarise,emergency-fromcounteraccord-

ingtoGermanInstituteforStandardizationEN809plan.According

to this norm the Errichter/operator must decide this.

10

1. Select necessary program/hydraulics.

2. Opencontrollercasing(“C.1.Wall

installation”onpage8).

3. Stripcablesby55mmmax.,insert,t

thestrainreliefdevices,stripthelast

8-9mmofthewires.

4. Open the terminals using a suitable

screwdriver(Fig.C.2.1.)andmake

electrical connections on the control-

ler.

5. Retterminalconnectioncoverand

fastenscrew.

6. Switch on mains voltage and place

controller in operation.

C.2.2.

Installation

C.3. Installing the temperature sensors

Thetemperaturesensorcablesmustberoutedseparatelyfrommainsvoltage

cablesandmustnot,forexample,beroutedinthesamecableduct!

ThecontrolleroperateswithPT1000temperaturesensorswhichareaccuratetothe

degree,thusensuringoptimalcontrolofsystemfunctions.

Ifdesiredthesensorcablescanbeextendedtoamaximumof30musing

acablewithacross-sectionofatleast0.75mm².Makesurethatthereisno

contact resistance!

Position the sensor precisely in the area to be measured!

Onlyuseimmersion,pipe-mountedorat-mountedsensorssuitableforthe

specicareaofapplicationwiththeappropriatepermissibletemperaturerange.

Caution

Caution

11

Installation

Low voltagemax.12VAC/DC

Terminal Connectionfor

S1(2x) Collector

S2(2x) Pool

S3(2x) Flowsensor(optional)

Mains voltage230VAC50-60Hz

Terminal Connectionfor

N MainsneutralconductorN

R1 Filter pump

N MainsneutralconductorN

L Mains phase conductor L

N MainsneutralconductorN

R2 Ballvalve,heatpump

or auxiliary pump

R2 Ball valve

The PE protective conductor must be

connected to the PE metal terminal

block!

max.12V

Caution

Mainsvoltages230VAC

Danger

D. Terminal connection diagram

Low voltage Relays Mains

MainsRelaisKleinspannungen

S3

S3 S2 S2 S1 S1 R2 R1LN N NR2

Flow sensor

Ballvalve,

heat pump

or auxiliary

pump

Pool

Supply

Collector

Filter pump

12

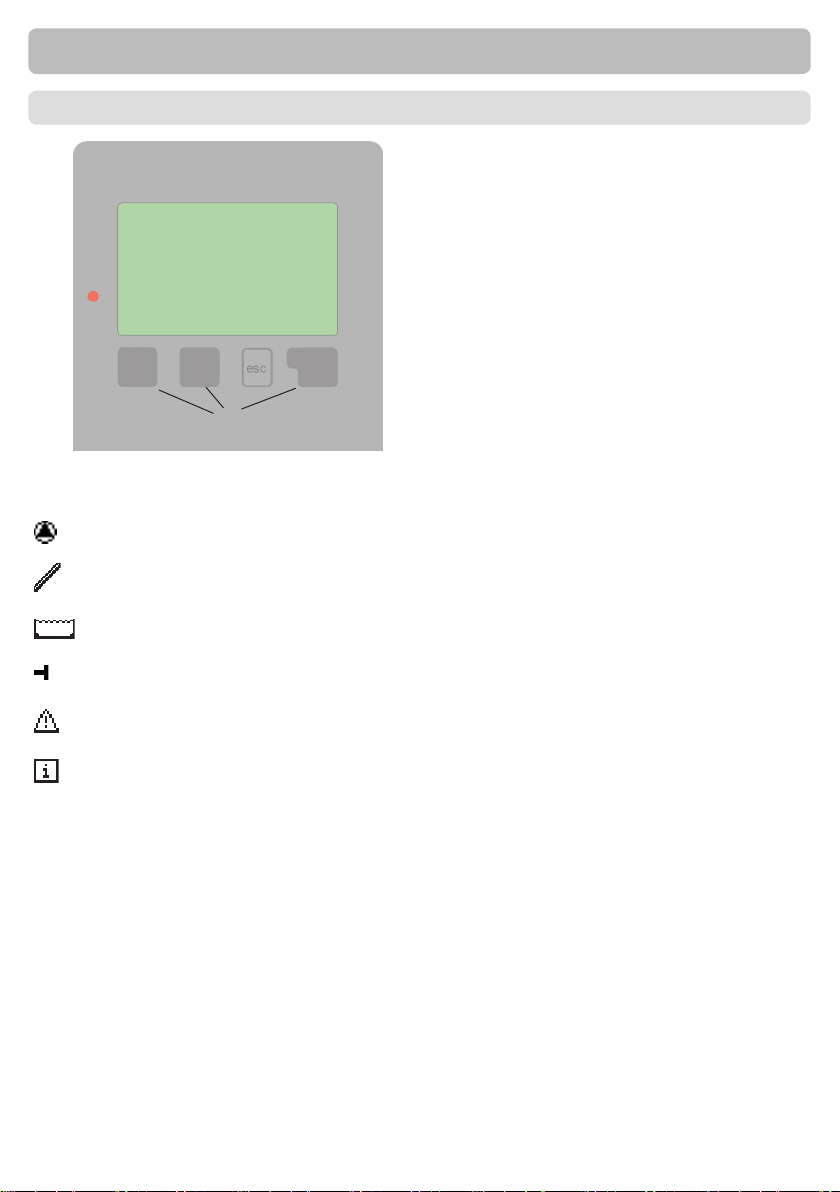

Examplesofdisplaysymbols:

Pump(rotatesinoperation)

Collector

Pool

Temperature sensor

Warning / Error message

Newinfos

(1)

(2)

(3)

(4)

Thedisplay(1),withitsextensivetextand

graphicsmode,isalmostself-explanatory,

allowingeasyoperationofthecontroller.

Tochangefromtheoverviewtotheset-

tingsmenu,pressthe„esc“key.

ThegreenstatusLED(2)lightsupwhena

solarrequirementistaktiv(Ballvalueon/

o)OtherfeaturesoftheLEDaredis-

cribed in nChapter Z.1.

Inputsaremadewith4buttons(3+4),

whichhavedierentfunctionsdepending

on the context.

The„esc“key(3)isalwaysusedtocancel

or exit a menu.

Ifapplicabletherewillbearequestfor

conrmationastowhetherthechanges

which have been made should be saved.

Thefunctionofeachoftheotherthree

keys(4)isshowninthedisplaylinedi-

rectlyabovethekeys;theright-handkey

generallyhasaconrmationandselection

function.

Examplesofkeyfunctions:

+/- =enlarge/shrinkvalues

▼/▲ =scrolldown/upmenu

yes/no = approve/cancel

Info =additionalinformation

Back =topreviousscreen

ok =conrmselection

Conrm =conrmsetting

Operation

E.1. Display and input

13

E.2. Commissioning help

E.3. Free commissioning

Ifyoudecidenottousethecommissioninghelp,youshouldmakethenecessaryset-

tingsinthefollowingsequence:

-Menu 10. Language

- Menu 7.2. Time and date

- Menu 7.1. Program selection

-Menu 5. Settings,allvalues

-Menu 6. Protectivefunctions,ifnecessary

-Menu 7. Specialfunctions,ifnecessary

Finally,themenu“4.2.Manual”onpage18shouldbeusedtotesttheswitchout-

putswiththeconsumersconnectedandtocheckthesensorvaluesforplausibility.

Then the automatic mode can be switched on.

Commission

Caution

Observetheexplanationsfortheindividualparametersonthefollowing

pagesandcheckwhetherfurthersettingsarenecessaryforyour

application.

display.Pressingthe“esc”keytakesyoubacktothepreviousvaluesoyoucanlookat

theselectedsettingagainoradjustitifdesired.Pressingthe“esc“keymorethanonce

takesyoubackstepbysteptotheselectionmode,thuscancellingthecommissioning

help.Finally,themenu“4.2.Manual”onpage18shouldbeusedtotesttheswitch

outputswiththeconsumersconnectedandtocheckthesensorvaluesforplausibility.

Then the automatic mode can be switched on.

Thersttimethecontrolleristurnedonand

afterthelanguageandtimeareset,aquery

appears as to whether you want to para-

metrise the controller using the commissioning

help or not. The commissioning help can also

be terminated or called up again at any time in

thespecialfunctionsmenu.Thecommission-

ing help guides you through the necessary ba-

sicsettingsinthecorrectorder,andprovides

briefdescriptionsofeachparameterinthe

Caution

Observetheexplanationsforthetheindividualparametersonthefol-

lowingpagesandcheckwhetherfurthersettingsarenecessaryforyour

application.

14

E.4. Menu sequence and menu structure

Operation

The graphics or overview mode appears

whennokeyhasbeenpressfor2minutes

or when the main menu is exited by press-

ing “esc“.

The up and down buttons are used to

scrollthroughthelistofsensorsand

relays.

Youcanenterthemainmenubypressing

the“esc“key.Thefollowingmenusare

available:

Current temperature values with explana-

tions

Functioncontrolofthesystemwithoperat-

ing hours etc.

Automaticmode,manualmodeorswitch

unito

Setparametersneededfornormalopera-

tion

Frostprotection,anti-seizingprotection

etc.

Programselection,sensorcalibration,

clock,additionalsensoretc.

Against unintentional setting changes at

critical points

Fordiagnosisintheeventofanerror

Language selection

Select graphics mode or overview mode

1. Measurement values

2. Statistics

3. Display mode

4. Operating mode

5. Settings

6.Protectivefunctions

7.Specialfunctions

8.Menulock

9. Service values

10.Language

15

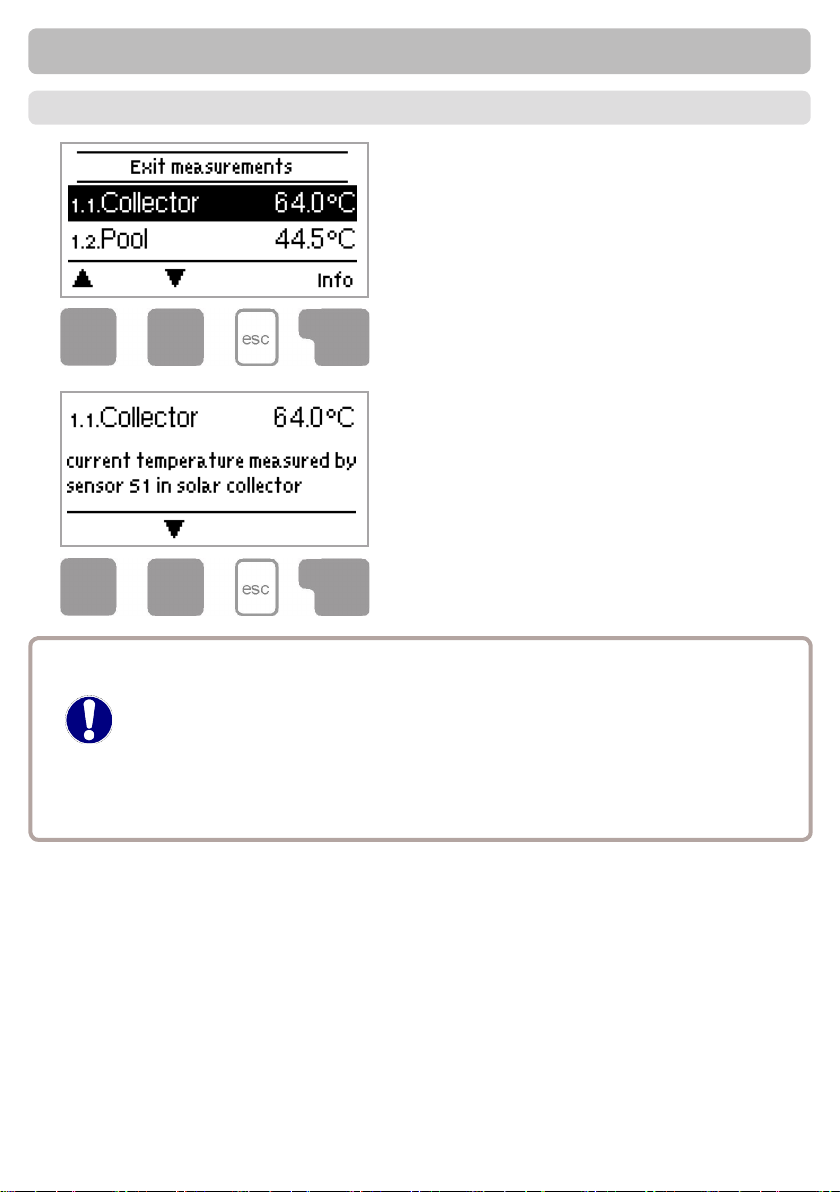

Caution

The measurement values are explained

with a help text when selected.

Selecting “Overview” or “esc” exits the

Infomode.

If“--”appearsonthedisplayinsteadofthemeasurementvalue,then

theremaybeafaultyorincorrecttemperaturesensor.Ifthecablesare

toolongorthesensorsarenotplacedoptimally,theresultmaybesmall

deviationsinthemeasurementvalues.Inthiscasethedisplayvalues

canbecompensatedforbymakingentriesonthecontroller.Followthe

instructions under “7.3. Sensor calibration” on page 23.

What measurement values are displayed depends on the selected pro-

gram,theconnectedsensorsandthespecicdevicedesign.

Measurement values

1. Measurement values

The menu “1. Measurement values” serves

to display the currently measured tempera-

tures.

The menu is closed by pressing the “esc”

keyorselecting“Exitmeasurementvalues”.

16

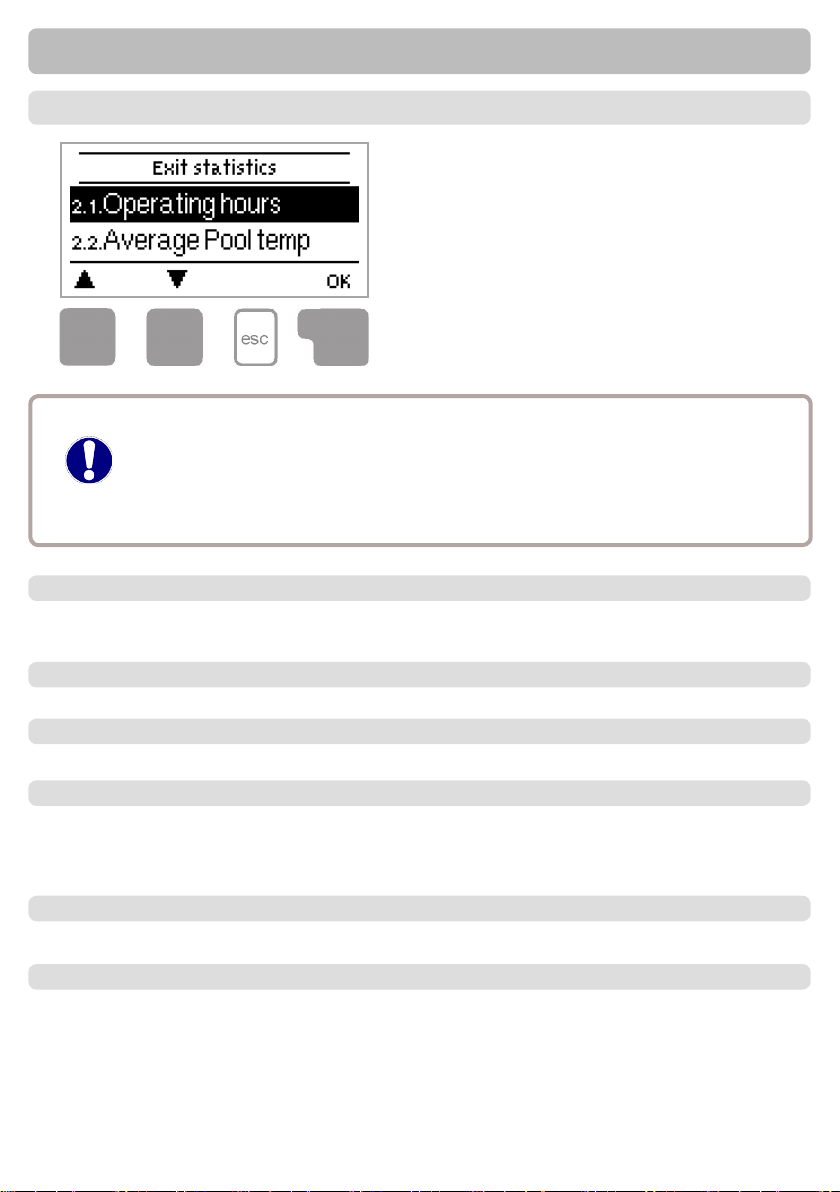

2. Statistics

Achtung

Themenu“2.Statistics”isusedforfunc-

tioncontrolandlong-termmonitoringof

the system.

The menu is closed by pressing the “esc”

keyorselecting“Exitstatistics”.

Foranalysisofthesystemdataitisessentialforthetimetobesetac-

curatelyonthecontroller.Pleasenotethattheclockonlyhasabattery

reservefor24hoursandmustthereforeberesetafterwards.Improper

operationoranincorrecttimemayresultindatabeingdeleted,recorded

incorrectly or overwritten.

Themanufactureracceptsnoliabilityfortherecordeddata!

Statistics

2.1. Operating hours

Displayofoperatinghoursofthepumpconnectedtothecontroller;varioustime

ranges(day-year)areavailable.

Displays the average pool temperature.

2.2. Average pool temperature

2.3. Heat output

Displays the system’s heat output. See also “7.6. Heat quantity” on page 25

2.4. Graphic overview

Thisprovidesaclearlyorganiseddisplayofthedatalistedunder2.1....2.2.asabar

graph.Varioustimerangesareavailableforcomparison.Thetwoleft-handkeyscanbe

used to page through the data.

2.5. Message log

Displaysthelast20eventsoccurringinthesystemwithindicationofdateandtime.

Resettinganddeletingtheindividualanalyses.Thefunction“Allstatistics”clearsall

analyses but not the error messages.

2.6. Reset/clear

17

The menu “3. Display mode” is used to

denethecontroller’sdisplayfornormal

operation.

This display appears whenever two min-

utesgobywithoutanykeybeingpressed.

The main menu appears again when a

keyispressed.

The menu is closed by pressing the “esc”

keyorselecting“Exitdisplaymode”.

Display mode

3. Display mode

3.1. Schematic

Ingraphicsmode,theselectedhydraulicsystemsaredepictedwiththemeasured

temperaturesandoperatingstatesoftheconnectedconsumers.

3.2. Overview

Inoverviewmode,themeasuredtemperaturesandoperatingstatesoftheconnected

consumersaredepictedintextform.

3.3. Alternating

Inalternatingmodetheschematicmodeandthentheoverviewmodeareactivefor5

seconds at a time.

Whenactive,thedisplay’sbacklightisswitchedoafter2minutesofinactivity.

3.4. Sleep mode

Caution

Ifamessageiswaiting,thebacklightisnotswitchedo.

18

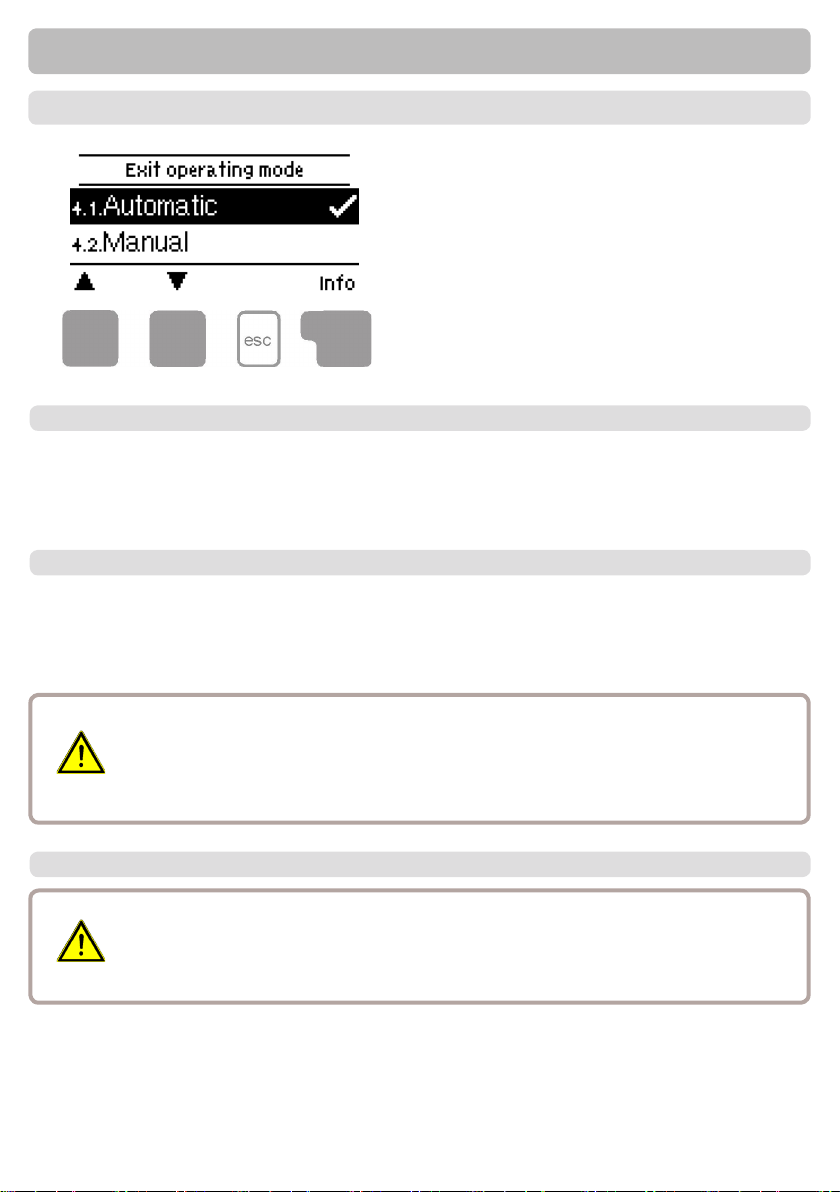

4. Operating mode

Inthemenu“4.Operatingmode”thecon-

troller can either be placed in automatic

mode,switchedoorplacedinamanual

operating mode.

The menu is closed by pressing the “esc”

keyorselecting“Exitoperatingmode”.

Operating mode

Automaticmodeisthenormaloperatingmodeofthecontroller.Onlyautomaticmode

providespropercontrollerfunctiontakingintoaccountthecurrenttemperaturesand

theparametersthathavebeenset!Afteraninterruptionofthemainsvoltagethecon-

troller automatically returns to the last operating mode selected!

4.1. Automatic

4.2. Manual

Therelayandthustheconnectedconsumerareswitchedonando,withnoregard

tothecurrenttemperaturesandtheparameterswhichhavebeenset,bypressinga

key.Themeasuredtemperaturesarealsoshowntoprovideanoverviewandfunction

control.

Danger

Whenoperatingmode“Manual”isactivated,thecurrenttemperaturesand

theselectedparametersarenolongerconsidered.Thereisadangerof

scalding or serious damage to the system. The operating mode “Manual”

mayonlybeusedbyspecialistsforbrieffunctiontestsorduringcommis-

sioning!

4.3. O

Whentheoperatingmode“O”isactivated,allcontrollerfunctionsare

switchedo.Thiscanlead,forexample,tooverheatingonthesolarcol-

lector or other system components. The measured temperatures are still

displayed to provide an overview.

Caution

19

5. Settings

Settings

Thenecessarybasicsettingsrequiredforthe

controlfunctionaremadeinmenu“5.Set-

tings”.

Caution

This does not under any cir-

cumstancesreplacethesafety

facilitiestobeprovidedbythe

customer!

Themenuisclosedbypressingthe“esc”key

or selecting “Exit settings”.

Thefollowingpagescontaingenerallyvaliddescriptionsforthesettings.

Enumerations may vary.

Caution

5.1. Tmin S1

Enable/start temperature at sensor 1

Ifthisvalueisexceededatsensor1andtheotherconditionsarealsomet,thenthe

controllerswitchestheassociatedpumpand/orballvalueon.Ifthetemperatureat

sensor1dropsbelowthisvalueby5°C,thepumpand/orthevalveareswitchedo

again. Setting range: 0 °C ... 99 °C / Default: 20 °C

5.2. Tmax S2

Switch-otemperatureatsensor2

Ifthisvalueisexceededatsensor2,thecontrollerswitchestheassociatedpumpand/

orvalveo.Ifsensor2fallsbelowthisvalueagainandtheotherconditionsarealso

met,thecontrollerswitchesthepumpand/orballvalueonagain.

Setting range: 0 °C ... 99 °C / Default: 30 °C

Danger

Temperature values which are set too high can lead to scalding or dam-

age to the system. Scalding protection must be provided by the cus-

tomer!

20

Settings

ReferencesensorsareusuallyS1andS2.

IfS3isconnected,theswitchOΔT-OisbetweenS2andS3.

5.3. ∆TR1

Switch-on/switch-otemperaturedierenceforrelayR1

Ifthistemperaturedierenceisreached,theballvalueatR2andthepumpatR1are

switchedon.WhenthetemperaturedropstoΔT-O,pump/valveareswitchedo.

Setting range: ΔT-On 4 °C ... 20 °C / Default 10 °C

ΔT-O 2 °C ... 9 °C / Default: 3 °C

Ifthesettemperaturedierenceistoosmall,thismayresultinineec-

tiveoperation,dependingonthesystemandsensorpositions.

Caution

Caution

5.6. Followup/Switch-odelay

5.7. Delay / Switch-on delay

Aftertheswitch-oconditionsforthesolarpumparemet,thepumpkeepsrunningfor

thetimesethere.Iftheswitch-oconditionschangeduringthistimeandarenotmet

anymore,thepumpskeepsrunning.

Setting range: 0 ... 30 min / Default: 1 min

Whenallswitch-onconditionsaremettoactivatethepump,thepumpisnotswitched

onforthetimesethere.Thispreventsthatoncloudyday,thepumpsturnonforshort

sunshine.

Setting range: 0 ... 30 min / Default: 1 min

Filter pump run time

5.8. Hourlylterpumpruntime

ThePoolTDCM+controlsthepooltemperaturetakingintoaccountsolarenergy

andtheruntimeofthelterpump.DuringEcomodethelterpumpruntimeiscalcu-

latedregardingthehourlyanddailylterruntimes.

Setting range: o, daily 0:00 ... 23:59 hour / Default: daily 0:00 ... 23:59 hour

Thismenuisusedtosetthehourlyminimumlterpumpruntime.

Ecomode:Ifthesolarpumpwasnotactiveduringthelasthour,thelterpumpis

switchedonforthesettime.

5.4. Tset S2

5.5. Hysteresis

Targettemperatureforsensor2.Belowthistemperaturetheheatingisswitchedonuntil

Tsoll+Hysteresis is reached. Setting range: 0 °C ... 40 °C / Default: 20 °C

Hysteresisforheating.Setting range: 0 °C ... 10 °C / Default: 5 °C

Table of contents

Other Sorel Controllers manuals

Popular Controllers manuals by other brands

PRIZM

PRIZM Petit Crouto PRIZM v4 user manual

Honeywell

Honeywell H46E installation instructions

Metso

Metso neles ND9000H Installation, maintenance and operation instructions

LSIS

LSIS MASTER-K200S Instructions & Programming

Emerson

Emerson CSB700 Series instruction manual

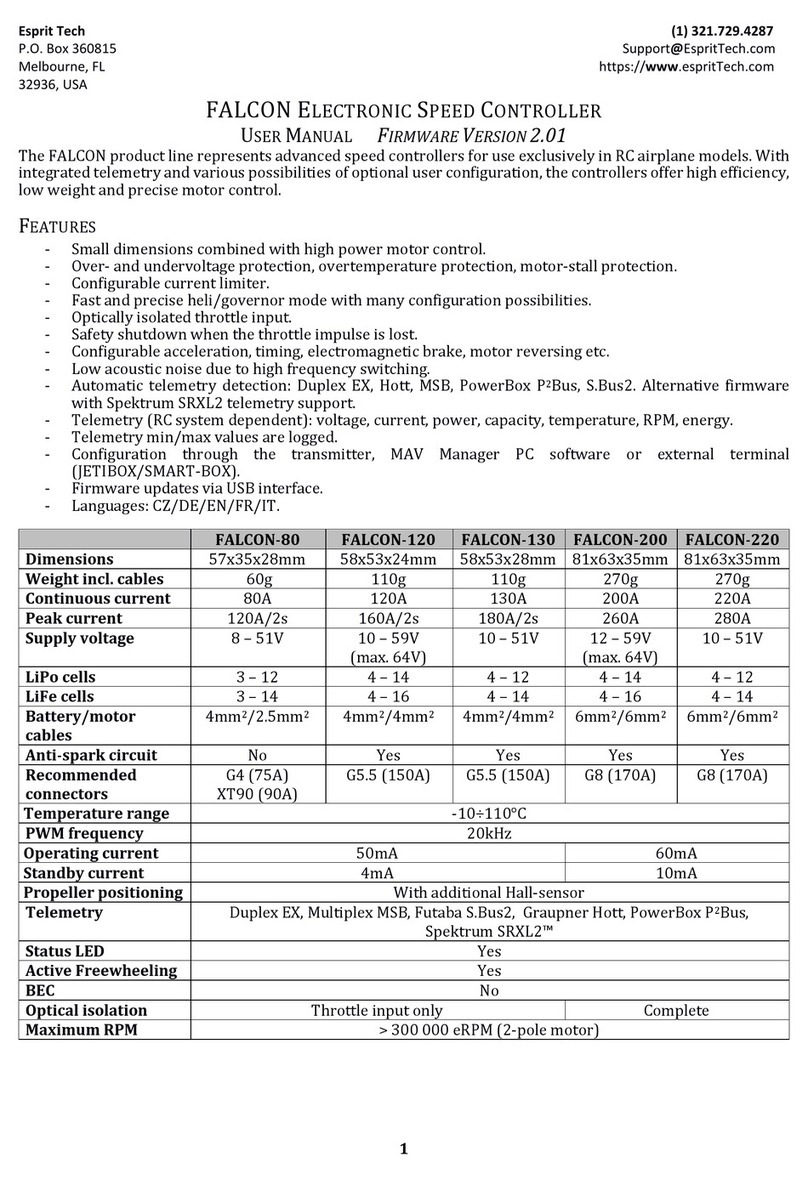

Esprit Tech

Esprit Tech FALCON-200 user manual