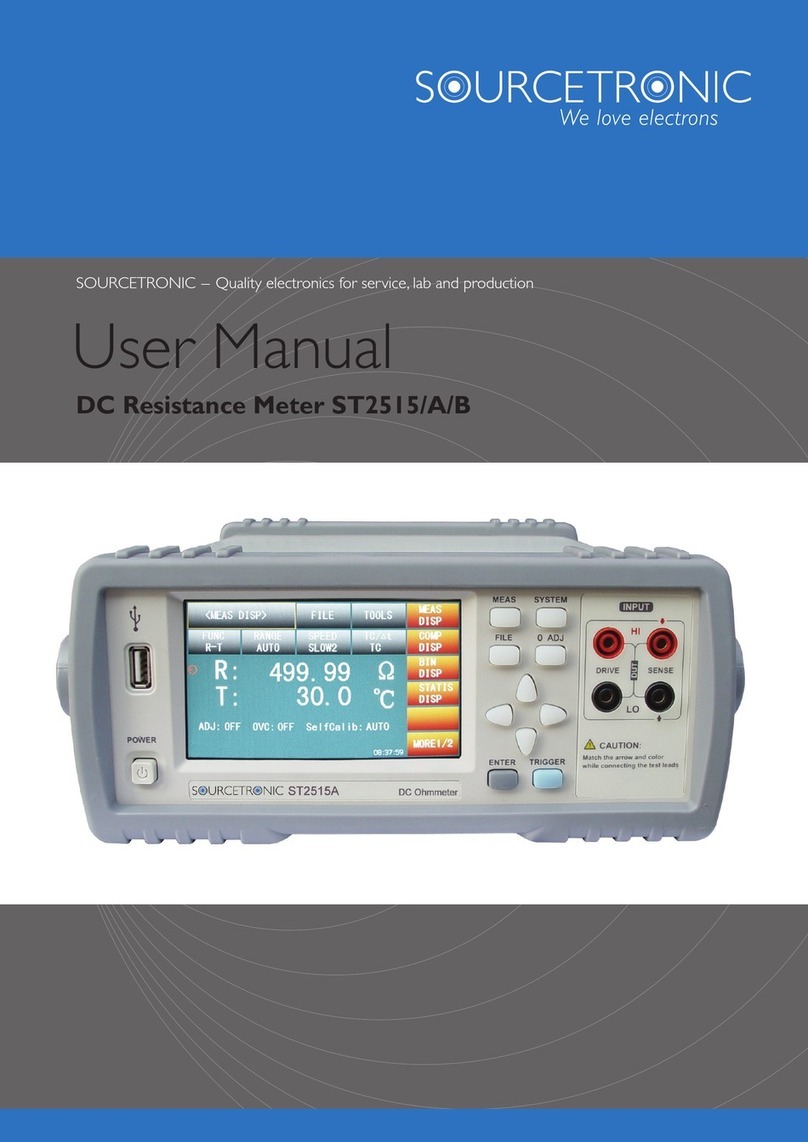

Sourcetronic MPK-2000e User manual

3

MPK-2000e

Digital micro-ohmmeter

User’s guide

GU-1294

© 2008 SOURCETRONIC. All rights reserved.

Printed in Germany.

4

Safety Precautions

•

This equipment should be operated only by qualified and duly trained people,

closely observing the corresponding safety regulations and instructions

contained in the present User guide.

•

It should be checked that the item to be measured is voltage free.

•

Before starting with the measurements, be sure that the battery is well charged

and that the line voltage is between specified limits.

•

Do not connect or disconnect the test leads during the measurement.

•

There are no adjustable parts or parts that can be replaced by the user within the

equipment. Taking out the Control Panel in order to have an access to the

internal parts may be dangerous as there are high voltages inside, capable of

causing fatal accidents.

•

Cleaning of this instrument should be carried out using a soft cleaning liquid,

after verifying that it doesn't attack the plastic parts used in the case and in the

Control Panel of this equipment.

This equipment should be used only by a trained and competent

person, strictly applying suitable safety rules.

Used symbols

Caution, refer to User Guide.

5

Index

1. Description...........................................................................................................6

1.1. Operating principle........................................................................................6

2. Control panel........................................................................................................7

3. Power supply .......................................................................................................8

3.1. Battery condition ...........................................................................................8

3.2. Battery charger .............................................................................................8

4. Measurement.....................................................................................................10

5. Messages...........................................................................................................12

6. Some notes about accuracy...............................................................................13

7. RS232 output.....................................................................................................14

8. Cleaning.............................................................................................................14

9. Replacement fuse..............................................................................................14

10. Technical specifications...................................................................................15

11. Warranty ..........................................................................................................17

6

1. Description

The MPK-2000e micro-ohmmeter is a portable, microprocessor controlled

instrument, used to accurately measure very low contact resistances of

breakers and switches, busbars, transformers and engines windings, etc,

with test currents from 1 mA to 10 A.

• Kelvin architecture (four-terminal method).

• Digital reading, alphanumeric display.

• Up to 4½ digits readings.

• Powered by rechargeable battery or mains supply.

• 0.1 µΩresolution.

• 200 Ωmaximum reading.

1.1. Operating principle

This device uses the Kelvin Bridge architecture, with four terminals,

avoiding testing leads resistance to cause error during measurement. The

operator may choose test current and the reading is obtained by

comparison through internal high-stability standards. The result appears

in the alphanumeric display that is very easy to read.

7

2. Control panel

Fuse.

Power cord connector.

On/Off switch.

Battery charge indicator.

Current terminal (C+).

Potential terminal (P+).

Potential terminal (P-).

Current terminal (C-).

RS232 data output.

Alphanumeric display. Shows both

the measured resistance value and

messages to the operator.

Start key.

Stop key.

Hold key. It retains the last

measurement in the display.

Battery key. To measure the battery

charge condition.

Test current control.

Range and test current selector.

On led.

8

3. Power supply

Mains supply or internal battery powered

Battery: rechargeable, 12 V - 7 Ah.

Mains: 100 - 240 V~

3.1. Battery condition

The charge condition of the battery can be verified before or during the

resistance measurement. In order to achieve that, the operator has to

press the battery key while the equipment is turned on. The bargraph

shows remaining charge as a percentile value. If during measurement the

charge of the battery achieves a critical level, the display will show the

BAT message notifying that the charge level is low. After a few minutes

the measurement will be automatically interrupted in order to preserve the

battery from a deep discharge that is prejudicial for its expected useful

life.

3.2. Battery charger

This equipment has an internal battery charger with a smart,

microprocessor-controlled circuit, which adjusts the battery charge to the

optimized parameters to ensure the maximum service life.

Charging procedure:

•

Check that the On/Off switch is in Off.

•

Connect the equipment to the mains supply.

•

The battery charge indicator will keep on lightning with a red light

up to completing the charge. At that point, it will change to a green light,

being like this up to the equipment disconnection from the mains supply.

9

If, during the battery charge, the equipment is turned ON, the charge will

be momentarily

interrupted, returning to the charge process once the

equipment is turned OFF.

The rechargeable battery does not show the “memory effect” and there

are no restrictions to start charging it as many times as is needed.

However the battery could be damaged

if remains in deep discharge for a

while.

To avoid this effect, charge the battery before

left the equipment in

storage and don’t let pass more than 30 days without recharge, even if

the instrument wasn’t used (under storage, the battery loses part of it

s

charge).

At the end of battery useful life, the battery must be recycled or

disposed of properly, in order to protect the environment.

10

4. Measurement

It should be checked that the item to be measured is voltage free.

1. Before turning the equipment On, connect the test leads to the item to

be measured and to the front panel terminals.

The alligator clamps in the drawings are only for illustration.

2. Using the test current selector , choose the range and the current

to be used.

3. Choose the power supply to use. If you are going to use the battery,

advance to the following point. If you are going to use the mains

supply, plug the power cord into the connector .

4. Switch the equipment On using the On/Off .

5. The PRESS START message will appear showing that measurement

can be started. Press the Start key. Depending on the position of

the test current control the LOW CURRENT message will turn

up.

11

6. Turning the test current control clockwise increases the current.

Adjust this control until obtaining the desired value or until the current

indicator (bargraph) indicates 100%. The bargraph will show the test

current value as a percentage of the nominal value selected by using

the test current selector .

7. The lowest current for measuring is 10% of the nominal value. It is

important to consider that the measurement errors increase while test

current decreases. The equipment accuracy is specified for test

currents higher than 80%.

8. The display will show the resistance value measured and the

corresponding unit (Ω[ohms], mΩ[milli-ohms] or µΩ[micro-ohms]).

9. The value can be retained in the display by pressing the hold key.

Pressing this key again, the value will be released.

10. Press the Stop key in order to finish the measurement. Do not turn

Off the equipment without pressing the Stop key before.

11. Finally, when finishing measurements, turn the equipment Off using

the On/Off switch.

Precaution:

Do not connect or disconnect the test leads during the

measurement.

12

5. Messages

SOURCETRONIC MPK-2000e

When turning the equipment On using the On/Off switch, this

introductory message appears for a while. During that time, the

equipment carries out some functional checking.

WAIT...

This message appears each time the equipment needs to adjust any

parameter in order to optimize the readings.

PRESS START

The equipment is ready to start a measurement, thus the operator has to

press the Start key.

LOW CURRENT

It shows that the test current is not enough to carry out the reading. It

appears at the beginning of each test and it keeps on being there up to

the operator rotates the test current control clockwise, as necessary

for the test current to be higher than 10 % of the nominal current in the

scale. The inappropriate connection of the cables may cause a difficult

circulation of test current. If this message keeps on being displayed,

please check that the current cables are connected appropriately.

OVERRANGE

It indicates that the measured resistance is higher than the maximum

value readable in the selected range.

H

Indicates that the value is the one retained in the memory when pressing

the hold key.

BAT

It shows that the battery is quite discharged. It is necessary the battery to

be recharged.

13

6. Some notes about accuracy

In order to obtain the specified accuracy, the operator has to adjust the

test current to a value higher than the 80% of the nominal value. If it were

necessary, it is possible to use a lower current, but by doing this the

accuracy will be affected.

MPK-2000e has an auto-compensation system that automatically

eliminates the error produced by internal offset. Thus, it is not necessary

to carry out measurements by reversing the polarity in order to compute

the average value. Nevertheless, if the operator suspect that there is a

difference of temperature between the contact points that would can

generate thermoelectric voltages, it is necessary to carry out two

measurements by reversing the current cables and so, the circulation

sense of the current through the resistance under measurement. The

resistance value to be measured will be the average between the values

in one sense and in the contrary (direct and inverse current).

14

7. RS232 output

The equipment has an RS232 data output in the control panel that can

be used to register measurements in a serial printer or data collector. The

outputs are the following ones:

Pin 2: Rx ; Pin 3: Tx ; Pin 5: Gnd;

Rate: 4800 bps

8 bits - no parity - 1 stop bit (8,n,1)

Note: In order to assure the compatibility with most printers available in

the market, the resistance units are shown with the following symbols:

uR = micro-ohm

mR = milli-ohm

R = ohm

8. Cleaning

The panel, terminals and connectors of the equipment must stay dry and

clean. Cleaning should be made using a wet cloth in water and a soft

detergent or isopropyl alcohol (be sure that the products to be used for

cleaning does not affect plastic goods).

9.

Replacement fuse

To check the instrument fuse , remove it with a screw driver. If the fuse

is ruptured replace it by another with the following specifications:

Fuse Schurter, model SPT 5x20 (Time-lag) 5A/250V. High breaking capacity.

15

10. Technical specifications

Test currents :

1 mA - 10 mA - 100 mA - 1 A - 10 A.

Each current may be continuously adjustable from

0 to 100%.

Resistance ranges :

0 - 2000 µΩ@ 10 A

0 - 20 mΩ@ 10 A

0 - 200 mΩ@ 1 A

0 - 2000 mΩ@ 100 mA

0 - 20 Ω@ 10 mA

0 - 200 Ω@ 1 mA

Resolution :

0.1 µΩ@ 10 A

Output voltage :

Up to 10 Vd.c. @ 1 A (open circuit).

Measurement principle :

Four-terminal, Kelvin-type.

Basic accuracy :

± (0.10% of reading + 0.005% of full range)

Advanced features :

Digital direct reading of very low resistances in the

alphanumerical display, with up to 4½ digits. Very

fast and accurate measurements.

Serial data output :

RS232 @ 4800 bps. Suitable for data collection in

an external serial printer, computer or data-logger.

Environmental protection :

IP54 with closed lid.

Safety class :

Meets the requirements of IEC 61010-1:1990,

IEC 61010-1:1992 amendment 2

Power supply :

Rechargeable battery 12 V - 7 Ah or 100-240 V~

mains supply.

Built-in battery charger :

100-240 V~ mains supply.

Operating temperature

range :

-5°C to 50°C

Storage temperature range

:

-25°C to 65°C

Humidity range :

95% RH (non condensing)

16

Weight :

Approx. 8,8 kg (including battery and accessories)

Dimensions :

378 x 308 x 175 mm

Accessories :

2 Combined current and potential leads (1.8 m).

1 Communication cable (RS232).

1 Power cord.

1 User guide.

1 Carrying bag.

Subject to technical change without notice.

17

11. Warranty

SOURCETRONIC warrants to the original purchaser that each instrument it

manufactures will be free from defects in material and workmanship under normal

use and service. The warranty period is valid for 12 months, except the built-in

rechargeable battery that has 6 months, and begins on the date of shipment. The

manufacturer's warranty does not apply to any product or accessories which, in the

manufacturer’s opinion, have been misused, altered, neglected, or damaged by

accident or abnormal conditions of operation and handling.

To obtain warranty service, send the equipment, with a description of the difficult,

shipping and insurance prepaid, to SOURCETRONIC. The manufacturer assumes

no risk for damage in transit. SOURCETRONIC will, at its option, repair or replace

the defective equipment free of charge or refund your purchase price. However, if

SOURCETRONIC determines that the failure was caused by misuse, alteration,

accident or abnormal condition or handling, you will be charged for the repair and

the repaired equipment will be returned to you transportation prepaid.

This warranty is exclusive and is instead of all other warranties, express or implied,

including but not limited to any implied warranty or merchantability or fitness for a

particular purpose or use. SOURCETRONIC will not be responsible for any special,

indirect, incidental, or consequential damages or loss of data, whether in contract,

or otherwise.

For application or operation assistance or information on SOURCETRONIC

products, contact:

SOURCETRONIC

Georg-Groening-Strasse 47, D-28209 Bremen, Germany

Fax: (+49) 421 – 277 99 98 - email: info@sourcetronic.com

Liability limitation

The liability for malfunctioning of the equipment is limited to the application of the

warranty pursuant to the aforementioned provisions. The manufacturer does not

take any responsibility for any eventual damage due to the use or impossibility to

the use of the equipment such as accidents in the field, loss of profit, etc.

18

Notes

Table of contents

Other Sourcetronic Measuring Instrument manuals

Sourcetronic

Sourcetronic MPK-102e User manual

Sourcetronic

Sourcetronic TH2516 Series User manual

Sourcetronic

Sourcetronic ST2515 User manual

Sourcetronic

Sourcetronic ST2822 User manual

Sourcetronic

Sourcetronic ST2684A User manual

Sourcetronic

Sourcetronic ST2822D User manual

Sourcetronic

Sourcetronic MPK-204e User manual

Sourcetronic

Sourcetronic ST1778A User manual

Sourcetronic

Sourcetronic ST2638 Series User manual

Sourcetronic

Sourcetronic ST2829A User manual